Knowledge Center

Delrin CNC Machining: The Comprehensive Guide

What is Gear Machining? Expert Guide to Processes & Materials

Is Delrin the Same as Acetal: Key Differences Explained

All Articles

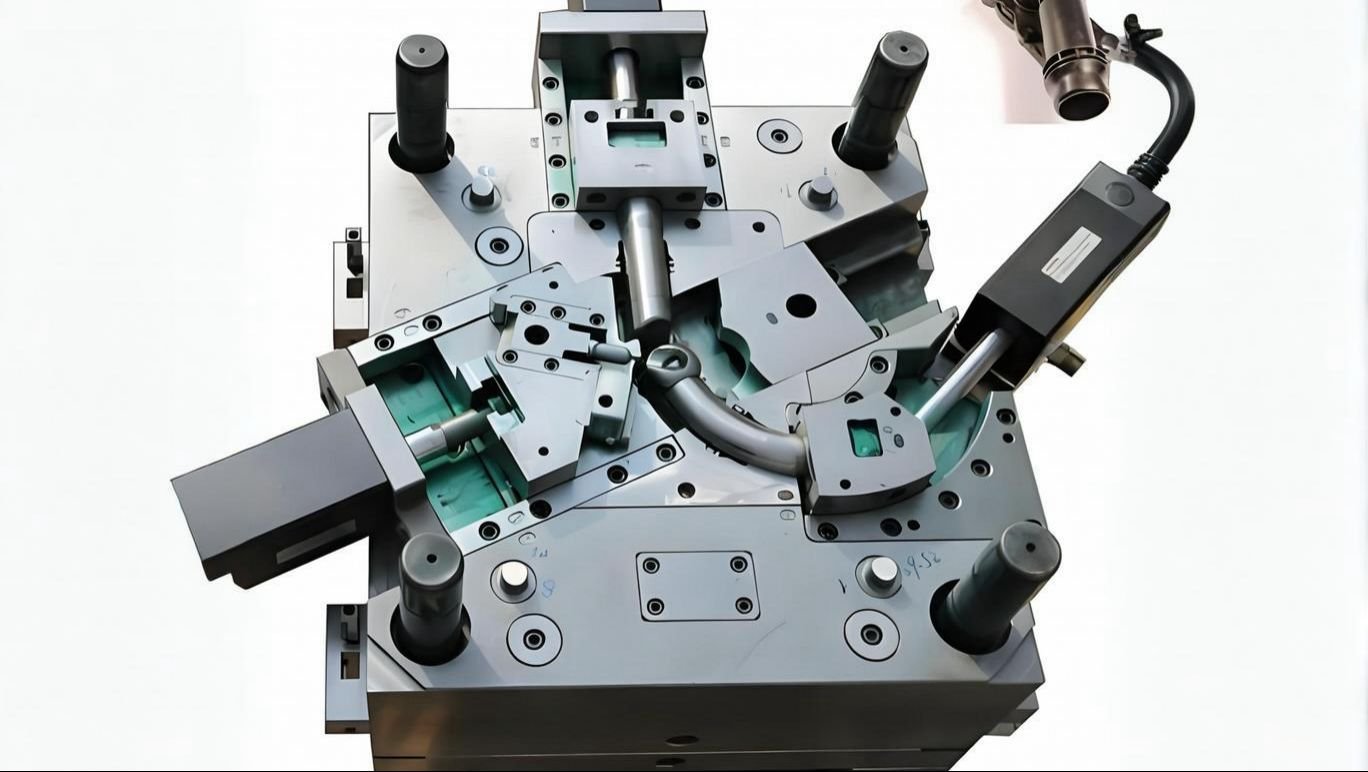

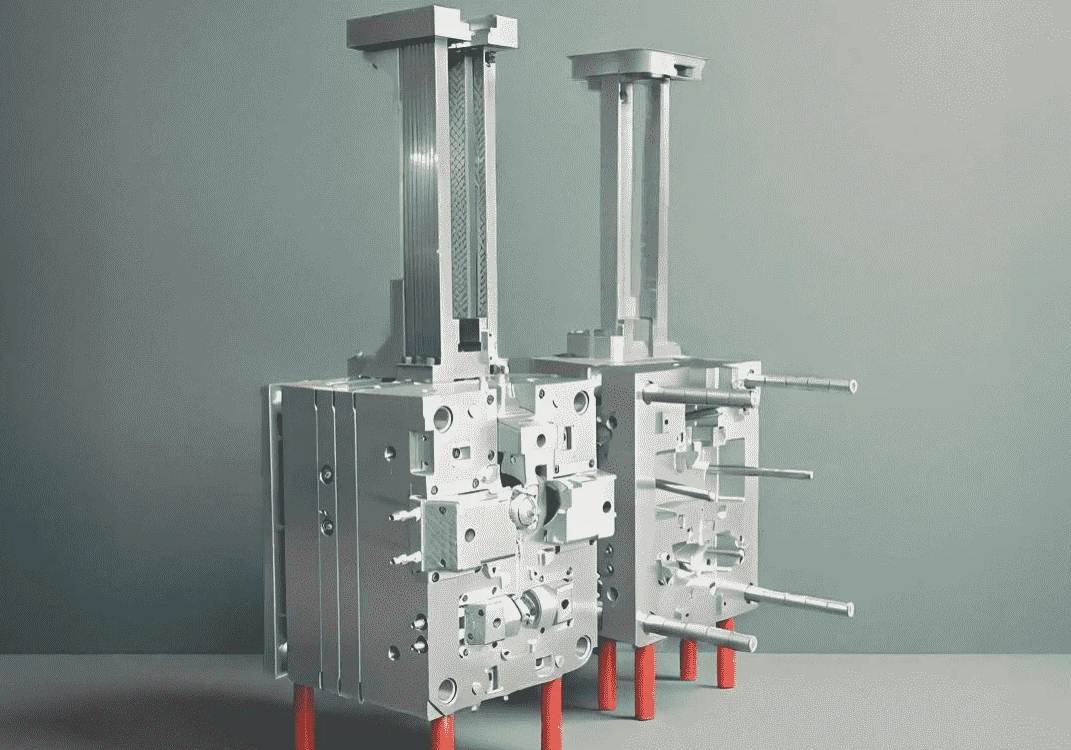

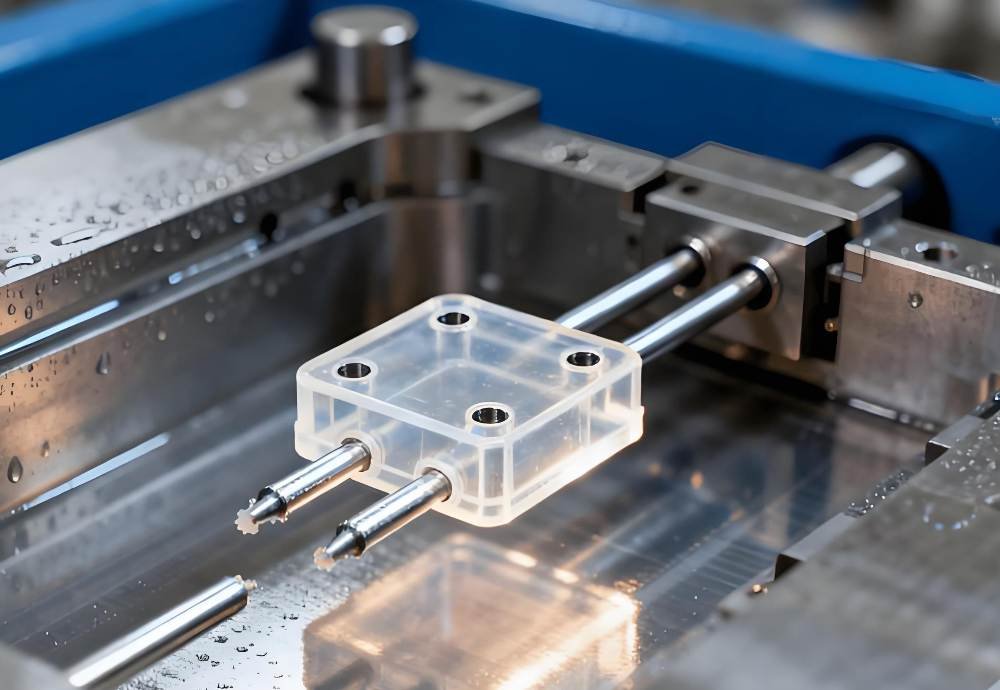

A Complete Guide to Prototype Injection Molds: Process, Materials, and Benefits

Get production-grade plastic parts in days using prototype injection molds. Validate designs, cut market risk, and save capital before committing to full tooling.

From Prototype to Mass Production: Fecision’s Turnkey Mold Solutions

Bridge the gap from concept to market with Fecision’s turnkey mold solutions. Get single-source accountability, accelerated speed, and flawless quality for mass production.

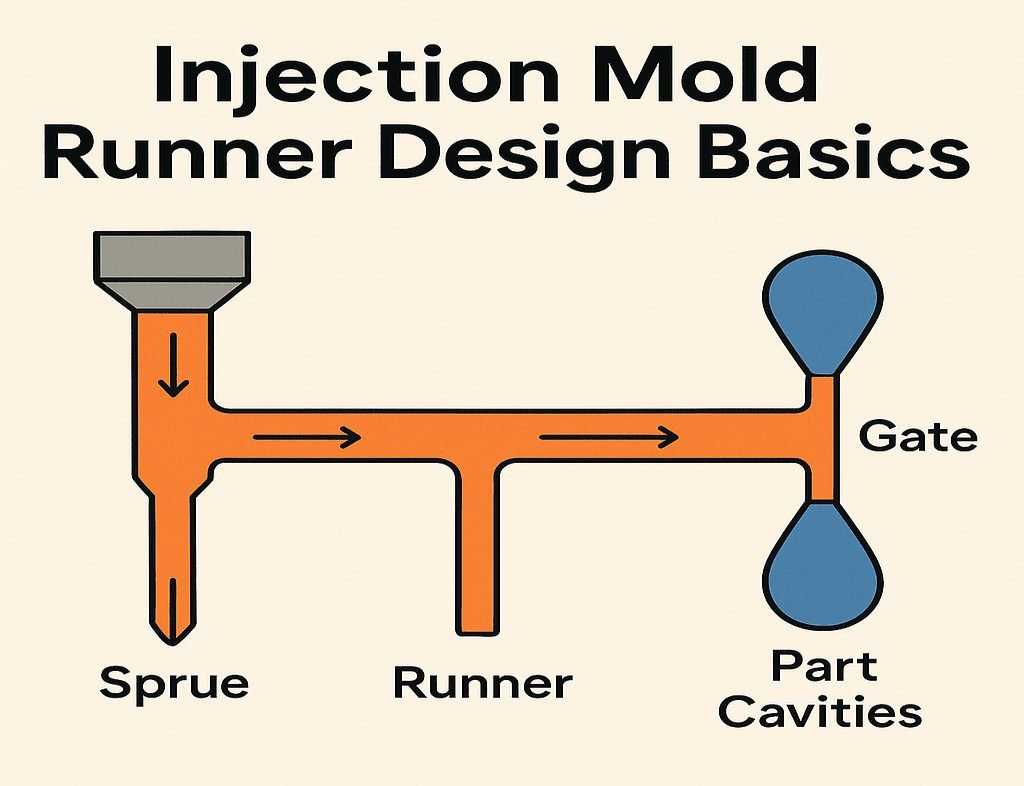

Injection Mold Runner Design Basics: Types, Functions, and Best Practices

Learn the basics of injection mold runner design, including types, functions, and best practices to improve flow balance, part quality, and production efficiency.

What Is Family Mold? Types, Design & Applications

Discover the cost and time savings of family injection mold strategy. Learn types, design rules, and applications for efficient, high-quality production of multi-part plastic assemblies.

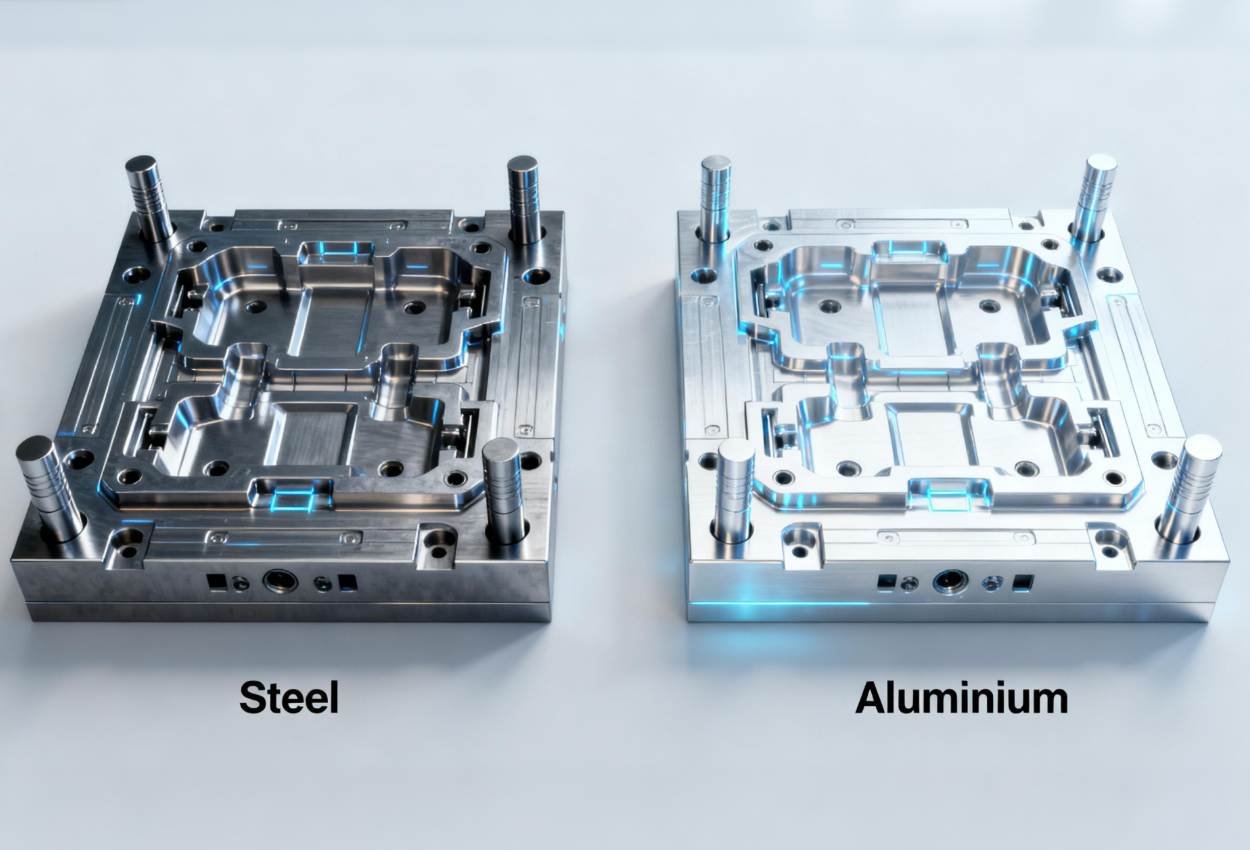

Steel vs. Aluminum Injection Molds: What are the Differences?

Aluminum vs. steel injection molds? Uncover the core differences in thermal speed, cost, and durability to pick the right metal and multiply your project’s long-term margin.

10+ Questions to Ask Before Picking Injection Mold Manufacturers

Stop wasting money on bad molds. Use these 10+ key questions to vet any injection mold manufacturer, avoid five-figure re-tooling costs, and secure your project’s success.

What Is Feeding System in Injection Mold?

Master injection molding feed system design. This guide covers sprue sizing, runner balancing, gate freeze-off, and choosing the perfect hot, cold, or insulated runner for efficiency.

SPI Mold Classification: 5 Injection Mold Classifications

Understand the SPI mold classification system and master the division standards and application scenarios of the 5 injection mold types.

What is Rapid Tooling? How It Works and Its Advantages

Understand the definition, specific operation process and outstanding advantages of rapid tooling to select a suitable tooling solution for your project.

Mold Design for Insert Molding: A Detailed Guideline

Stop scrapping parts due to poor design. Master insert molding rules, material compatibility, and key geometry to build reliable, high-strength metal-plastic components efficiently.

Injection Mold Gate Design: The Complete Basics to Get Started

The gate is your profit lever. Discover the complete guide to injection molding gate design, covering every type, troubleshooting defects, and advanced strategies for optimized tooling.

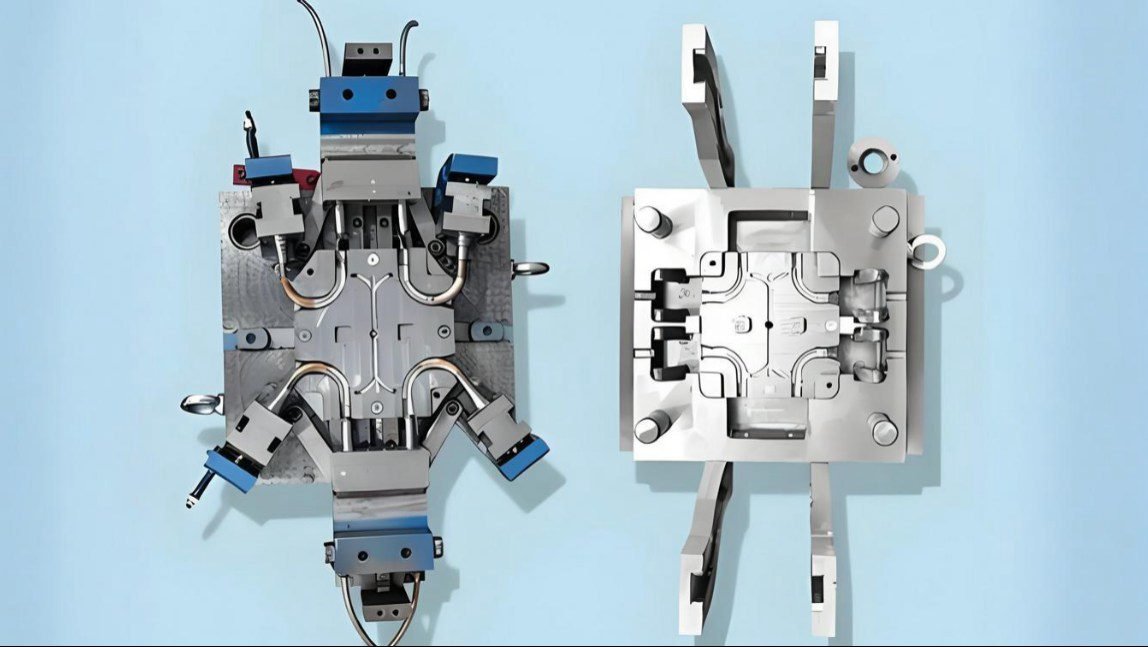

Beyond the Basics: Advanced Mold Tooling for Complex Electrical Terminals and Interconnects

Explore the world of Mold Tooling for sophisticated electrical components. Get insights into manufacturing molds for complex geometries and thin materials with Fecision’s expertise.

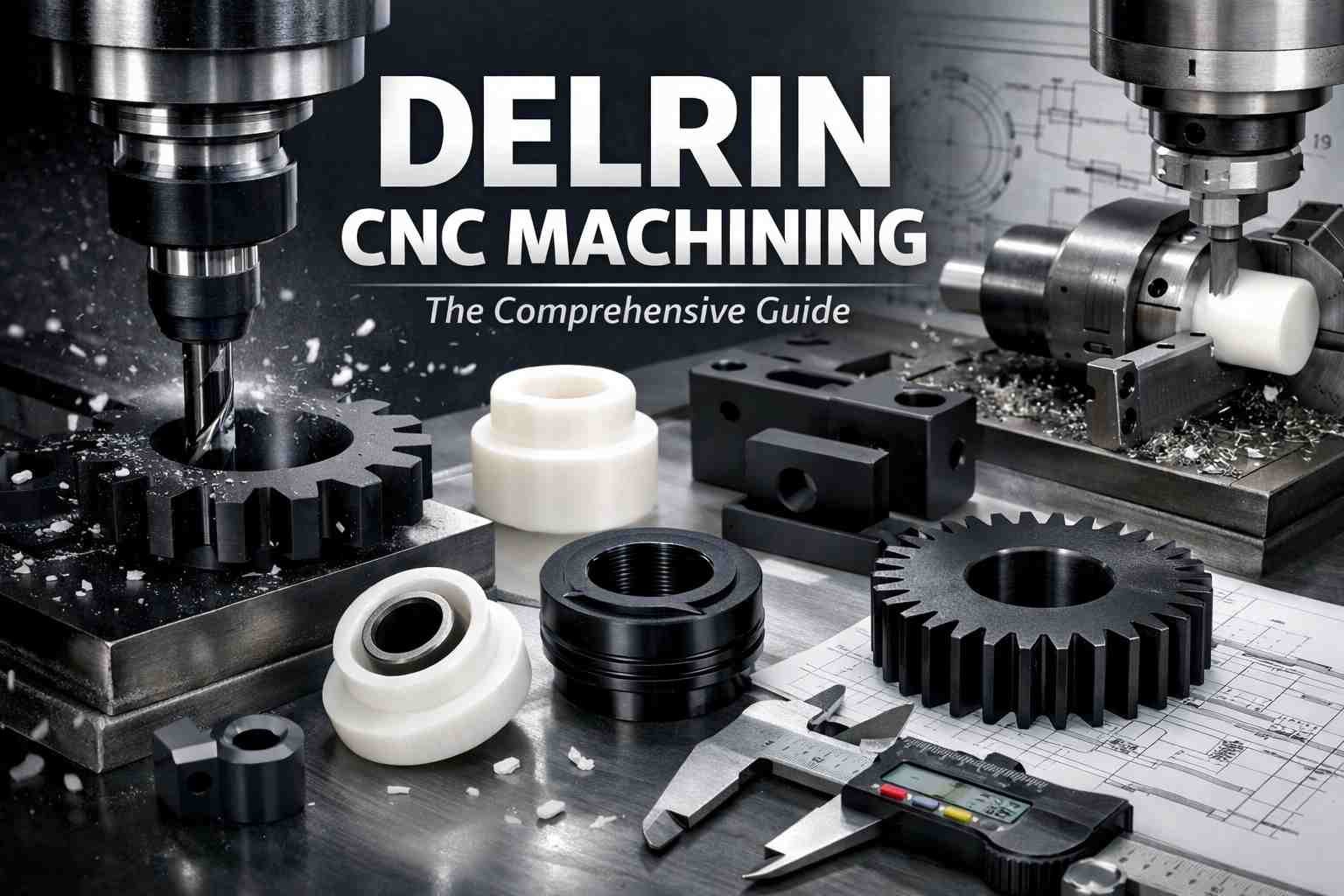

Delrin CNC Machining: The Comprehensive Guide

Learn Delrin CNC machining benefits, processes, tolerances, and applications. Discover how Fengchi delivers precision POM and acetal machined parts.

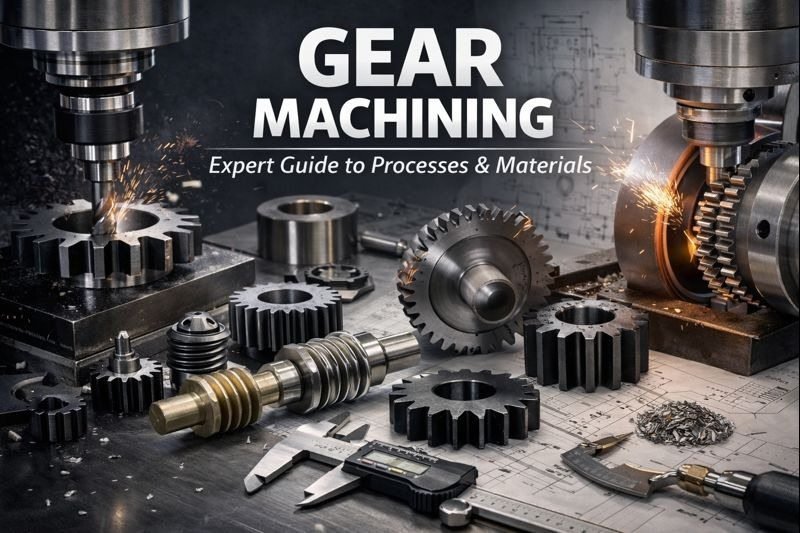

What is Gear Machining? Expert Guide to Processes & Materials

Learn what gear machining is, key processes, materials used, and tolerances. Discover why professional gear manufacturers matter for quality, durability, and performance.

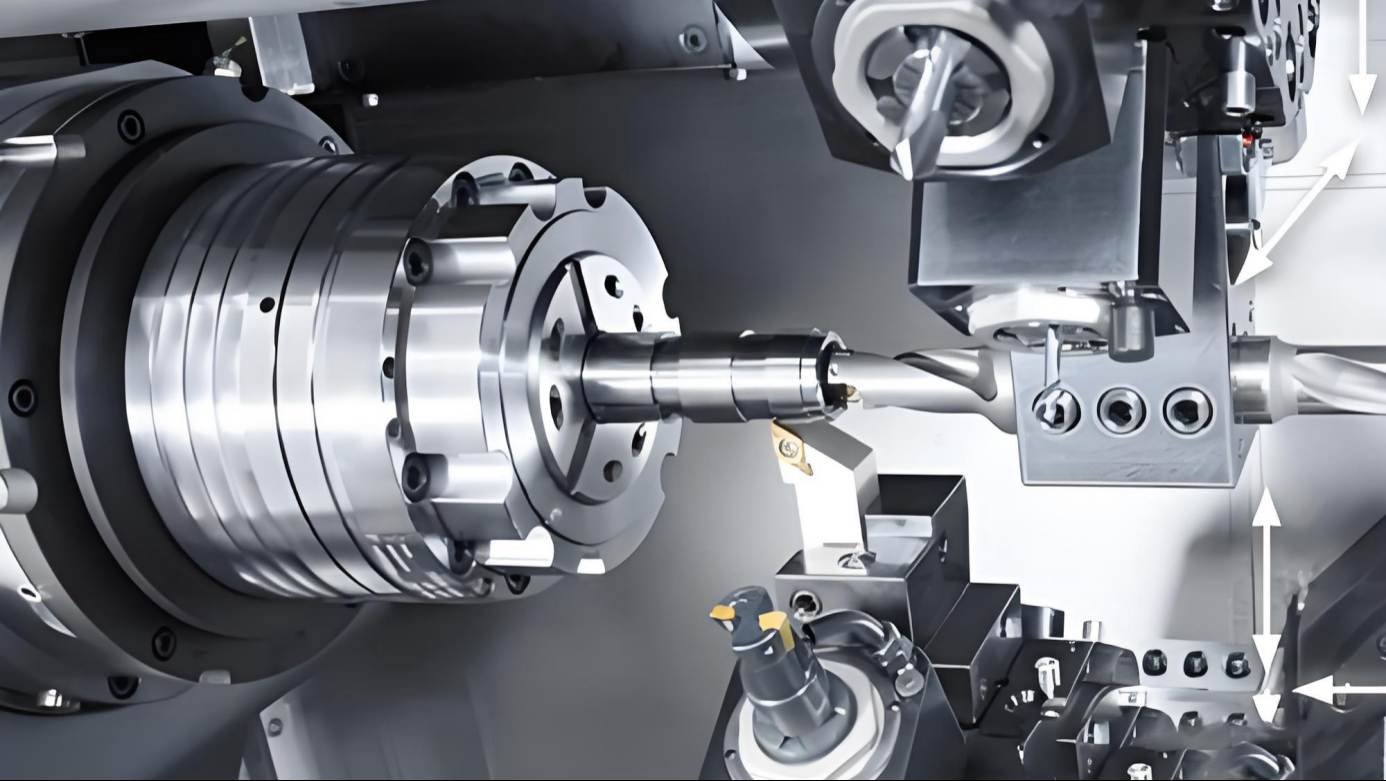

Metal CNC Machining: What It Is, How It Works & Why It Matters in Modern Manufacturing

Learn what metal CNC machining is, how it works, and why it’s essential for modern manufacturing. Discover benefits, applications, materials, and precision solutions.

CNC Machining vs Conventional Machining: A Complete Comparison Guide

Compare CNC machining vs conventional machining for precision, cost, materials, volume, and when to choose each. Learn how Fecision CNC supports custom manufacturing from your drawings.

Invar CNC Machining: Processes, Advantages, and Finishing

Maximize stability with Invar CNC Machining. Discover the different Invar grades, critical expert tips, and specialized processes for aerospace and optical parts.

Explore Types of Vertical Mills for Your CNC Milling Needs

Explore various types of vertical milling machines to meet CNC milling requirements and provide efficient, precise equipment selection references for precision part machining.

Titanium CNC Machining Explained: Why It’s the Gold Standard for Aerospace and Medical Parts

Learn how titanium CNC machining delivers unmatched strength, precision and quality in aerospace and medical industries. Learn why Fecision leads in titanium manufacturing.

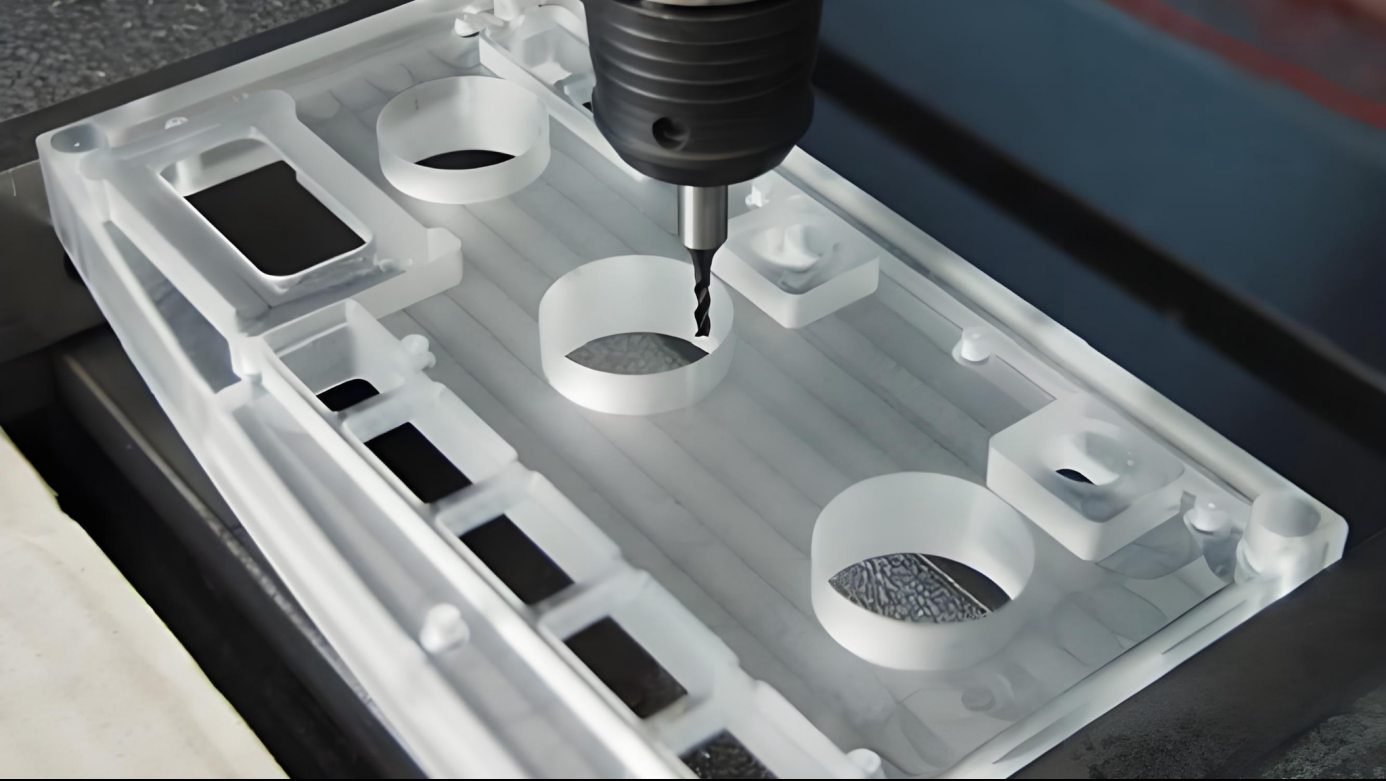

Expert Tips on CNC Plastics Selection

Learn expert tips on CNC plastic selection. Discover the best materials—from ABS to PEEK—for strength, heat, and chemical resistance in your precision project.

CNC Router vs CNC Mill: What’s the Difference?

Detail the differences between CNC routers and CNC mills to help select the right equipment for metal and non-metal machining.

CNC Machining Coolant: How It Works and Its Importance

Understand the working principle and importance of CNC machining coolant, and master its key role in improving machining quality and protecting equipment.

Machining Rake Angle Guide: Choosing the Right Angle for CNC

Gain an in-depth understanding of the machining rake angle guide, master the selection skills of rake angles in CNC machining, and choose the appropriate angle for different machining scenarios.

CNC Machining Complex Parts: Techniques and Best Practices

Learn the core technologies and best practices for CNC machining of complex parts to master the key methods for improving machining accuracy and efficiency.

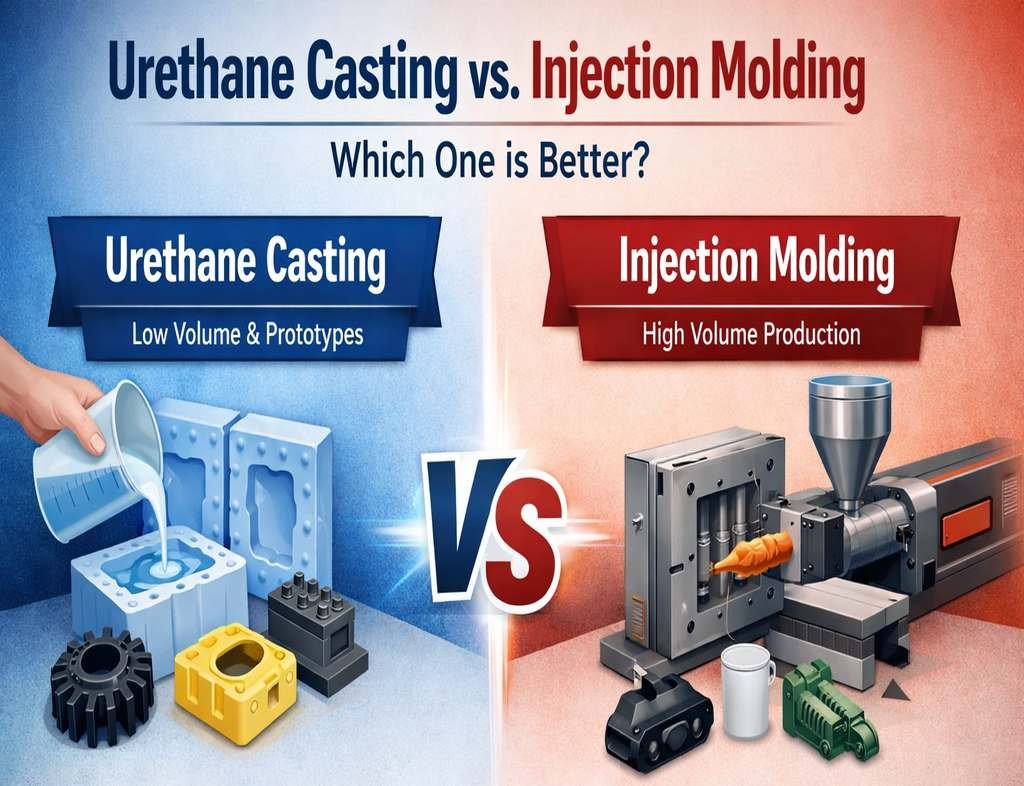

Urethane Casting vs Injection Molding: Which One is Better?

Compare urethane casting vs injection molding for cost, speed, materials, and volume. Learn which manufacturing method is best for your project.

What Is HDPE Injection Molding? A Complete Guide for Manufacturers

what HDPE injection molding is, its process, benefits, and temperatures. And how to choose the right HDPE molding service.

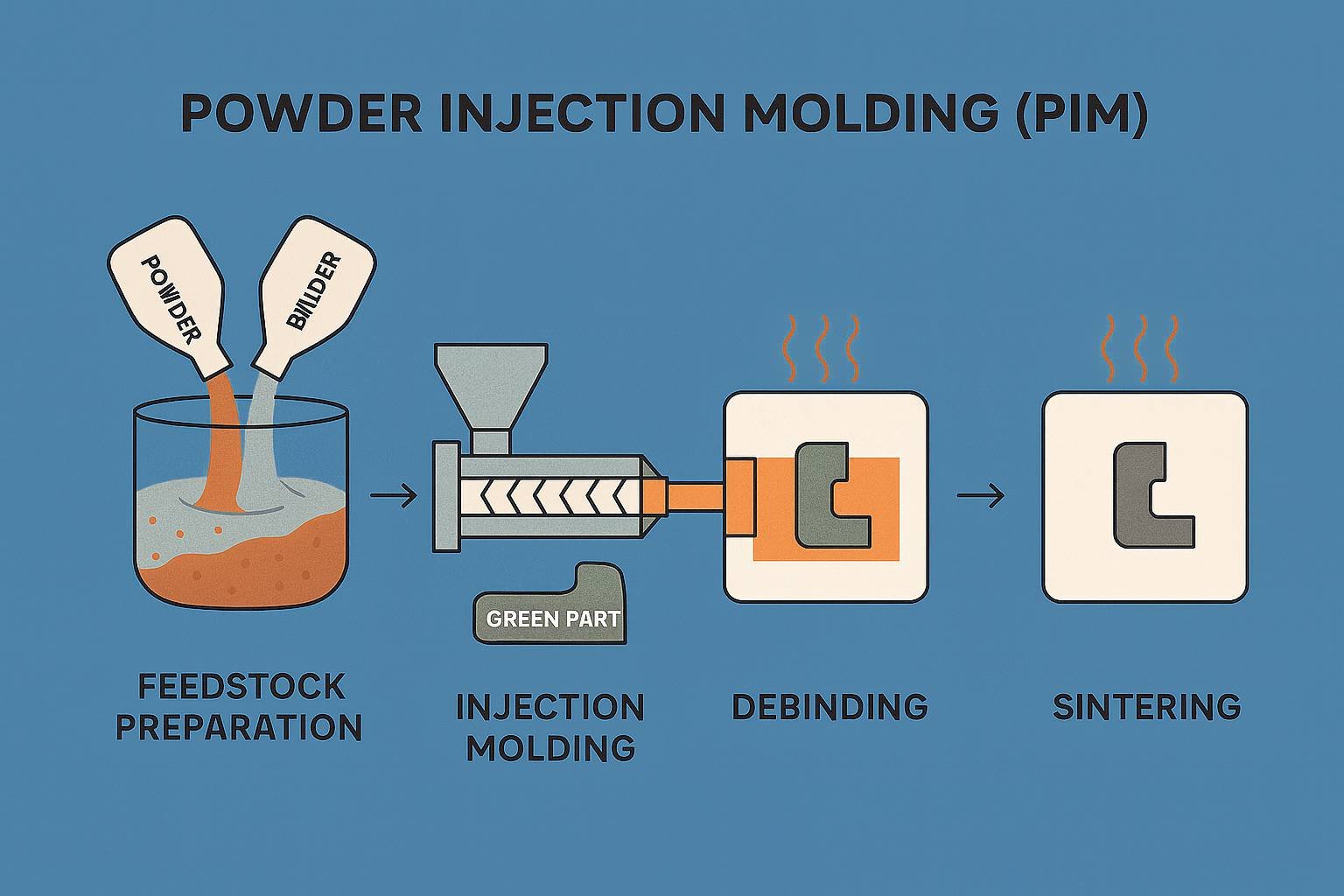

Powder Injection Molding (PIM) Explained: Process, Materials & Industrial Applications

Learn how Powder Injection Molding works, its materials, benefits, and industrial applications. A complete guide for manufacturers seeking precision and efficiency.

Acetal(POM) Injection Molding: A Comprehensive Guide for Your Projects

Elaborate on the key process points and parameter configurations of acetal (POM) injection molding to provide professional guidance for the stable production of wear-resistant and high-rigidity products.

The Complete Guide to Thermoplastic Injection Molding for Manufacturing Success

Learn how thermoplastic injection molding works, materials used, benefits, and how to choose the right manufacturing partner for high quality production.

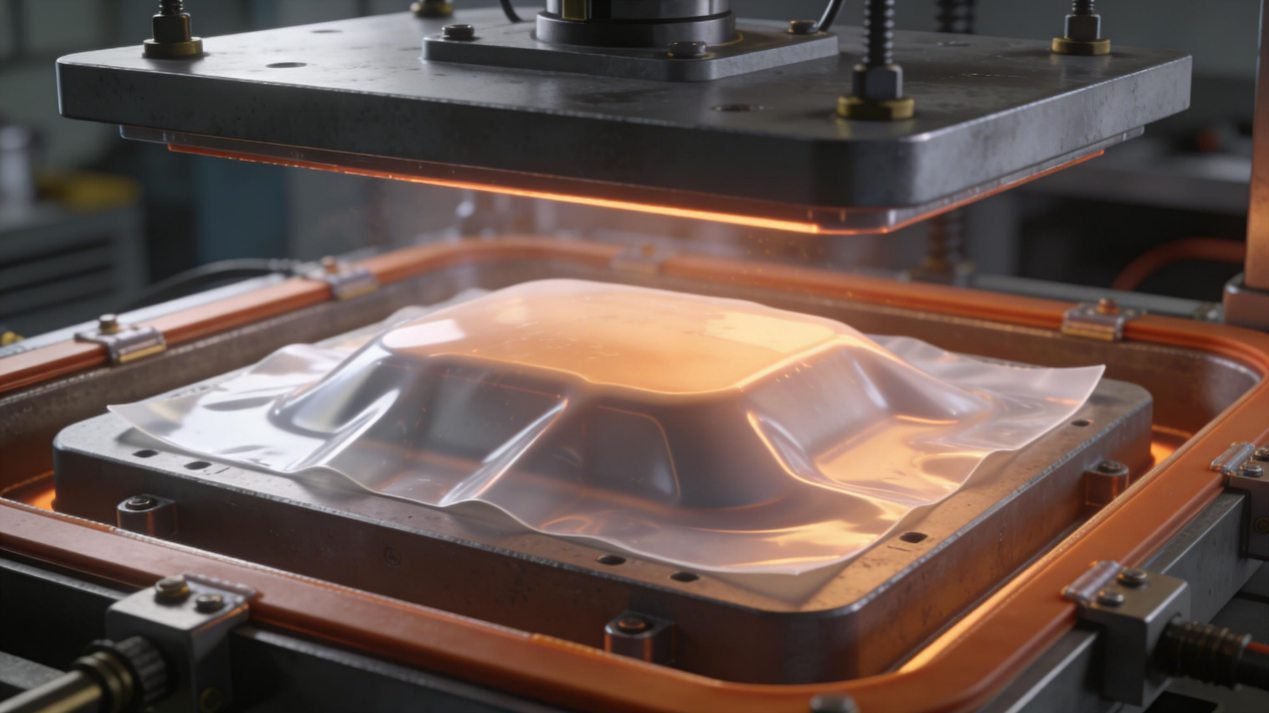

What Is Vacuum Forming and How Does It Work?

Discover how vacuum forming creates high-quality plastic parts. Our guide explains the vacuum forming process, its advantages and limitations, common materials, and key applications.

Blow Molding vs. Injection Molding: Deep Comparison

Learn how to choose between blow and injection molding. Discover the most effective molding method for producing plastic parts.

Secondary Processes for Injection Molding: Enhancing Your Parts

Analyze the core methods and advantages of injection molding secondary processes to provide professional guidance for optimizing the surface quality and service performance of plastic parts.

How to Determine the Right Injection Molding Machine Tonnage for Your Project

Analyze the core basis and calculation methods for injection molding machine tonnage selection to guide the matching of suitable injection molding equipment for different projects.

PVC Injection Molding: Everything You Need to Know

Learn how PVC injection molding works, its key benefits, common defects, and why Fecision is the ideal partner for high-quality custom PVC parts.

LDPE Injection Molding: A Comprehensive Guide

Elaborate on the key process points and parameter settings of LDPE injection molding to provide professional guidance for the efficient molding of flexible plastic products.

Understanding PBT Injection Molding for Plastic Parts

Analyze the key process points and adaptability of PBT injection molding to provide professional technical guidance for the efficient and stable production of plastic parts.

Improve Quality with Six Sigma in Manufacturing

Implement the Six Sigma management system to improve manufacturing standards, control production deviations and achieve steady improvement in product quality in the manufacturing industry.

What Is Subtractive Manufacturing? A Complete Beginner’s Guide

What is subtractive manufacturing? Learn how it works, its advantages, limitations, and how it compares to additive manufacturing in this beginner-friendly guide.

Blind Holes in Machining: Purpose, Design, and Engineering Uses

Analyze the purposes, design key points and engineering applications of blind holes in machining to provide scientific design and application references for precision part processing.

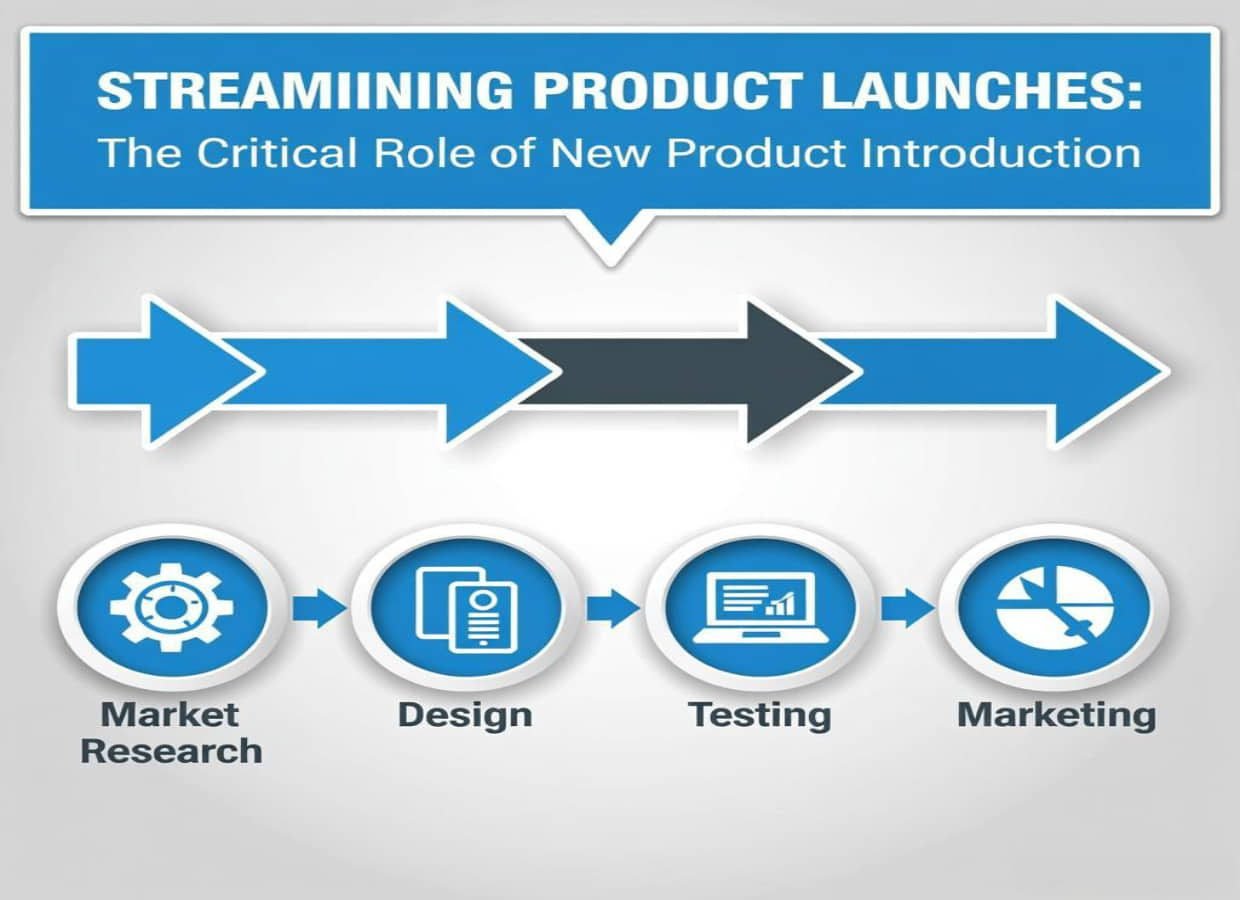

Streamlining Product Launches: The Critical Role of New Product Introduction

Explore the critical role of New Product Introduction (NPI) in streamlining product launch processes to help enterprises efficiently advance new product implementation and seize market opportunities.

On-Demand Manufacturing: How It Works and Its Advantages

Elaborate on the implementation methods and application value of on-demand manufacturing to enable enterprises to flexibly adapt to market changes and improve production supply chain efficiency.

Computer-Aided Manufacturing: How CAM Works and Its Benefits

Analyze the working principle and core advantages of Computer-Aided Manufacturing (CAM) to help improve production automation levels and machining efficiency.

Beyond ISO: How Certifications Guarantee Unrivaled Quality

Explore the importance of ISO Certifications, including IATF 16949, AS 9100, and ISO 13485, in ensuring consistent quality and compliance.

Common Plastic Joining Techniques for Your Projects

Learn effective plastic joining techniques for connecting plastic parts. Explore common methods and key considerations for choosing the best connection technique for your needs.

Understanding Design for Assembly (DFA) and Its Importance

Learn about Design for Assembly (DFA) and its importance in simplifying product assembly. Discover key principles and best practices for efficient assembly tooling.

A Complete Guide to Injection Molding Tolerances.

Discover the key factors affecting injection molding tolerances, types of tolerances, and proven tips to control size variations for precise, high-quality plastic parts.

Threaded Holes Explained: Types, Methods, and Best Practices

Learn about threaded holes, including types, manufacturing methods, and best practices for successful machining. Improve your product quality with our expert guide.

ISO Certifications for Plastic Injection Molding

Discover the importance of ISO certifications for plastic injection molding and how they ensure quality standards in custom plastic injection molding services for various industries.

Is Delrin the Same as Acetal: Key Differences Explained

Elaborate on the compositional characteristics and application differences between Delrin and acetal to facilitate the precise selection of suitable materials based on operating conditions.

Cast Aluminum vs Forged Aluminum: Which One Is Better?

Analyze the core characteristic differences and application advantages of cast aluminum and forged aluminum to help select suitable aluminum material forming processes based on operating conditions.

Invar vs Kovar: A Comprehensive Comparison

Provide a comprehensive comparison of the characteristics, properties and application scenarios of Invar and Kovar to offer professional references for material selection in precision manufacturing.

Non-Ferrous Metals: Types, Properties, and Applications

Understand the classification, key properties and applicable fields of non-ferrous metals to help select the right materials for precision manufacturing.

Alloy Steel vs Cast Iron: Which Material is Right for You?

Understand the performance differences and application fields between alloy steel and cast iron to provide clear references for selecting suitable materials.

ASA vs ABS: Choosing the Right Filament for Your Projects

Understand the core differences and key usage points between ASA vs ABS to easily select the right 3D printing filament for various projects.

Why Nickel Alloys Shine: Key Properties and Applications

Explore the world of Nickel Alloy: Understand its properties, types, and industrial applications. Your comprehensive guide to Nickel Alloy advantages and limitations.

Inconel 718 vs Inconel 625: Which Nickel Alloy is Right for You?

Inconel718 vs Inconel625: Compare material properties, machinability, and uses. Find out which nickel alloy is right for your project and how to choose the best one.

Discover PC Plastic: Properties, Processing Methods, and Uses

Learn about PC Plastic: its properties, processing methods, and common uses. Discover if PC Plastic is safe and recyclable in our ultimate guide.

PLA Plastic: What You Need to Know About Polylactic Acid

Discover the ultimate guide to PLA Plastic, exploring its properties, advantages, and applications. Learn about its biodegradability and uses in various products.

PS Plastic: Types, Properties, and Applications Explained

Get to know PS Plastic: its properties, applications, and comparison with other plastics like polypropylene. Your ultimate resource.

PE Plastic Guide: Properties, Processing, and Applications

Get the inside scoop on PE Plastic with our comprehensive guide. Explore its benefits, types, and applications, and understand how it’s processed and recycled.

Sulfuric Acid Anodizing: Process, Types & Applications

Analyze the process principle, types and applications of sulfuric acid anodizing to provide professional technical solutions for corrosion resistance, wear resistance and surface modification of aluminum parts.

Pad Printing Guide: How It Works and Its Benefits

Elaborate on the operating mechanism and application value of pad printing technology to facilitate high-quality printing on complex-shaped workpieces and enhance the standardization of product identification.

Nickel Plating Explained: Types, Benefits, and Applications

Analyze the types, core advantages and industrial applications of nickel plating to provide a reliable surface treatment solution for corrosion resistance, wear resistance and appearance enhancement of metal parts.

Bead Blasting: A Comprehensive Guide

Provide a comprehensive overview of the characteristics and application fields of bead blasting technology to offer professional references for the process selection of workpiece surface treatment.

Guide to the Aluminum Anodizing Finishes

Analyze the various surface effects, advantages and applicable scenarios of aluminum anodizing to assist in the selection of surface protection and appearance design for aluminum parts.

Tumble Finishing: Process, Benefits, and Industrial Applications

Analyze the process flow, core advantages and industrial applications of tumble finishing to provide efficient solutions for deburring and improving the surface finish of parts.

Vapor Polishing for Plastic Parts: Process and Benefits

Understand the processing flow and application value of vapor polishing for plastic parts to provide a reference for efficient surface treatment solutions for precision plastic components.

What is Hard Anodizing? Process, Features, and Uses Explained

Analyze the process principles, core characteristics and application scenarios of hard anodizing to help you fully understand this surface treatment technology.

Plasma Cutting Explained: Process, Materials, and Benefits

Gain an in-depth understanding of the process principles, applicable materials and core advantages of plasma cutting to help select the right metal cutting solution.

Black Oxide Coating: Properties, Advantages, and Uses Explained

Understand the properties, advantages and uses of black oxide coating to provide references for the selection of workpiece surface treatment.

Electroplating Explained: Process, Benefits, and Applications

Learn about Electroplating: a comprehensive guide covering the process, benefits, and applications. Discover how electroplating works and its uses in various industries.

Mold Polishing Techniques And Standards For Perfect Surface Finish

Learn mold polishing techniques, standards, and best practices for perfect surface finish, durability, and plastic injection mold quality.

Forged vs Cast Golf Clubs: What Are the Differences?

Cast vs Forged Golf Clubs: Compare the unit economics and supply chain impact for your next product line. Align manufacturing with your MOQ and cost goals.

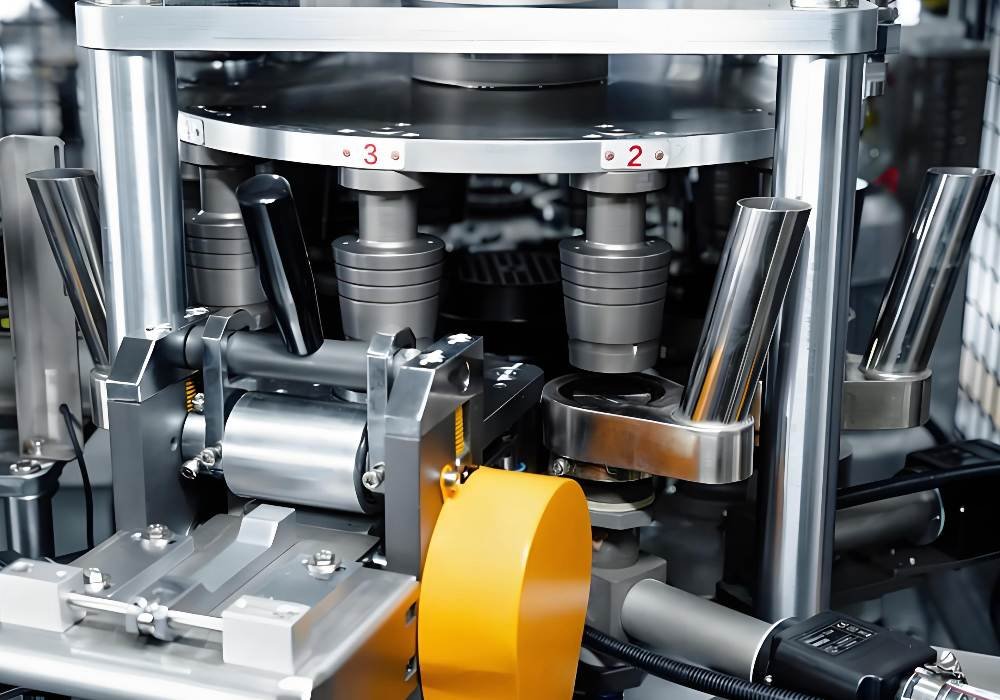

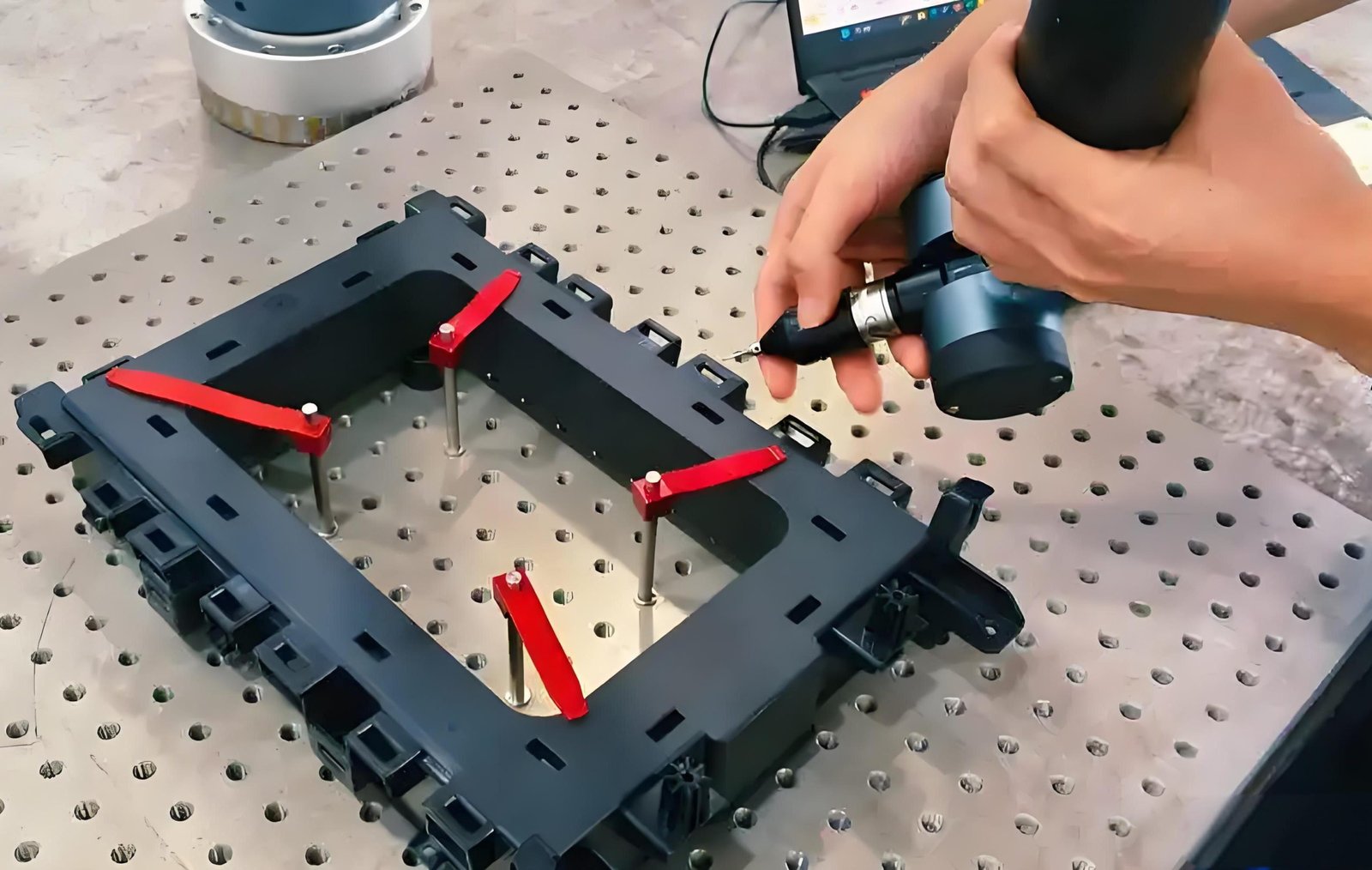

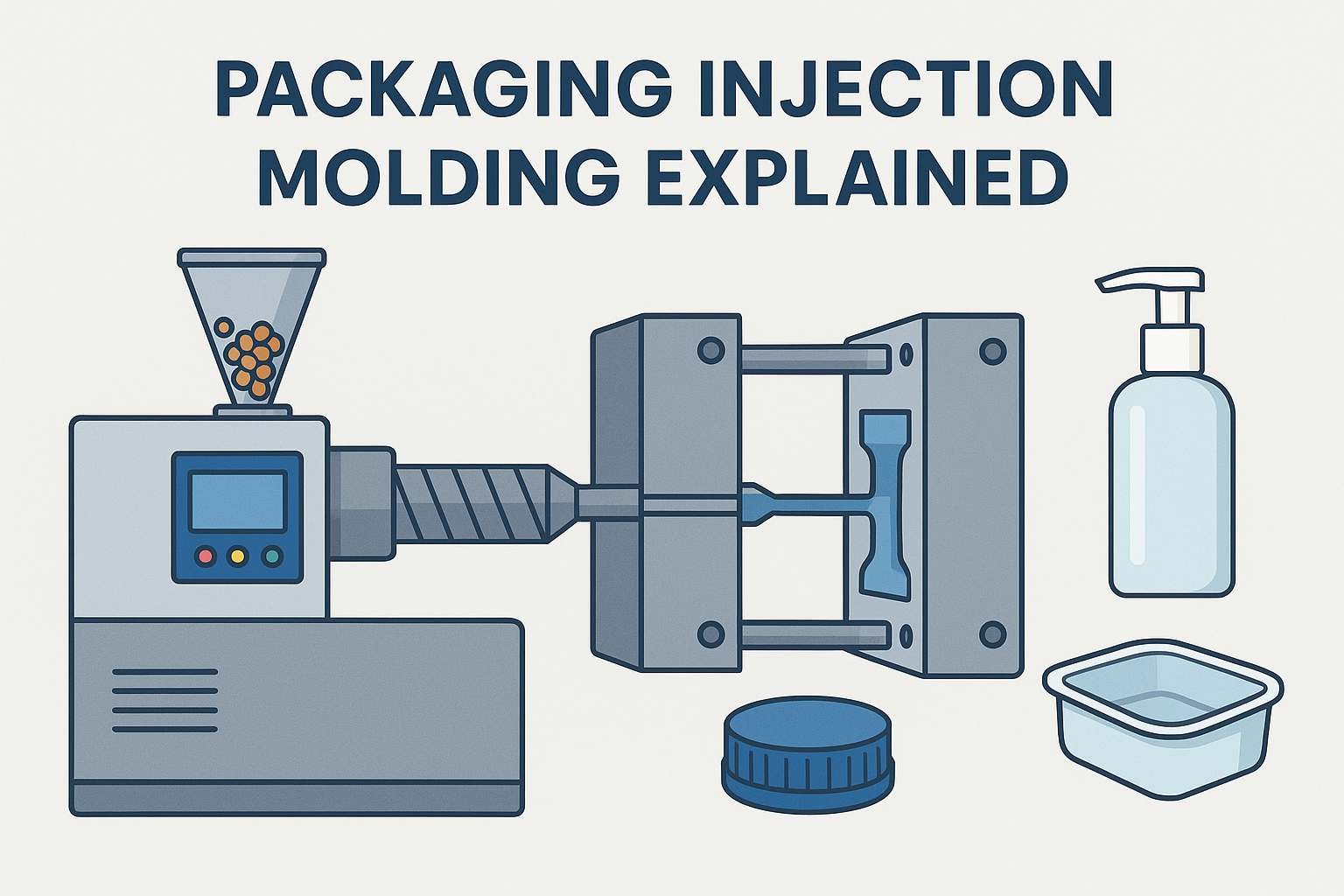

Packaging Injection Molding Explained: Processes, Materials, and Benefits

Learn how packaging injection molding works, key materials, and major benefits. Discover why it’s essential for high-volume, precise, and sustainable packaging.

How Fecision Helps the Connector Industry Manufacture High-Precision Parts

Fecision’s custom connector mold services: IATF/ISO certified, micro-tolerance precision & fast prototype-to-production. Perfect for automotive, telecom, aerospace & medical.

Forged vs Cast Wheels: Which Is Better for Performance and Durability?

Compare forged vs cast wheels to choose the best option for performance, durability and value. Learn the differences to make the right upgrade for your vehicle projects.

Forged vs Cast Crankshaft: Which Is the Right One for You

Analyze the core differences and application advantages of forged/cast crankshafts to help select suitable crankshaft manufacturing processes based on engine operating conditions.

The Complete Guide to Gear Hobbing: How It Works and Why It Matters

Elaborate on the working principle and core value of gear hobbing to provide efficient processing solutions and technical references for precision gear manufacturing.

Plastic Enclosure Design for Injection Molding: 10+ Guides to Consider

Master injection molded enclosure design. Learn 10+ DFM principles, including wall stock, draft, and snap-fits, to eliminate warpage and cut tooling costs for high-volume production.

Medical Injection Molding Explained: How Precision Plastics Power Modern Healthcare

Learn how medical injection molding powers modern healthcare with precision, efficiency and reliability in producing high quality medical devices.

CNC Robotics Components: Your Guide to Machining Parts for Automation

Unlock micron-level accuracy for your automation project. Discover how CNC machining creates the durable, complex CNC robotics components needed for modern robots.

Self-Lubricating Bearing Guide: How It Works, Types, and Advantages

Analyze the working principle, types and core advantages of self-lubricating bearings to provide a reference for efficient and wear-resistant solutions in the selection of mechanical transmission systems.

CNC Machining for Aerospace: Complete Guide to Know

This guide explores aerospace CNC machining, the precision manufacturing process that creates safe, lightweight, and efficient aircraft and spacecraft components.

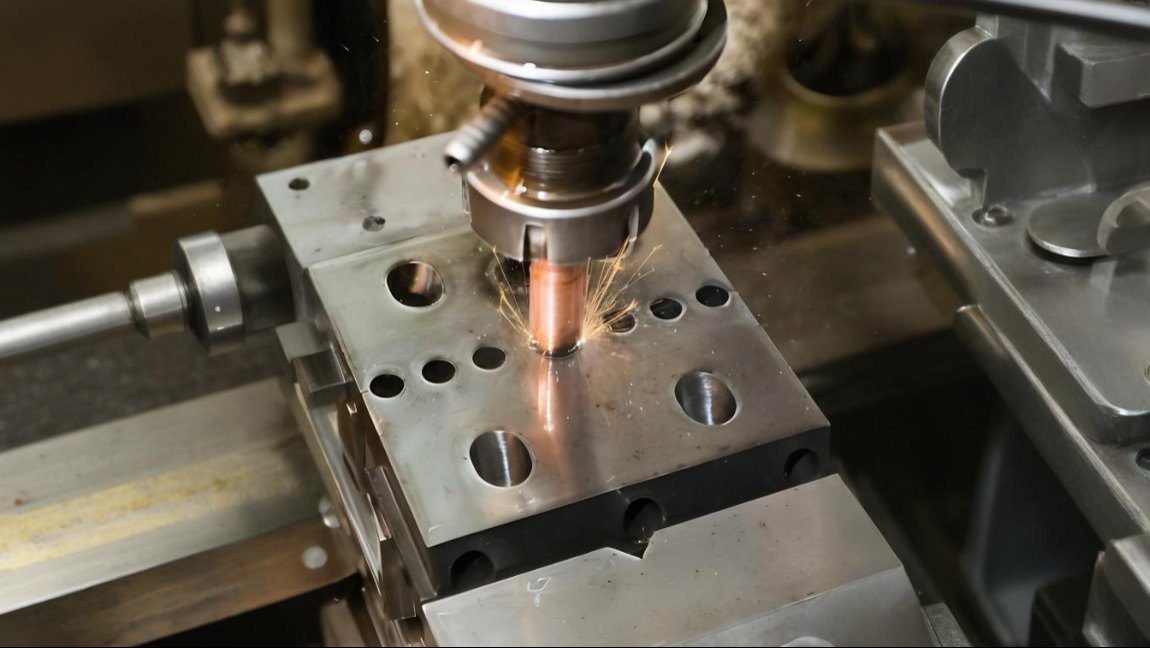

Copper Alloy EDM Electrodes for Electrical Discharge Machining

Understand the characteristics, application scenarios and advantages of copper alloy electrodes for electrical discharge machining (EDM) to provide professional references for EDM electrode selection.

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.