Casting is one of the oldest ways to shape metal into useful parts. It is used to make things like car parts and machine covers. Casting lets manufacturers create detailed shapes quickly and efficiently.

A very important part of casting is the gating system. This system controls how the molten metal flows into the mold. If the gating system does not have a proper design, the metal won’t fill the mold properly. It can cause defects, waste material, and slow down production.

Here we will explain what a gating system in casting is, the parts included in gating system in sand casting, and more.

What Is Gating System in Casting?

The gating system in casting is the path that molten metal takes to get into the mold. The metal starts in the pouring basin, then flows down the sprue, moves through runners and gates, and finally fills the mold cavity where the part is formed.

The gating system controls how fast the metal flows into the mold.

- If the metal flows too quickly, it can cause problems like air bubbles or corrosion.

- If it flows too slowly, the metal might cool down before filling the mold fully. It hurts the quality of the final part.

The size and shape of the gating system are carefully arranged when making the mold. A poor design can lead to serious defects in the casting.

Key Roles of Gating System in Casting

A well-designed gating system in casting process does a lot of important jobs:

- Guiding Molten Plastic

It moves the hot metal smoothly from the pouring basin into the mold. The metal might splash or cool unevenly, causing weak spots in the final part without this.

- Flow and pressure control

It controls how fast and how much metal enters the mold. This keeps the flow steady and stops air bubbles from getting trapped which can make the part weak.

- Temperature management

The gating system makes sure the metal stays hot enough to fill the whole mold properly since molten metal cools fast. This avoids problems like incomplete parts or cold spots.

- Efficient Production

A smart gating system cuts down waste, speeds up production, and makes it easier to take the finished part out without damage. It also reduces extra work like grinding or machining afterward.

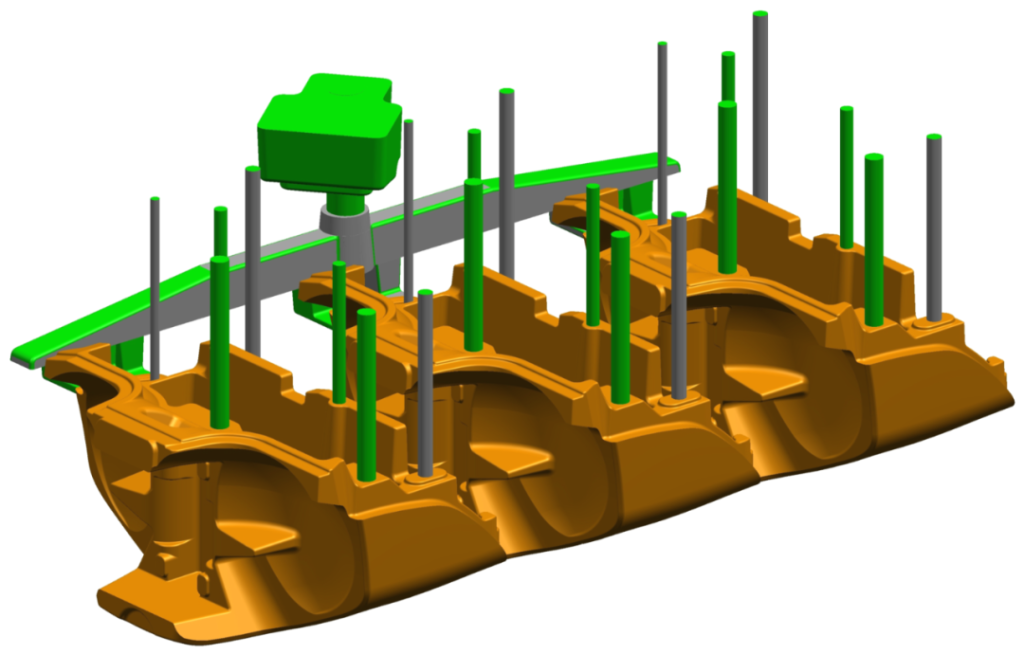

Key Components of Gating System in Casting

Here are the key components of gating system in casting to know:

- Pouring Basin

The pouring basin is a funnel-shaped opening at the top of the casting system. Here molten metal is poured in from ladles. It helps control how fast the metal flows and slows down the metal to reduce splashing and turbulence. It also helps catch dirt and waste material before the metal moves further into the mold.

- Sprue

The sprue is a vertical channel that carries hot metal down from the pouring basin. It is designed to keep the metal flowing smoothly and prevent air bubbles. The sprue also controls how fast and how much metal enters the mold, which helps prevent splashing or turbulence that can cause defects.

- Risers

Risers act like little tanks that hold extra metal. They feed the mold as the metal cools and shrinks. These help in making sure the part stays fully filled and does not have empty spaces inside.

- Runner

A runner is a horizontal channel that connects the sprue well to the gates. Molten metal flows from the sprue into the runner, which helps slow down the fast-moving metal coming down the sprue. This makes sure the mold cavity fills evenly and smoothly.

The runner needs to be completely filled with molten metal to stop dirt or slag from getting into the mold. It also helps the metal to keep flowing steadily.

- Gate

The ingate is the point where the molten metal moves from the runner into the mold cavity. This is basically where the part starts to form. There can be one or several ingates depending on the part.

There are two main types of gates:

- Small gates slow down the flow for parts that cool slowly.

- Large gates allow faster flow for parts that cool quickly.

Gates should have smooth, rounded edges because sharp edges can crack during pouring. Cracks can let sand get into the molten metal. It causes defects in the final part.

Different Types of Gating System in Casting to Know

There are different kinds of gates and gating systems. Each made for certain types of metal, mold shapes, and how many parts you need to make.

These include:

Edge Gate

This gate sits at the edge of the mold. It is simple and easy to design and remove. Edge gates might cause a little splashing but work well for smaller or simpler parts where the surface finish is not very important.

Cashew Gate

Cashew gates guide the metal smoothly into the mold which is shaped like a curved hook. They reduce splashing and help fill the mold evenly. These are great for parts with odd shapes to make sure the metal flows well.

Tunnel / Submarine Gate

These gates are hidden inside the mold, letting metal flow in without disturbing the surface. They are perfect for making lots of parts quickly especially in automated die casting. Tunnel gates last longer and need less cleaning afterward.

Diaphragm Gate

Diaphragm gates spread the metal evenly into big or complicated molds. They help fill thin or tricky sections uniformly and reduce defects. They are used when parts need consistent filling across many narrow areas.

Thermal Gate

Thermal gates keep certain areas warm to stop the metal from cooling and hardening too soon before it fills the mold. This helps make very precise parts where controlled cooling is important for strength and quality.

Valve Gate

Valve gates let you control the flow of metal very carefully. They are often used in automated or high-precision casting. This is especially when filling several mold cavities at the same time. This helps make sure every part comes out with the same good quality.

Key Principles to Follow for Gating System Design in Casting

Here are simple things to consider when it comes to design of gating system in casting:

- Try to place the cavities and gate openings evenly on both sides to avoid uneven pressure that can cause overflow.

- Arrange the cavities and gates so the mold stays as small and compact as possible.

- Keep the flow paths short and straight with the right size. Avoid sharp bends and make the surfaces smooth to reduce heat loss and keep the metal flowing well.

- Make sure the metal reaches all parts at the same time when using multiple cavities. Balance the channels that split the flow evenly.

- Keep the gating system as small as possible while still filling the mold completely to save material.

Get the Quality and Reliable Metal Casting Services with Fecision!

Fecision offers expert metal casting services including die casting and sand casting to meet various industrial needs. Our team can help design gating systems that produce high-quality parts without defects.

Fecision has the knowledge and skills to provide reliable production and consistent results.