Modern manufacturers develop diverse metals and alloys to produce precision, high-performance stamped parts. Selecting the right material requires matching properties to both stamping techniques and application needs—considering tensile strength, hardness, ductility, and machinability to prevent breakage while maintaining formability. These factors ensure structural integrity during stamping. In this guide, we explore key criteria for material selection and identify optimal metals for your project.

Key Factors in Metal Stamping Material Selection

When you choose the best material for your metal stamping project, you had better consider the following factors. The key factors in metal stamping material selection include:

- Tensile Strength

Tensile strength measures the material’s ability whether it is easy to resist fracture when exposed to external forces. The material you select has tensile strength during your processing.

- Weldability

In the welding step, you should consider the weldability of the material used in this necessary process. If you use a welding material with low weldability, you need to use advanced tools and techniques, which will negatively influence your schedule and budget.

- Corrosion Resistance

If the metal stamping material is used in a harsh environment. You can choose some material with excellent anti-corrosion properties.

- Formability

The formability of a material can be influenced by whether this material is made into a certain shape successfully. For example, the material that has the best formability can be extended to wire or other thin or elongated shapes without breaking.

- Cost Considerations

Material cost and production cost are also key factors that you need to consider. You need to balance the final effects and the cost. Take titanium, for example. Even if titanium has the best performance, its cost for some specific projects is really high. If the material needs to be some special handling or processing, it may increase your production cost.

- Surface Finish

Metal stamping services only focus on the process of stamping, you also need to consider the final appearance of the metal parts. For instance, stainless or brass should have a surface finish, and then your customer would like them with a visually appealing finish.

Top Metals for Stamping Compared

Metal stamping is used in different industries and is suitable for different materials. Each material has its unique characteristics and is used at different times. Here are some extensively used materials in sheet metal stamping.

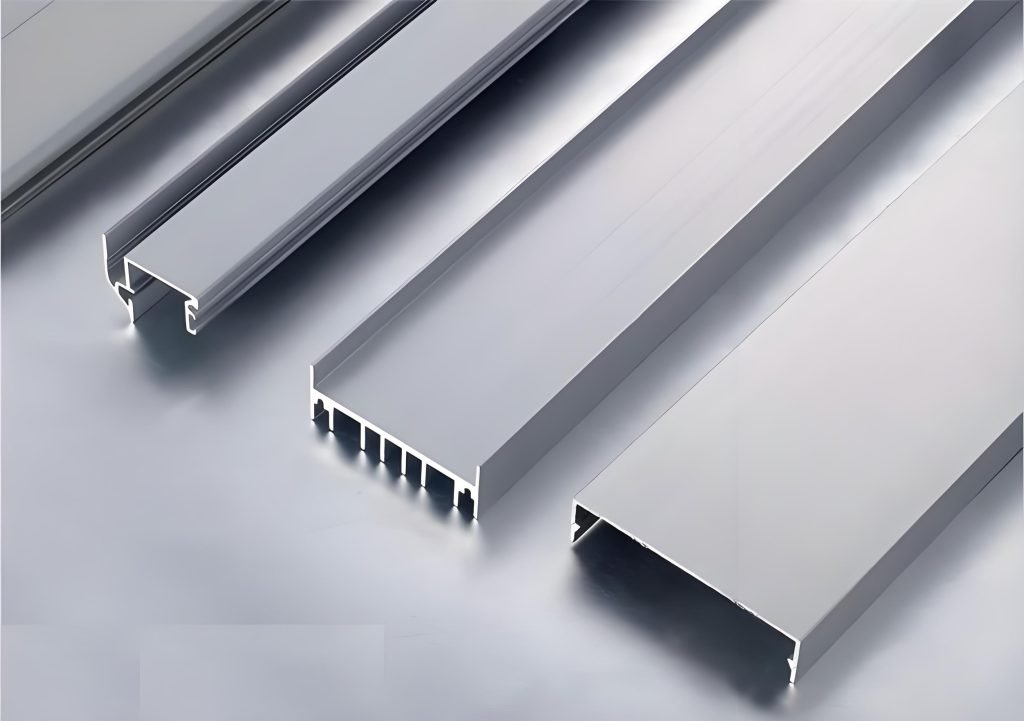

1. Aluminum

Aluminum is a highly stable material; its unique performance is more attractive and can be satisfied to a wide range of applications.

Characteristic and application:

- Lightweight

The most notable characteristic of aluminum is its low density. This makes aluminum fit for the application that needs weight reduction, like aircraft, cars, or other electric products.

Corrosion protection: Aluminum has natural corrosion protection properties, making it suitable for some outdoor applications or products often used in humid environments, including marine equipment and construction components.

- Electrical conductivity

Even though aluminum is not as conductive as copper, it is still a good conductor of electricity and heat. It is the affordable alternative in electrical and thermal applications.

- Plasticity and malleability

Aluminum is easy to process and form. It can create complex and exquisite shapes. It is very beneficial in modern design and manufacturing.

Challenges and considerations:

- Strength Limitations

Although aluminum is very important because of its lightweight, its strength is lower than steel. This would limit its use in some high-intensity applications.

- Surface finishing

To improve its appearance or further enhance its corrosion resistance. Aluminum is usually anodized or painted.

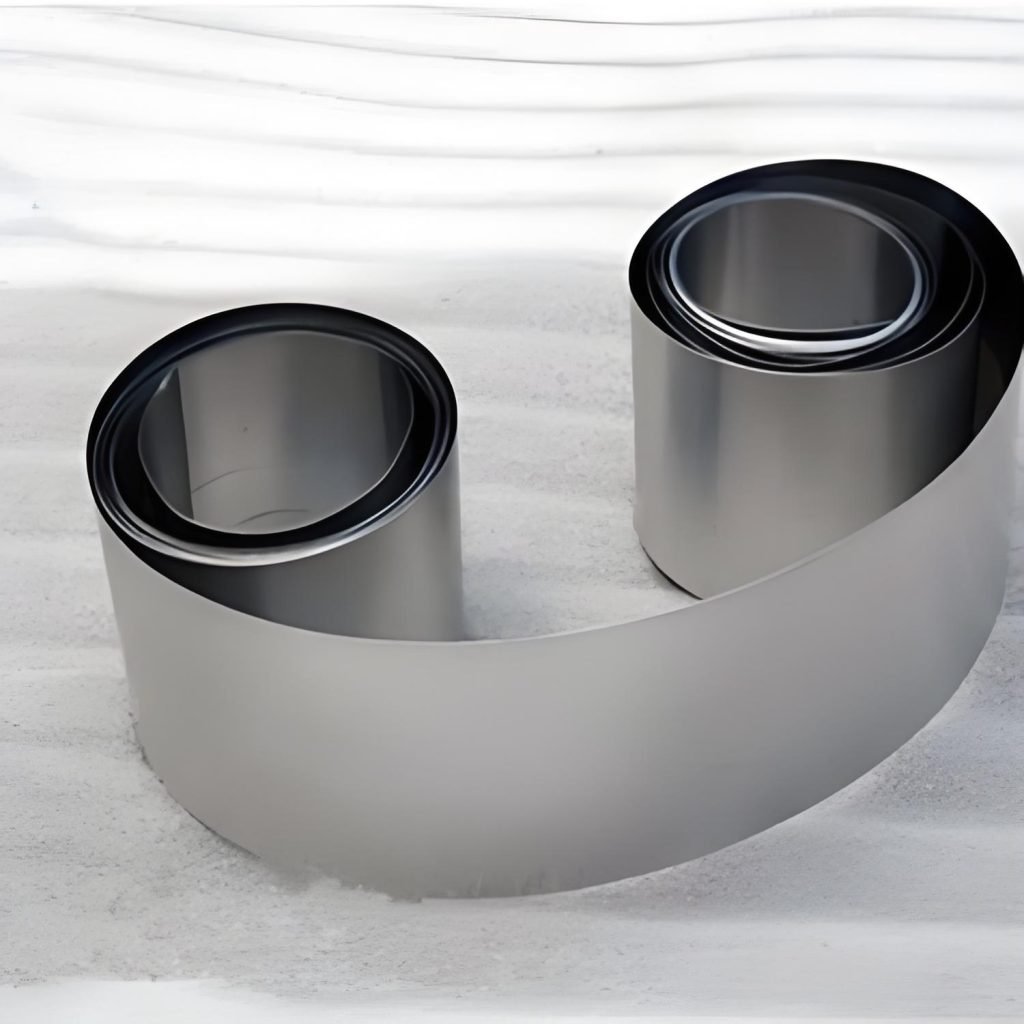

2. Stainless Steel

Stainless steel is a kind of alloy, and its characteristics include the presence of chromium. This makes stainless steel anti-corrosive and improves its practicality in many applications.

Characteristic and application:

- Anti-corrosion

Stainless steel is defined as anti-corrosive and rust-resistant. It is an alternative material exposed to the wet environment, chemicals, and salt.

- Aesthetics

Its sleek and modern appearance is very attractive for consumer products, architectural and kitchen appliances.

- Heat resistance

Some stainless steels can withstand high temperatures and are suitable for applications such as exhaust systems and heat exchanges

- Hygienic characteristics

The stainless steel surface is non-porous, and it is often used in medical equipment, food processing, kitchen appliances, etc.

Challenges and considerations:

- Cost

Stainless steel is usually expensive than steel because the properties are enhanced.

Processing and hardening: It would be hardening quickly in processing and forming. It needs professional tools and techniques.

- Variability in grades

There are more than 150 kinds of grades to choose. You need to choose the proper grades of stainless steel. This may be complex for somebody else.

3. Brass

Brass is an alloy of copper and zinc and a popular choice among metal stamping materials. Brass is a unique material in metal stamping.

Characteristic and application:

- Acoustic performance

Brass is known for its excellent acoustic properties and is used in the production of musical instruments such as horns and bells.

- Maintainability

Brass can be highly machinable, and they are preferred for precision parts, including gears, valves, and fittings.

- Anti-corrosion

Brass has excellent anti-corrosion properties, especially in water environments. Suitable for pipelines, marine environments, decorative items, etc.

- Aesthetic appeal

Brass has a distinctive golden appearance and is often used in architecture and interior design.

Challenges and considerations:

- Cost

Metal stamping manufacturers may consider the cost of brass. Brass is more expensive than other metals like aluminum and steel.

- Variable Properties

The prosperity in brass is different from the proportion between the amounts of brass and zinc. You need to select the specific brass to fit the application.

- Lead content

Some brass contains lead to enhance the processability. However, in the application where lead exposure is at risk, this may be a question. You need to consider using the brass without the lead.

4. Copper

Copper is a very widely used material in metal stamping. Many manufacturers choose copper as a metal stamping material because of its unique strength, electrical and other properties.

Characteristic and application:

- High strength and hardness

Brass is well-known for its high strength and hardness. Compared with steel, copper is the preferred choice for aircraft, precision parts and connectors.

- Excellent electrical and thermal conductivity

This material is non-magnetic and does not produce sparks. In the natural gas and oil industry, you need to consider this.

- Corrosion resistance

Copper has excellent corrosion resistance, especially in marine environments and industrial gases, which increases durability.

Challenges and considerations:

- Cost and availability

When using copper, you need to handle it carefully and take some safety measures. If you inhale beryllium dust and smoke, you may be in danger.

5. Steel

Steel is the basic material for metal stamping. It is popular because of its strength, versatility, and cost-effectiveness. As the fundamental parts for many projects, it is very important to know the performance and application, and then you can select the best material.

Characteristic and application:

- Strength and Durability

Steel has high tensile strength and is the ideal choice for components subject to significant stress or weight. For example, car parts, architecture and industry.

- Versatility

It can offer various grades, so steel can be customized and fit the specific need, no matter higher strength and better weld-ability, and anti-corrosion.

- Cost-effective

Compared with other metals, the price of steel is more economical and the first choice for someone with a conscious budget.

- Magnetic Properties

Some steels are more magnetic, which makes them more beneficial to some televisions, engines, and transformers.

Challenges and considerations:

- Easy to corrode

If steel is exposed to wet and oxygen, steel is easy to rust. This registration is needed to further protect finishing or handling, especially in outdoor and harsh environments.

- Weight

In some high-weight requirements of weight, such as some specific car or aircraft, the density of steel is a drawback.

6. Titanium

Titanium is a high-performance material in metal stamping. It is famous for its unique strength-to-weight ratio and other performance.

Characteristics and applications:

- Exceptional strength-to-weight ratio

One of the exceptional properties is that the strength-to-weight ratio is the highest in all metals. This makes it an ideal choice for aircraft, marine, and car. In this application, strength is really important, but weight is minimized.

- Anti-corrosion

even in salt water or other harsh environments, titanium is very resistant to corrosion. This characteristic makes it the ideal choice in marine applications and chemical processing.

Challenges and considerations:

- Cost

Titanium is more expensive than many other metals, which reflects its advanced properties and the complexity of its production and processing.

Partner With Best Metal Stamping Service Provider

With decades of expertise serving automotive, medical, electronics, and consumer goods industries, Fecision delivers superior custom metal stamping and automated assembly solutions. We provide complete finishing services – from coating and plating to specialized treatments like PVD/CVD and anodizing – ensuring both durability and premium aesthetics.

Our material experts guide you through selection, whether you need:

- High-strength steel for automotive components

- Corrosion-resistant alloys for medical devices

- Precision copper for electronics

Our streamlined process includes:

- Free T1 prototype for approval

- Material selection guidance

- High-volume production capacity