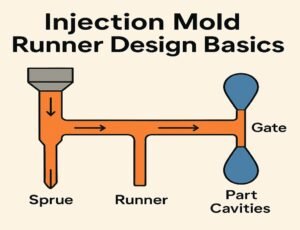

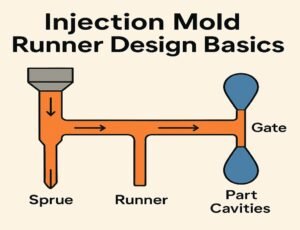

Injection Mold Runner Design Basics: Types, Functions, and Best Practices

Learn the basics of injection mold runner design, including types, functions, and best practices to improve flow balance, part quality, and production efficiency.

Learn the basics of injection mold runner design, including types, functions, and best practices to improve flow balance, part quality, and production efficiency.

Discover the cost and time savings of family injection mold strategy. Learn types, design rules, and applications for efficient, high-quality production of multi-part plastic assemblies.

Aluminum vs. steel injection molds? Uncover the core differences in thermal speed, cost, and durability to pick the right metal and multiply your project’s long-term margin.

Stop wasting money on bad molds. Use these 10+ key questions to vet any injection mold manufacturer, avoid five-figure re-tooling costs, and secure your project’s success.

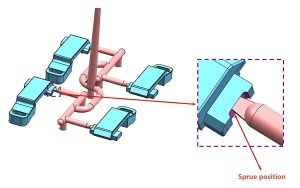

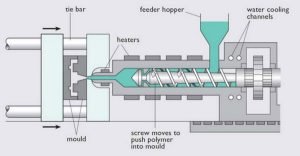

Master injection molding feed system design. This guide covers sprue sizing, runner balancing, gate freeze-off, and choosing the perfect hot, cold, or insulated runner for efficiency.

Understand the SPI mold classification system and master the division standards and application scenarios of the 5 injection mold types.

Understand the definition, specific operation process and outstanding advantages of rapid tooling to select a suitable tooling solution for your project.

Stop scrapping parts due to poor design. Master insert molding rules, material compatibility, and key geometry to build reliable, high-strength metal-plastic components efficiently.

The gate is your profit lever. Discover the complete guide to injection molding gate design, covering every type, troubleshooting defects, and advanced strategies for optimized tooling.

Explore the world of Mold Tooling for sophisticated electrical components. Get insights into manufacturing molds for complex geometries and thin materials with Fecision’s expertise.

Explore how advanced materials and coatings boost mold part durability, reduce maintenance, and enhance part quality. Contact Fecision for custom mold component manufacturing.

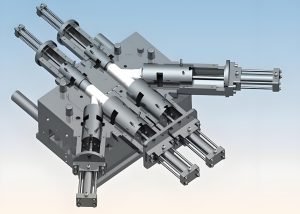

You need high-quality molded parts for your robotics projects. Our precision mold tooling services deliver intricate, reliable components for the evolving robotics industry and EOAT needs.

You can rely on Precision Molds for automotive injection molding and stamping solutions that meet stringent industry standards. Explore our services today.

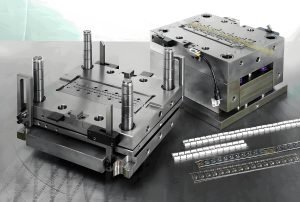

Get familiar with the multi cavity mold in injection molding. This tool reduces cost and production time, making it the ideal process for manufacturing plastic parts in high volumes.

Discover how Fecision’s precision molds ensure high-reliability connectors for automotive and aerospace. Learn about stringent demands, advanced materials, and quality standards.

Explore how Fecision’s expertise in precision stamping delivers high-quality Connector Components with tight tolerances and complex shapes.

Discover the ultimate guide to Stamping Mold Materials. Learn about different steel types, their properties, and how to choose the right material for durability and performance.

Optimize your stamping die design with expert insights on overcoming common challenges like die wear and material thinning.

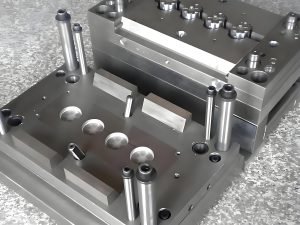

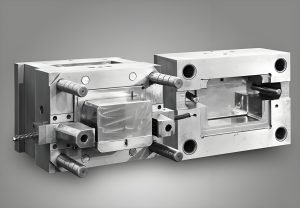

Understand two plate and three plate molds for injection molding. This guide explains their structure, advantages, and disadvantages to help you pick the right mold for your part.

Injection mold bases are the core of your tooling. Explore this guide on mold base materials, design considerations, and types to optimize your part quality and costs.

Learn how aluminum injection molds speed production, cut costs, and compare to steel. Discover the benefits and how to make molds.

Learn the importance of Maintenance of Injection Molds for optimal performance. Discover tips and best practices to extend mold lifespan and improve product quality.

Deciding between soft tooling vs hard tooling? Our guide breaks down the pros, cons, and ideal applications for each manufacturing method to help you make an informed choice.

Compare single cavity vs multi cavity mold to choose the right solution for your production needs. Learn cost, speed, and design factors.

Understand mold texturing: its role in injection molding, manufacturing process, and surface texture types. Learn about standards and costs.

Discover the key to high-precision EDM with our guide to electrodes. Explore the different materials and designs that ensure perfect molds every time.

Your ultimate guide to stamping die expenses. Learn about design, material, and volume impacts, and master cost-saving techniques for efficient production.

Explore different types of electrical terminals and master ten essential ones. Learn selection tips for reliable electrical terminals and connectors for secure, efficient connections.

Master injection molding lifter design with this guide. Explore lifter mechanisms in injection molding, their types, and best design tips. Partner with Fecision for expert lifter solutions.

Uncover the specifics of sprue in injection molding process. By following practical steps, you can improve operations and address common issues.

For plastic product manufacturers, knowing what drives injection molding cost is crucial. This article explores the complexities of injection mold costs, highlighting factors that shape total costs. Understanding these helps optimize costs for your project.

Learn what draft angles are in mold design, their importance, and how to calculate them for smooth production.

Learn how to calculate punch and die clearance for clean metal cuts. Simple steps, tips, and formula for perfect results.

Discover what a mold trial is, its types, steps, and why it’s key to quality control. Learn how mold trials cut defects and boost efficiency in manufacturing.

Do you want to know how long a mold really lasts? It’s not a straightforward answer. Mold lifespan depends on many factors, from materials to maintenance. Let’s dive into its life cycle.

Learn about what tooling in manufacturing is, what tooling means in terms of quality and costs, and the differences between soft vs hard tooling. See how tooling can affect your manufacturing.

What are the various types of injection molds? Study designs by feeding system, cavities, and plates to gain knowledge that will help you determine the right mold to effectively create plastic parts with high quality.

Learn how to design molds for plastic injection molding with key tips on flow, cavity and core design, cooling, ejection, and material selection for quality parts.

Learn the role of the core in injection molding, its types, design considerations, and how it works with the cavity to produce precise plastic parts.

Unlock superior plastic parts with valve gate injection molding. Learn how precise control, reduced waste, and enhanced aesthetics make it the ideal choice for high-quality production.

Are you looking to clean injection molds? Learn how to do it the right way to prevent defects, extend mold life, and reduce production downtime.

Discover how punch and die systems shape metal with precision. Learn types, materials, and selection tips for top fabrication results.

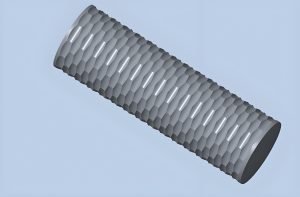

Learn about the purpose of a runner in injection molding, types of runner systems and how design affects part quality, efficiency and cost.

Discover the main obstacle to passive heat sinks limited heat dissipation and how CNC machining and materials science are solving it.

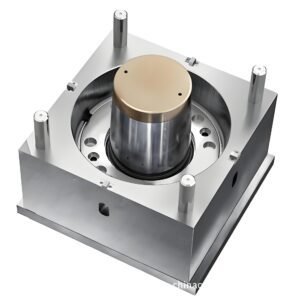

Learn what a mold cavity is in injection molding, its types, roles, and how it impacts product shape, quality, and production efficiency.

Boost injection molding efficiency and quality. Discover how porous metal improves venting, reduces defects, and extends mold life.

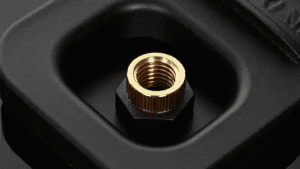

Do you know what injection molding inserts are? Here you will learn how these inserts work to improve design, functionality, and efficiency in molding.

What is a return pin for mold? Explore its function in return pin injection molding, different types, material choices, and why quality mold components are essential for efficient production.

What are the differences between injection molding sliders and lifters? Expert insights for better mold design and performance. You won’t be confused after reading!

Discover the world of electrical connectors! Learn about how electrical connectors are made, including the basic raw materials, and the advanced processes like injection molding and stamping.

Confused about which injection mold tool steel to use? Discover the best options for durability, cost, and performance, customized to your project’s needs.

Do you know why a locating ring in injection molding is used and why it is essential for precision? Discover its role in ensuring accurate mold alignment.

Maximize efficiency with the right Injection Mold Cooling System. Learn key design tips, components, and maintenance for top performance.

Learn how the right Sprue Bushing improves injection molding flow, cycle time, and part quality. Boost performance with expert tips.

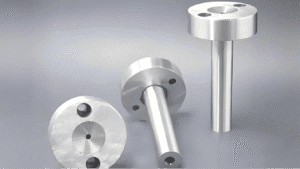

Guide pins are the driving force behind seamless injection molding. Learn how they ensure precise alignment, reduce wear, and improve operational efficiency.

Unlock the secret to perfect plastic parts! Discover how core pins, the unsung heroes of injection molding, craft intricate details and hollows. Learn about materials, custom vs. standard, and find the best manufacturer for your precision needs!

Discover the best metals for your LSR Injection Mold. Ensure durability, precision, and cost-efficiency with expert material selection tips.

Discover the key differences between ejector pins and ejector sleeves in injection molding and how they impact part quality, cycle time, and tooling.

Discover how ejector systems in injection molding work, their key components, and why they’re essential for fast, damage-free plastic part production.

Here, we have discussed Core Pin vs Ejector Pin in terms of 1. location, 2. function, 3. movement, 4. material, 5. design, 6. temperature management …