Need CNC-robot parts with soft-grip handles, color-coded buttons, or clear windows—without extra assembly? Stop painting or gluing plastics. Two color injection molding seamlessly fuses two materials into a single, highly durable component in one automated cycle. It simplifies complex designs and cuts your total manufacturing costs.

This article explains the core principles of the two color injection molding process, detailing its significant advantages and workflow. You will learn about its key applications and how it technically differs from general two-shot molding.

What Is Two Color Injection Molding?

Two color injection molding, often called 2K or bi-injection, is a cutting-edge plastic molding technology. It lets you mold two distinct materials or colors into a single, integrated part during one machine cycle. The result is a seamless product with a strong, permanent molecular bond, simplifying complex assembly.

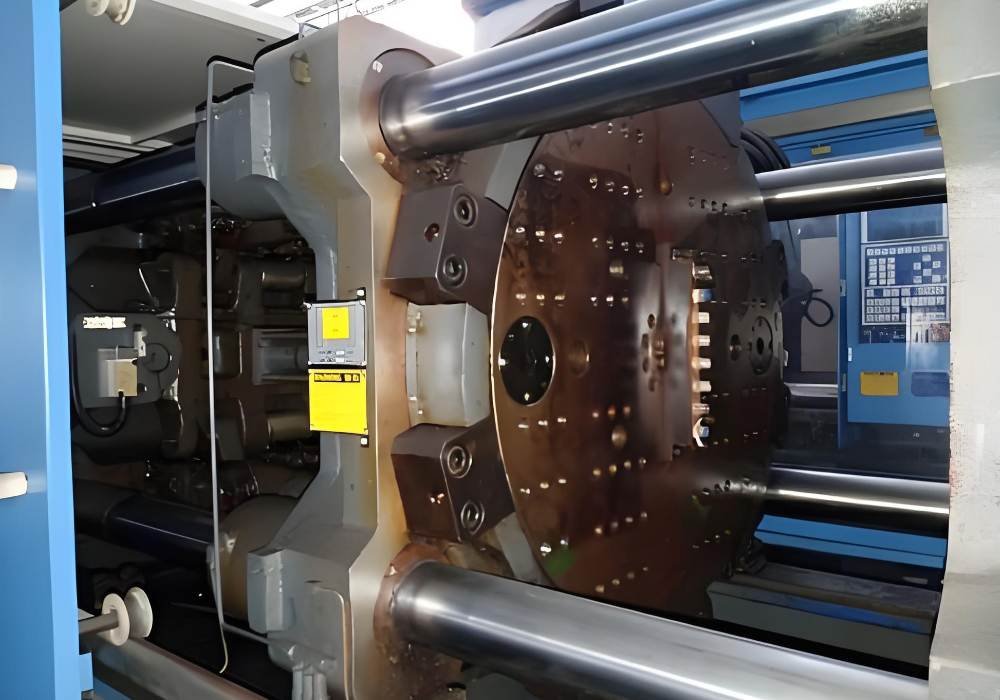

This advanced process requires a specialized machine equipped with two independent injection barrels and nozzles. It injects two separate molten polymer streams sequentially or simultaneously into a common or rotating tool. This highly controlled action creates exceptional, molecular-level adhesion between the materials, forming a single, superior component.

The core value proposition of this technology is that it replaces secondary operations like painting, welding, or using snap-fits and inserts. It drastically cuts labor costs and boosts part integrity. Manufacturers can achieve IP-rated sealing, soft-touch zones, or clear viewing functions all in one automated step.

Advantages of Two Color Injection Molding

You will find that shifting to two color injection molding process offers significant upgrades over traditional manufacturing. Let’s look at the powerful benefits this integrated approach brings to your product line.

Superior Cosmetics, Zero Post-Processing

The process can achieve impressive visual results without any need for pad-printing, laser-etching, or spray lines after molding. Get sharp, clear 2 color injection molding logos, chrome-like borders, or frosted textures straight off the press.

This immediate cosmetic completion simplifies your supply chain dramatically. By eliminating secondary finishing steps, you reduce lead times, avoid vendor management issues, and ensure consistent color and texture quality across every single component.

Enhanced Functional Integration

Two color plastic injection molding allows you to combine materials for superior function in ways single-material molds cannot. For instance, it enables the combination of PP with TPE for seals that can withstand repeated dishwasher exposure, or the blending of nylon with silicone to create gaskets that withstand extreme temperatures.

This functional fusion is critical for robust product design. Combining rigid skeletons with flexible over-molds or clear windows in a single step helps achieve crucial features like IP-rated sealing and effective light piping directly within the part.

Unmatched Molecular Durability

Unlike parts that are merely glued or snapped together, the second shot forms a true chemical cross-link with the first material. This strong bond is extremely durable under stress.

Your integrated parts will survive harsh conditions and rigorous testing. They can withstand 1,000+ dishwasher cycles, the –40 °C cold shock common in automotive applications, or high-pressure fluid exposure better than any assembled product.

Significant Cost Reduction

The whole manufacturing process is consolidated into one efficient cycle. It happens on one machine with one operator and one primary quality control step, eliminating multiple handling points.

This integrated approach cuts three costs: sub-assembly labor, expensive adhesives, and work-in-progress inventory. And the streamlined cycle then lowers your cost-per-part significantly during high-volume production.

Clear Sustainability Benefits

Manufacturing with 2 color injection molding often results in a significantly lower scrap rate compared to multi-step assembly lines. Since there are no paint solvents or waste adhesives, it inherently supports cleaner production.

By using a mono-cycle process, you also save substantial energy. This single-machine operation is more efficient than running two separate molds plus an entire painting booth, helping your products meet REACH and RoHS compliance standards.

Ready to save on assembly and achieve superior quality? Fecision’s engineers can assess your design today.

How Does Two Color Injection Molding Work?

Understanding two color injection molding process steps helps you appreciate the precision required for successful two-shot parts. The journey starts before the machine even begins the injection sequence.

Preparation and Material Drying

Each plastic resin, whether it’s the base material or the second color, is carefully prepared. Manufacturers should use independent hopper and dryer sets to thoroughly dry each resin. This prevents defects like splay marks. Color masterbatch or pre-colored pellets are then fed to separate barrels, sized for the required shot volume ratio.

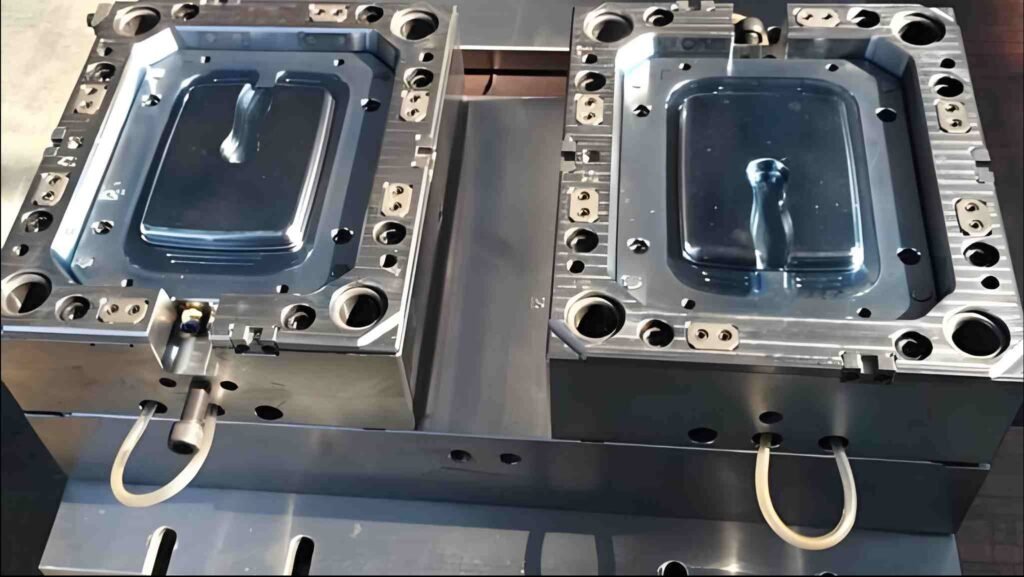

First Shot: Creating the Substrate

The molding cycle begins when the core-back or rotating mold closes the first cavity. The first polymer is then injected. This material is precisely controlled for temperature and shear rate to form the rigid skeleton or the aesthetic base layer of the finished part.

Part Transfer and Tool Movement

Once the first shot is sufficiently cured, a highly repeatable mechanism moves the part for the second injection. Options include a rotary platen, an index plate, a robotic arm, or a sliding plate. The chosen method impacts cycle time and capital cost, but extreme precision ensures the second shot is flash-free.

Second Shot: Over-Melt Bonding

The transfer mechanism positions the substrate part under the second nozzle into the final cavity. The melt temperature of the second plastic is often tuned slightly higher than the first. This thermal adjustment slightly re-melts the boundary layer, promoting true chemical fusion rather than just a mechanical lock.

Cooling and Ejection Strategy

The part is cooled efficiently using strategically placed channels near the knit line to reduce the risk of warping. Valve-gate sequencing should be used to prevent flow marks and improve part appearance. Finished parts are then carefully handled by a robot or conveyor for scratch-free removal.

Integrated Quality Control

Modern two-shot machines often integrate advanced vision systems for quality control. Integrated cameras verify color boundary accuracy and detect defects like short shots or blush. Bad parts are then automatically diverted to a grinder for closed-loop regrind use.

Applications of Two Color Injection Molding

The versatility of two color plastic injection molding means it is usable across nearly every industry. From medical devices to automotive components, the benefits can translate equally to high performance products.

Automotive Interior & Exterior

Two color injection molding process is widely used in vehicles. Look for soft-touch TPE steering wheel grips, two-tone dash bezels, and back-lit PC indicator housings. It’s also used for matte/gloss logo badges, which pass rigorous fogging, UV, and scratch tests without needing any paint.

Consumer Electronics

You’ll find two-shot parts everywhere in electronics. Examples include phone cases with transparent antenna windows and remote-control keys combining silicone with a rigid PP base. It’s also used for wearable housings that bond glossy, UV-stable PC with antibacterial TPU.

Medical & Diagnostics

The medical industry relies on this precision for safety and function. Typical applications are color-coded syringe plungers and surgical tool handles made from bonded PC and TPE. Clear and opaque diagnostic cassettes are also produced, often using biocompatible ISO 10993 materials without adhesives.

Packaging & Personal Care

In packaging, it creates highly functional and visually appealing items. Examples include flip-top caps that combine a living hinge with a soft grip band, and dual-color toothbrush handles. Perfume buttons with a crystal-clear viewing slot are also common, supporting 100% PP recyclability.

Industrial Tools

It enhances the durability and ergonomics of industrial equipment. This includes power-drill housings with an anti-slip TPE over-mould, and two-shot meter faces that combine a clear lens with an opaque frame. It’s also used for vibration-damping grips on pneumatic wrenches.

Two Color Injection Molding vs Two Shot Injection Molding

While both terms cover multi-material processes, they describe different production methods. Use this table to compare their key differences. It will help you select the right tooling approach for your specific project requirements.

Defining the Difference

| Comparison Point | Two Color Injection Molding (Rotary-Platen View) | Two Shot Injection Molding (Broader View with Robot/Slide) |

| Tool Concept | Rotating mold stays inside one press; the part moves twice | Any method to move substrate: rotary, robot, slide, or manual |

| Cycle Feel | Transfer is integral to clamp motion; feels like one seamless process | Extra robot or manual handling can break rhythm; speed varies widely |

| Capital Entry | Higher upfront cost; requires complex mold and specialized rotary press | Lower entry cost; can retrofit a standard press with automation |

| Volume Sweet Spot | Favors high, steady demand where the complex tool amortizes quickly | Flexible; robot cell suits pilot runs and mid-volume batches |

| Precision & Repeatability | Highly repeatable cavity alignment via internal mechanical indexing | Accuracy depends on robot calibration; manual loading adds variability |

| Material Pair Freedom | Must use resins that chemically bond; limited for loose inserts | Tolerates poor chemical bond; allows embedding metal or circuit board inserts |

| Part Geometry Limits | Rotation requires balanced cavities; no loose inserts allowed | Robot can stage inserts, cables, or PCBs before the second shot |

| Transition Quality | Ideal for sharp, flash-free cosmetic parting lines | Slight witness line possible from robot repositioning; may need cleanup |

| Process Risk Profile | One integrated cell; single point of failure (e.g., heater fault stops the line) | Robot step adds handling risk but keeps first-shot press independent |

| Business Flexibility | Tool changes are costly; best when the design is completely locked | Robot cell can be easily re-tasked to other jobs, aiding prototyping |

Making the Right Choice: A Strategic Perspective

The decision between two color injection molding vs two shot injection molding is a strategic decision based on volume, design stability, and cost. Use the following points to guide your material and tooling investment decision.

Opt for Two Color Injection Molding when:

- Rotary-platen volume is acceptable and design is stable. This dedicated equipment is best for high, consistent volumes where the design is locked and unlikely to change, maximizing return on the complex mold investment.

- Cosmetic knit-line must be invisible (high-end robot covers, medical housings). The highly controlled, servo-driven rotary process ensures the tightest tolerance and the most visually seamless transition between the two materials.

- Secondary labor (paint, weld, adhesive) cost already exceeds tool amortization in business case. If your current assembly costs are high, the single-cycle process offers rapid savings that quickly justify the higher initial tooling expense.

Opt for the broader Two Shot Injection Molding toolkit when:

- Insert placement (metal, PCB, cable) is required inside the second cavity. The flexibility of a robot allows it to stage non-plastic components before the second shot, which is impossible with a rotating tool alone.

- Annual demand is uncertain or split into several low-to-mid volume launches. A robot cell offers greater adaptability for smaller batches and staggered production runs, reducing the risk associated with high-volume tool dedication.

- Existing standard press must stay available for other jobs; robot cell can be wheeled away. The mobile nature of a robotic cell permits you to utilize standard presses for subsequent parts. It’s a practical way to use the same equipment for multiple part types, which improves overall utilization.

Conclusion

Two color injection molding has established itself as a mainstream solution as the process of merging aesthetics, ergonomics, and assembly savings into a single cycle automated process. The process handles everything from soft-grip surgical tools to back-lit automotive knobs. It’s a proven way to combine multiple components in a single cycle, offering undeniable efficiency and quality gains that secondary operations simply cannot match.

Fecision specializes in the precise delivery of complex, multi-material components, perfectly aligned with your two color injection molding needs. Our facility uses dedicated rotary-platen presses and advanced cavity-pressure sensors to ensure perfect molecular bonds and repeatable cosmetic results for your CNC-robot parts and grips.

We streamline your project from concept to delivery. Our experienced engineers provide same-day DfM analysis, suggesting ideal resin pairs and optimizing tool design to guarantee flash-free part ejection. With ISO certifications and a strong commitment to quality, we deliver complex, high-precision two color parts reliably.

Ready to simplify your multi-material part assembly? Contact us now to discuss your two color plastic injection molding design.