How does a power tool handle feel rock-solid yet velvety-soft in your palm—without a single screw or drop of glue? This simple, dual-material performance is the result of a single, highly efficient manufacturing process.

If you’ve ever asked that question, the answer is 2 shot injection molding. Below, we’ll cover how the 2 shot injection molding process flows, its pros and cons, and critical success parameters. This guide will also show you its hottest market applications and how this technique compares to traditional overmolding.

What Is Two Shot Injection Molding?

Two-shot injection molding is a smart way to make complex parts with two materials in one go. It’s a single-cycle, dual-resin process that creates one permanently bonded component right inside the mold. This means you get a complete part straight out of the machine, which eliminates all the time and cost of manual assembly later.

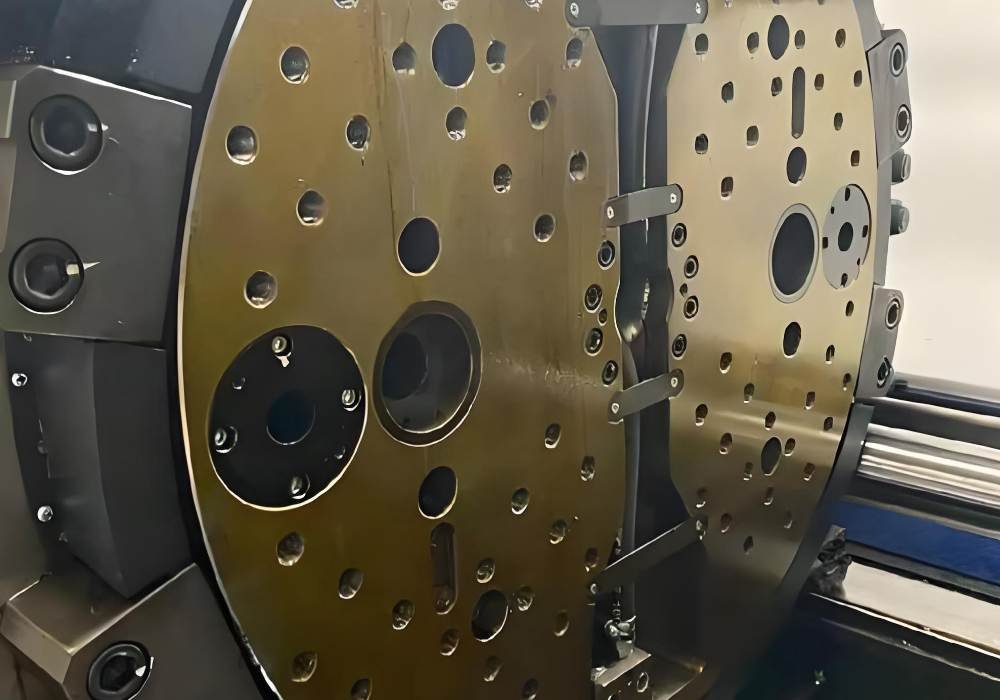

Special presses use a rotary or index platen to make this happen. You mold the first material, the substrate, and then the platen quickly moves it to a second cavity. The second material—maybe a soft grip or different color plastic—is injected onto the still-hot surface. This contact creates an incredibly strong, molecular bond.

Advantages and Disadvantages of Two Shot Injection Molding

This innovative process offers clear benefits over traditional methods, but it also comes with specific challenges. It is important to understand both sides of the conflict before making the leap to this technology.

1. Advantages

The benefits of combining materials in a single cycle can significantly improve your product quality and reduce long-term operational costs.

Eliminated Assembly Labour

Imagine a process where one press and one operator make a finished, two-material product. You save a noticeable amount of cost per part in downstream labor because you have zero fasteners and no separate assembly station. This single-cycle efficiency is a huge financial win.

Superior Bond Strength

When the second melt meets the first shot while it is still hot, the resins blend slightly at the interface. This inter-molecular entanglement delivers peel strengths multiple times higher than parts joined with adhesive or ultrasonic welding. Your product will simply last longer.

Design Freedom

This process lets you combine materials with radically different properties. For example, you can combine clear PC windows with soft TPE in a single 2 shot plastic injection molding cycle. This creates tactile “soft windows” that would be impossible to assemble later on.

Lower Total CO₂ Footprint

By removing the need for transport between separate molding and assembly stations, you gain efficiency. Reducing the number of steps and associated logistics also leads to a smaller carbon output impact for your overall manufacturing process.

2. Disadvantages

The advantages here are significant; however, there will be hurdles to overcome first, which are related to the overall cost and complexity of the process.

Higher Tooling Investment

The complexity of the process does come with a price. You need two-cavity sets and specialized rotary hardware to shuttle the part. This sophisticated tooling pushes the mold cost noticeably higher than a simple single-shot tool.

Material Compatibility Limits

You can’t just bond any two resins together. Not all materials bond effectively, so you must choose wisely. Pairing a hard material like PP to a soft material like TPE usually needs a tie-layer resin or a mechanical interlock design feature to create a strong joint.

Longer Development Lead-Time

A simple mold takes weeks; a 2 shot mold takes months. The process requires more detailed work upfront. Flow simulation, adhesion testing (DOE), and temperature zoning of the mold can add weeks to your product’s development lead time versus standard overmolding.

Part-Volume Threshold

The high cost of the specialized mold means this process isn’t for small runs. Low-volume programs rarely amortize the mold premium. Your break-even point where the labor savings justify the tooling cost is normally in the tens of thousands of shots.

2 Shot Injection Molding Process Step-by-Step

Understanding the sequence of events inside the machine reveals the efficiency of this manufacturing method. Here is the step-by-step breakdown of how a complex 2 shot part is created in a single machine cycle.

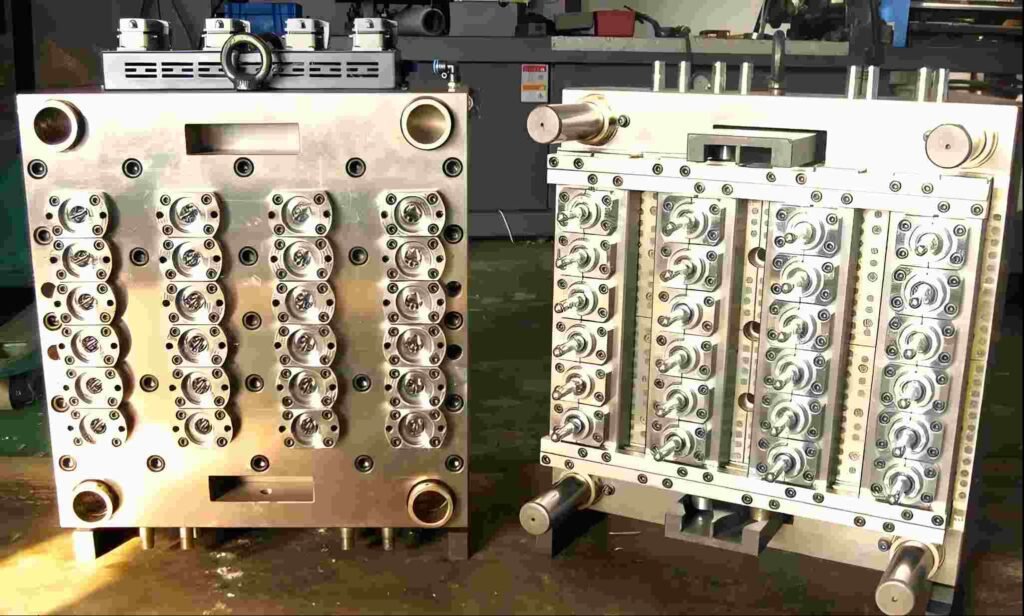

1. Mold Design & Build

The design phase is absolutely critical for this process to succeed. The tool must be built to the most exacting standards. Mold builders ensure the steel for the second cavity is safe and the shut-off heights are matched within microns. This high precision prevents any material from leaking, or “flashing,” after the mold rotates.

2. First Shot Injection

The process kicks off with the first shot, which forms the rigid base, or substrate, of your part. The primary resin fills the first set of cavities (Cavity A). Once the mold is full, hold pressure to pack the plastic tightly, and a brief cooling cycle immediately begins to stabilize the core.

3. Mold Rotation/Index

This movement is the key to the whole operation. The rotary platen spins—or sometimes a robot transfers the core—in less than a second. The still-warm first-shot part is now precisely registered in the second cavity set (Cavity B), ready for the next material to be injected.

4. Second Shot & Bonding

The second material, often a soft elastomer or a different color resin, is then injected into Cavity B. The temperature should be appropriate to avoid deforming the first-shot part. The molecular-level adhesion that creates the strong bond happens instantly at this interface.

5. Cooling & Ejection

The final stage is cooling. Uniform cooling channels in both halves of the mold ensure synchronous material shrinkage. Once complete, the finished parts eject with living-hinge quality seams or perfectly crisp color boundaries.

6. In-Line Quality Check

For high-volume, critical parts, quality control is often integrated. Advanced vision systems verify the absence of defects like short shots. They also measure TPE thickness and log cavity pressure curves for comprehensive traceability.

Key Parameters for Successful Two Shot Molding

Success in this demanding process depends on tight control over many variables. To ensure perfect adhesion and a repeatable part, you must optimize these specific technical parameters during design and production.

Material Pairing

You must choose materials that bond well chemically and physically. Always refer to supplier charts but it is best to mold your own tensile buttons to confirm bond strength. Safe pairs include ABS with TPE, PC with TPU, and LSR 2 shot injection molding pairs with PBT for medical parts.

Interface Temperature Window

For the best bond, you need to keep the surface of the first shot warm. Keep this first-shot surface above its Glass Transition Temperature (Tg) when the second melt arrives. You can achieve this using variotherm zoning or induction heaters in the mold.

Injection Sequence Timing

The timing between the two shots is a delicate balance. You should only delay for a fraction of the full cooling time of the first shot. Wait too long and you’ll get a weak, “cold weld”; wait too short and the second shot will deform the soft substrate.

Rotary Platen Repeatability

The mechanical tolerance of the machine is critical. The hydraulic servo drive must be able to position the platen in hundredths of a millimeter. If it deviates from this precision, you will get unacceptable “ghosting” or blending on the color boundary.

Vent & Overflow Strategy

Molding two materials increases the chance of air entrapment. You need to add micro-vents at predicted weld lines to let air escape. Overflow wells are also used to trap any cold slugs, preventing blemishes at the critical bond-line.

Shrinkage Compensation

The two materials will shrink at different rates after molding, and you must model this differential shrinkage using flow software. Amorphous substrates over-molded with TPE often need pre-crowned or domed interfaces to end up perfectly flat.

Thinking about designing your next complex part? Get a Design for Manufacturing (DFM) analysis from Fecision today to ensure your concept is perfect for 2 Shot Molding!

Applications of Two Shot Injection Molding

Because of its unique ability to combine form and function into a single component, 2 shot molding has become indispensable across numerous industries. Let’s look at some of the most common products that leverage this technology.

Consumer Electronics

Look no further than your smartphone bumper frames. They use a hard PC skeleton for protection and a soft TPU grip for ergonomics. The 2 shot injection molding market ships hundreds of millions of these units annually, proving its dominance in this sector.

Automotive Interior

Modern steering-wheel switches are complex parts made simple with 2 shot. They often integrate an ABS substrate, a light-guiding PMMA layer, and a soft-touch TPE, all in one 2 shot plastic injection molding cycle. This allows them to pass rigorous cold-weather drop tests.

Medical & LSR 2 Shot

Precision medical devices rely on the integrity of this process. A common application is a PC blood-filter housing with an LSR 2 shot injection molded septum or valve. This single-part creation eliminates the post-assembly sterilization risk.

Power Tools

The powerful tools you use at home or work are often 2 shot parts. The core drill housing is made of a strong glass-filled nylon, while the grip is an over-molded TPE. This design significantly reduces hand-arm vibration for the user.

Packaging & Caps

Even simple packaging benefits from this technique. Many flip-top closures are made of a PP living hinge combined with a TPE seal. This process achieves a perfect hermetic line right out of the mold, completely replacing the need for a separate liner.

2 Shot Molding vs Overmolding

When designing a multi-material product, you will face a decision between 2 shot molding and classic overmolding, and it is important to know in advance how they differ regarding processing and cost implications.

Process Continuity

The primary difference is the cycle count. The 2 shot injection molding process is single-press, single cycle. Traditional overmolding needs two molds and often requires a robot or operator for manual loading. This basically doubles the cycle time.

Bond Strength Comparison

The fact that the interface is hot in 2 shot molding is a huge advantage. This hot-interface bonding gives significantly higher peel values than overmolding. Overmolding often relies on mechanical snaps or chemical primers, which typically result in a lower bond strength.

Piece-Part Cost Cross-Over

The best process choice depends on your volume. For moderate-to-high volumes, the 2 shot process wins on overall cost. However, below a few thousand parts, the lower mold capital expenditure of overmolding often offsets the extra labor cost.

Design Geometry Limits

Overmolding is more flexible and can fully encapsulate electronic components or metal inserts. 2 shot excels at sharp color boundaries and complex interfaces. However, it usually requires a certain degree of draft angle for the part to rotate successfully.

Material Flexibility

Overmolding is a bit more forgiving with materials because the two parts cool completely before the second shot. The 2 shot process needs the materials to have overlapping temperature windows for bonding, or you must rely on a tie-layer or mechanical interlocks.

Quick Comparison: Key Differences

| Comparison Area | 2 Shot Molding | Overmolding |

| Process Continuity | Single-press, Single-cycle | Two-presses, Two-cycles |

| Tooling Cost | High Investment | Lower Initial Cost |

| Piece-Part Cost | Lower (High Volume) | Higher (Includes Labor) |

| Bonding Mechanism | Hot/Molecular Adhesion | Mechanical or Primer |

| Bond Strength | Superior Peel Values | Generally Lower |

| Cycle Time | Faster | Slower/Double Time |

| Design Flexibility | Excellent Color Seams | Better for Encapsulation |

| Material Needs | Overlapping Temp Window | More Tolerant |

Conclusion

Two shot injection molding is a transformative technology. It takes multi-material product concepts and turns them into a single-cycle reality, instantly cutting labor, boosting bond strength, and raising your design freedom. From high-integrity LSR 2 shot injection molding for medical seals to colorful, ergonomic consumer gadgets, the 2 shot injection molding market is steadily expanding its reach.

Fecision specializes in 2-shot injection molding services with the capability to manage your specific needs. We use advanced technology like CMM and Vision inspection systems, ensuring dimensional accuracy and consistent part quality across runs. Our 24/7 production and automated cells achieve high volume, making your two-shot tooling investment highly cost-effective and ensuring dimensional accuracy.

When you partner with Fecision, you benefit from our expert team and quality commitment (ISO 9001 and ISO 13485 certified). We take on complicated work such as LSR 2 shot injection molding, and we assure not only reliability with on-time delivery but also guarantee tolerances as close as ±0.001 inches (0.025 mm) on our complex multi-material components. Contact Fecision for a quote right now!