There are numerous obstacles to overcome when designing a plastic component. The undercut is one of the most popular undercut styles. In injection molding, an undercut is any feature that prevents a part from smoothly ejecting from the mold. Simple examples include clips, grooves, side holes, and threads.

It raises costs, slows production, and damages parts if they are not properly managed. Therefore, before you start tooling, you need to learn how to handle them. This guide explains what an injection molding undercut is, why it matters, and how to account for it in your design. Additionally, you will learn how mold makers safely release undercut features using tried-and-true techniques.

What Is An Undercut In Injection Molding?

Any feature that prevents straight ejection from a mold is referred to as an undercut. The part is trapped when the feature strikes the cavity or core when the mold halves open.

Common examples include:

- Side snaps and clips

- Internal grooves or recesses

- Threaded sections on caps or fasteners

Undercuts must be found during the design phase. Costly redesigns and tooling changes are avoided with early detection. Keep in mind that not all protrusions are undercuts. Properly drafted surfaces typically eject without any problems. When you ask, “What is an undercut in injection molding?” always consider the direction of ejection first.

Why Undercuts Matter In Plastic Parts

Undercuts are frequently necessary for strength and functionality. They enable mechanical features like snap fits and secure locking. But there are trade-offs:

Challenges created by undercuts:

- Increase tooling complexity and machining time

- Extend cycle times due to extra mechanisms

- Raise the risk of defects and lower yield

Ignoring them can result in scrap or rework, which can slow production. Poor undercut design compromises long-term durability and assembly quality in critical applications. Effective design strikes a balance between manufacturability and functionality, ensuring that the part functions without incurring unnecessary costs.

Common Types Of Injection Molding Undercuts

Undercuts come in different forms, and each one requires a specific solution. By understanding the types, you can quickly identify them and develop the right mould strategy.

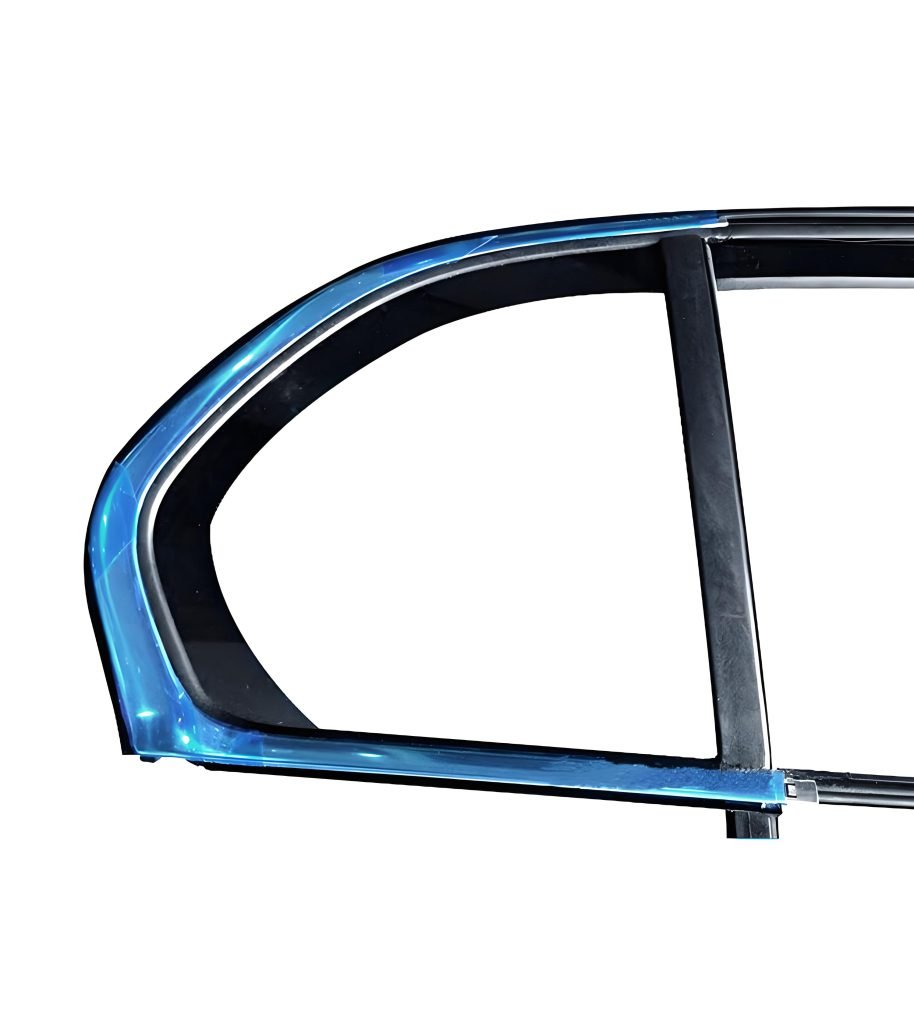

- External Undercuts: These characteristics, such as ribs, rings, or flanges, are visible in an outer space. To remove the part from the mold, they typically require side actions.

- Internal Undercuts: These consist of recessed details, latch pockets, and grooves located within cavities. To release such features without damaging the part, collapsible cores are frequently used.

- Side Undercuts: Snap-fit housings often feature side undercuts that are oriented perpendicular to the mold opening. Usually, lifters or sliders are used to release these regions.

- Threaded Undercuts: Specialized mechanisms are required for parts with screw threads or caps. They are released using collapsible cores or unscrewing units, particularly in high-volume manufacturing.

- Undercut Variations: Simple fixes, such as occasional hand trimming, can be used to control shallow undercuts. To ensure smooth ejection, deep or intricate undercuts require sophisticated mechanical actions.

Injection Mold Undercut Design Considerations

The parting line location has a direct impact on the size and presence of undercuts, so it must be planned early in the design process. Always use draft angles to facilitate ejection because they minimize mold wear and friction during release. The choice of material is also crucial. Select resins that shrink steadily and predictably, as too much shrinkage can make undercut tolerances more difficult.

Wall thickness and flow balance must be considered. Sink marks or voids are frequently caused by uneven walls close to undercuts. Durability is increased, and stress concentration is decreased by adding radii around sharp edges. For mating parts, carefully define tolerance stack-ups and leave enough space to accommodate shrinkage.

Lastly, focus on the specifics of the processing. To prevent air traps around undercuts, install gates and vents to regulate airflow. To avoid premature wear, consider the surface finish where snaps or seals engage.

Methods To Deal With Undercuts In Injection Molding

There are several proven methods for releasing parts with undercuts. The right choice depends on design complexity, production volume, and budget. Below are the most common methods available.

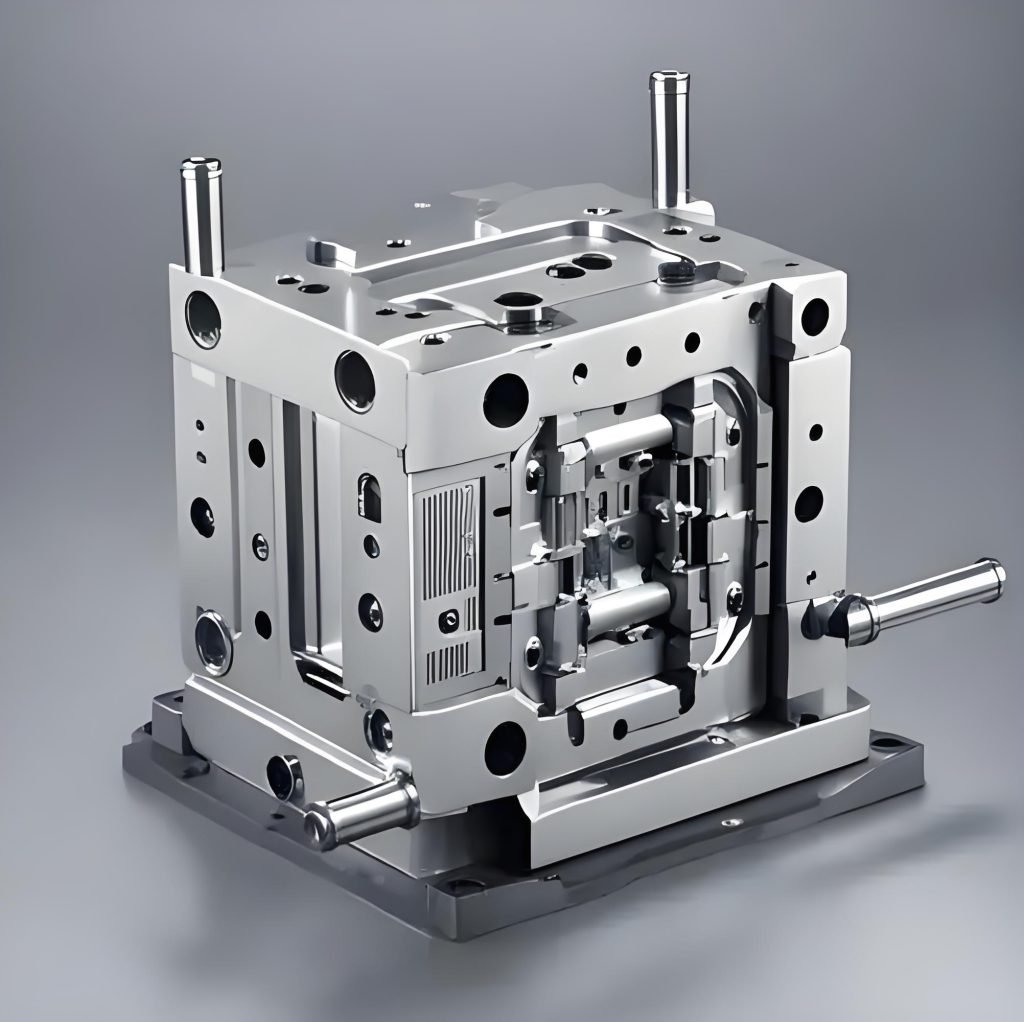

- Side Actions or Sliders: Sliders are useful for releasing side and external undercuts because they move sideways during ejection. It is reliable, but it raises the cost of long-term maintenance and tooling.

- Collapsible Cores: To release internal features, particularly deep threads, these cores contract inward. That ensures constant quality and guards against part damage by collapsing inside the cavity.

- Unscrewing Mechanisms: For threaded undercuts, such as bottle caps or fasteners, rotating mechanisms are employed. They are ideal for high-volume runs and eliminate the need for secondary operations, even though they increase cycle time.

- Hand-Loaded Inserts: Hand-loaded inserts are a cost-effective option for small production runs. They are better suited for limited runs or prototypes because they require manual handling during the moulding process.

- Design Modification: Eliminating the undercut is sometimes the best course of action. Part geometry can be modified, the design can be divided, or snap features can be replaced with more straightforward options. These adjustments often expedite production and reduce tooling costs.

- Hybrid Solutions: Combining approaches provides the best balance in complex situations. For instance, you could combine a detachable insert with a shallow slider. This method preserves part of the functionality while optimizing costs.

Cost And Production Impact Of Undercuts

Undercuts significantly increase tooling complexity and overall cost. Adding sliders, unscrewing units, or collapsible cores raises mold price because they require extra machining and precision assembly. Each additional mechanism also extends the cycle time and creates higher maintenance demands due to the movement of components.

Despite these challenges, undercuts can sometimes reduce downstream labor by eliminating separate assembly steps, which saves cost in the long run. Before deciding on a solution, you must evaluate production volume, part value, and expected lifecycle. For small batches, manual inserts are often the most economical choice.

Conclusion

Now you know what injection molding undercut are and why they are important. Making wise design decisions reduces costs, enhances quality, and mitigates risk. To select the best option, always plan undercut features and consult with skilled mold makers.

At Fecision, we review your designs, minimize the risk of undercuts, and create sophisticated tooling, such as sliders and collapsible cores, by combining our expertise in mould manufacturing with CNC machining. We assist you in obtaining parts you can rely on with accuracy, reliability, and economical service.