Precision Injection Molding Plastic Parts

Start your project now

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive AS9100 Quality Mangament

Faster Lead Time for Production Needs

In-Process Inspection with CMM

Injection Molding Service

Key Features

Efficiency

High production rates with minimal waste, allowing for cost-effective manufacturing of complex parts.

Precision

Exceptional dimensional accuracy and repeatability, ensuring consistent part quality across production runs.

Versatility

Ability to work with a wide range of materials and produce complex geometries with varying textures and finishes.

Prototyping vs. Production

We offer solutions for every stage of your product lifecycle, from rapid prototyping to large-scale production runs.

Prototyping

Rapid turnaround (2-4 weeks)

Cost-effective design validation

Material testing and selection

Design refinement and optimization

Production

Optimized for cost efficiency

Strict quality control protocols

Consistent part-to-part repeatability

Scalable production capabilities

Injection Molding Types

Standard Injection Molding

Insert Molding

Overmolding

Gas-Assisted Injection Molding

Micro Injection Molding

Two-Shot Injection Molding

In-Mold Decration/Labeling

Injection Molding Capabilities

Our advanced manufacturing facilities are equipped to handle a wide range of injection molding requirements, from small, intricate parts to large components.

Standard | Technical Data |

Tolerances | As tight as ±0.001 inches (0.025 mm) |

Dimensional Stability | Parts maintain shape and size over long production runs |

Cycle Time | Range from 15 to 60 seconds per part |

Output | Up to 1000+ parts per hour |

Material Waste | Less than 5% |

Recyclability | Many plastics such as PET, PP, and ABS, are recyclable |

Cost Per Unit | Offset by low per-unit costs in mass production |

Tooling Longevity | Hundreds of thousands to millions of cycles |

Surface Finishes | Typically Ra 0.4 – 1.6μm |

Energy Efficiency | Up to 30% improvement |

Material Variety | Over 200 different plastic materials |

Production Capacity

- Up to 10 million units annually

- 24/7 production capabilities

- Automated production cells

- Lean manufacturing processes

- Flexible production scheduling

Quality Control

- CMM (Coordinate Measuring Machine)

- Vision inspection systems

- Statistical Process Control (SPC)

- First Article Inspection (FAI)

- Automated dimensional checking

Value-Added Services

- Assembly and kitting

- Packaging solutions

- Inventory management

- JIT (Just-In-Time) delivery

- Supply chain integration

Ready to Start Your Injection Molding Project?

Contact us today to discuss your project requirements and get a free quote from our injection molding experts.

Injection Moldable Plastics

We work with a comprehensive range of engineering plastics and specialty materials to meet the unique requirements of your application.

Acrylonitrile Butadiene Styrene (ABS)

- Properties:

- Application:

Polyethylene (PE)

- Properties:

①LDPE is flexible, transparent, and has good chemical resistance.

②LLDPE offers enhanced strength and toughness compared to LDPE.

③HDPE is more rigid, has higher tensile strength, and excellent chemical resistance.

- Applications:

①LDPE is often used for making plastic film and packaging materials.

②HDPE is suitable for manufacturing durable pipes and storage containers.

Polypropylene (PP)

- Properties:

- Application:

①Automotive: Bumpers, battery casings, and interior trim.

Polystyrene (PS)

- Properties:

- Application:

①GPPS is often used for making disposable cutlery, packaging materials, and optical lenses.

Polycarbonate (PC)

- Properties:

- Application:

①Medical: Surgical instruments, dialysis machine housings.

②Aerospace: Aircraft canopy windows.

③Electronics: LED light covers, smartphone screens, electronic device enclosures.

④Automotive: Headlight lenses

Nylon (PA)

- Properties:

- Application:

①Automotive: Gears, bearings, and fuel system components.

②Industrial: Conveyor belts, machine parts.

③Consumer: Zippers, sports equipment (e.g., ski bindings)

Polyvinyl Chloride (PVC)

- Properties:

- Application:

①Construction: Pipes, window frames, and roofing membranes.

Polyethylene Terephthalate (PET)

- Properties:

- Application:

①Packaging industry: bottles for beverages, food containers, and some types of blister packaging

Polybutylene Terephthalate (PBT)

- Properties:

- Application:

①Electrical: Connectors, circuit breakers.

②Automotive: Sensor housings, headlight reflectors

Polyphenylene Sulfide (PPS)

- Properties:

- Application:

①Automotive: Under-the-hood components (e.g., fuel pumps).

②Aerospace: Engine covers, brackets.

③Industrial: Chemical processing pumps

Thermoplastic Polyurethane (TPU)

- Properties:

- Application:

①Medical: Catheters, prosthetics.

②Consumer: Smartwatch bands, shoe soles.

③Industrial: Seals and gaskets.

Common Finishes for Injection Molding

We offer a variety of surface treatment options to enhance the appearance, functionality, and durability of your injection molded parts.

Spraying Coating

Spraying or electrostatic coating applies layers (e.g., UV-curable paint, anti-scratch coatings).

Laser Engraving

Laser ablation creates permanent markings (logos, serial numbers) without affecting structural integrity.

Pad Printing

Transfer logos, labels, or designs onto complex surfaces, offering high precision, durability, and customization.

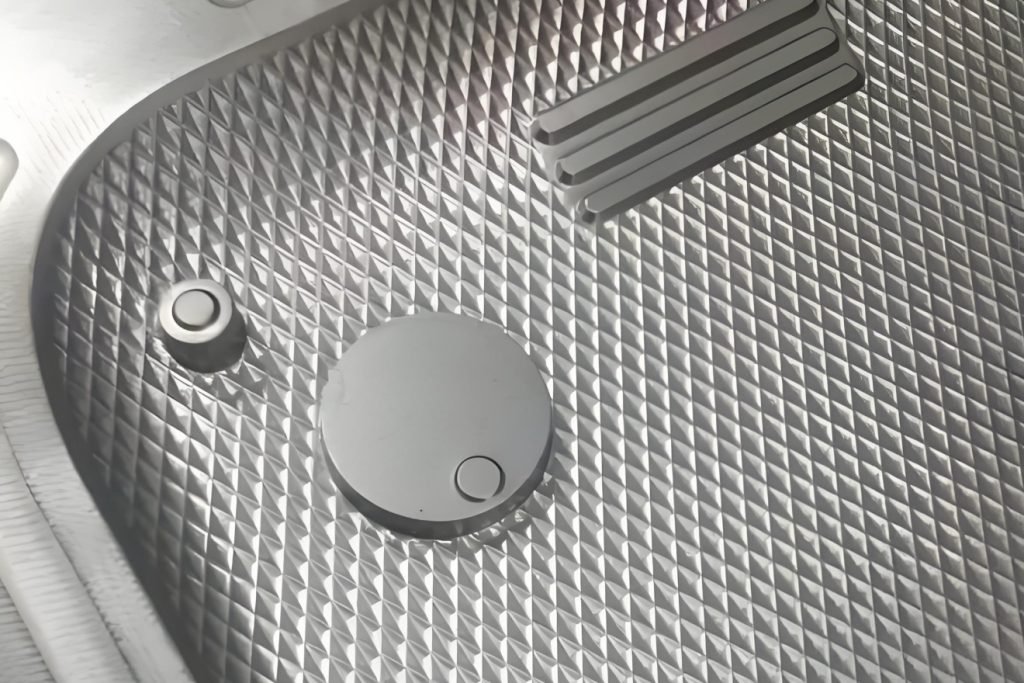

Texturing

Create patterns, grains, or matte effects on plastic parts using chemical etching or laser engraving.

Sandblasting

Compressed air propels abrasive materials like sand or grit at high speed onto an object’s surface, cleaning it, roughening it for better adhesion, or creating a matte finish.

Electroplating

Depositing metal layers (e.g., chrome, nickel) onto plastic surfaces via electrolysis.

- Chrome Electroplating

- Nickel Electroplating

Heat Transfer Printing

Use heat and pressure to apply designs, logos, or patterns onto molded parts. Provide vibrant colors, durability, and versatility for decorating plastics

Polishing

Use abrasives, compounds, or buffing tools to refine a surface, reducing roughness, enhancing smoothness

- Mechanical Polishing

- Chemical Polishing

The Injection Molding Process

Our streamlined injection molding process ensures precision, efficiency, and consistent quality from design to delivery.

Design & Engineering

Our engineering team collaborates with you to refine your part design for manufacturability, ensuring optimal mold flow, material selection, and cost efficiency.

Injection Molding

Molten plastic is injected into the mold cavity under precise pressure and temperature conditions. The material cools and solidifies into the desired part shape.

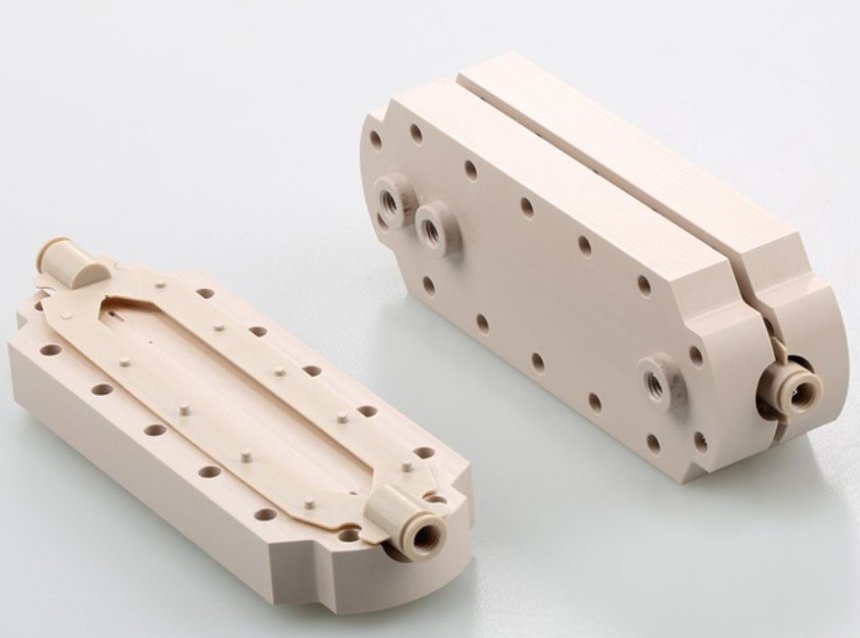

Mold Design & Fabrication

We design and manufacture precision molds using advanced CNC machining and EDM processes, ensuring durability and dimensional accuracy for consistent part production.

Part Ejection & Inspection

Finished parts are ejected from the mold and undergo rigorous quality inspection to ensure they meet all specifications and tolerances.

Material Preparation

Plastic resins are carefully selected, dried if necessary, and prepared for molding. Colorants and additives are precisely mixed to achieve the desired properties.

Finishing & Assembly

Parts may undergo additional processing such as surface treatment, painting, or assembly before final packaging and delivery.

Injection Molding Project Timeline

We understand the importance of timely delivery. Our streamlined processes ensure efficient project execution from concept to completion.

Design review, DFM analysis, material selection, and prototype development if needed.

★ 1-2 weeks

Mold design, CNC machining, EDM, polishing, and mold testing to ensure proper function.

★ 4-8 weeks

Production of initial samples, dimensional inspection, functional testing, and design refinement if necessary.

★ 1-2 weeks

Full-scale production based on order quantity, with ongoing quality control and inspection.

★ variable

Surface treatment, assembly, packaging, and shipping according to your specifications.

★ 1-2 weeks

Note on Timeline

Timeline estimates are based on standard projects. Complex molds, special materials, or additional requirements may affect delivery time.

Injection Molding Applications

Industries We Serve

Medical

Surgical instruments and tools

Drug delivery devices

Medical device housings

Disposable medical products

Automotive

Engine parts and underhood components

Electrical connectors and housings

Trim pieces and decorative elements

Gaskets and seals

Aerospace

Avionics housings and panels

Structural components

Insulation and thermal management parts

Fluid handling components

Robotics

Grippers and end effectors

Structural frames and brackets

Sensor housings and covers

Gear housings and transmission parts

Electronics & Semiconductor

Connector components

Heat sinks and thermal management parts

Insulators and shielding components

Semiconductor handling trays

Industrial Equipment

Valves and fluid handling parts

Control panel components

Handles and grips

Wear-resistant components

Custom Injection Molding Design Guidelines

Proper design is critical for successful injection molding. Follow these guidelines to optimize your part design for manufacturability, cost, and performance.

Wall Thickness

Maintain uniform wall thickness throughout your part to prevent sink marks, warping, and internal stresses.

- Keep wall thickness between 0.8mm and 3mm for most applications

- Maximum thickness variation should not exceed 25%

- Use gradual transitions between different wall sections

Undercuts

Minimize or avoid undercuts whenever possible, as they complicate mold design and increase cost.

- Consider alternative designs that eliminate undercuts

- Use side actions or lifters for necessary undercuts

- Threaded features often require unscrewing mechanisms

Draft Angles

Include proper draft angles on all vertical surfaces to facilitate easy part ejection from the mold.

- Minimum draft angle of 0.5° per side for most applications

- Increase draft angle for deeper cavities and textured surfaces

- Consider 1°-2° draft for parts with tight tolerances

Ribs & Bosses

Use ribs to increase part stiffness without increasing wall thickness. Bosses provide strong mounting points.

- Rib thickness should be 50-70% of the nominal wall thickness

- Height of ribs should not exceed 3 times the wall thickness

- Bosses should have a diameter 2-3 times the hole diameter

Radii & Fillets

Use generous radii and fillets at all corners to improve part strength and mold filling.

- Minimum internal radius of 0.5mm

- External radii should be at least 1.5 times the wall thickness

- Sharp corners create stress concentrations and molding difficulties

Parting Lines

Consider the location of parting lines early in the design process to minimize their visual impact.

- Place parting lines in less visible areas when possible

- Design for a straight, simple parting line if possible

- Account for potential flash along the parting line

Need Help with Your Design?

Our engineering team provides comprehensive design for manufacturability (DFM) analysis to optimize your part design for injection molding.

We can help identify potential issues and suggest improvements to reduce costs and improve quality.

Injection Molding Advantages

Injection molding offers numerous benefits that make it the preferred manufacturing process for a wide range of industries and applications.

Cost Efficiency

Lower per-unit costs for high-volume production, with minimal material waste compared to other manufacturing processes.

High Precision

Exceptional dimensional accuracy and repeatability, ensuring consistent part quality across production runs.

Design Flexibility

Ability to produce complex geometries with varying wall thicknesses, undercuts, and intricate details.

Production Speed

Fast cycle times and high production rates, enabling quick turnaround for large quantities.

Material Versatility

Compatible with a wide range of plastics and composites, each offering unique properties for specific applications.

Automation Potential

Easily integrated with automation systems for part removal, inspection, and assembly, reducing labor costs.

Why Fecision for Injection Molding?

Quality Commitment

ISO 9001, ISO 13485, and IATF 16949 certified facilities with rigorous quality control processes.

Expert Team

Experienced engineers and technicians with deep expertise in injection molding processes.

Advanced Technology

State-of-the-art equipment and software for precision molding and quality assurance.

On-Time Delivery

Reliable production scheduling and logistics for consistent on-time delivery.

Customer Focus

Collaborative approach with dedicated project managers for personalized service.

Innovation

Continuous improvement and investment in new technologies and processes.

How to Work with Us

Submit Drawings

For a free quote, please submit a product description along with a technical drawing. We also offer reverse engineering services to assist you.

DFM & Quotation

We will provide a DFM (Design for Manufacturability) report or mold flow analysis report. Please be aware that further discussions may be needed during the process.

Mold Manufacturing

Upon your confirmation to the mold design, our team will begin making mold components, which will then be sent for inspection and assembly.

Injection Molding

Once the mold is complete, we will initiate the plastic molding process. A T1 sample will be provided for you to check whether the product details align with your specifications. After approval we will continue massive production.

Delivery

Your custom-designed plastic parts undergoes thorough inspection, will be carefully packaged, and delivered to you.

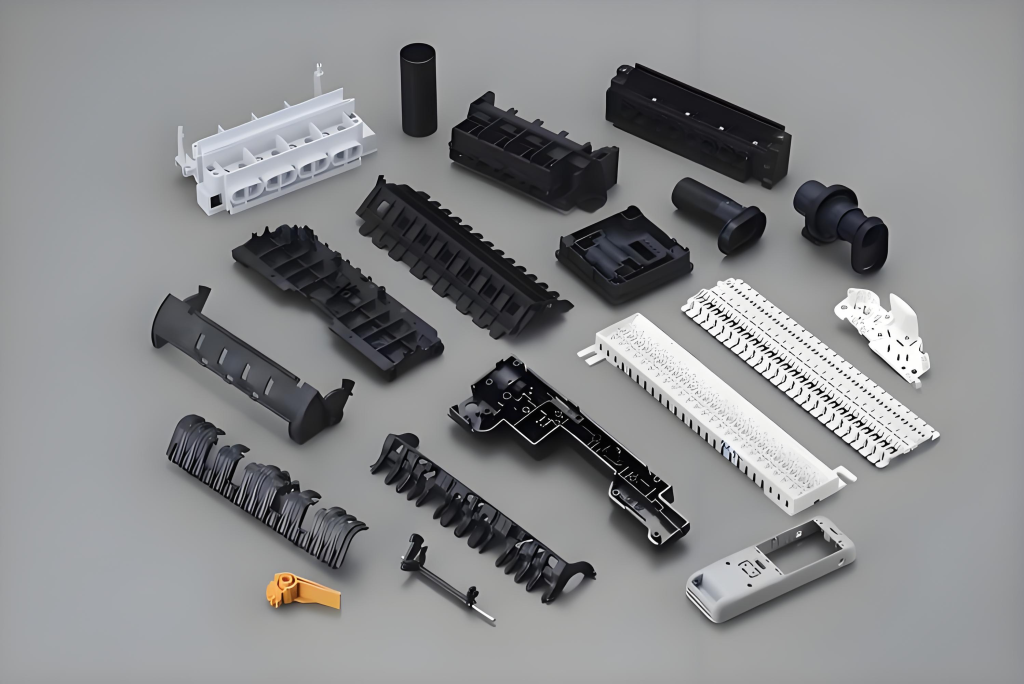

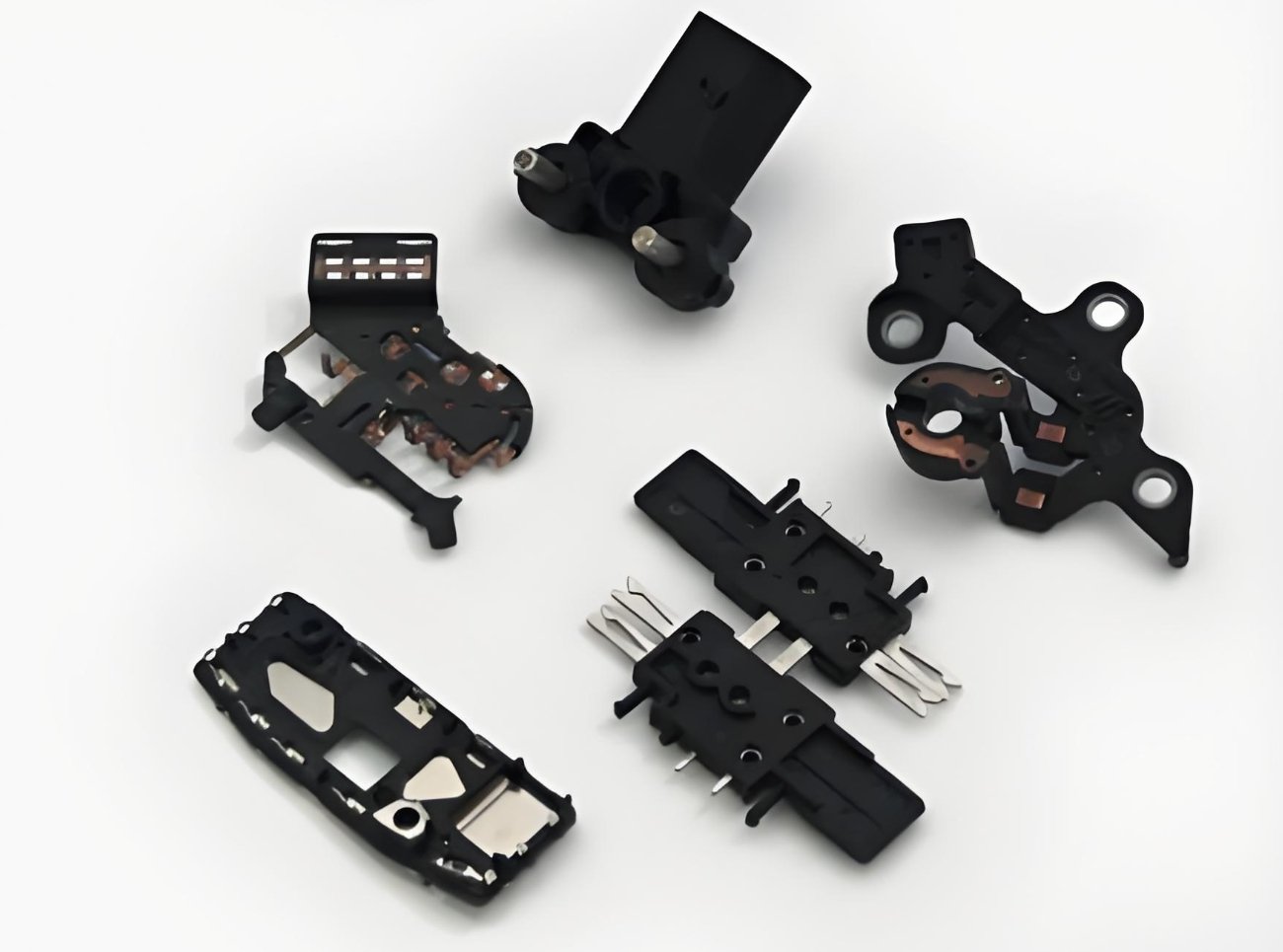

Injection Molding Product Gallery

Contact Us for Injection Molding Services

Ready to discuss your injection molding project?

Request a quote, and our experts will contact you shortly.

Injection Molding FAQs

1-3 weeks for prototype production. Once tooling is completed, production typically takes 1-2 weeks for small to medium runs, and larger runs can be completed in several weeks depending on order size.

Design limitations involve factors such as mold flow, part ejection, and cooling efficiency. To ensure successful molding, designs should minimize undercuts, maintain consistent wall thickness, and incorporate draft angles for easy part removal.

The minimum order quantity depends on the specific project. We offer flexibility to handle both small batch and high-volume production, tailored to meet the unique requirements of each client.

We are committed to delivering the highest quality parts right from the start. That’s why Fecision offers DFM analysis at no charge, ensuring you have all the confidence you need before placing your injection molding order.

For short-run or low-volume production, we provide flexible options and utilize cost-effective tooling solutions to ensure the process remains efficient and economical for smaller quantities.