The decision on injection molding vs thermoforming is often the first and most important decision in product development. It determines everything from the cost of the project to the speed of launch. We will break down the two processes simply so you can see the option that fits your part, budget, and timeline.

What Is Injection Molding?

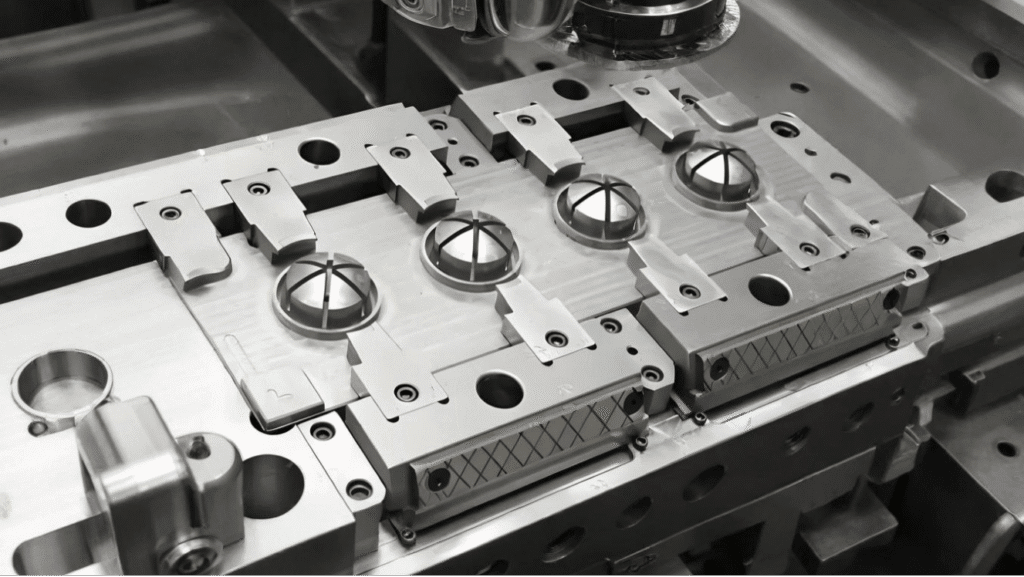

Injection molding is a very accurate, high-pressure process. It begins with polymer pellets, which will be melted. The melted plastic is then injected powerfully into a unique, water-cooled, double-sided steel mold, under extremely high pressures. Seconds later, the plastic solidifies, and the mold opens and ejects out the finished part, which is made to very tight tolerances, and is ready for extensive, automated, “lights-out” production.

What Is Thermoforming?

Thermoforming begins with heating an extruded plastic sheet until it is pliable and elastic. This softened sheet is then stretched over a single-sided aluminum mold. A vacuum, pressure, or a mechanical plug is utilized to force the sheet uniformly over the shape of the mold. After cooling, a trimming process (5-axis) is required to cut the part from the sheet. The result is typically a very large, lightweight shell. It is ideal for prototypes, moderate volume requirements, and quick design changes.

Injection Molding vs Thermoforming: Key Differences Explained

To appropriately assess injection molding vs thermoforming for your project, you need a clear breakdown of how the two methods compare to one another. In this section, we are comparing the options in the most critical areas, from tooling costs to final part quality.

Tooling Complexity & Up-front Spend

Injection molds need hardened steel to handle high pressure. They require two matching halves and complex internal systems. This means they demand a huge investment both in money and time up front. Thermoforming tooling is simpler. It uses single-sided aluminum molds, which dramatically cuts down on the price and the time it takes to get them made.

Volume Sweet Spot

Injection molds can have a number of cavities, which means that once the machine starts, it can produce thousands of parts in a short amount of time. As your needed quantity rises, injection molding becomes more economical. Thermoforming, however, usually makes one part per cycle. This keeps the cost and effort per piece steady, making it better for lighter, less demanding production volumes.

Part Size & Geometry Freedom

Injection molding is amazing for parts that fit in your pocket or hand. It handles intricate features like ribs, threads, undercuts, and flexible living hinges easily. Thermoforming is better for broad, shallow shapes. You can make panels that are a meter wide without a problem. Deep shapes risk the plastic thinning out or forming unwanted webbing, though.

Tolerance & Wall Control

Injection molding provides fantastic precision, with uniform walls and tolerances measured in hundredths of a millimeter. This is key for high-spec items. Thermoformed walls start with the same thickness as the sheet’s original thickness. However, they can thin a lot in sharp or deep areas. Overall, its tolerance is typically looser, falling in the tenths of a millimeter range.

Materials & Waste Profile

Injection molding utilizes plastic pellets within its process; therefore, it can be utilized for specialized, highly-filled, or high-temperature grades of plastic resin. It usually generates minimal amounts of scrap, only the runner piece. Thermoforming uses plastic sheets, which can be colorful or pre-textured. This process leaves a significant skeletal plastic perimeter that must be either recycled or sometimes discarded.

Cycle Speed & Lead to Market

Injection molding cycles are incredibly fast, sometimes lasting only seconds. But the process to get your first part takes many months because of the detailed steel mold work. Thermoforming cycles take about a minute or so. However, the molds can be made in just a few days, which drastically speeds up your entire product development timeline.

Surface Strategy

Injection molding can texture both sides of the part. It also supports advanced techniques like in-mold decoration and tiny engraving. Thermoforming only transfers the detailed, cosmetic look to the side touching the mold. The other side might look basic and could require a secondary painting step if a perfect look is important.

Comparison Table Between Injection Molding vs Thermoforming

The table below gives a concise, quantitatively organized overview of most of the comparison criteria in effective information. It will help facilitate your decision-making early on.

| Decision Factor | Injection Molding | Thermoforming |

| Tooling Cost | Significantly higher, requires complex steel molds | Much lower, uses simpler aluminum molds |

| Volume Suitability | Ideal for very high-volume production | Better for low to moderate volumes |

| Part Size & Geometry | Excels at small, intricate, complex 3D parts | Best for large, broad, shallow shapes |

| Tolerance & Wall Control | Extremely high precision, uniform wall thickness | Lower precision, walls can thin in deep areas |

| Material Range | Very wide range, including engineered resins | More limited to sheet-extruded plastics |

| Cycle Speed | Very fast part production cycles | Slower part production cycles |

| Lead Time (Tooling) | Long, due to complex mold manufacturing | Short, molds can be made quickly |

| Surface Finish | High quality on both sides, supports textures | Good on mold side only, free side may be plain |

| Waste Profile | Minimal scrap, high material utilization | Significant skeletal waste after trimming |

| Complex Features | Easily creates undercuts, threads, snap-fits | Difficult for undercuts, threads, needs post-processing |

| Ideal Use Cases | Precision components, high-quantity consumer goods | Large enclosures, prototypes, bridge production |

Thermoforming vs Injection Molding Cost: Which Is More Cost-Effective?

Understanding the cost crossover is an important step for making a smart investment decision. We’ll look at the key thermoforming vs injection molding cost you need to consider.

Tooling Investment

Simple aluminum thermoform molds will typically cost you between $1,000 and $10,000. They’re an affordable starting point. In contrast, even the most basic steel injection tools start near $10,000. The price quickly goes up as your part becomes more complicated.

Break-even Crossover

Injection molding starts to provide a positive return on investment once your batch size reaches about 1,000 to 10,000 pieces. Thermoforming remains the cheaper option for smaller runs. Specifically, for lots between 50 and roughly 1,000 parts, it saves you money, especially if your part has a large surface area.

Material Utilization

In thermoforming, the sheet skeleton waste adds a notable percentage to your material cost, even after you account for the value of regrinding it. Hot-runner injection molding is much more efficient; waste stays at a very minimal level. This difference means big savings when you use expensive, high-performance engineering resins.

Energy & Labor Per Kilo

Large hydraulic injection presses use slightly more power per kilogram of plastic. However, they are producing four to eight times more parts every hour. This high output essentially neutralizes the energy and labor cost gap when you are running at high production scale.

Bottom line

Thermoforming is your winner for cash-flow purposes—think prototypes, short runs, or giant plastic panels. Injection molding takes the crown when your annual volumes climb into the mid-thousands or when a specific, high-precision resin is an absolute must-have for your product.

When to Use Injection Molding?

You should always match the thermoform vs injection molded parts process to the specific needs of your product. Here are the five key scenarios where injection molding is the only rational choice for your long-term success.

High Annual Volumes

If your project requires consistently high numbers of parts, this process is built for you. Multi-cavity tools are designed to flood your warehouse with finished parts rapidly. This efficient system is the main factor that drives your unit economics and per-piece cost down into the lowest possible range.

Micro-to-Medium Precision

When your parts must fit perfectly and repeatedly, only injection molding provides the required accuracy. Think of small medical luers, complex electronic connectors, or gears that absolutely must sit within a tiny, hair’s-width tolerance window to function correctly.

Complex 3-D Geometry

This process is ideal when your design has complex internal and external features. Features like secure snap-fits, durable living hinges, internal undercuts, and even over-molding with metal inserts are all inherently natural and easily achieved within a functional two-sided tool.

Performance Resins

Parts that need special performance for strength or heat resistance will require specific materials: Glass-filled nylon, PPS, and LCP grades. These highly engineered resins cannot easily be processed by the sheet-extrusion methods that are used for thermoforming, making injection the only option.

Long-Life Programmes

If you anticipate a very long life cycle for your product, the initial tooling expense is worth it. Hardened steel tools are rated to perform for over a million shots. This exceptional durability spreads the expensive initial outlay over many years of steady, reliable production demand for your company.

Bonus Tip – Is Injection Molding Right for Your Project?

If you need precision finer than 0.1 mm, forecast sales in the mid-to-high thousands per year, or require specific engineered resins, then injection molding will be your reasonable long-term approach. This high-volume, high-accuracy process handles complex materials and geometry better than any alternative method.

When to Use Thermoforming?

Sometimes speed and size are far more critical than extreme precision, and that is where thermoforming shines. Here are the five best-case scenarios for choosing this faster, more flexible process.

Prototype or Bridge Production

When time is short, thermoforming is a great asset to your roadmap. Simple aluminum tools can be quickly machined in a matter of days. This speed makes it perfect for pilot lots or bridge production while you wait for the much longer-lead injection steel to be completed on the mill.

Large, Thin-Walled Panels

Thermoforming is the undisputed choice for manufacturing very large components that are relatively thin. This category includes big medical-device housings, the complete bodywork for recreational vehicles, or even aircraft interior panels that are significantly larger than one square meter in total area.

Cosmetic, Textured Surfaces

If you want a great appearance without needing expensive secondary finishing, thermoforming can deliver this. Using pre-coloured ABS or PMMA sheets eliminates any need for secondary painting. The grain or texture transfers directly from the simple mold face for you.

Rapid Design Evolution

This process provides excellent flexibility if you expect to make design changes later on. Need to quickly tweak your draft angles or add a few vent slots to the design? A single-sided aluminum tool can usually be re-cut overnight, which greatly supports a rapid design iteration cycle.

Sustainable Light-Weighting

You can achieve both strength and a lower weight with specialized thermoforming techniques. Twin-sheet forming can yield strong, hollow ribs within the part without needing a gas-assist process. This approach helps shave off crucial weight compared with using solid, heavy injection molding alternatives.

Bonus Tip – Is Thermoforming Right for Your Project?

You should choose thermoforming when your required volumes sit below five figures annually, your parts sprawl beyond a few hand-spans in size, or your roadmap promises multiple design spins. This process offers a faster start, lower tooling cost, and better flexibility for large, less precise parts.

Conclusion: Match the Process to the Part, Then Match the Partner

Thermoforming vs injection molding are not competitors; they are two different tools for plastic manufacturing that can work together as two complementary, powerful approaches. You should use injection molding when high precision, large volume, and long-term durability are more important than the higher initial tooling cost. Conversely, you should switch to thermoforming when speed, sheer size, and managing immediate cash-flow are the most critical items on your agenda.

Fecision offers Injection Molding for projects demanding high precision and large volumes. Leveraging advanced machinery and certified quality processes, we ensure your complex parts—using engineering resins—are produced with micron-level repeatability. We guarantee consistent quality and deliver your high-volume orders reliably on time and within budget.

For projects where size and speed are key, our Thermoforming service is the smart choice. We are able to produce low-to-moderate volumes of prototypes and large enclosures, with simpler aluminum tooling. Our knowledge allows for flexibility in design, with a quick turnaround, regardless of size, to bring your large parts to market easily and cost-effectively. Contact Fecision today to get your free quote and expert guidance on the ideal process for your unique parts!