Urethane Casting vs Injection Molding: Which One is Better?

Compare urethane casting vs injection molding for cost, speed, materials, and volume. Learn which manufacturing method is best for your project.

Compare urethane casting vs injection molding for cost, speed, materials, and volume. Learn which manufacturing method is best for your project.

what HDPE injection molding is, its process, benefits, and temperatures. And how to choose the right HDPE molding service.

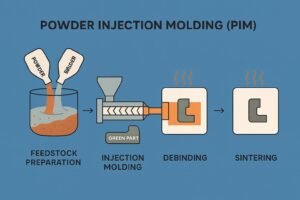

Learn how Powder Injection Molding works, its materials, benefits, and industrial applications. A complete guide for manufacturers seeking precision and efficiency.

Elaborate on the key process points and parameter configurations of acetal (POM) injection molding to provide professional guidance for the stable production of wear-resistant and high-rigidity products.

Learn how thermoplastic injection molding works, materials used, benefits, and how to choose the right manufacturing partner for high quality production.

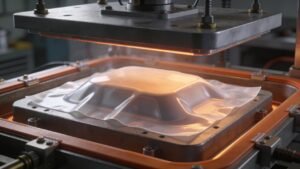

Discover how vacuum forming creates high-quality plastic parts. Our guide explains the vacuum forming process, its advantages and limitations, common materials, and key applications.

Learn how to choose between blow and injection molding. Discover the most effective molding method for producing plastic parts.

Analyze the core methods and advantages of injection molding secondary processes to provide professional guidance for optimizing the surface quality and service performance of plastic parts.

Analyze the core basis and calculation methods for injection molding machine tonnage selection to guide the matching of suitable injection molding equipment for different projects.

Learn how PVC injection molding works, its key benefits, common defects, and why Fecision is the ideal partner for high-quality custom PVC parts.

Elaborate on the key process points and parameter settings of LDPE injection molding to provide professional guidance for the efficient molding of flexible plastic products.

Analyze the key process points and adaptability of PBT injection molding to provide professional technical guidance for the efficient and stable production of plastic parts.

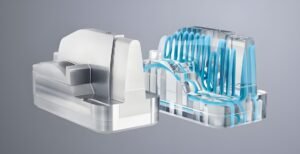

Unlock faster production cycles and higher quality parts with conformal cooling channels. Learn how this advanced technique revolutionizes injection molding efficiency.

Unlock high-performance TPU injection molding. Find essential tips on drying requirements, mold cooling strategies, and optimizing your part design for elasticity and strength.

Provide a comprehensive introduction to PETG injection molding process parameters and performance advantages to offer technical references for the production of food-grade and medical-grade plastic products.

Stop assembly: Learn how two color injection molding fuses two plastics into one durable, high-precision part, saving time and labor costs.

Learn about beryllium copper stampings for EV battery contacts, medical devices, and non-sparking safety applications. Achieve extreme reliability and precision.

Analyze the forming processes, mechanical properties and application fields of cast steel and forged steel to facilitate scientific material selection decisions for core components of industrial equipment.

Learn how Water Assisted Injection Molding works, the benefits, materials, and industrial applications for faster, lighter, and high-precision production.

Need custom plastic solutions? Understand thermoforming types, capabilities, and material selection for high-precision, large, or small plastic components.

Forging vs casting: what’s the difference? Learn which method makes stronger metal parts, compare forged vs cast metal, and discover when to choose casting or forging.

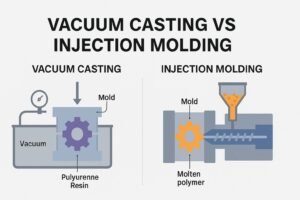

Compare Vacuum Casting vs. Injection Molding. Learn the key differences, advantages and costs to choose the right process for your manufacturing needs.

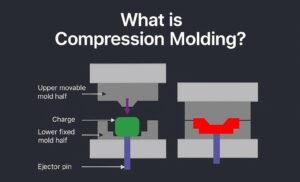

What Is Compression Molding? Learn the complete process, materials and applications behind this cost effective manufacturing method for strong, precise parts.

Learn the benefits of thin wall injection molding to achieve ultra-lightweight plastic parts and faster production, saving material and shortening cycle times.

Discover how silicone overmolding enhances product design, durability, and comfort across industries. Learn its process, benefits, and real-world applications.

Analyze the process principle, high-efficiency advantages and application scenarios of aluminum casting to provide an economical and reliable forming solution for the mass production of metal products.

Discover two-shot injection molding: single-cycle, dual-material precision. Cut assembly costs and boost product strength now.

Easily learn about alloy casting: how to change metal strength, pick your best material, and see how processes like die casting really work.

Leverage expert tips to avoid common mistakes in injection molding design, optimize product design schemes, and improve the efficiency and quality of injection molding production.

Discover how prototype injection molding helps you test designs fast. Discover the benefits and process steps of rapid injection moulding prototyping.

TPE injection molding is the key to flexible, durable parts. Discover the comprehensive process, key design principles, and applications of TPE and TPU in our comprehensive guide.

Need large plastic components? Review the large part injection molding process, materials, and machine selection for making strong, dimensionally stable parts.

Choosing between injection molding and extrusion? Compare process, cost, geometry, and precision to select the right method for your plastic parts. Get the key differences explained.

Understand the key advantages of injection molding, including efficient mass production and high precision, to provide references for project selection.

Learn the differences between injection molding’s elevated precision and cost-effective tooling of thermoforming. Use our guide to match your part with the appropriate manufacturing method.

Learn how automotive plastic parts drive vehicle efficiency, comfort, and design freedom. Explore key material applications and the critical steps for efficient production and finishing.

Experience the benefits of EVA injection molding! In this guide, you will learn how to leverage this foam molding technique that provides high-quality products for footwear, sporting goods and other applications.

Learn the essential guide to medical silicone molding – discover LSR injection process stages, advantages, material selection, and key applications in FDA-compliant manufacturing.

Need plastic optics fast? Explore optical injection molding solutions for your high-volume production of precision plastic lenses, light guides, and other critical optical components.

Learn what an undercut in injection molding is, why it matters, and how injection mold undercut design impacts part quality.

Discover how PET injection molding works, key temperatures, and applications. Discover the comprehensive PET injection molding process.

PE Injection Molding Guide To HDPE, LDPE, And LLDPE Applications

Need plastic parts fast? This guide explains what short run injection molding is and how it offers a quick and cost-effective way to get high-quality parts for low-volume production.

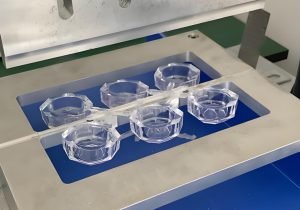

Get this complete guide to clear plastic molding. You’ll learn about various materials like acrylic and polycarbonate, common applications, and the benefits of using this advanced manufacturing process.

Need high-speed, low-cost plastic parts? This guide to PS injection molding explains everything from material selection to mold design. Learn the process for your next project with expert advice.

Vacuum casting delivers production-quality parts without expensive tooling. Learn the process, material selection, design rules, and applications for rapid, low-volume plastic production.

This guide covers the different types of ejection systems in injection molding. It will touch on the functions, the key components, and how to choose the right ejector system for your plastic part design.

Learn how to identify and fix common injection molding defects. Explore causes and solutions with a practical troubleshooting guide.

Learn how to choose the right injection molding gate type to optimize your part design! This guide covers different gate types, their pros, cons, and how to select the best one for your project to reduce defects and costs.

Ready to produce your plastic parts? This guide describes the main plastic manufacturing process and helps you choose the most appropriate one for your project, maintaining precision and quality.

Get perfect plastic parts every time. This guide to injection molding parameters will help you optimize settings like temperature, pressure, and cycle time to improve quality and productivity.

Discover what splay in injection molding is, what causes it, and practical fixes and prevention tips to produce defect-free parts.

Learn the key differences between injection molding and compression molding. Discover cost, process, and best use cases for projects.

Glass filled nylon injection molding uses nylon with glass fiber. Discover what it is, its benefits, types, process tips and more here.

A gating system in casting guides molten metal into the mold, ensuring smooth flow and minimizing defects. Learn about its types, key components, and design principles.

Learn 5 effective ways to maintain perfect color consistency in injection molding. Solve common challenges and ensure high-quality, uniform results.

Injection molding cycle involves several key phases. This guide explains each step, factors that affect cycle time, and practical ways to improve efficiency and part quality.

What ejector pin marks are in injection molding? Explore their causes, effects on product quality, and proven prevention methods.

Learn what rapid injection molding is, how the process works, the materials used, and why it is beneficial to create prototypes and low-volume parts.

Do you want to create plastic parts that are strong but lightweight? Gas assisted injection molding can create them, reducing your material cost and allowing for your design to be more flexible.