When it comes to manufacturing plastic parts, urethane casting or injection molding often presents a critical decision point for product developers. Urethane casting takes a methodical approach, carefully filling silicone molds with liquid resin that cures into precise replicas. Meanwhile, injection molding throws molten plastic under high pressure into metal molds, producing parts at significantly higher speeds.

The choice between urethane casting vs injection molding ultimately depends on your production volume and timeline requirements. Urethane casting is best for early prototypes and small batches. Injection molding works better for later-stage prototyping and larger production runs. This article will help you understand the key differences and decide which process works best for your project.

What Is Urethane Casting?

Urethane casting is a manufacturing method that uses soft tooling to create small quantities of high-quality plastic, rubber and silicone parts. This method relies on basically just a silicone mold that captures the details of a master pattern, which is usually created either through 3D printing or CNC machining.

The way it works is that you place the master model inside a sealed box, cover it in liquid silicone and let it set. Once the silicone has hardened, you carefully cut the mold in half to release the master model. Then, liquid polyurethane resin is poured into the resulting cavity and cured either at room temperature or in an oven under vacuum conditions to prevent air bubbles.

Key Benefits of Urethane Casting

One of the biggest advantages of urethane casting is the low tooling cost. Silicone molds are considerably less expensive than metal injection molds, making this ideal for small production runs or frequent design changes.

Other benefits include:

- Fast turnaround times

- Excellent surface finish

- High design flexibility

- Easy handling of undercuts

- No draft angle requirement

- Ideal for functional prototypes

Because of these benefits, urethane casting is often preferred during the early stages of product development.

Limitations of Urethane Casting

Urethane casting has certain limitations despite its flexibility. The process is restricted to polyurethane materials, which generally possess low heat resistance, UV stability, and chemical resistance than many thermoplastics.

Additionally, silicone molds degrade over time, leading to:

- Higher per part cost

- Limited production volume

- Less consistent tolerances

- Smaller maximum part sizes

These factors make urethane casting unsuitable for large scale manufacturing.

What Is Injection Molding?

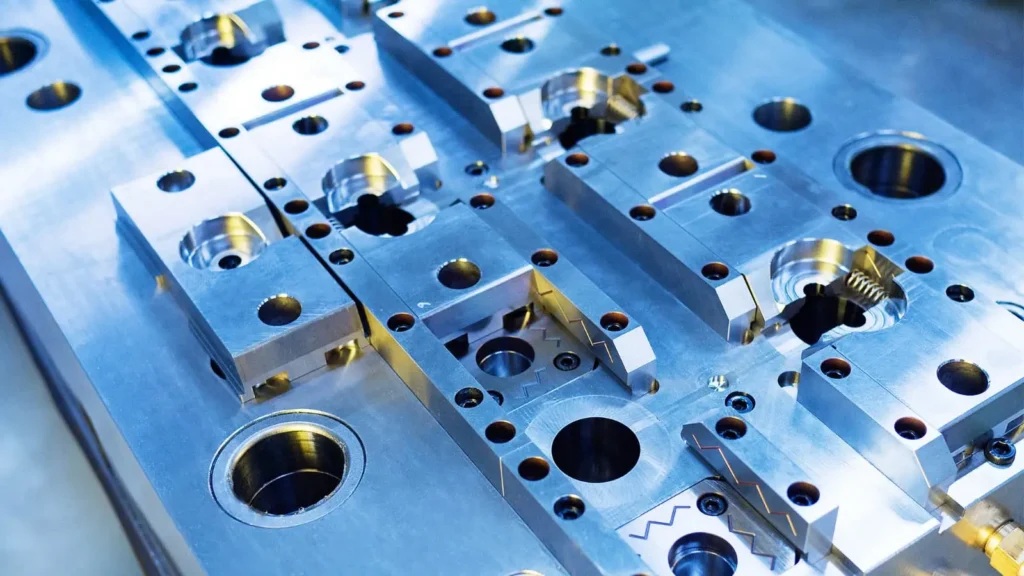

Injection molding is a highly automated manufacturing process used for producing medium to high volume parts. This machine uses metal molds, generally made from either aluminum or steel, to form parts from thermoplastic materials.

There are a total of 6 essential steps involved in the process, which include clamping, injection, dwelling, cooling, mold opening, and part removal. The plastic pellets when fed into the barrel which contains high heat are mixed by a screw conveyor and then forced with high pressure into a precision machined metal mold through a gate or runner. This process allows the manufacturers to create parts which are smaller than a rice grain, to parts as large as the airframe of an aircraft.

Advantages of Injection Molding

Injection molding provides the following major advantages:

- Excellent dimensional accuracy

- Tight tolerances

- Wide range of materials

- High repeatability

- Lower cost per part at scale

- Support for complex geometries

- Minimal material waste

Because of these benefits, injection molding is widely used for consumer products, automotive parts, medical devices, electronics, and industrial components.

Disadvantages of Injection Molding

The biggest drawback of injection molding is the high upfront tooling cost. Metal molds can cost thousands, or even tens of thousands of dollars and require weeks to manufacture.

Other disadvantages include:

- Longer initial lead times

- Strict design rules

- Higher cost for design changes

- Less economical for low volume runs

This makes injection molding less suitable for early prototyping or small batches.

Urethane Casting vs Injection Molding: Key Differences

Choosing between urethane casting and injection molding depends on understanding their main differences. Each method has unique benefits based on your project needs.

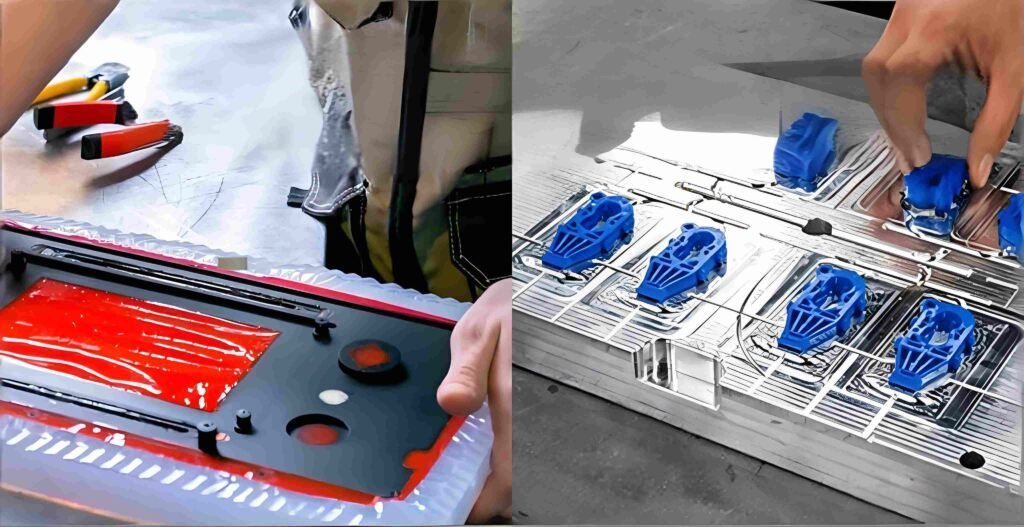

1) Applications

Injection molding is very viable when it comes to making high volumes of parts that need high levels of accuracy and uniformity. It is widely applied in automotive parts, aerospace parts, electronic parts, and medical apparatus. Urethane casting is more in low volume production and easy applications. It is frequently applied in prototyping, functional testing and initial product development.

2) Production Volume

Another crucial point of difference is production capacity. Urethane casting is normally used to cast up to 20-25 parts per silicone mold, which makes it suitable when it comes to 1 to 100 units. On the other hand, injection molding is more successful in high volume production where metal molds may be used to create hundreds of thousands of parts leading to a very low unit cost once initial tooling costs are amortized.

3) Material Options and Properties

Cast urethane offers similar engineering plastics such as ABS, polycarbonate and many more with different properties. Injection molding offers more than 25,000 types of engineering materials, including thermoplastics with enhanced mechanical, thermal or chemical properties. That’s really something for parts that require certain performance qualifications.

4) Urethane Casting vs. Injection Molding Cost

Urethane casting uses less start-up tooling, which is generally between a few hundred and a few thousand dollars. The per part cost is more, however, because it is a manual process. Even with MUD inserts, higher initial tooling costs are used in injection molding. In spite of this, the process is highly automated and thus reduces the cost per part by a big margin when the volumes are high.

5) Tolerances of Cast Urethane vs Injection Molding.

Urethane casting will typically hit tolerances of ±0.010” for the first inch and ±0.005” for each additional inch. Injection molding usually can deliver tighter ±0.005” for the first inch and ±0.002” for each additional inch. This is mostly because of the flexible mold of silicone vs. the metal tooling that is rigid.

6) Wall Thickness

Both processes perform best when parts have consistent wall thicknesses. Uniform walls help reduce defects and improve structural integrity. Injection molding requires careful control of wall thickness based on the selected thermoplastic, as different materials shrink at different rates. Urethane casting is more forgiving and typically supports wall thicknesses ranging from 1 to 5 mm.

7) Undercuts of Injection Molding vs Cast Urethane

Because silicone molds are so flexible, urethane casting can handle undercuts with ease, just stretch the mold a bit to get the part out. Injection molding, on the other hand, can also do undercuts, but you usually need some mechanisms like sliders or lifters in the tool, which can make the tool itself a lot more complicated and expensive.

8) Lead Times

Urethane casting provides shorter lead times, since silicone molds can be prepared quickly. Sample parts can be available in a few weeks and are suitable in projects that are fast moving. Injection molding takes longer to design and fabricate the mold. But after the tooling is done, one is able to produce parts at a very high rate and quantity.

Comparison Table

| Characteristic | Urethane Casting | Injection Molding |

| Tooling Cost | $1,000-$5,000 (silicone molds) | $10,000-$100,000+ (metal molds) |

| Setup Time | 1 to 2 weeks | 4 to 8 weeks |

| Ideal Production Volume | 1 to 100 parts | 100 to 10,000+ parts |

| Parts per Mold | 20 to 25 parts per mold | Hundreds of thousands |

| Tolerances | ±0.005″ to ±0.015″ | ±0.001″ to ±0.005″ |

| Cost per Part | $20-100 | $2-10 (low volume), <$1 (high volume) |

| Lead Time | 3 to 5 days for mold, 5 to 10 days for parts | 6 to 10 weeks for initial samples |

| Material Options | Limited formulations mimicking ABS, polycarbonate | 25,000+ engineered materials |

| Key Advantages | Cost effective toolingDesign flexibilityRapid productionGood for prototyping | High efficiencySuperior precisionConsistent qualityCost effective at scale |

| Manufacturing Process | Manual pouring of liquid resin into silicone molds | Automated injection of molten plastic into metal molds |

When Should You Choose Urethane Casting?

Urethane casting would be an excellent choice when the project is low-volume, timelines are short, and the design requires flexibility.

Choose urethane casting if:

- It needs low volume production.

- The cost of injection molding tooling is more than the budget.

- There is a need to have a temporary solution between prototyping and full production.

- Designs, materials or market response require a test.

- Strict deadlines require components in 3-5 days.

- Quicker time to market is a priority.

- Components contain complicated shapes, tiny undercuts or pliable materials.

- Precision is necessary (tolerances of +-0.010 in + 0.003 in/in)

When Should You Choose Injection Molding?

High volume and long term production that require rigid quality are best suited to injection molding.

Choose injection molding if:

The volumes of production are above 100 parts, particularly thousands or more.

At scale, lower cost per part is required.

Precision and repeatability are important.

Close tolerances and uniform quality are needed.

Designs also contain thin walls and delicate details.

Long term usage requires durable metal tooling.

The products should conform to the industry or regulations.

The design has been laid down and may not be altered.

Automation at a reduced cost of labor is desirable.

Conclusion

There is no universal winner in the debate of urethane casting vs injection molding. The best option depends on your project goals. Urethane casting is better for speed, flexibility, and low volume production. Injection molding is better for precision, scalability, and long term cost efficiency. Many successful companies use both processes, starting with urethane casting for validation, then transitioning to injection molding for mass production.

Ready to Start Your Project? At Fecision, we help businesses choose the right manufacturing solution, from prototyping to full scale production. Our experienced engineering team can guide you through urethane casting, injection molding, and every step in between. Get expert manufacturing support today Fecision. Let us turn your ideas into high quality molded parts, efficiently, accurately, and cost effectively.