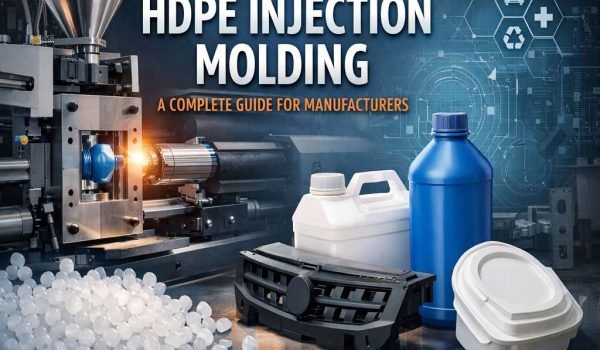

High Density Polyethylene (HDPE) is one of the most widely used thermoplastics in modern manufacturing due to its durability, versatility, and cost efficiency. HDPE plays a critical role in countless products we rely on daily, from everyday packaging to demanding industrial components. Injection molding of HDPE stands out as a highly efficient way to produce complex, high volume plastic parts with consistent quality among the many processing methods available.

The importance of HDPE plastic injection molding continues to grow as manufacturers seek materials that balance performance, scalability, and sustainability. Industries such as packaging, automotive, medical, and consumer goods increasingly rely on HDPE for molded components. This article explores the material properties, molding process, temperature control, shrinkage behavior, and how to choose reliable HDPE injection molding services for your production needs.

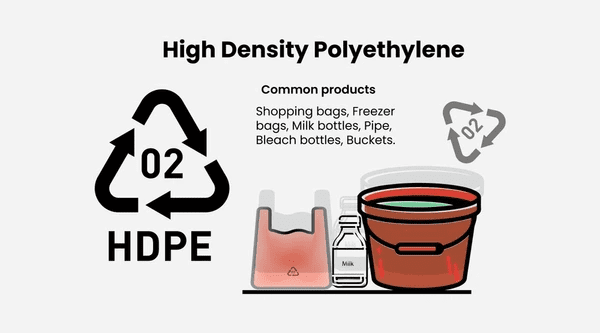

What is HDPE?

High Density Polyethylene (HDPE) is one of the thermoplastic polymeric compounds that are prepared by polymerizing ethylene. In contrast to low density polyethylene (LDPE), HDPE possesses a linear structure, with minimal amounts of branching. This enables the polymer chains to be tightly packed, thereby increasing the density, stiffness and mechanical strength.

Due to this design, HDPE provides a very good combination of toughness and elasticity. It is also non-toxic, waterproof and fully recyclable and this makes it a perfect material to be used in both industrial and consumer applications.

The most important features of HDPE are:

- Large strength to density ratio.

- Good chemical and moisture resistant.

- High impact resistance, including low temperatures.

- Good electrical insulation characteristics.

- High service life in tough conditions.

These are the attributes as to why manufacturers in the various industries are using HDPE in injection molded components that are needed to last consistently throughout time.

Why HDPE is Usually Chosen Over LDPE and PP

Manufacturers are more likely to use HDPE as compared to LDPE (Low Density Polyethylene) and polypropylene (PP) in injection molding because it has better rigidity, higher tensile strength as well as better chemical resistance. Whereas LDPE is more flexible and PP is higher in heat resistance, HDPE has a balanced performance profile, which can be applied to a broader variety of structural and industrial components.

Can HDPE be Injection Molded?

The answer is yes. HDPE is highly compatible with injection molding and can be easily molded on regular injection molding equipment. A great strength is that HDPE does not need pre drying prior to processing unlike hygroscopic plastics like nylon or PET. This will save on the preparation time, the expense on energy usage and the cost of production.

The HDPE pellets melt well, flow consistently and cure almost instantly, thus preferred when the high volume production process is needed and has a short cycle time. This is one of the reasons why HDPE is a favorite material in mass production.

How the HDPE Injection Molding Process Works

The HDPE injection molding process is a well controlled sequence of steps to ensure consistent quality and repeatability.

Preparation and Feeding of Material.

The injection molding machine has a hopper where HDPE resin pellets are loaded. Although it does not have to be dried, it should be clean and should not be contaminated. The additives can include UV stabilizers, antioxidants, or even color masterbatches depending on the usage.

Melting and Injection

The pellets pass through the heated barrel with the help of a rotating screw. That is heated slowly all along the barrel, so that there is even melting. When the HDPE attains the required viscosity the screw forces the melted plastic into the mold cavity at high pressure.

Cooling and Solidification

Cooling off is after filling the mold. The mold has cooling channels that circulate water or oil to cool the mold. This step takes the majority of the cycle time and has a direct influence on the quality of parts, shrinkage, and warpage.

Ejection and post processing.

Lastly, after hardening, ejector pins remove the part off the mold. The further processing can involve cutting the extra material, finishing a surface or quality check.

Common Applications of HDPE Injection Molded Parts

HDPE injection molding is widely used across many industries because it’s strong, reliable and affordable.

- Packaging Components: HDPE is an often used material in creating bottle tops, closures and food containers. HDPE parts are applied in many everyday products as they have resistance to moisture and household chemicals and can be used regularly.

- Industrial Containers and Caps: HDPE is applied in industrial purposes as containers, drums, and pallets. These products are made to deal with difficult environments, outdoors, and interaction with chemicals without easily breaking and degrading.

- Automotive Parts: HDPE injection molded parts are utilized in automobiles in the form of interior-based parts, fluid containers and other protective parts. It has a lightweight impact and sound resistant quality. Hence, it can be used in any exterior or interior automotive component.

- Medical and Food Grade Applications: HDPE is applied in medical equipment housing, laboratory equipment, and packaging. It is preferred in food related products as it is non toxic and has no harm with direct contact with food items.

Advantages of HDPE Injection Molding

Manufacturers choose HDPE for several key reasons:

- Manufacturers select HDPE due to a number of strong reasons:

- Stable global supply of material which is cost effective.

- Short cycle time, which is suitable for high volume manufacturing.

- Good chemical and moisture resistant.

- A high impact strength and durability.

- Easy to carry, the shipping and material costs are low.

- Recyclable, which helps in attaining sustainability.

- Regular quality part production by automated manufacturing.

These benefits make HDPE injection molding services especially attractive for manufacturers seeking scalable and reliable solutions.

Common Challenges and How to Fix Them

Even experienced manufacturers run into several common problems during HDPE injection molding processes. Knowing these challenges and how to fix them is the key to consistent production quality.

1) Warping and Shrinkage

HDPE components are able to bend or shape after moulding. This normally occurs as a result of uneven cooling of the part or internal stress of the part. To prevent this, maintain the same wall thickness, ensure that the mold cools down evenly and control the holding pressure and time such that the part shapes as it cools.

2) Sink Marks & Voids

Sink marks resemble small dents on thicker sections of a cast part. They take place when the plastic material undergoes a greater contraction than the surface. To minimise such defects, enhance the design of the moulds, provide an adequate cooling period and use the appropriate pressure during the filling phase.

3) Flow Lines & Short Shots

Flow lines appear as visible streaks on the surface and may interfere with the look of the product. Short shots occur when the mold is not filled to the full extent. They can both be resolved through enhancing the flow of the material, injection speed, and ensuring that the mold and the gates are clean and well-designed.

HDPE Injection Molding Temperature Guide

Getting the right temperature is essential for consistent melt flow and high quality HDPE parts. Maintaining stable processing temperatures helps prevent defects and ensures reliable production performance.

Typical HDPE Injection Molding Temperature Range

The optimal melt temperature range for HDPE typically runs from 180°C to 280°C. However, special grades require different environments. Over heating may lead to degradation, discoloration and weakening of components, hence it is important to do it correctly.

Barrel and Mold Temperature Guidelines

Heating the barrel zones gradually ensures uniform melting and reduces the risk of material degradation or flow inconsistencies. Mold temperatures are usually held between 20°C & 60°C depending on part thickness, the level of dimensional accuracy needed and the surface finish you’re looking for.

Impact of Incorrect Temperature Settings

If the temperatures are too low, you might get short shots and a poor surface finish. If temperatures run too high, the material can degrade, flashing may occur, and shrinkage can increase, each of which can compromise part quality.

HDPE Injection Molding Grades & Material Selection

There’s a range of HDPE injection molding grade options available, each tailored to specific performance needs. These grades vary in molecular weight, density and additives.

Factors to Consider When Selecting a Grade

- Melt Flow Index (MFI): Lower MFI grades have higher strength but reduced flow, while higher MFI grades fill thin walls more easily.

- Impact Strength: Applications that need toughness benefit from high impact HDPE grades.

- FDA or Industrial Compliance: Food, medical & pharmaceutical applications require certified grades that meet regulatory standards.

Matching Grade to End Use Applications

Choosing the right grade is key to getting optimal performance, durability and cost efficiency. Working with experienced HDPE injection molding services will help manufacturers select the best option.

Choosing the Right HDPE Injection Molding Services

Selecting the right HDPE injection molding partner is key to getting product quality and production success right. Look for a manufacturer with strong technical experience and a proven track record with similar projects.

Make sure the company can handle your required production volume and uses modern equipment for accurate and efficient manufacturing. Good quality control systems help ensure consistent results.

Industry experience also matters. Different industries follow different standards. A knowledgeable partner understands HDPE and can support you through design, material selection, and production.

For professional HDPE injection molding support, visit Fecision and connect with the experts who can help turn your idea into a successful product.

HDPE vs Other Plastics in Injection Molding

Compared to materials like polypropylene (PP) or ABS, HDPE offers:

- Better chemical resistance than ABS.

- Higher impact resistance than PP in some applications.

- Lower material cost than many engineering plastics.

However, HDPE is less rigid than ABS and may not be suitable for high temperature structural parts. Choosing the right material depends on application requirements.

Conclusion: Is HDPE Right for Your Manufacturing Needs?

HDPE injection molding is a reliable and affordable option for many industries. It offers good strength, chemical resistance, and efficient production, making it ideal for high volume manufacturing. HDPE works best when durability, moisture resistance, and scalability are important. It might not be suitable in extreme circumstances, but a great balance of performance and cost when run through the experienced HDPE injection molding services.

Are you looking for a trusted manufacturing partner to bring your HDPE products to life? Fecision provides reliable HDPE injection molding services from material selection and mold design to high volume production. Our experienced team ensures quality, accuracy, and cost efficiency for every project. Visit Fecision today and let us support your HDPE injection molding project with confidence.