Plastic injection molding is widely used across various industries due to its versatility and efficiency. Its popularity isn’t just because of the rapid production process but also the wide range of materials available. When you need a product or part with specific properties, ypu have multiple injection molding materials to choose from.

So, what types of plastics are used in injection molding? Understanding these materials is crucial for a successful production plan. This guide explores the 10 most popular molding materials, categorized into three main plastic types—crystalline, semi-crystalline, and amorphous—highlighting why manufacturers prefer them.

Part 1: The 10 Most Popular Materials for Your Plastic Injection Molding Project

Plastic injection molding is widely used in manufacturing various plastic parts due to its versatility, precision, and cost-effectiveness. The success of a project depends on selecting the right material for the job. Here are the ten most popular injection molding materials, their properties, applications, pros, and cons.

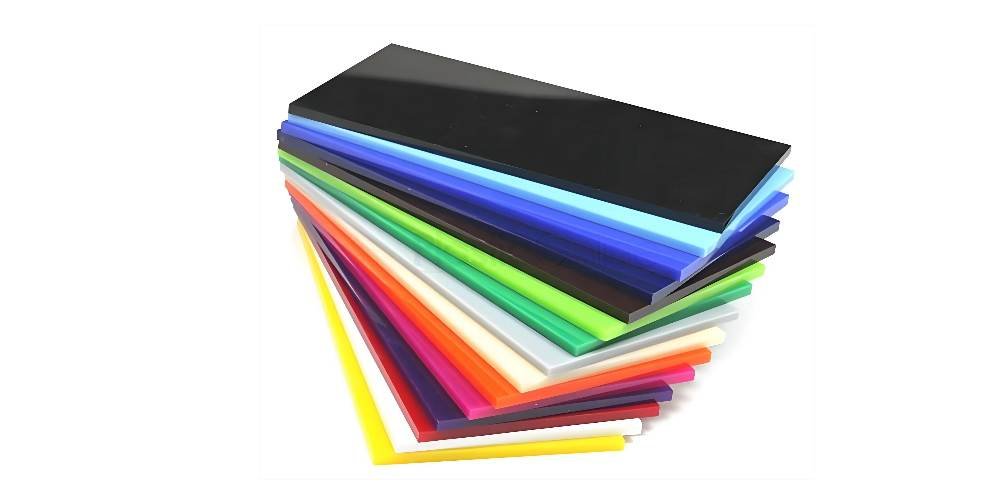

1. Acrylic (PMMA)

Acrylic, also known as poly (methyl methacrylate) (PMMA), is a lightweight, transparent thermoplastic with glass-like clarity and excellent optical properties. It’s commonly used in applications requiring transparency, high light transmission, and resistance to UV light and weathering. Acrylic is also shatter-resistant, making it a popular choice for various architectural and outdoor components.

Pros:

- High optical clarity and light transmission.

- A shatter-safe item provides a safer alternative to glass when conceivably needed.

- Resists UV and weather, recommending use outdoors.

- Doesn’t absorb odors or moisture.

Cons:

- Prone to stress cracking under heavy loads.

- Easily stained by oils, greases, and solvents.

- Poor resistance to high-impact forces.

Applications:

Applications for acrylic injection molding include windows, greenhouses, solar panels, bathroom enclosures, and other transparent components for architectural, lighting, and outdoor applications.

2. Acrylonitrile Butadiene Styrene (ABS)

ABS is a widely used thermoplastic due to its toughness and ease of molding. It has a relatively low melting point and is compatible with various colors and textures. ABS is known for its strength and impact resistance, particularly in low temperatures, making it ideal for consumer and industrial products. However, its performance diminishes in outdoor environments due to poor UV resistance.

Pros:

- High impact strength, even at low temperatures.

- Easy to mold, supports colorants and surface textures.

- Cost-effective for mass production.

- Provides a shiny and attractive surface finish.

Cons:

- Poor UV resistance, not ideal for outdoor applications.

- Not very resistant to water and weathering.

- It emits harmful smoke when burned.

Applications:

ABS injection molding is used to manufacture various plastic parts, including keyboard keys, protective headgear, electrical outlet plates, automotive wheel covers, consumer goods, sports equipment, and industrial fittings.

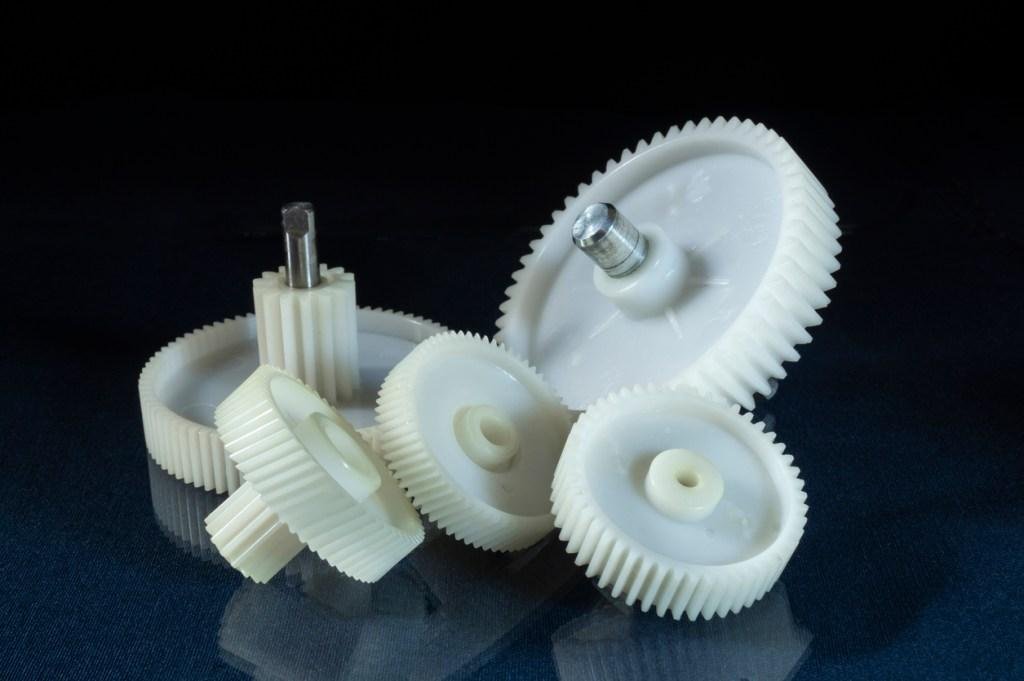

3. Nylon (Polyamide, PA)

Nylon is a synthetic polyamide known for its excellent toughness, high heat resistance, and good abrasion resistance. It also offers good fatigue resistance and noise-dampening properties. Although it is not inherently flame-resistant, flame-retardant versions are available. Nylon’s resilience makes it ideal for high-wear applications, but molding can be challenging due to shrinkage and moisture absorption.

Pros:

- Excellent toughness and abrasion resistance.

- High heat resistance, suitable for mechanical parts.

- Good fatigue and noise-dampening properties.

- It can be reinforced with glass fibers for greater strength.

Cons:

- Prone to UV degradation and moisture absorption.

- Difficult to mold due to shrinkage.

- Poor chemical resistance against strong acids and bases.

Applications:

Nylon injection molding is used for substantial mechanical parts like bearings, bushings, gears, slides, casings, snap-fit closures, threaded inserts, kinetic parts, jigs, and fixtures.

4. Polycarbonate (PC)

Polycarbonate is a strong, lightweight, transparent thermoplastic with excellent light transmission, optical clarity, and durability. Unlike acrylic, polycarbonate can withstand higher temperatures and offers superior impact resistance. However, it is not scratch-resistant, and its high processing temperatures make mold more expensive than other plastics.

Pros:

- Stronger and more durable than glass.

- Excellent optical clarity and light transmission.

- Good temperature stability.

- Uniform shrinkage, allowing for precise dimensional control.

Cons:

- Not scratch-resistant, prone to surface damage.

- High processing temperatures lead to higher molding costs.

- UV degradation over time unless stabilized.

Applications:

Polycarbonate injection molding is used for machinery guards, tinted windows, LED diffusers, and precise urethane and silicone casting molds. However, due to its BPA content, it is not recommended for food preparation or storage.

5. Polyethylene (PE)

Polyethylene is one of the most widely used plastics in the world. It is available in different densities, such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE), each offering varying flexibility, strength, and optical properties. PE plastics are cost-effective, resistant to moisture, and suitable for various applications.

Pros:

- Excellent chemical resistance and moisture resistance.

- Flexible, depending on the grade (LDPE or HDPE).

- Low cost, widely available.

- Suitable for food-grade applications.

Cons:

- Poor UV resistance and outdoor durability.

- Limited high-temperature performance.

- Prone to deformation under stress.

Applications:

Applications for polyethylene injection molding may be limited to indoor applications because of their poor UV resistance. Because they cannot withstand high service temperatures, these plastic materials may not be suitable for some processing applications. Injection molded polyethylene is often used in products such as housewares, toys, food containers, and automotive parts.

6. Polyoxymethylene (POM)

Polyoxymethylene (POM), or acetal, is a high-performance thermoplastic that combines rigidity, strength, and low friction. It is commonly used for mechanical parts that require high precision, such as gears and bearings. POM has excellent chemical resistance, low moisture absorption, and superior dimensional stability.

Pros:

- Excellent rigidity and dimensional stability.

- It has a low coefficient of friction and is ideal for moving parts.

- Good chemical resistance and low moisture absorption.

- High wear resistance.

Cons:

- Prone to UV degradation.

- Low impact strength in pure form.

- High shrinkage during molding, requiring careful processing.

Applications:

With its low coefficient of friction, injection-molded POM is used in bearings, gears, conveyor belts, and pulley wheels. Additional applications include fasteners, eyeglass frames, parts for knives and firearms, lock systems, and high-performance engineering components.

7. Polypropylene (PP)

Polypropylene is the second most commonly used plastic in the world. It is known for its excellent chemical resistance, high melting point, and good resistance to moisture. Polypropylene retains its shape even after being bent or twisted and is highly recyclable. However, it is flammable, degrades under UV exposure, and is difficult to bond or paint.

Pros:

- Excellent chemical and moisture resistance.

- High melting point, ideal for high-temperature applications.

- Flexible and retains shape under stress.

- Recyclable, making it an eco-friendly choice.

Cons:

- Highly flammable.

- Poor UV resistance leads to degradation in sunlight.

- Difficult to bond, paint, or coat.

Applications:

Applications for polypropylene injection molding include toys, storage containers, sporting goods, packaging, appliances, and power tool bodies.

8. Polystyrene (PS)

Polystyrene is a lightweight, low-cost thermoplastic known for its ease of molding and clarity. It is resistant to moisture and bacterial growth, making it suitable for medical and food-related applications. However, PS can be brittle in its general-purpose form and has lower impact resistance compared to other materials.

Pros:

- Lightweight and inexpensive.

- Excellent clarity, making it ideal for transparent products.

- Good chemical resistance, especially to diluted acids and bases.

- Resistant to moisture and bacterial growth.

Cons:

- Brittle, especially in general-purpose grades.

- It has low impact strength and is not suitable for high-stress applications.

- Prone to UV degradation.

Applications:

Polystyrene injection molding has applications in medical, optical, electrical, and electronic industries. Because of its higher impact strength, HIPS is often used with appliances and equipment, while injection-molded GPPS is used in plastic toys, cases, containers, and trays.

9. Thermoplastic Elastomer (TPE)

Thermoplastic Elastomer (TPE) is a hybrid material that combines the flexibility and resilience of rubber with the processing ease of plastics. TPEs can be stretched and return to their original shape when stress is removed. They are commonly used in applications requiring elasticity but are prone to creep over time and lose their rubber-like properties at high temperatures.

Pros:

- Flexible, rubber-like material that’s easy to mold.

- It can be stretched and returned to its original shape.

- Recyclable, reducing environmental impact.

- Cost-effective compared to silicone rubbers.

Cons:

- Liable to creep under sustained pressure.

- Loses elasticity at higher temperatures.

- It is more expensive than other plastics.

Applications:

Applications for TPE injection molding include footwear, medical devices, auto parts, and pet products. It is widely used in automotive weather seals, shock dust boots, medical breathing tubes, valves, catheters, and ventilation masks.

10. Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) is a highly versatile material that offers flexibility and toughness, making it ideal for applications requiring rubber-like elasticity. It outperforms TPE in resistance to extreme temperatures, chemicals, and abrasion. However, TPU requires drying before processing and may be too rigid for certain applications.

Pros:

- Excellent abrasion and chemical resistance.

- Superior temperature and ozone resistance.

- Highly elastic with good load-bearing capabilities.

- It can replace hard rubber in many applications.

Cons:

- Requires drying before processing.

- It can be too rigid for specific applications.

- Higher cost compared to other plastics.

Applications:

Applications for TPU injection molding include footwear, gaskets, caster wheels, sporting goods, and cases or enclosures for electronics and medical devices. In medical applications, TPUs are sometimes used as an alternative to polyvinyl chloride (PVC), which can cause skin irritation.

Part 2: What are the Factors Affecting Material Selection in Injection Molding?

Material choice in injection molding is a blend of technical and practical knowledge that is a decisive factor during product development. Below are the most significant aspects:

Mechanical Properties

When selecting a material for its intended purpose, it is essential to consider factors such as strength, toughness, flexibility, and wear resistance. For example, automotive parts may require high impact strength, while consumer products might prioritize durability over stiffness.

Thermal Properties

The material’s ability to endure processing and operational temperatures is a crucial factor. For high-temperature applications, materials with excellent heat resistance, such as polycarbonate and PEEK, are typically the best choices.

Environmental Considerations

The material’s durability under UV exposure, moisture, chemicals, and extreme temperatures should be carefully assessed. For outdoor applications, materials like acrylic or polyethylene with strong UV resistance are recommended, while polypropylene tends to degrade under UV exposure.

Cost and Availability

Cost-effectiveness and material availability usually determine the decision-making process, particularly in the case of mass production. Common plastics such as polypropylene or polyethylene are cheaper and easier to find; however, specialized materials could raise production costs.

Part 3: How to Choose Material for Your Plastic Injection Molding Project

One of the key decisions in your injection molding project is selecting the most suitable material for your product to meet its specific requirements. Here’s how you can make that choice:

Define Functional Requirements

Start by determining the mechanical, thermal, and environmental requirements. Does your product need to be highly durable, lightweight, or resistant to harsh conditions? Materials like ABS might be a good choice for products requiring impact resistance, while polypropylene could be better for those needing chemical resistance.

Consider Manufacturing Constraints

Each material has unique processing requirements—some may need high temperatures or specialized molds. It’s essential to evaluate these factors, considering both cost and production time.

Assess Cost Constraints

For large-scale production, maintaining a balance between quality and cost is crucial. Materials like polyethylene or polystyrene are common for non-critical applications, while high-performance options such as polycarbonate or advanced nylon provide superior strength and durability at a higher cost.

Regulatory and Compliance Factors

Certainly, in some cases, industries need materials that meet the standards set by their regulatory bodies, such as the health and food industry. Products like medical-grade TPE and polycarbonate are made for only such functioning.

Part 4: Additives Selection for Injection Molding Materials

Additives are vital in improving the traits of the base polymer. Properly selecting additives may boost the mold’s performance and service time.

Types of Additives

Some of the appreciated additives are colorants (for pigmentation), stabilizers (for UV or thermal stability), flame retardants (for fire resistance), and plasticizers (for flexibility).

Improving Material Properties

Various additives can improve the mechanical properties of the material, such as impact resistance or tensile strength. For instance, facing polypropylene with glass fibers makes it sturdy and thus suitable for the most demanding tasks.

Cost and Environmental Impact of Additives

While additives don’t always guarantee better quality, they can significantly enhance performance. However, they may also increase costs and negatively impact the environmental footprint. Therefore, it’s crucial to balance material quality with ecological considerations.

Part 5: The Future of Injection Molding Materials

The world of plastic injection molding materials is always moving ahead. Technological changes outpace the production of quality, sustainability, and improvement in manufacturing.

Sustainability Trends

It is well known that companies are increasingly prioritizing sustainable plastics, such as biodegradable and recyclable materials derived from renewable resources. Polylactic acid (PLA), a bio-based plastic, is gaining interest across various industries due to its biodegradability and eco-friendly properties.

Advanced Performance Materials

High-performance thermoplastics like PEEK (Polyether ether ketone) and PEI (Polyetherimide) are emerging as solutions for demanding applications requiring high heat, chemical resistance, and mechanical strength. These materials will continue to grow as industries like aerospace and medical devices push for stricter performance standards.

Smart Materials

The future may also see the rise of “smart” materials in injection molding, which can adapt to environmental changes or perform additional functions, such as self-healing plastics or materials that can change shape or color based on temperature or light.

Part 6: Conclusion

choosing the right injection molding materials is critical for achieving optimal part performance, durability, and aesthetics. Each material has distinct qualities that suit specific industries and applications. From the adaptability and affordability of polypropylene to the strength and dimensional stability of ABS, the clarity and heat resistance of polycarbonate, and the durability of nylon, there is a material for every need. Understanding each material’s properties ensures the best results for your application, whether it’s in automotive, medical, or electronics industries.

At Fecision, we provide expert injection molding services paired with extensive material knowledge to help you select the ideal polymer and produce high-quality, custom components. Get in touch today to explore our injection molding capabilities and turn your designs into reliable, precision-engineered parts.

Part 7: FAQs

What is the most commonly used material in injection molding?

Polyethylene (PE) and polypropylene (PP) are the most widely used materials due to their cost-effectiveness and versatility.

How do additives affect injection molding materials?

Additives can enhance the properties of the base polymer, such as improving impact resistance, UV stability, or flame resistance. However, they can also increase the material’s cost and environmental footprint.

What are the key factors to consider when selecting a material for injection molding?

Mechanical properties, thermal stability, environmental conditions, cost, and availability are all essential considerations when selecting the right material.

Can materials like PLA be used in injection molding?

Yes, PLA (Polylactic Acid) is an eco-friendly material used in injection molding, especially for applications requiring biodegradable plastics, such as packaging or disposable items.