On molded plastic parts, silver streaks or cloudy marks are common. Splay is what those marks are. Despite their small size, they have a lower quality and cost you money. Splay occurs during injection when gases or moisture build up inside molten plastic. Streaks are left behind when these gases escape to the surface.

Customers reject splay parts because they appear weak and flawed. Ignoring it is a waste of time and resources. The good news is that you can prevent splay from happening again by addressing the issue. This guide explains what injection moulding splay is, its causes, and how to prevent and correct it.

What Is Splay In Injection Molding?

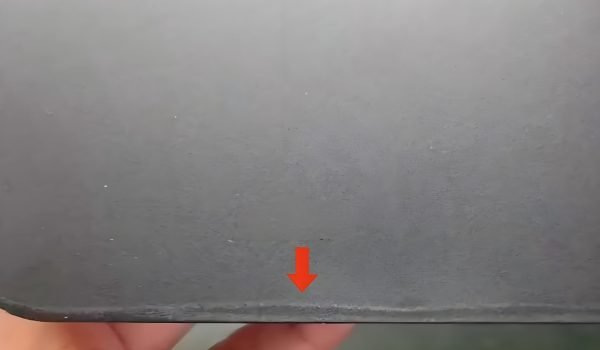

On molded parts, splay is a cosmetic defect that manifests as white or silver striations. These streaks typically impact the part’s surface finish and follow the direction of the resin flow.

How It Happens:

During the injection process, splay occurs when gas or moisture condenses within the molten material. This gas escapes to the surface after being injected into the mold, leaving behind hazy or visible lines.

Why It’s A Problem:

Many people believe that splay only affects appearance, but it also indicates weaknesses and internal stress. These flaws may lead to failure under load, poor durability, and cracks.

Impact On Industries:

Even minor flaws can lead to part rejection in industries such as consumer goods, medical, and automotive. Clients anticipate a flawless finish and robust construction.

Key Takeaway:

Controlling splay during production is essential if you want parts that are sturdy, appealing, and of excellent quality. Eliminating splay begins with understanding what it is.

Signs That Indicate Splay On Molded Parts

You can identify splay defects by looking for common signs.

- Silver or White Streaks: On the surface, thin lines typically follow the direction of the resin flow.

- Cloudy or Blurred Patches: Some areas appear as fuzzy patches or stress marks.

- Uneven Gloss Levels: While some parts have a normal finish, others seem dull.

- Weak Weld Lines: Poor bonding at weld points may occur due to trapped gas during the molding process.

Detecting these signs early reduces scrap, saves cost, and keeps your production efficient.

What Causes Splay In Injection Molding?

Without an understanding of its causes, splay cannot be effectively addressed or corrected. The primary causes are as follows:

- Moisture in resin: Nylon and PET are two examples of plastics that absorb moisture from the atmosphere. During molding, water turns into steam if it is not adequately dried. Bubbles produced by that steam result in splay marks.

- Improper drying: Incorrect settings allow moisture to remain in the resin even when using a dryer. Splay defects are caused by low temperatures or insufficient drying time.

- Excessive shear heat: Friction inside the barrel and gate increases with rapid injection speed. As a result, heat is produced, polymer chains are broken, and gas is released as splay.

- Air traps Occur When Air becomes trapped during injection due to inadequate venting in the mold design. The part develops lines as a result of the trapped air burning.

- Degraded material: Resin that is old or contaminated degrades rapidly. Gases released during this breakdown manifest as splay on the final component.

Targeting the appropriate solution is made easier when you are aware of these causes.

How To Fix Splay Injection Molding?

Actionable solutions:

- Dry resin properly: Observe the drying guidelines provided by the material supplier. Use a dehumidifying dryer for hygroscopic resins, such as nylon.

- Adjust barrel temperature: Inspect for overheating. If the temperature of the barrel and nozzle is too high, lower it. Avoid thermal deterioration.

- Lower injection speed: Reduce shear heat by slowing down the injection rate. Reducing speed stops gas formation and resin degradation.

- Improve ventilation: Clean the existing vents and add more if necessary. Safe release of trapped gases is made possible by proper venting.

- Use virgin material: Avoid overusing regrind. Before processing, always ensure that there is no contamination.

These actions can solve most splay problems in your production line.

How To Get Rid Of Splay In Injection Molding?

A proactive strategy is required to stop splay. Start with routine maintenance for your equipment. Maintain the cleanliness of heaters, vents, and dryers to ensure optimal performance. Replace heaters and worn seals on time. By taking these precautions, air and moisture are kept out of the process.

Sensors and automation facilitate prevention. Check the dryness of the resin using real-time moisture sensors. Install sensors for pressure and temperature to monitor processing conditions. To be informed when values deviate from the range, set up alerts. It prevents flaws before they arise.

Moreover, preventive audits are crucial. Plan to inspect the mold vents, hoppers, and dryers. Early detection of loose seals or clogged vents is key. Take care of them before they lead to downtime and scrap.

Lastly, provide your operators with training. Early indications of splay can be recognized by trained personnel. They can swiftly change the machine’s settings. Long-term control is ensured by combining technology, audits, and training.

Why Fixing Splay Matters For Your Business

Resolving splay injection molding flaws is crucial for ensuring quality control and achieving cost-effectiveness. Every broken component necessitates additional scrap or rework. Both increase production cost and waste valuable resources. If your customers see parts that are splayed, you run the risk of losing their trust and harming your brand’s reputation.

Additionally, defects increase downtime and slow down production. Eliminating splay increases overall efficiency, speeds up cycles, and decreases scrap. It is always more profitable to prevent problems than to fix them later. You can maintain consistent product quality and protect your earnings in a competitive market by managing inventory.

Conclusion:

Injection molding splay is a significant issue that impacts customer satisfaction, cost, and quality. When moisture, trapped gases, or high shear heat are involved, it manifests as silver streaks. It can be fixed by improving mold venting, reducing speed, adjusting temperature, and drying the resin. Maintenance, appropriate material storage, and process monitoring are the keys to long-term prevention.

To assist you in creating parts free of flaws, Fecision offers professional injection molding services and precision mold solutions. Take charge of your process now by collaborating with professionals. Bid farewell to splay and consistently produce flawless parts.