Miniaturized 5G backplanes and automotive radars rely on connectors with pins held to tight tolerances. This micron-level precision starts in connector mold manufacturing, where Fecision sets new standards. As a leading provider of custom connector mold and high-precision mold tooling, we specialize in turning complex design requirements into production-ready parts faster than ever.

Below, we’ll explore why sub-micron tolerances are key to market success,s, the defining traits of high-quality precision connector parts, and how Fecision’s tailored solutions solve the biggest pain points in connector manufacturing.

Why Precision Matters in Connector Manufacturing

High-speed, high-reliability systems demand flawless performance, making tight tolerances in connector manufacturing essential. The precision of your connector injection mold directly impacts signal integrity, durability, compliance, and production efficiency—here’s how:

Signal Integrity Begins at the Pin

A small offset in a fine-pitch array can add crosstalk in high-speed links, reducing your overall system performance. Mold tooling accuracy is therefore the first—not the last—guardian of your Bit Error Rate (BER) budgets and must be prioritized from the start. For telecom and data-center applications, this precision ensures consistent signal transmission in high-frequency environments.

Vibration & Thermal Fatigue Resistance

Electric Vehicle (EV) battery harnesses see constant shock loads and significant temperature variations during operation. A poorly designed automotive connector mold can produce mis-molded plastic ribs that create arcing gaps at high voltage. High-precision connector mold manufacturing stops this micro-motion from the start, ensuring long-term safety and reliability in EV and industrial applications.

Regulatory Compliance

Standards like USCAR-2, IEC 60512, and MIL-DTL-38999 all demand low-level contact resistance drift after exposure to harsh environments. Precision molding gives your designers built-in compliance margins, allowing parts to meet regulatory requirements easily, rather than needing after-the-fact fixes—critical for aerospace, defense, and medical connector applications.

Assembly UPH (Units-Per-Hour)

Pick-and-place lines run at very high cycle rates to maximize efficiency and reduce costs. Custom connector parts with tight true-position can eliminate the need for vision re-alignment systems, significantly adding to your throughput. For many clients, this increased volume is often enough to pay for the entire mold tooling program in just a few months.

Top 8 Characteristics of High-precision Molded Connector Parts

The best connectors share several key attributes beyond simple dimensional accuracy. These eight features are non-negotiable for success in high-reliability applications.

1. Sub-µm Dimensional Accuracy

Pin pockets located within extremely tight windows ensure coplanarity across many-way connectors, eliminating the need for costly and time-consuming secondary machining processes. This level of accuracy is critical for large, complex arrays in 5G and medical devices.

2. Mirror-grade Surface Finish

A low Ra (roughness average) on mating faces is essential because it significantly lowers the required insertion force during assembly. Furthermore, a smoother finish can reduce the consumption of expensive gold plating material, lowering your overall component cost. These are the key benefits of optimized connector injection mold designs.

3. Ultra-tight Tolerance Windows

Critical over-mold diameters in high-precision mold tooling must be held to very small tolerances to guarantee press-fit compliance in the final assembly without measurable distortion. This ensures the mechanical strength and integrity of the assembled connector structure for harsh applications.

4. Complex Geometry Readiness

Custom connector mold solutions can handle challenging features like thin LCP walls, micro vent channels, and gentle-draft snap beams. All these geometries must be released smoothly, often using collapsible cores and air bladders, all integrated within the same connector mold.

5. Material Integrity

The connector mold manufacturing process must control factors like gate blush, weld lines, and fiber orientation within the resin. This control is vital so that the dielectric constant varies minimally when the connector operates over the higher gigahertz (GHz) frequency bands.

6. Long-term Stability

Post-mold in-situ annealing cycles are necessary to lock the crystallinity of the plastic material. This ensures that the parts shrink minimally after high-temperature aging tests, providing long-term stability and preventing performance degradation over time.

7. Multi-cavity Consistency

High Cpk (Process Capability Index) on pin-to-pin spacing is required across multi-cavity family molds. This consistency is rapidly validated using on-press laser micrometers in seconds, guaranteeing every part meets your rigorous specifications.

8. Cost-optimized Precision

Intelligent runner balancing and conformal-cooled inserts in high-precision molds cut the required cycle time for manufacturing while simultaneously holding tighter tolerances. This advanced approach proves that achieving both high accuracy and manufacturing economy can successfully coexist.

Key Challenges in Connector Parts Manufacturing (And How We Solve Them)

While the goals of high precision are clear in connector industry, manufacturers face many difficult hurdles on the shop floor. Dealing with material science and machine dynamics is crucial.

Micro-shrink Variability

Semi-crystalline resins can shrink differently depending on the plastic’s shear forces during injection. Without custom connector mold flow simulation, cavities may fall out of spec after the tool steel is cut. Our pre-production analysis ensures custom connector mold cavities stay in spec, avoiding costly and time-consuming rework.

Thin-wall Fill & Pack

When very thin walls are being molded, the plastic material freezes extremely fast. Conventional injection units can stall, creating short shots that look acceptable on the surface. Our precision connector mold designs and advanced injection techniques eliminate short shots and knit-line cracks—verified via SEM inspection.

Core Shift & Pin Float

High-cavitation tools experience high cavity pressure during the filling stage. Slender core pins can deflect under this pressure, unintentionally enlarging holes beyond what is acceptable for proper plated-through yields. Manufacturers must use special tools to ensure support.

Gold-plate Adhesion Over-mold

Residual hydrocarbons from mold release agents can unfortunately migrate deep into the plastic surface. This can cause blistering under a thin gold flash layer later on. This is an invisible killer that leads to failure in critical RF connectors, requiring tight process control. Our strict process control in connector mold manufacturing prevents contamination, critical for RF and medical connectors.

Dimensional Drift in SMT Reflow

The peak temperatures of the Surface Mount Technology (SMT) reflow process can re-crystallize some types of resins. This thermal effect causes a shift in datums. The tool must be steel-safe compensated before the first shot, not after the parts are already showing problems.

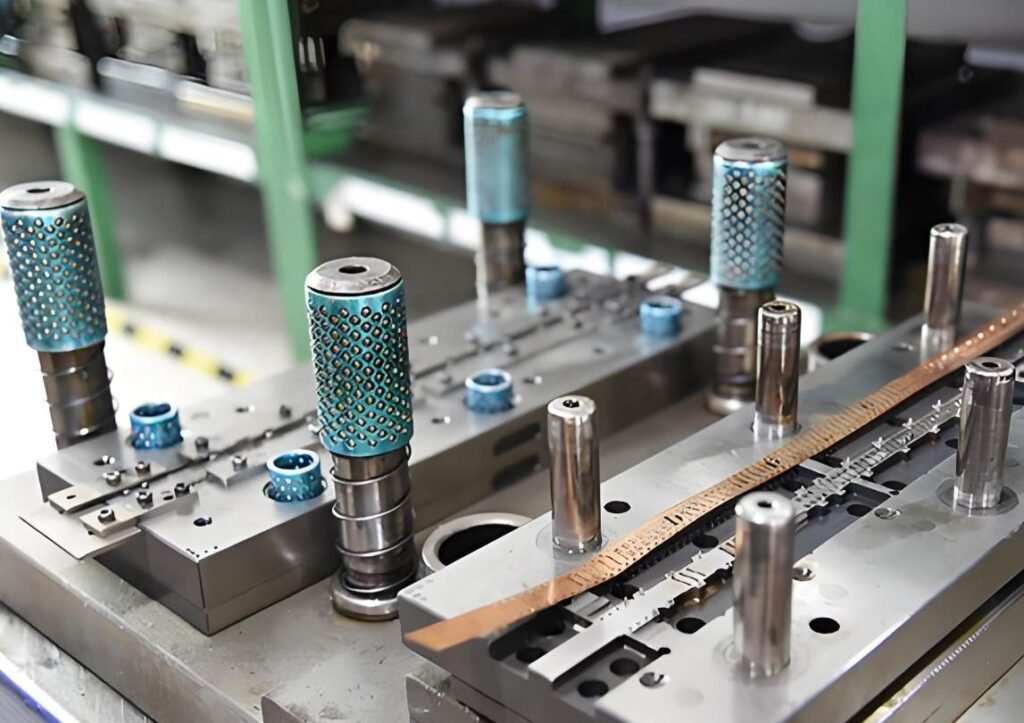

How Fecision Delivers Superior Connector Mold Manufacturing

Fecision delivers excellence by combining strict quality systems with cutting-edge technology. We focus on controlling every variable in the process, from the steel we select to the final validation report, to solve your precision connector mold challenges—from design to production:

Ultra-Tight Tolerance Machining

Achieving high-precision connectors requires mold components machined to the smallest margins. We use top-tier equipment and materials to guarantee this essential, foundational accuracy for every part we produce.

Our high-precision mold tooling uses advanced equipment to consistently achieve micro-tolerances (±0.005 mm CNC and EDM)—crucial for modern fine-pitch connectors and complex shapes in automotive, telecom, and aerospace applications. This extreme level of precision is mandatory for all high-performance applications we handle.

Design-for-Manufacturability Up-Front

We focus on preventing issues before the mold is even cut, using a collaborative Design-for-Manufacturability (DFM) approach to optimize your custom connector mold design. This ensures optimal production from the very first design concept.

Our expert engineers conduct DFM reviews early, optimizing geometry, runner layout, and tolerance stack-up. We also offer mold flow simulation to predict and prevent problems like warp, weld-lines, and fill, avoiding costly rework.

Complex-Geometry Expertise

Modern connectors often have intricate internal features, like locking clips and micro-mechanisms. Fecision’s precision connector mold tools use slides, lifters, and unscrewing mechanisms to manage these challenging features perfectly in a single injection shot.

Our molds use sophisticated slides, lifters, and unscrewing mechanisms to create complex features, including ultra-thin walls and core-pulls, in one cycle. We also provide precise insert, over-mold, and two-shot solutions for multi-material components.

High-Performance Material Mastery

Working with advanced connector resins demands specific process knowledge and careful control. We specialize in materials that require high heat and precise processing to ensure zero manufacturing defects.

For connector injection mold applications, we have proven mold designs for challenging resins like LCP, PPS, and PEEK, managing high melt temperatures and precise control. Our use of conformal cooling channels significantly reduces cycle time while maintaining tight part dimension quality.

Rigorous Quality & Validation Protocol

Precision is useless without verifiable proof, so we use a comprehensive quality system. This ensures every component meets the highest standards and provides full traceability documentation.

Every core and cavity is precisely checked using in-process and final CMM inspection against your design print. Our documented trial schedule and certified ISO/IATF systems provide full quality assurance documentation and traceability for every custom connector mold.

Rapid Prototype-to-Production Path

We focus on minimizing delays in the critical transition from prototype design to full-scale production. This integrated approach ensures your new connector products reach the market much faster.

Our steel-safe strategy allows for quick design tweaks using soft-tools or pilot inserts, shortening the T1 delivery time. Handling design, machining, assembly, and validation internally eliminates frustrating hand-off delays between different vendors.

Ready to eliminate yield loss and accelerate your high-precision connector project? Contact Fecision today for a custom tooling consultation.

Precision in Action: Industry-Specific Connector Mold Solutions

The true test of precision molding is how the parts perform in extreme real-world applications. Here are examples of how Fecision’s custom connector molds drive reliability in critical sectors.

Automotive: xEV High-voltage HVIL Connectors

Our automotive connector mold produces LCP positioning fingers with a very tight true-position throughout severe thermal shocks and extreme vibration. The key benefit for you is reduced fretting corrosion and extended warranty compliance for your high-voltage harnesses.

Telecom / Data-center: High-speed Backplane Connectors

Fecision’s telecom connector molds produce perfectly skew-matched twinax pockets for high-speed differential pairs. This precision keeps the required insertion loss low, which is essential for consistent signal performance at high frequencies. The benefit is a lower Bit Error Rate (BER), which enables you to achieve a much higher aggregate bandwidth in your data center hardware.

Aerospace & Defense: MIL Circular Series Connectors

We over-mold composite rear shells that hold extremely tight concentricity, allowing the connectors to survive severe vibration and harsh salt-fog environments. This level of precision provides you with assurance for critical applications like mission-critical radar and avionics systems.

Medical: Disposable Ultrasound Catheter Connectors

Fecision uses specialized medical-grade resins for injection molding of micro-connectors, strictly controlling pin planarity for the fragile flex-circuit weld. The resulting benefit is an improved Signal-to-Noise Ratio (SNR), which ultimately enhances the image clarity during delicate medical procedures.

Conclusion

Precision connector mold manufacturing is no longer a luxury in the highly competitive connector industry—it is the absolute price of admission. From achieving your 5G latency budgets to meeting strict EV safety mandates, every micron saved in the mold manufacturing stage echoes through decades of field reliability for your products.

Fecision is your certified partner for engineering high-precision connector molds. We are your comprehensive, single-source solution for injection molds, stamping dies, and die-casting molds, all built to micro-tolerances. You will benefit from our expert DFM support, mastering advanced resins (like LCP and PEEK), and rigorous quality systems (ISO/IATF/ISO 13485) to guarantee flawless performance in automotive, aerospace, and medical applications.

Ask our engineers for a DFM review on your high-precision part today!