The appearance of silver streaks is one of the most frequent defects in injection molding. These present thin, shiny lines on the part surface. The presence of these streaks diminishes the visual appearance of the part and may lead to unsatisfying delivery to customers. In many cases, the silver streaks are due to problems in molding.

If not managed, they can result in defects and more waste. This makes it especially important to know the causes of silver streaks and what to do to eliminate them. Manufacturers can reduce or eliminate silver streaks by maintaining good temperature, injection speed, and material quality.

In this post, we look at how to prevent silver streaks in injection molding. Adherence to these techniques will enhance product quality and satisfy customers.

Control of Melt Temperature

One of the primary triggers of silver lines in injection molding is the wrong melt temperature. Melt temperature is the temperature at which the plastic resin melts prior to being injected into the mold. It is crucial to keep this temperature constant and within the correct range for that particular material. If the melt temperature is too hot, the material can degrade or even burn on the press. This results in the finished part having bubbles and lines of gas. Conversely, the resin does not flow properly if the melt temperature is too low. The filling of the molding die is not well-circulated, and the reflex silver pattern also emerges to the surface.

Uniform temperatures are necessary to sustain the smooth flow of resin. This minimizes imperfections and enhances the surface finish. Molders need to check and adjust temperature settings on the injection machine frequently. This is also avoided when taking proper care to use a good temperature controller. Different materials additionally need different temperature settings, which must be strictly adhered to per manufacturer guidelines.

By properly regulating the long-term temperature, producers can prevent the frequent reasons for making silver streaks. It is such straightforward solution to reduce the chance of defects and enhance the quality of your parts that are injection molded. It also saves time and money by reducing the amount of rework and scrap.

Optimizing Injection Speed and Pressure

The velocity and pressure of injection are the major contributors to avoiding silver streaks in the articles being formed. Injection speed refers to how fast the molten plastic is injected into the mold. Injection pressure is the pressure to fill the mold cavity. Both must be adjusted very carefully for the smooth, even flow of material.

If the feed rate is increased, the resin is likely to be cut or stretched. This traps air or also makes small lines that look like silver steaks on the surface. On the other hand, if the speed is too slow, the plastic may get chilled prematurely, resulting in unfilled edges and surface inconsistencies.

Errors in injection pressure are likely to give rise to similar difficulties. Backpressure may be such that the resin enters too rapidly, entrapment of air or melt fracture occurs. If pressure is too low, weak wall fill could result and an inconsistent surface finish.

Injection rate and pressure should be controlled to prevent silver marks. Begin with the manufacturer’s recommended settings and tweak them toward better tuning as you observe the effect. Experiment to find out what speed and pressure profiles should be selected for the material and mold design.

These parameters should be adequately controlled to obtain high-quality part surfaces free from defects. It also minimizes cycle time and waste. By setting the injection speed and pressure properly, etc., the occurrence of silver streaks can be greatly suppressed, and the quality of products can be improved.

Proper Material Drying

Absorbed water in plastic resin is one of the biggest reasons for silver streaks in injection molding. Resin that holds water, however, will heat moisture into steam when it melts. This vapor forms bubbles and lines on the part surface. So, it is very important to dry the material before molding.

The majority of plastic resins tend to absorb moisture from the atmosphere while in storage or at the time of handling. The soil penetrates, and an insufficient drying of this moisture remains within the resin pellet, and defects occur. Different materials have different drying times and temperatures. Failure to follow these limits can degrade the surface finish.

To ensure proper drying, follow these key steps:

- Use the right drying equipment: Desiccant dryers and dehumidifying dryers are commonly used for effective moisture removal.

- Follow material supplier recommendations: Check drying time and temperature for each resin type to avoid over- or under-drying.

- Store resin properly: Keep resin in sealed containers or dry conditions to prevent moisture absorption before use.

Correct drying also prevents the formation of silver or hot spots, besides balancing the mechanical properties of the end product. Bubble generation and other surface defects are decreased in probability. Time invested in drying pays for itself in the quality of the final product by eliminating inconsistency, waste and scrap.

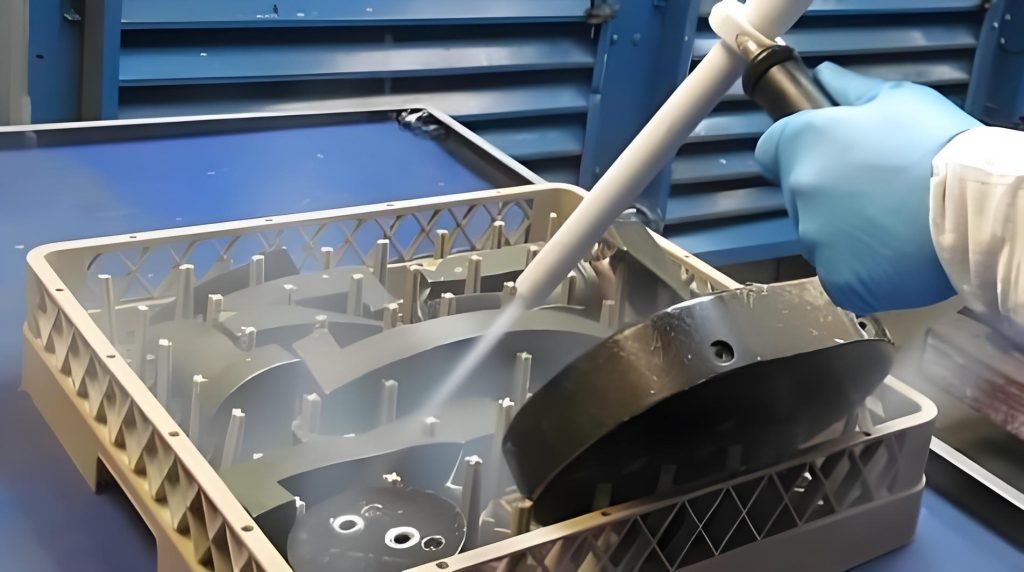

Regular Cleaning of the Mold

Clean the mold properly to prevent silver streaks in injection molding. Residues such as burned plastic, dust or grease can accumulate in molds over time. These impurities influence the molten resin flow and result in surface defects in the part, such as silver marks.

Periodically washing away these and other undesirables allows the mold to operate freely. Suppose the surface of the mold is dirty or damaged. In that case, the resin will not flow uniformly, resulting in uneven cooling with visible streaks. So, cleaning should be included in the maintenance of the mold.

Cleaning methods vary depending on the mold type and material. Common techniques include:

- Manual cleaning: Using brushes and cloths to remove dirt and residue from accessible mold areas.

- Chemical cleaning: Applying solvents or cleaning agents designed to dissolve stubborn residues without damaging the mold.

- Automated cleaning: Using ultrasonic cleaners or specialized equipment for deep cleaning, especially for complex molds.

Besides cleaning, inspection allows you to evaluate any worn or damaged parts that might impact product quality. Regular cleaning and maintenance after production runs keep buildup down and help maintain mold performance.

Molds These, in turn, keep molds clean, reducing the likelihood of silver streaks and improving the surface finish of molded parts. It also prolongs the life of the mold -alleviating costly downtime due to the need for mold repairs or slow mold cleaning.

Use of High-Quality Resins

The resin selection is crucial to avoid streaks of silver in injection molding. Molded goods often cause defects such as silver streaks due to poor quality resins or contaminated resins. Premium resins equal, smoother, clearer parts and less waste.

Crappy resin quality often results in kinky melt, trapped air and uneven flow. These problems result in the generation of streaks and have a detrimental effect on the final product. It is thus important to have a reliable material specification and work with trusted resin suppliers.

Using high-quality resin offers several benefits:

- Better flow characteristics: High-quality resin melts evenly, filling the mold properly and reducing defects.

- Less contamination: Cleaner resins contain fewer foreign particles that can cause streaks or discoloration.

- Improved mechanical properties: Parts made with good resin are stronger and more durable.

And then there’s resin handling. Removing moisture from containers that are tightly sealed will allow dry storage and prevent contamination. Resin from different batches or suppliers should not be mixed unless compatibility is demonstrated.

Manufacturers minimize the risk of silver streaks by spending money on good resins and by handling them correctly. It results in higher surface finish quality, fewer rejects, and more satisfied customers. In the end, it reduces the expense of scrap and rework as well.

Why Choose Fecision for Your Injection Molding Needs

If you want high-quality injection molded parts without silver streaks, then your partner in sourcing matters! Fecision is a leader in the field, providing professional injection molding solutions dedicated to precision and quality.

Their team of experts carefully monitors every part of the process, from the melt temperature to the material drying and, finally, mold maintenance to produce flawless final results. Fecision is exclusively high-quality resins and is subjected to rigorous quality control, excellent surface quality, and reduced surface defect rate.

By teaming up with Fecision, you can take advantage of cutting-edge technology and decades of expertise that translate to reliable, high-quality plastic parts. Whether you are looking for standard or custom-made components, Fecision has trustworthy products with competitive prices for you.

Final Thoughts

Silver streaks can also damage the quality and aesthetics of injection molded parts. However, these can be overcome by managing the significant process variables. We need to keep the melting temperature right so the resin will flow well without burning or cooling. Air pockets and also the fact of not being properly filled can be avoided by regulating the volume of the injected gas/liquid, increasing the side’s air pressure and injecting speed and precision ratio. Correctly drying stuff erases the moisture that leads to steam blobs and streaks. Frequent cleaning of the mold prevents any buildup that may interfere with the flow of resin.

Lastly, good quality resins with uniform integrity results in fewer defects and stronger parts. By using these easy yet crucial steps, printers can easily minimize (or altogether eliminate) silver streaks. Which results in improved product quality, less waste and happier customers. It is important to control the molding process in order to achieve clear, smooth, and defect-free plastic parts.