Large part injection molding takes the form of thermoplastic pellets and converts them into durable, dimension-critical parts, which are measured in feet. From refrigerator liners to tractor hoods, it provides high strength, low weight, and repeatable quality for a variety of component sizes.

This guide covers the essentials of large-part injection molding. You will learn its definition, the dominant processes and materials for molding large plastic parts, and the key industries that use these components every day.

What Is Large Part Injection Molding?

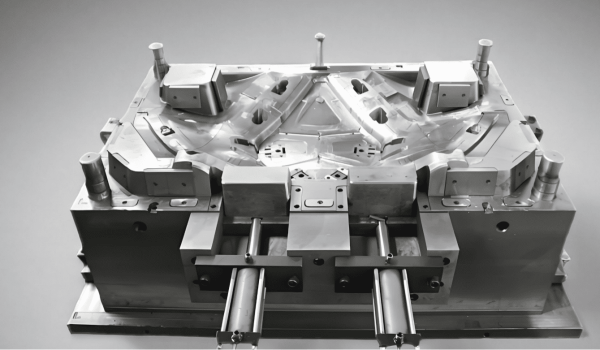

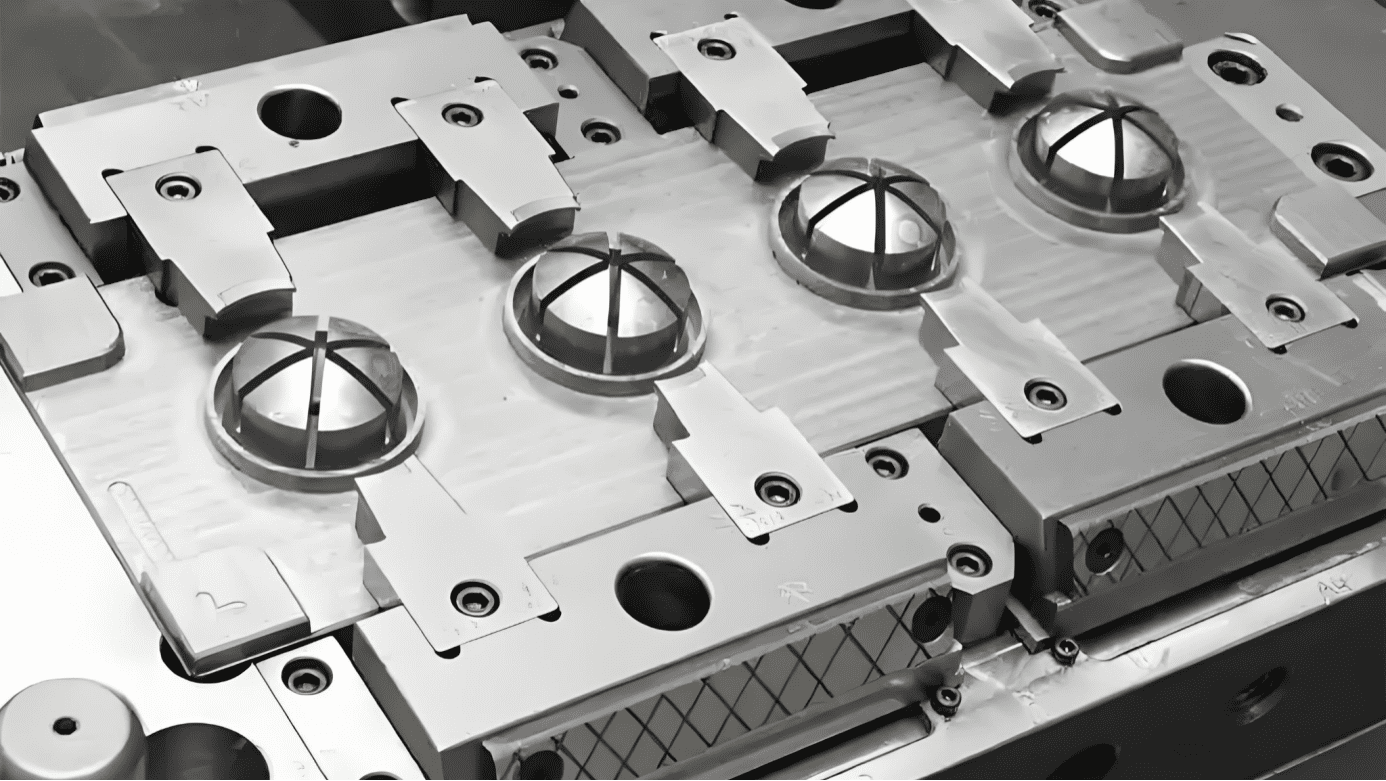

Large part injection molding, or large-tonnage molding, consists of manufacturing large plastic components from specialized equipment. This process requires much more than just getting a bigger machine, as the part becomes more complicated, making small details – like gate placement and wall design – extremely important. This process requires massive steel molds that take longer to build and have a higher initial cost.

The core process forces melted plastic into a mold cavity under high pressure. You need enough clamping force to keep the mold halves shut against that pressure. This force scales directly with part size –it often starts around 500 tonnes for smaller parts and goes up from there. This technology is used across many industries to create everything from vehicle dashboards to large industrial containers.

Large Part Injection Molding Processes

Here you’ll find the methods used most for oversized components: the fundamental cycle, specialized molding techniques, and secondary steps to finish your large injection molded parts.

The Standard Injection Molding Cycle for Large Parts

This is the important and sequential set of actions that are performed to create a single large plastic part in a completed cycle.

Step 1: Mold Preparation & Clamping

First, the mold must be cleaned and set up perfectly. Then, the two mold halves are securely clamped together with immense force. You need a large-tonnage machine to withstand the extremely high pressures of the injection process.

Step 2: Injection & Filling

Next, the plastic resin is melted and then injected into the mold cavity at very high pressure. This step is critical to ensure that the material fills the entire, often complex, cavity and accurately replicates your part design.

Step 3: Cooling & Solidification

Once filled, the molten plastic inside the mold is allowed to cool down and solidify. For your plastic injection molding large parts, this phase takes a long time. It is the most critical step to prevent warping and to guarantee dimensional stability.

Step 4: Ejection & Post-Processing

When the part is finally cooled, the mold opens, and the finished component is robotically ejected. The part then goes through inspection for any injection molding defects and may require trimming or other simple finishing operations.

Specialized Molding Techniques

A number of advanced techniques, such as sink marks, high weight, and internal stresses, have surfaced to address the challenges of injection molding large flat parts and to ensure your quality requirements are achieved.

Gas-Assist Molding

This advanced method injects pressurized nitrogen gas after the initial plastic shot. This creates hollow channels inside the part and reduces material usage and overall component weight for you. The gas will also eliminate sink marks in thick areas and improve dimensional stability, which is vital to large panels, handles, and any component requiring high integrity.

Structural Foam Molding

The process mixes a special foaming agent with the polymer to create your part, with a solid outer skin and a lightweight, rigid foam core. This provides excellent stiffness. The technique is perfect for you when producing very large components that require high stiffness but low internal stress, like industrial pallets or machine housings.

Finishing and Alternative Processes

After molding, your large injection molded parts often require finishing. Also, for certain large geometries, an alternative production method may be more suitable than injection molding.

Post-Processing and Decoration

This critical stage includes operations like pad printing. This method uses a flexible silicone pad to effectively transfer detailed graphics and logos onto surfaces. This is perfect for adding branding or labels to the irregular surfaces of large components like bins and containers.

Blow Molding as a Complementary Technology

While it is not an injection molding process, blow molding is also very relevant for larger hollow parts. This involves inflating a heated plastic parison inside a mold. It forms seamless, hollow parts like large tanks or drums, which offer a very economical approach to those specific geometries.

Materials Used for Large Injection Molded Parts

Selecting a resin is also an important factor in making sure your final part meets performance demands. The following is a list of common materials for high-performance large-scale projects.

High-Density Polyethylene (HDPE)

This versatile, economical thermoplastic has excellent chemical resistance and high resistance to impact. It is a semi-crystalline material with an excellent strength-to-density ratio, meaning that it is strong and durable, and is suitable for heavy-duty applications.

The excellent flow properties of HDPE are particularly beneficial when filling your large mold cavities. Due to its robust, weather-resistant properties, HDPE is used in the production of plastic molding large parts, for example, industrial pallets, storage containers, outdoor furniture, etc.

Acrylic (PMMA)

Acrylic is a transparent, glass-like plastic. You might know it by the brand name Plexiglas. It has excellent optical clarity, adequate rigidity, and excellent resistance to weather exposure.

It will not yellow or degrade from UV light exposure, making it a great option for outside usage. PMMA can be seen in large light covers, protective transparent shields, and architectural panels when clarity is very important.

Nylon (Polyamide – PA)

Nylon is a strong engineering thermoplastic that provides excellent toughness, wear resistance, and thermal stability. High mechanical strength and excellent resistance to abrasion are also provided.

Glass fibers are commonly used to reinforce nylon to greatly improve its stiffness and heat resistance, making nylon perfect for demanding structural components, including plastic injection molding large parts of an automotive engine, and large mechanical housings.

Structural Foam Materials

This is a unique process where a foaming agent is mixed with the polymer. It creates a distinct structure. The resulting part has a solid outer skin and a microscopically lightweight foam core.

Structural foams have a very high stiffness-to-weight ratio and low internal stress, leading to excellent stability in dimension. This technique is perfect for you when producing large, rigid structures like machine enclosures and equipment doors.

How to Choose the Right Injection Molding Machine for Large Parts

Choosing the right machine is important. An undersized press makes bad parts and can break itself. Here’s how to get the sizing right.

Gauge Part Footprint & Mass First

You must first map the maximal length, width, and projected area of your part. Many standard presses quickly max out around 4 ft×4 ft clear space. Also, weigh the part plus the runner system to verify the machine bed can handle the total mass without deflection.

Size the Clamping Unit to Cavity Pressure

Large-part jobs typically demand a high clamping force, often 1,000 t to 10,000 t or more, to resist separation during injection. You must match the projected area multiplied by a material-specific pressure factor. Anything less risks resin flash along the mold’s split line.

Check Shot Volume Reserve

You should convert your total part and gating volume into a polystyrene-equivalent mass (grams/ounces). It is crucial to select a barrel rated at least 20% above this figure. This reserve covers potential design changes and cushions any necessary process variability.

Confirm Mold-to-Platen Compatibility

You need to outline the actual mold shoe dimensions to ensure they fit safely within the machine’s platen borders. You must also account for tie-bar spacing, platen thickness, and ejector stroke so the large tool can open and release the final part without interference.

Seek Advanced Features That Support Large-Part Molding

Look for advanced features like multi-zone barrel and hot-runner control for a uniform melt across your big shots. You should also seek servo-hydraulic or all-electric drives for energy savings and highly repeatable clamp and injection profiles.

Industries and Applications of Large Part Injection Molding

Large part molding is the backbone for numerous sectors, transforming designs into durable, functional components. Let’s look at the key industries that rely on these large-scale parts every day.

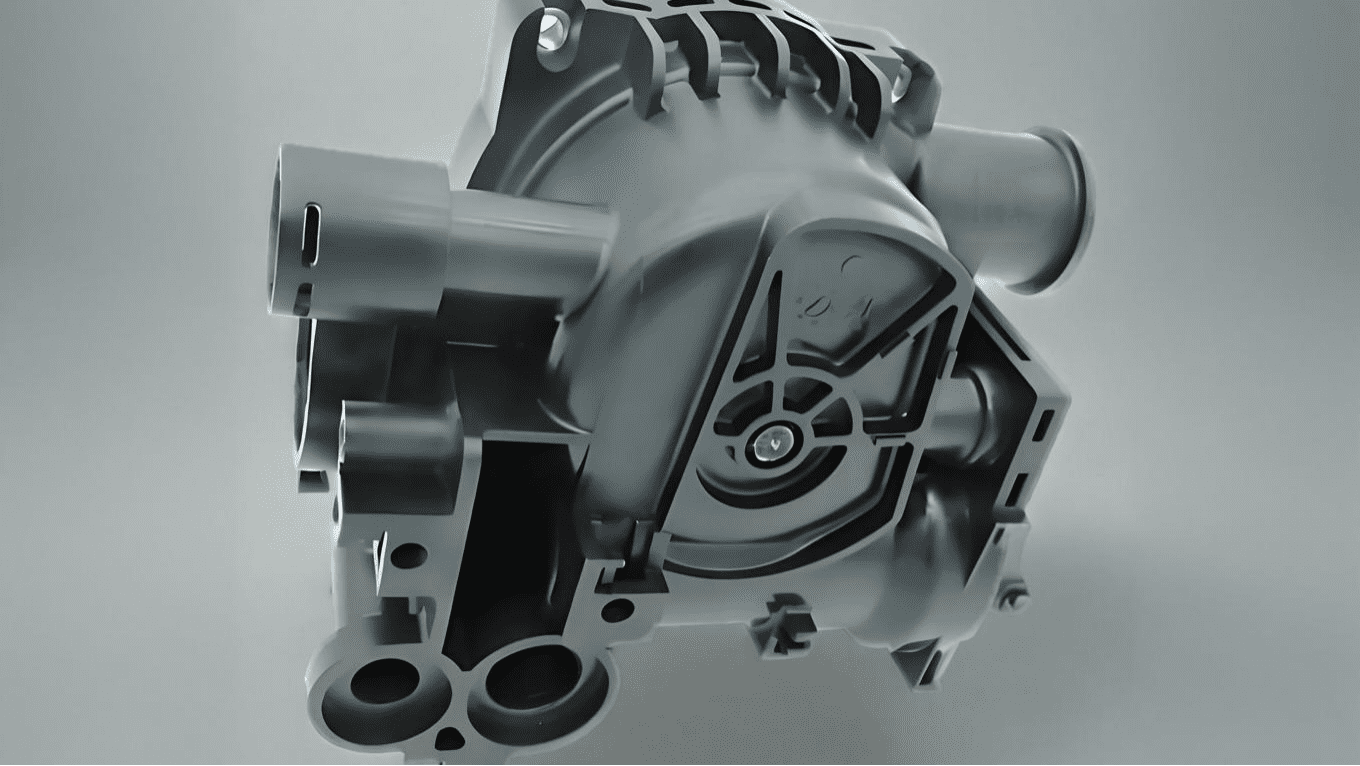

Transportation and Automotive Sector

The production of large plastic parts utilizing injection molding is predominantly employed in the automotive sector. Components must adhere to strict design criteria for safety, durability, and aesthetics, requiring producers to ensure precision in the molding process.

Notable applications include both exterior and interior parts, including large bumpers, fenders, grills, door panels, etc. This process allows for the mass production of lightweight parts, directly contributing to better vehicle utility and safety.

Aerospace and Aviation Field

The aerospace industry needs materials that are both strong and light. That’s why we now see more large plastic components in aircraft design.

Usage is expanding from interiors to structural components, including airframe sections, wing components, and engine housings. Advanced polymers match metal’s strength but weigh much less. This cuts fuel burn and reduces how often parts need maintenance.

Consumer and Industrial Electronics

The electronics and robotics manufacturing industries utilize this process to create the large housings and structural frames that provide the outer designs of major appliances and devices. Quality molding is critical for these everyday items.

This includes the outer shells and bases of these appliances, including refrigerators and washing machines. It also includes the internal frames for televisions and other large-screen displays. Injection molding produces robust, aesthetically pleasing casings that protect sensitive components cost-effectively.

How to Choose a Large Part Injection Molding Partner

Selecting the right manufacturing partner is as critical as the design itself. A capable large part injection molder ensures not only quality and precision but also project efficiency and cost-effectiveness. Use the following criteria to vet potential suppliers for your large part injection molding companies and your large part injection molding projects.

| Evaluation Criteria | Key Questions & Evidence to Request | Why It Matters for Large Parts |

| 1. Production Capacity | • Can they provide a list and photos of presses (e.g., 2,000 t machines)? • Ask for case studies with “part-in-press” photos of similar-sized components. | Verifies they have the physical machinery (tonnage, platen size) necessary to produce your part without capacity constraints. |

| 2. Tooling Expertise | • Do they own large CNC machines capable of machining 2 m×1.5 m steel blocks (e.g., P20, H13)? • Is mold design and manufacturing handled in-house? | Ensures they can build and maintain the large, high-quality molds required, keeping changes and repairs under one roof for better control. |

| 3. Engineering Support (DFM) | • Request a sample DFM report. It must include gate location, warpage simulation, and cooling analysis. • The absence of weld-line analysis is a major red flag. | A strong DFM process is crucial to anticipate and prevent defects like warping and weak spots in large, complex geometries before cutting steel. |

| 4. Quality Assurance | • Confirm ISO 9001 (or IATF 16949 for automotive) certification. • Is their CMM large enough for your part? Ask for GR&R studies. | Certifications prove a structured quality system. A large CMM and low GR&R ensure your part can be measured accurately and consistently. |

| 5. Vertical Integration | • Are secondary services (painting, welding, assembly) available on-site? • How do they handle logistics and kitting? | On-site services streamline production, reduce shipping damage risk, and significantly shorten lead times for complex assembled products. |

| 6. Sustainability Commitment | • Inquire about closed-loop water systems, regrind protocols, and carbon reduction goals (Scope 2). • Ask if they track ESG metrics. | Demonstrates a forward-thinking partner that can help you meet corporate sustainability targets and comply with evolving OEM requirements. |

Why Choose Fecision for Large Part Injection Molding?

Fecision delivers reliable, custom large part injection molding service tailored to your project requirements. We are a dedicated partner ensuring part integrity across large surface areas through structured quality control and engineering expertise. Our fully equipped facilities support high-volume demands for large components with 24/7 automated production and integrated on-site services like assembly and Just-In-Time (JIT) delivery.

Our partnership advantages include:

- Verified Production Capacity: Handles 10 million units annually via 24/7 automated cells.

- In-House Tooling Expertise: Optimizes complex large mold designs for perfect structure.

- Advanced DFM Culture: Uses SPC/FAI for strict dimensional stability on long runs.

- Audited Quality Stack: Achieves tight tolerances, ±0.025 mm, with CMM/vision systems.

- Integrated Secondary Suite: Provides on-site assembly, kitting, and JIT delivery.

- Sustainability Focus: Supports ESG using recyclable plastics and under 5% waste.

Are you ready to convert metal or metal sheet assemblies into lighter, one-piece, large injection molded parts? Contact Fecision directly to discuss your specific large-tonnage requirements!