Automotive Injection Molding: What Do You Need to Know About It?

Learn how automotive injection molding works, its benefits, common applications, and materials used to create durable, cost-effective, and high-quality vehicle parts.

Learn how automotive injection molding works, its benefits, common applications, and materials used to create durable, cost-effective, and high-quality vehicle parts.

Trapped air, malfunctioning equipment, and poor material selection may cause burn marks in injection molding. Learn about mold design, equipment issues, and material handling to ensure defect-free plastic parts.

Trying to choose between reaction injection molding and injection molding? Learn the key benefits and best uses to see which one is the right fit for your project.

Explore the world of aerospace plastic injection molding. This guide covers everything from material selection and precision manufacturing to common parts used in modern aviation.

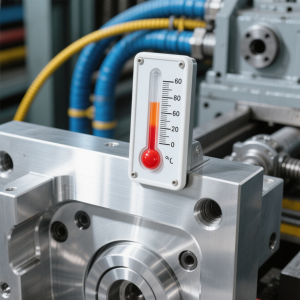

What is mold temperature, and how does mold temperature affect in injection molding? Here is a complete guide from explanation to useful handling tips. Read on.

Encounter Reaction Injection Molding to build strong, lightweight, and intricate parts. Find the process, benefits, and material types.

Find the right injection molding machine for your needs. Check out our roundup of Top10 Injection Molding Machine Manufacturers, covering types, technical parameters, and more.

Ever squint at a plastic part and spot tiny black dots? What are they? Where are they from? Let’s dig into these pesky black specks—because they’re more than just eyesores.

Understand what demolding is when it comes to injection molding. A proper demolding will minimize defects, improve production speed and cost for your high-quality plastic parts.

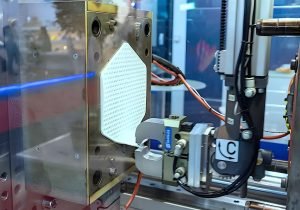

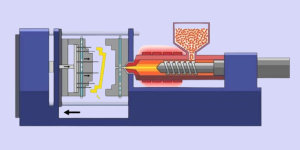

Wondering how an injection molding machine works? Learn the process: clamping, injection, cooling—key stages in plastic part production.

Estimate injection molding costs easily! Learn about mold types, materials, and design tricks to keep your plastic part production on budget.

What if a single gap ruined your parts? Injection mold shut offs are precision steel seals that stop molten plastic leakage, slashing rework costs for medical batches or auto line shutdowns. Mold integrity, guaranteed.

Learn how to eliminate flow marks in injection molding. Discover causes and effective solutions to achieve high-quality, defect-free plastic parts.

Discover key strategies to avoid voids in injection molding: adjust pressure, temperature, cooling. Fix design/material issues, refine processes for defect-free parts.

Discover what a slider in injection molding is, how it works, its components, types, and applications. Learn how sliders solve undercut challenges in mold design for precision part production.

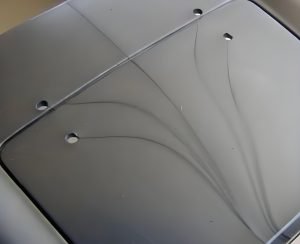

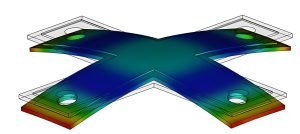

Discover warpage in injection molding: its causes, prevention techniques, and impact on part quality. Learn how material, process, and mold design affect warpage and how to ensure high-quality plastic parts.

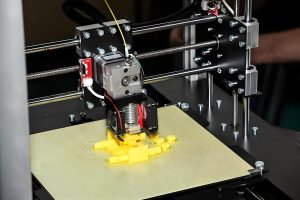

Additive manufacturing builds objects layer by layer for complex, custom designs, while subtractive manufacturing cuts away material for strong, precise parts.

Discover why short shots occur in injection molding and how Fecision’s solutions prevent defects with simple, effective strategies.

Metal Casting vs. 3D Printing? Have a better understanding of the differences between these manufacturing processes to choose the appropriate manner to manufacture your parts.

Do you want to upgrade your cast metal? Dive into our easy guide on heat treating! Learn how to boost strength, toughness, and durability for all your projects. It’s metal magic!

An In-Depth Guide to Casting in Manufacturing: Types, Applications, and Challenges

Discover how overmolding works to create multi-material injection molded parts with enhanced functionality and design flexibility.

Polyamide vs Polyester: Compare their benefits, properties, and uses to make an informed decision for your application needs.

Casting and molding are key manufacturing processes—but how do they differ? Learn the differences between these two methods and their real-world applications.

Learn how to Avoid silver streaks in injection molding by controlling temperature, injection speed, material drying, mold cleaning, and using quality resins for better parts.

Struggling with injection molding defects like short shots or burns? Discover essential venting in injection molding guidelines. Learn how proper injection mold vents enhance quality and cut costs.

Discover what EV metal part stamping is, its benefits, common materials, and key processes like progressive and transfer die stamping. Learn design tips and how precision metal stamping is crucial for EV manufacturing.

Discover the key differences between overmolding vs insert molding—two essential injection molding techniques for manufacturing. Learn their unique features, applications, and benefits to optimize your production process.

Don’t know what the difference between silicone and RTV silicone is? Discover the key differences, including their properties, uses, and curing processes.

Learn how to effectively prevent weld lines in injection molding. Discover expert tips on part design, mold adjustments, and process optimization to achieve strong, flawless plastic parts.

Struggling with injection molding flash? Understand the root causes of excess plastic and implement proven methods to achieve perfectly molded components.

Explore the critical role of medical plastic injection molding in producing precise and reliable chemistry reagent discs for modern healthcare diagnostics.

Learn about Overmolding in injection molding, its operations, design tips, and materials. Discover its benefits, challenges, and applications in various industries.

Discover how Hot Runner injection molding works, its components, benefits, and ideal use cases for efficient, high-volume plastic production.

Choosing between HCR and LSR for your medical device? This guide compares high consistency rubber and liquid silicone rubber, highlighting key differences in properties, processing, and medical-grade considerations to help you make the right choice.

Metal stamping materials have a great influence on metal stamping for shape and form without breaking. In this guide, we’ll give a guide on the factors and best metals for sheet metal stamping.

Navigating biocompatibility testing for medical devices? Explore ISO 10993 and USP Class VI standards, including FDA requirements and implications for silicone.

Learn how to reduce shrinkage in injection molding with tips on material selection, mold design, and process optimization for better accuracy.

What sets platinum grade silicone apart from medical grade silicone? Discover crucial differences, applications, and why the right type matters.

Compare LSR injection molding vs. HCR injection molding for medical and industrial use. Learn pros, cons, and applications of each silicone molding method.

Learn expert tips to prevent air bubbles in plastic injection molding with smart design, proper drying, and expert troubleshooting. Achieve flawless, durable parts.

Explore the four essential types of metal stamping—progressive, transfer, deep draw, and multi-slide metal stamping—and learn which method best fits your needs.

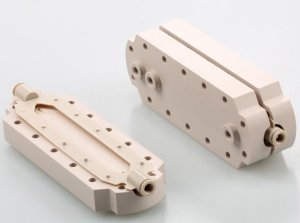

Discover the key components of electrical connectors, their functions, materials, and tips for choosing the right connector for any application.

What are connector contacts, and how do you choose the right ones? Discover the key factors to consider when selecting contacts for maximum performance.

Familiarize yourself with ISO 10993 biocompatibility standards for medical-grade silicone. Learn about its testing requirements and the processes involved.

Confused by hot stamping vs. cold stamping? This guide breaks down the key differences, benefits, and limitations of each metal stamping process to help you choose the best method for your manufacturing needs. Learn more!

Have you ever wondered why some silicone is used in cooking while some is used in surgical operations? Let’s take a closer look at medical grade silicone vs. Silicone and uncover the key differences among them!

Unravel the mystery of the parting line in injection molding! This article explores its definition, formation, various types, and crucial design considerations to optimize your plastic part development.

Optimize your production process by understanding cooling time in injection molding. Learn about different methods and techniques to optimize cooling time.

Curious about how complex metal parts are made? Discover the fascinating world of sheet metal stamping, from raw material to precision-formed components.

Insert Molding is an injection molding process where pre-manufactured inserts are placed into the mold before injecting molten plastic. After cooling, the inserts and plastic bond together to form an integrated part.

Explore hot runner vs cold runner injection molding. Learn the key differences, pros, and cons of choosing the right process for your plastic parts manufacturing.

Injection blow molding (IBM) ensures precision, efficiency, and minimal waste. Discover how it benefits aerospace and industrial equipment manufacturing.

Why does injection molding wall thickness decide if your design sinks or swims? Want parts that survive real-world chaos? Nail the Goldilocks zone: balanced walls, smart ribs, and material mastery. Your mold’s counting on it.

Not sure which metal is best for your die-casting project? Discover the most common metals used and which one fits your manufacturing needs.

Learn how to prevent sink marks in injection molding with expert tips on material selection, design optimization, and processing techniques.

UHMW injection molding is changing the way high-performance parts are manufactured. Learn how to optimize processing for this high-performance material.

Learn the die casting process, including materials, techniques, and best practices for creating high-quality metal parts with precision and efficiency.

Modern injection molding technology allows EPDM rubber to transform into complex shapes efficiently. Want to know exactly how to do it? Can EPDM rubber be injection molded?

Learn how injection molding works, its parts, step by step process, material options and applications in modern manufacturing.