A fractional-millimeter wall reduction can cut your cycle time by a third—yet it can also trigger frustrating short shots instantly. Mastering thin wall injection molding is the fastest way to turn plastic into profit without adding unnecessary material. It’s a core skill for modern manufacturing.

This guide will equip you with the essential knowledge for success. We will explore the exact definition, the hottest applications of thin wall injection molding, and how to select high-flow resins. You’ll also learn key design tips and a detailed troubleshooting guide for common defects.

What Is Thin Wall Injection Molding?

Thin wall injection molding is used to produce plastic parts with a thin wall thickness range of about 0.5 to 1 mm. The material is injected into the mold effectively under pressures of 30,000 psi and in very rapid cycle times, often under 10 seconds. This calls for powerful machinery to drive the various operations and swift controlled movements to prevent the molten plastic from freezing before the mold is full. For a part to be considered “thin wall,” the flow-length-to-thickness (L/t) ratio is generally required to be 100 or 150 or greater.

Core Advantages

Thin-wall injection molding is popular because of the massive benefits it offers your business. You get advantages in material use, speed, and product design.

Material Thrift

You can achieve significant material savings by using thin walls. Compared to conventional 2–3 mm walls, you can see up to 10–40% resin reduction. This directly impacts your raw material costs, making high-volume production much more profitable.

Cash-Cycle Shrink

Thin-walled parts cool much more quickly than thick parts. The expedited cooling process will minimize the cooling time required within your cycle. Less cooling time will allow for increased parts per hour manufactured, therefore increasing overall throughput.

Light-Weighting

A wall thickness of 0.5 mm or less will reduce the weight of the part by 10-40%. Weight reduction is an essential factor in many industries, such as automotive, where less weight can help achieve fuel efficiency and stringent emissions.

Consumer Appeal

Consumers love products that have a slender, lightweight feel. Thin-wall injection molding gives you this appearance that matches the trends of premium electronics and modern food containers. The result feels high-quality and streamlined—exactly what buyers expect now.

Typical Applications of Thin Wall Injection Molding

This fast, precise process is the engine of many products you deal with on a daily basis. Thin-wall injection molding is a leading innovation in several major industries.

Food Packaging Explosion

Think of your yogurt containers and butter tubs. Thin wall injection molding makes those mono-layer PP tubs, IML dairy cups, and snap-fit lids. This process keeps your food safe and uses noticeably less resin per container, which is great for the environment and your budget.

Medical Disposables

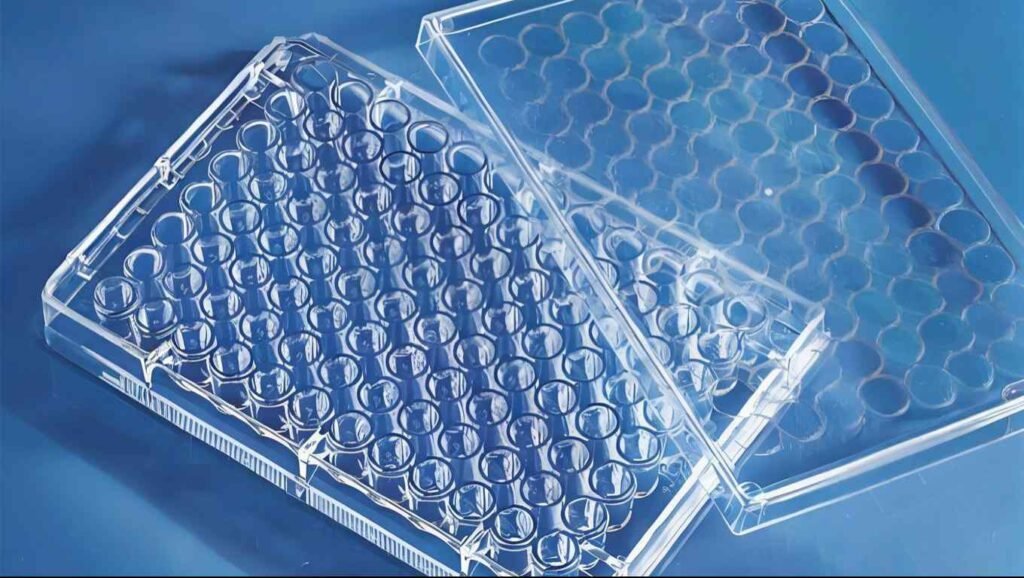

The medical field heavily relies on this technology. You’ll find sub-half-millimetre syringe barrels, micro-plates for Polymerase Chain Reaction (PCR), and pipette tips with very minimal wall thickness. These parts are molded in controlled clean rooms with cycle times measured in mere seconds to meet the massive demand for single-use items.

Electronics Miniaturization

As devices get smaller, thin-wall injection molding is critical. Smart-phone mid-frames and lens housings depend on it. This allows manufacturers to add necessary features like antennas, ribs, and bosses without sacrificing valuable battery space or reducing signal transparency. Thin walls let your device be powerful and slim.

Automotive Light-Weighting

The auto industry uses thin-wall parts to shed weight. Sub-millimetre door-trim carriers save several kilos per vehicle while still passing strict impact tests for safety. The process also produces lightweight speaker grilles that can clip straight onto dashboards, often eliminating the need for heavy metal inserts.

Fast-Moving Consumer Goods

This covers high-volume, low-margin products where every gram saved is a profit boost. Examples include travel-size aerosol caps, single-dose coffee capsules, and razor handles with complex snap hinges. When you make millions of units, small material savings quickly add up to significant earnings.

How to Choose Materials for Thin Wall Molding?

Selecting the right plastic resin is perhaps the most critical step. The material must flow under high stress and cool rapidly without sacrificing strength.

Flowability Index

You must target high MFR (Melt Flow Rate) grades as the flow-distance-to-thickness ratio (L/t) should exceed 150. Using high-flow resins means you can lower the required injection pressure. This helps a lot in preventing frustrating issues like short shots where the mold cavity isn’t completely filled.

Impact & Drop-Test Performance

To ensure your parts will be rigid and not shatter easily, you could use a Notched Izod value of 640 J/m (ASTM D256A) at room temperature as a benchmark. If your packaging will be frozen, you will carefully assess the materials’ low-temperature impact values to ensure they remain strong.

Thermal & Barrier Requirements

If you make containers that will need to be sterilized (like retort cups for heating), then you will need PP with a high heat-deflection temperature (usually in the range of 70–95 °C). Coffee capsules, for example, will need particular barrier layers to cut down oxygen transmission with a total wall thickness of less than 1 mm.

Shrinkage & Dimensional Stability

Amorphous resins such as PETG and COC typically result in lower post-mold shrinkage, which is advantageous for managing critical dimensions. For semi-crystalline grades, the proper use of additives like nucleating agents can assist. These help the material hold its flatness and shape on thin parts like battery covers.

Regulatory Alphabet Soup

Before you begin, you are required to wade through a long list of regulatory considerations. This may include standards such as FDA, EU 10/2011, USP Class VI, RoHS, and REACH. In order to save time and money, your company should only short-list material grades that have been pre-approved with specific masterbatches. This avoids costly re-certification when you eventually scale up production.

Design Tips for Thin Wall Injection Molding

Getting the geometry right is essential in thin wall molding. You can use these proven rules to help you formulate the design and then check for manufacturability and performance.

Keep Walls Uniform

Maintain your wall thickness ideally between 0.5 and 1 mm. When wall thickness must change, use very gradual transitions, not sharp steps in thickness. This design rule is key to reducing both warpage and unwanted sink marks on the finished part surface.

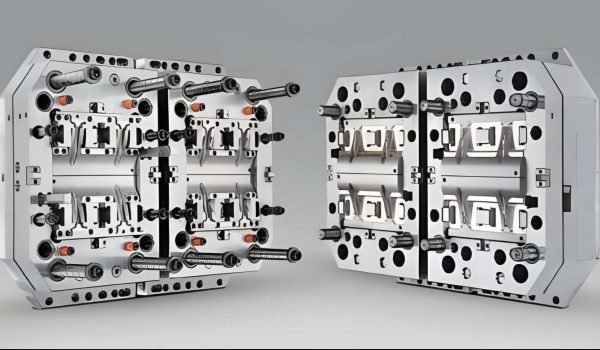

Gate Like a Fire Hose

You need to get the plastic into the mold cavity as fast as possible. Use large or multiple gates to ensure the filling is balanced and quick. A valve-gated hot runner system is an excellent way to eliminate the appearance of weld lines without causing stress by over-packing the mold.

Rib & Boss Micro-Rules

When designing ribs for support, their thickness should be 50–60% of the main wall thickness. The rib height should be no more than three times the thickness, with a gentle 1–2° draft angle. For bosses, the Outer Diameter (OD) should relate to the screw diameter. Always add an inside radius to prevent the plastic from showing stress whitening.

Cooling Channel Density

To manage the heat, insert high-conductivity materials like Copper-Beryllium (Cu-Be) at the gate lands. Place conformal cooling channels very close to the cavity surface. The goal is to hold the temperature difference across the core within just a few degrees, which is how you effectively trim the cycle time.

Vent Deep, Vent Wide

You must let the air escape from the mold quickly. Add vents that are perpendicular to the knit lines where the melt streams meet. The vent depth must be precisely set to release air without causing a flash. On very high-speed machines, consider using a pre-vacuum or negative-pressure valve for best results.

Ejection Without Distortion

To ensure the part releases cleanly, use a slight draft angle and control the stripper-ring clearance precisely. You should also use low-pressure air poppet valves positioned strategically under ribs. This allows parts to release cleanly at a modest mold temperature without leaving behind problematic vacuum marks or causing distortion.

Facing complex geometry or strict material selection? Let our experts review your L/t ratio and design for a faster launch.

Common Issues & Thin Wall Injection Molding Troubleshooting

Even with perfect design, issues can occur. It is critical to quickly identify the defect and its cause to maintain high rates of production and low scrap rates for thin wall injection molding troubleshooting.

Short Shots & Hesitation

A short shot happens when the melt freezes before the cavity is fully filled. The root cause is that the high-speed material is cooling too fast. To fix this, you should raise the melt temperature moderately or boost the injection speed. You can also switch to a higher-MFR resin or enlarge the gate depth to improve flow.

Flash in Micro-Gaps

Flash happens when the clamp tonnage is below the required rule-of-thumb per unit of the projected area of your part. To fix it, first verify that your platen parallelism is perfect. You should use hardened inserts in the mold and consider reducing the packing pressure slightly.

Warpage & Twisted Corners

Warpage is typically caused by uneven cooling across the part or molecular/fiber orientation issues. The best fix is to carefully balance the coolant flow in your mold. You can also add diagonal ribs to the part design or lower the hold pressure to cut down on the internal residual stress.

Bubbles & Vacuum Voids

These defects are caused by trapped gas within the melt or by excessive plastic shrinkage. To fix it, make sure you properly dry any hygroscopic resins before use. You can also deepen the mold vents slightly or apply a brief post-injection compression phase during the cycle.

Brittle Breaks at Drop

A part that breaks easily is likely due to molecular degradation from high shear stress. This happens when the material is pushed too hard through small features. To correct it, limit the shear rate by enlarging the gate or reducing the injection speed. If allowed by the application, add an impact modifier to the resin.

Rapid Tool Wear

This problem occurs when an abrasive melt erodes softer steels in the mold. You’ll need to upgrade your mold steel from P20 to something tougher like 718HH or H-13. Applying a hard surface coating will also help protect the steel. You can reduce the overall wear by lowering the injection pressure, which can be done by using a hotter mold or an easier-flow resin.

| Defect | Primary Cause | Troubleshooting Fix |

| Short Shots | Melt freezes before fill | Raise melt temp, boost injection speed, enlarge gate |

| Flash | Clamp tonnage too low | Verify platen parallelism, use harder inserts, reduce pack pressure |

| Warpage | Uneven cooling | Balance coolant flow, add diagonal ribs, adjust hold pressure |

| Bubbles/Voids | Trapped gas | Dry resin, deepen vents slightly, apply short compression |

| Brittle Breaks | High shear degradation | Enlarge gate, reduce injection speed, add impact modifier |

| Tool Wear | Abrasive melt | Upgrade steel (e.g., to H-13), apply surface coating |

Conclusion

Thin wall injection molding is a powerful technology that slashes resin use and cycle time. Success requires your resin, gate strategy, and steel selection to work together as one integrated system, ensuring sub-1 mm walls become reliable, high-margin products.

Fecision has the experience in handling the rigorous demands of thin wall injection molding, considering the particularly relevant wall thickness guideline. Our state-of-the-art technology can hold tolerances as tight as ±0.025 mm on complex parts, assuring that your ultra-thin parts possess both the appropriate structural integrity and dimensional stability often needed, while substantially reducing defects such as warpage and sink marks.

We focus on optimizing your part’s geometry early through detailed DFM analysis, specifically addressing flow and material properties. This ensures that even when wall thickness deviates from the standard minimum, your part remains manufacturable. Our expertise with high-flow resins and precise tooling guarantees quick, balanced filling, maximizing efficiency and achieving fast cycle times essential for thin wall projects.

Got a high-volume project ready to go? Let our experts handle the challenge. Contact Fecision now to discuss your production needs!