Injection molding is a fantastic way to make plastic parts, but there’s a secret ingredient to success: proper injection mold venting. You might not think much about air, but in injection molding, it can make or break your product. This article will show you why venting in injection molding is so important, exactly where to put those air vents in injection molding in your molds, and how to design a super effective injection molding venting system. By the end, you’ll know exactly how to make your plastic injection mold venting process shine with smart venting injection molding.

The Importance of Proper Mold Venting

Think of proper mold venting as a crucial step for getting great results. It does two main things for you:

Enhancing Part Quality

- Preventing Air Entrapment: Imagine molten plastic flowing into your mold. If there’s nowhere for the air to go, it gets stuck! Proper venting in injection molding can let that air and other gases escape. This means no annoying voids (empty spaces) in your parts, and a much stronger, better-looking final product.

- Improving Surface Finish: You want your parts to look smooth and perfect, right? Good venting helps you get that. It stops issues like flow lines and weld lines, which can totally mess up how your part looks and works.

Protecting Molds

- Preventing Mold Damage: When air gets trapped, it can build up a lot of pressure. Plus, those trapped gases can be corrosive. Both of these can seriously damage your expensive mold. Proper injection mold venting acts like a shield, protecting your molds and saving you from costly repairs and replacements down the road.

- Optimizing Production Efficiency: Nobody wants a slow production line. With proper air vents in injection molding, your mold fills faster, and your cycle times are quicker. This boosts your overall production efficiency and cuts down on wasted parts.

Common Defects from Poor Venting

If you don’t vent properly, you’ll see some common problems in your injection molded parts. These defects can be visible on the part or hit you with hidden costs.

Visible Part Defects

| Defect | What Happens | Why It Occurs |

| Burns at End of Fill | Blackened or scorched marks appear on the part’s surface. | Trapped air compresses and overheats as plastic fills the cavity. |

| Short Shots | Incomplete parts with missing sections. | Air pockets block the plastic flow, preventing full cavity filling. |

| Weak Weld Lines | Visible seams where plastic flows meet; these areas break easily. | Trapped air weakens the bond between merging plastic fronts. |

| Flow Marks/Surface Blemishes | Streaks, lines, or rough patches on the part’s surface. | Air disrupts smooth the plastic flow, causing uneven cooling and surface defects. |

Hidden Production Issues

| Hidden Issue | Impact | Why It Happens |

| Longer Cycle Times | Increased production time per part, reducing output and raising costs. | Compressing trapped air delays cooling and ejection, slowing the entire cycle. |

| Mold Corrosion | Premature wear and damage to expensive molds, requiring repairs/replacement. | Moisture in trapped air reacts with mold steel, causing rust and pitting. |

Where to Vent Injection Molds?

Choosing the right spots for your vents is super important for successful venting injection molding. Here are the key areas where you should be placing them:

Parting Line Vents

The parting line of a mold is where the two halves of your mold come together, so quite naturally, this is the most common place to put injection mold vents. Vents along the parting line allow for the easy escape of air as the molten plastic flows into the mold cavity. One of the main benefits is the simplicity of installation and the ease of cleaning a vent while the mold is in the machine.

End-of-Fill Areas

End-of-fill areas are the very last areas the plastic visits on its way to filling the cavity. It is essential to put vents in these areas to exhaust any trapped air, which is a major cause of short shots and burn marks found at the end of the fill. Strategic placement is important in these areas to ensure that the parts are completely filled and aesthetically pleasing.

Around Ejector Pins

Ejector pins are used to push the part out of the mold. But they can also create small pockets that trap air. Putting vents around these types of pins helps relieve that trapped air, and ensures that your part will eject accurately from the mold, not being damaged by trapped air.

Deep Ribs & Bosses

Deep ribs (thin walls) and bosses (cylindrical protrusions), due to their thin and deep nature, can easily trap air. It’s essential to place vents in these areas. Venting here improves how efficiently the plastic fills these tricky features and prevents defects such as the “diesel effect” (where compressed air ignites) and burn marks that can occur in these deep sections.

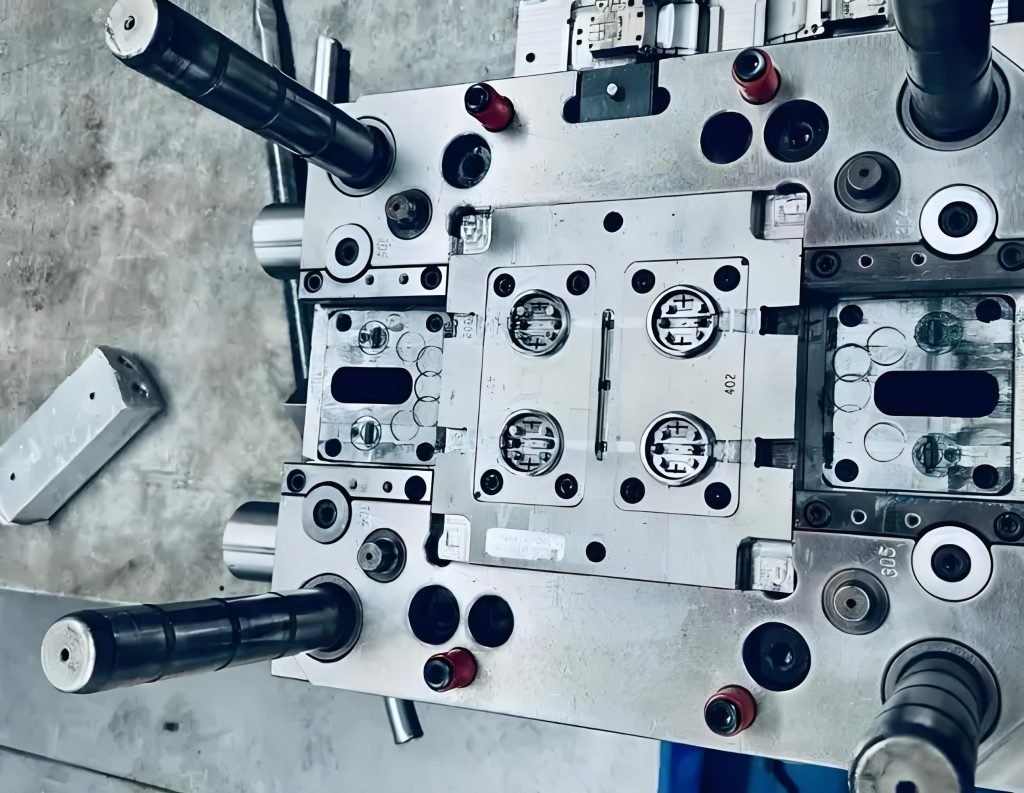

Inside Complex Geometries

Some parts feature truly intricate shapes, including hidden corners, undercuts, or even multiple cavities within a single mold. These complex designs create areas where air loves to hide. You need to be smart about where you place injection mold vents within these complex areas to ensure that the mold fills completely and uniformly, ultimately yielding a perfect part, even with the most challenging designs.

Around Slides & Lifters

Slides and lifters are mechanical components within the mold that help create undercuts or complex features. As they move, they can create air traps. Vents around these components are essential, as this not only prevents defects but also ensures that your mold’s mechanical components operate smoothly without air-related interference.

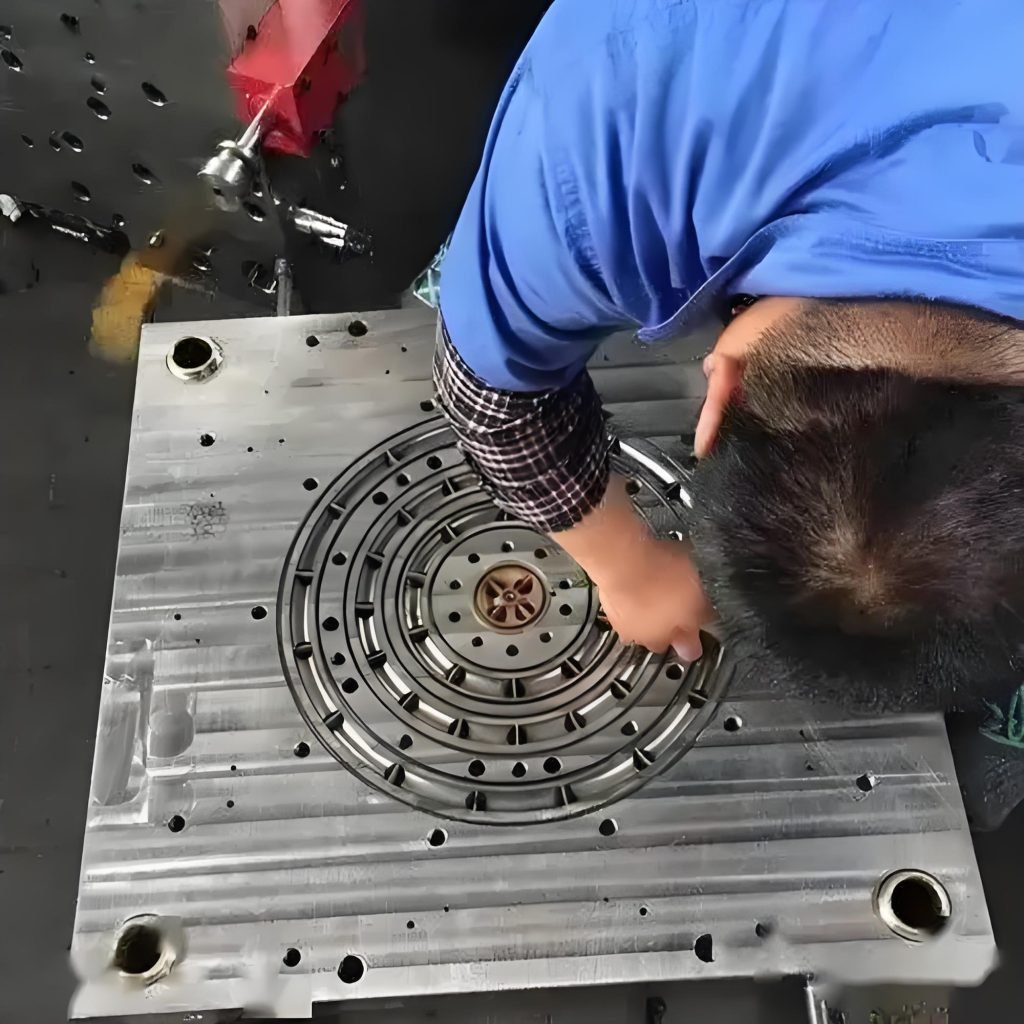

How to Vent Injection Molds

Designing a truly effective injection molding venting system requires careful thought. This guide outlines a step-by-step process to help you get it right:

Injection Molding Venting Design Guideline

Injection molding is a process that has a lot of complicated factors. Proper plastic injection mold venting will help preserve the faces of parts as trapped air and gases can escape, preventing defects and improving part aesthetics.

Assessing Venting Requirements

When considering your venting details, you need to think about how complex your part is and the size of the mold. Complex parts, with more places to trap gases, will typically require more venting holes to exhaust all trapped air vehicles. Larger molds have a larger volume for air and gases to build up in, meaning that larger molds will often require more venting holes to exhaust any air buildup occurring throughout the cavity.

Position and Quantity of Venting Holes

The positioning of holes is critical; they should generally be placed away from the plastic injection point. This strategic placement facilitates an even expulsion of gases as the plastic fills the mold. For hole quantity and distribution, prioritize the mold’s perimeter, where more injection mold vents are typically needed, with fewer in the very center. This guides the air out as the plastic flows towards the edges.

Hole Size Injection Mold Venting

For most applications, the hole diameter for venting should be between 0.25 mm and 0.5 mm. This range is usually small enough to prevent plastic from flashing out while still being large enough for air to escape effectively. For very specific or high-precision parts, micro-venting technology, which utilizes extremely tiny holes, can significantly increase venting efficiency in critical areas without causing flash.

Coordination of Mold Design and Venting System

Your cooling system and venting system must be designed together for them to work properly. Good cooling will help indirectly with the venting and allow you to correctly fill the mold with a steadier flow of molten plastic. Your material choice for the mold will also limit the design: for example, the thermal properties of the materials chosen will affect the movement of heat and how efficient your venting design will be.

Balancing Venting and Quality

A well-thought-out venting design is critical for avoiding defects. It will ensure the mold fills smoothly, significantly minimizing common issues in venting injection molding. Additionally, good venting contributes to a better surface finish on your molded parts without flow lines or blemishes.

Adjusting Venting Strategy

Venting requirements can shift as the plastic fills out various areas of the mold, meaning that what works at the start, might need some minor adjustments for the end of the fill. For this reason, you will want your venting design to be flexible enough to allow for small adjustments to accommodate the specific requirements of each phase of injection molding, to target optimized performance.

Venting Design and Cost Control

A precise and well-optimized venting design can actually reduce the overall complexity of your mold, which in turn can lower manufacturing costs for the mold itself. Moreover, a truly well-designed injection molding venting system makes your entire production process more efficient, reducing scrap and speeding up cycles, all while minimizing operational costs.

Venting Methods Explained

Parting Line Vents

Parting line vents are created directly at the parting line, the seam where the two halves of the mold meet. They are incredibly simple to implement and offer the significant advantage of being super easy to clean without even requiring the mold to be removed from the machine.

Vent Grooves

Vent grooves are shallowly cut channels on the mold surface that permit the release of trapped air. They are particularly useful for large to medium parts where significant amounts of gas need to be released during the molding process.

Ejector Pin Vents

Ejector pin vents involve machining small grooves or channels in the cored ejector pins to allow the escape of entrapped air through these channels. Air can become trapped easily within deeper or more intricate cavity features, and so this can be particularly effective in these situations.

Insert Piece Venting

In insert-piece venting, the injection mold vents are included in separate mold insert pieces that are then inserted into the main mold. This gives a lot of flexibility in the location of venting, while still not being detrimental to the overall structure of the main mold’s integrity.

Clearance Venting

Clearance venting, in a sense, takes advantage of the small gaps and clearances that exist between the separate mold components and permits the escape of air and gases through these areas. This can be physically organized very simply and easily in the overall design of the mold.

Porous Inserts Venting

Porous insert venting involves using mold inserts made from special breathable materials, often sintered metals. These materials have microscopic pores that allow for a continuous flow of gas during the injection process, making them excellent for ensuring consistent gas removal throughout the entire molding cycle.

Vacuum Venting Systems

Vacuum venting systems are a more active method that uses specialized vacuum devices to literally suck the air out of the mold cavity before the plastic is injected. This method is highly effective, especially for high-precision parts where even the smallest air traps can cause major issues.

Dynamic Gas Vents

Dynamic gas vents are advanced, specialized venting valves that actively manage and control the escape of air and gases from the mold. They can significantly enhance venting efficiency and can even be tailored to specific molding conditions and material characteristics for optimal results.

Fecision: Empower Best Practices for Effective Venting

Summary – Mastering Venting for Flawless Molding

At the end of the day, getting your plastic injection mold venting right in injection molding is non-negotiable. It’s how you get defect-free parts, speed up your production times, and make your expensive molds last longer. From putting your injection mold vents in just the right spot to using advanced venting techniques, every little detail matters when it comes to getting that air out.

Fecision’s Precision Venting Solutions

At Fecision, we specialize in high-performance venting system components and mold design for injection molding, ensuring gas-free, defect-free production with extended mold life. Our ISO 9001-certified manufacturing delivers ±0.003mm tolerances for micro-vents for precision applications in medical, electronics, and automotive molding, while our H13 steel and tungsten carbide vents withstand extreme temperatures (up to 400°C) for high-heat resins.

We offer rapid customization—including 8-day lead times on vent pins and porous inserts—along with ±0.005mm precision machining to prevent flash while optimizing airflow. Our MISUMI, HASCO, and OEM-compliant components ensure seamless integration, backed by end-to-end support from design to mass production.

High-Performance Venting Solutions – Engineered for Speed & Precision

- 7-Day Custom Vents – Fastest in the industry (50% faster than standard 15-day lead times)

- 90% Fewer Defects – Proven elimination of gas traps, burns and weak welds

- Free Moldflow® Analysis – Optimize venting design with our simulation expertise

Maximize mold performance – faster delivery, flawless parts, expert support. Need reliable and precise injection molding services or high-performance venting system components? Look no further. Contact Fecision today!