Companies are always searching for ways to make lighter, stronger, and more efficient plastic parts. Traditional molding methods cannot offer these complex hollow shapes in many of advanced products. Water assist injection molding (WAIM) solves the problem. WAIM helps manufacturers produce hollow or partially hollow plastic parts with better accuracy, faster cooling, fewer defects, and lower material use by using high-pressure water during the molding process.

WAIM is becoming a popular choice for engineers, and manufacturers who want results that traditional injection molding cannot achieve. This article explores how WAIM works, what makes it unique, and why industries rely on it for advanced industrial production.

What is Water Assisted Injection Molding (WAIM)?

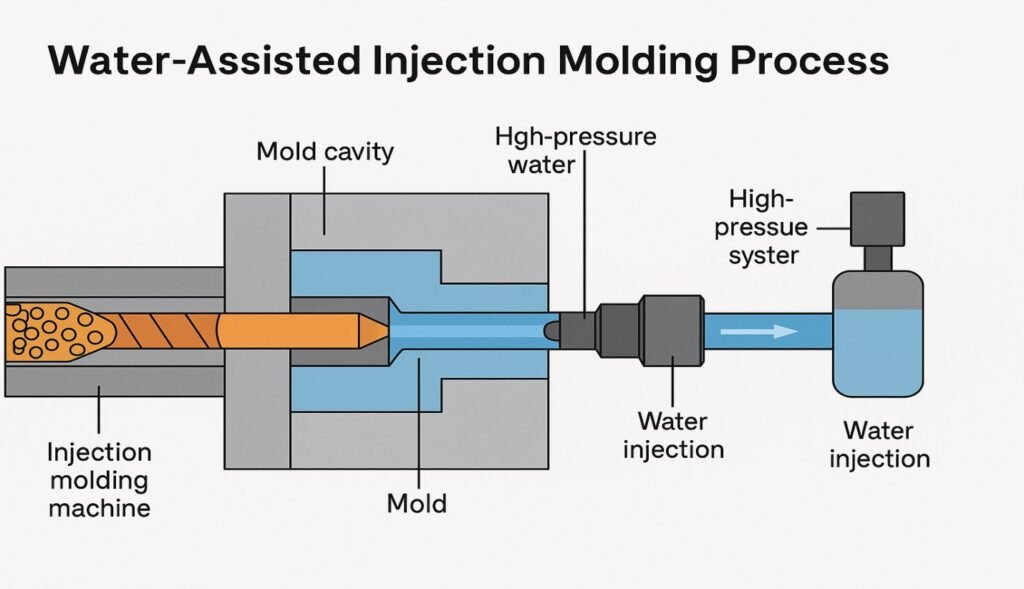

WAIM is an advanced form of standard injection molding. It does not fill the entire mold with solid molten plastic but rather injects high-pressure water into a partially filled mold, pushing the molten plastic outward and creating a hollow or partially hollow structure or design inside the part.

This method is particularly useful when parts require:

- Lightweight but strong structures

- Long tubes or channels

- Interior cavities

- Even cooling, less warpage

- Smooth internal surfaces

Since water has very high thermal conductivity, it cools the plastic faster and more uniformly compared to gas or air. This results in quicker production cycles along with high-quality, dimensionally correct parts.

How the Water Assisted Injection Molding Process Works

WAIM works by injecting high-pressure water into molten plastic inside the mold, creating a hollow cavity. The following steps explain how the process for water assisted injection molding is executed.

1) Injection of molten plastic into the mold

First, the granular plastic material is heated to a molten stage and then injected into a mold cavity. Commonly, this initial phase involves either the “short-shot method” or the “overflow method,” where either partial filling of the cavity takes place or the complete filling of the cavity with polymer, respectively. The polymer remains viscous so as to allow for the next phase of the process.

2) High-pressure water injection to form hollow sections

Water at high pressure enters through a specifically shaped nozzle. This water forms a solid interface at the front end, acting like a squeezing hammer, which pushes the still-molten core material toward the mold walls. Because water is incompressible, this displacement can be accurately controlled, usually requiring continuous volumetric flow.

3) Cooling and holding phase

In this stage, water pressure is maintained in the cavity and heat extraction is done from plastic simultaneously. Since the thermal conductivity of water is 20 times more compared to gas, cooling time can be reduced by 50-70%. Cooling from inside and outside provides dimensional stability.

4) Water evacuation and part ejection

Once cooling is complete, the water needs to be removed before the part can be ejected. There are several methods to evacuate the water:

- Steam pressure (effective for high-temperature materials like polyamides)

- Compressed gas injection through another syringe

- Gravity-based draining

After complete removal of water, the solidified part is ejected from the mold.

Materials Suitable for Water Assist Injection Molding

Material selection is the most critical factor in successful water assisted injection molding. The unique interaction between water and polymer is a significant determinant of final part quality and processing efficiency.

1) Polyamide, PA

Polyamide, known as nylon, is one of the best choices when it comes to WAIM because of its good strength, heat resistance, and stability. Special slow-crystallizing nylon grades prevent early hardening during molding. Types like PA6 and PA66, often glass-fiber-reinforced, work very well, offering great performance in automotive and industrial parts.

2) Polypropylene (PP)

When melted, polypropylene flows smoothly and allows water to form clean hollow channels in it readily. Polypropylene is cheap, sturdy, and chemical resistant. PP glass-fiber-filled also works well, and thus it has been popular in car parts and household products.

3. Acrylonitrile Butadiene Styrene (ABS)

ABS is tough, impact resistant, and gives a good surface finish. Its best processing occurs at a little higher mold temperature and holding time. It helps create hollow parts that have excellent dimensional accuracy.

4. Polyethylene (PE)

The WAIM process can also utilize various polyethylene types, such as LDPE and HDPE, along with LLDPE. HDPE provides strong skin core water channel layers, while LDPE can perform better under certain specific temperature and pressure conditions. These materials are common in tubes, containers, and light structural parts.

Material limitations and considerations

Material compatibility is a large concern; not all polymers are very compatible with water. Research has indicated that water pressure affects particle distribution. Higher pressures produce smaller polyamide particle distributions than their gas molded counterparts. The material selection must consider crystallization rates, thermal properties, and viscosity characteristics for optimal processing.

Advantages of Water Assisted Injection Molding

Manufacturers in various industries are embracing WAIM rapidly. Following are the key benefits of water assisted injection molding:

1) Shorter cycle times, improved cooling

One of the biggest advantages of WAIM is how quickly it cools the plastic. Since water cools 40 times faster than gas, the overall cycle time becomes much shorter. For example, a PP trolley that took 280 seconds with gas assist was made in just 68 seconds using WAIM. This means manufacturers can produce more parts in less time.

2) Lower material consumption

WAIM helps create thinner and more even walls inside the part. This reduces the amount of plastic needed without affecting strength. As a result, manufacturers save on material costs, especially during large production runs, while still making strong, lightweight parts.

3. Improved dimensional stability

The even distribution of pressure due to water injection gives rise to superior dimensional accuracy. Water generates a stable flow that keeps parts from deforming in any way during solidification, thus ensuring that components maintain their intended dimensions with greater precision.

4) Higher structural strength

The mechanical properties of WAIM parts are generally better despite using less material. This is because the optimized cooling process leads to more symmetrical material structures across the product section, hence improved performance characteristics.

5. Smooth internal walls & improved quality of product.

WAIM creates very smooth and clean inner walls. Unlike gas, water doesn’t mix with the plastic, so there are no marks or defects inside the part. This is especially useful for parts that carry fluids, where a smooth inside surface is important..

6. Reduce warpage and sink marks

Its uniform cooling from inside and outside reduces the internal stresses, thus providing pieces with reduced defects. Moreover, WAIM minimizes common issues found in injection molded parts like sink marks through even pressure distribution in solidification.

Industrial Applications of WAIM

Water assisted injection molding is now used across industries to manufacture lighter, stronger, and cheaper plastic products.

- Automotive Parts: WAIM is used in the automotive industry to make nylon cooling pipes, door handles, rocker covers, and fluid tubes that are strong, precise, and can be up to 42% lighter than metals.

- Consumer Products: WAIM finds applications in furniture arms, appliance handles, and tool grips. It gives the manufacturer a means to produce thin, stable, durable parts with smooth surfaces.

- Large hollow items: Besides that, the process is unmatched in producing structural items such as bottle crates, storage boxes, pallets, and shopping baskets. These larger items retain strength regardless of reduced material usage.

- Innovative designs: The manufacturers can produce some unique decorative products by injecting colored water inside transparent plastic parts. The water will remain inside, and the item will have a clear outer layer with a colored-water-filled core.

Gas Assisted versus Water Assisted Injection Molding

A key question manufacturers ask is how WAIM compares to gas-assisted molding. Below is a simple comparison of gas-assisted vs water assisted injection molding.

| Feature | Gas Assisted | Water Assisted |

| Cooling Speed | Slow | Very fast |

| Cycle Time | Long | Short |

| Hollow Shape Quality | Good | Excellent |

| Interior Surface | Less smooth | Very smooth |

| Material Use | Reduced | More reduced |

| Equipment Cost | Lower | Higher |

| Risk Issues | Gas marks, uneven surfaces | Water leakage, corrosion |

| Best For | Thin-walled parts, cosmetic surfaces | Long tubes, complex hollow parts |

Conclusion: WAIM is ideal for thick, hollow, complex parts that require strong structure and smooth interiors, while gas-assisted molding remains a better choice for thin-walled or highly cosmetic components.

Common Challenges and How to Avoid Them

While good in benefits, WAIM introduces several technical challenges on the manufacturer’s part.

1. Complete Water Removal

The defects may be caused by water left inside the part. Using steam pressure, compressed air, or proper placement of the injector ensures complete drainage.

2. Mold Corrosion Prevention

This wear from continuous exposure to water is reduced when anti-corrosion coatings or stainless-steel molds are used.

3. Water Pressure Control

Starting with low pressure and increasing quickly avoids surface ripples and allows for smooth inner channels.

4. Proper Venting

Poor venting results in burn marks and incomplete filling. Routine cleaning prevents vent blockage.

5. Material Compatibility

Some plastics absorb water or degrade when exposed to high moisture or temperature fluctuations. Proper resin selection is essential.

How manufacturers can implement WAIM successfully

Adopting WAIM requires careful planning and the right technology:

- Use high volumetric water flow for consistent displacement

- Characterized by low initial water pressure with rapid increase

- Position water injectors at the lowest point of the mold

- Choosing corrosion-resistant mold materials

- Ensure proper mold venting

- Use water recycling tanks for sustainability.

The balancing of process parameters with equipment design provides optimum results with long-term reliability.

FAQs about Water Assisted Injection Molding

What materials work best for WAIM?

The materials most commonly used are PP, PA, ABS, and PC because they handle the water pressure well and have stable melt characteristics.

Is WAIM suitable for complex hollow parts?

Yes, WAIM excels at curved, multi-branch, and deep hollow geometries.

Is WAIM environmentally friendly?

Yes, it reduces material usage, lowers the cooling time, and water can also be recycled.

Can WAIM replace gas-assisted molding completely?

No. Each technique has particular advantages. WAIM is better for large hollow channels, while gas-assist is better for thin-walled or cosmetic parts.

Conclusion

Water-assisted injection molding is one of the most effective and consistent processes for manufacturing quality hollow plastic parts today. It is truly a powerful solution for modern manufacturing, thanks to its ability to reduce cycle times, minimize material usage, improve dimensional stability, and deliver better product quality.

Industries are in increasing demand for lighter and stronger products with complex geometries; WAIM supplies the speed, precision, and economy necessary for competitive mass production.

If you’re looking for high-precision WAIM solutions or advanced injection molding systems, visit Fecision to explore reliable, industry-leading equipment.