Delrin CNC Machining: The Comprehensive Guide

Learn Delrin CNC machining benefits, processes, tolerances, and applications. Discover how Fengchi delivers precision POM and acetal machined parts.

Learn Delrin CNC machining benefits, processes, tolerances, and applications. Discover how Fengchi delivers precision POM and acetal machined parts.

Learn what gear machining is, key processes, materials used, and tolerances. Discover why professional gear manufacturers matter for quality, durability, and performance.

Elaborate on the compositional characteristics and application differences between Delrin and acetal to facilitate the precise selection of suitable materials based on operating conditions.

Compare urethane casting vs injection molding for cost, speed, materials, and volume. Learn which manufacturing method is best for your project.

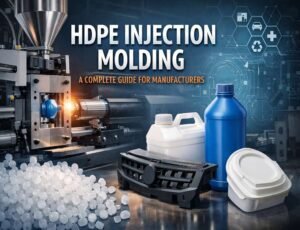

what HDPE injection molding is, its process, benefits, and temperatures. And how to choose the right HDPE molding service.

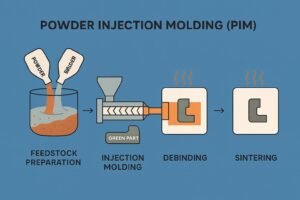

Learn how Powder Injection Molding works, its materials, benefits, and industrial applications. A complete guide for manufacturers seeking precision and efficiency.

Elaborate on the key process points and parameter configurations of acetal (POM) injection molding to provide professional guidance for the stable production of wear-resistant and high-rigidity products.

Learn how thermoplastic injection molding works, materials used, benefits, and how to choose the right manufacturing partner for high quality production.

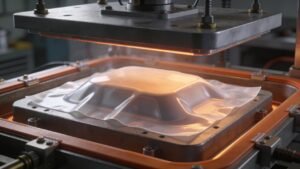

Discover how vacuum forming creates high-quality plastic parts. Our guide explains the vacuum forming process, its advantages and limitations, common materials, and key applications.

Learn how to choose between blow and injection molding. Discover the most effective molding method for producing plastic parts.

Analyze the core methods and advantages of injection molding secondary processes to provide professional guidance for optimizing the surface quality and service performance of plastic parts.

Analyze the core basis and calculation methods for injection molding machine tonnage selection to guide the matching of suitable injection molding equipment for different projects.

Learn how PVC injection molding works, its key benefits, common defects, and why Fecision is the ideal partner for high-quality custom PVC parts.

Get production-grade plastic parts in days using prototype injection molds. Validate designs, cut market risk, and save capital before committing to full tooling.

Cast vs Forged Golf Clubs: Compare the unit economics and supply chain impact for your next product line. Align manufacturing with your MOQ and cost goals.

Learn what metal CNC machining is, how it works, and why it’s essential for modern manufacturing. Discover benefits, applications, materials, and precision solutions.

Bridge the gap from concept to market with Fecision’s turnkey mold solutions. Get single-source accountability, accelerated speed, and flawless quality for mass production.

Elaborate on the key process points and parameter settings of LDPE injection molding to provide professional guidance for the efficient molding of flexible plastic products.

Analyze the key process points and adaptability of PBT injection molding to provide professional technical guidance for the efficient and stable production of plastic parts.

Compare CNC machining vs conventional machining for precision, cost, materials, volume, and when to choose each. Learn how Fecision CNC supports custom manufacturing from your drawings.

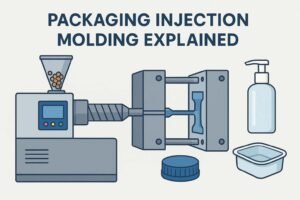

Learn how packaging injection molding works, key materials, and major benefits. Discover why it’s essential for high-volume, precise, and sustainable packaging.

Fecision’s custom connector mold services: IATF/ISO certified, micro-tolerance precision & fast prototype-to-production. Perfect for automotive, telecom, aerospace & medical.

Unlock faster production cycles and higher quality parts with conformal cooling channels. Learn how this advanced technique revolutionizes injection molding efficiency.

Unlock high-performance TPU injection molding. Find essential tips on drying requirements, mold cooling strategies, and optimizing your part design for elasticity and strength.

Provide a comprehensive introduction to PETG injection molding process parameters and performance advantages to offer technical references for the production of food-grade and medical-grade plastic products.

Implement the Six Sigma management system to improve manufacturing standards, control production deviations and achieve steady improvement in product quality in the manufacturing industry.

Compare forged vs cast wheels to choose the best option for performance, durability and value. Learn the differences to make the right upgrade for your vehicle projects.

Stop assembly: Learn how two color injection molding fuses two plastics into one durable, high-precision part, saving time and labor costs.

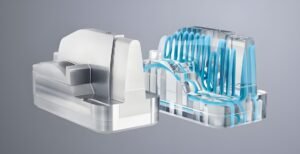

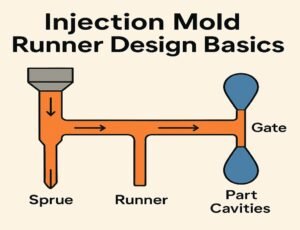

Learn the basics of injection mold runner design, including types, functions, and best practices to improve flow balance, part quality, and production efficiency.

What is subtractive manufacturing? Learn how it works, its advantages, limitations, and how it compares to additive manufacturing in this beginner-friendly guide.

Learn about beryllium copper stampings for EV battery contacts, medical devices, and non-sparking safety applications. Achieve extreme reliability and precision.

Analyze the forming processes, mechanical properties and application fields of cast steel and forged steel to facilitate scientific material selection decisions for core components of industrial equipment.

Analyze the process principle, types and applications of sulfuric acid anodizing to provide professional technical solutions for corrosion resistance, wear resistance and surface modification of aluminum parts.

Learn how Water Assisted Injection Molding works, the benefits, materials, and industrial applications for faster, lighter, and high-precision production.

Maximize stability with Invar CNC Machining. Discover the different Invar grades, critical expert tips, and specialized processes for aerospace and optical parts.

Need custom plastic solutions? Understand thermoforming types, capabilities, and material selection for high-precision, large, or small plastic components.

Discover the cost and time savings of family injection mold strategy. Learn types, design rules, and applications for efficient, high-quality production of multi-part plastic assemblies.

Forging vs casting: what’s the difference? Learn which method makes stronger metal parts, compare forged vs cast metal, and discover when to choose casting or forging.

Analyze the core characteristic differences and application advantages of cast aluminum and forged aluminum to help select suitable aluminum material forming processes based on operating conditions.

Analyze the core differences and application advantages of forged/cast crankshafts to help select suitable crankshaft manufacturing processes based on engine operating conditions.

Provide a comprehensive comparison of the characteristics, properties and application scenarios of Invar and Kovar to offer professional references for material selection in precision manufacturing.

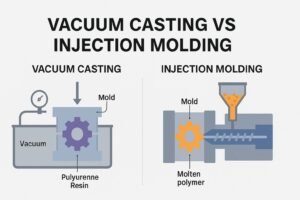

Compare Vacuum Casting vs. Injection Molding. Learn the key differences, advantages and costs to choose the right process for your manufacturing needs.

Elaborate on the operating mechanism and application value of pad printing technology to facilitate high-quality printing on complex-shaped workpieces and enhance the standardization of product identification.

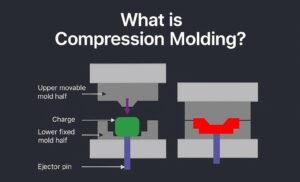

What Is Compression Molding? Learn the complete process, materials and applications behind this cost effective manufacturing method for strong, precise parts.

Explore various types of vertical milling machines to meet CNC milling requirements and provide efficient, precise equipment selection references for precision part machining.

Learn the benefits of thin wall injection molding to achieve ultra-lightweight plastic parts and faster production, saving material and shortening cycle times.

Analyze the types, core advantages and industrial applications of nickel plating to provide a reliable surface treatment solution for corrosion resistance, wear resistance and appearance enhancement of metal parts.

Discover how silicone overmolding enhances product design, durability, and comfort across industries. Learn its process, benefits, and real-world applications.

Analyze the process principle, high-efficiency advantages and application scenarios of aluminum casting to provide an economical and reliable forming solution for the mass production of metal products.

Learn how titanium CNC machining delivers unmatched strength, precision and quality in aerospace and medical industries. Learn why Fecision leads in titanium manufacturing.

Provide a comprehensive overview of the characteristics and application fields of bead blasting technology to offer professional references for the process selection of workpiece surface treatment.

Analyze the various surface effects, advantages and applicable scenarios of aluminum anodizing to assist in the selection of surface protection and appearance design for aluminum parts.

Analyze the process flow, core advantages and industrial applications of tumble finishing to provide efficient solutions for deburring and improving the surface finish of parts.

Learn expert tips on CNC plastic selection. Discover the best materials—from ABS to PEEK—for strength, heat, and chemical resistance in your precision project.

Elaborate on the working principle and core value of gear hobbing to provide efficient processing solutions and technical references for precision gear manufacturing.

Master injection molded enclosure design. Learn 10+ DFM principles, including wall stock, draft, and snap-fits, to eliminate warpage and cut tooling costs for high-volume production.

Analyze the purposes, design key points and engineering applications of blind holes in machining to provide scientific design and application references for precision part processing.

Learn how medical injection molding powers modern healthcare with precision, efficiency and reliability in producing high quality medical devices.

Understand the processing flow and application value of vapor polishing for plastic parts to provide a reference for efficient surface treatment solutions for precision plastic components.

Discover two-shot injection molding: single-cycle, dual-material precision. Cut assembly costs and boost product strength now.