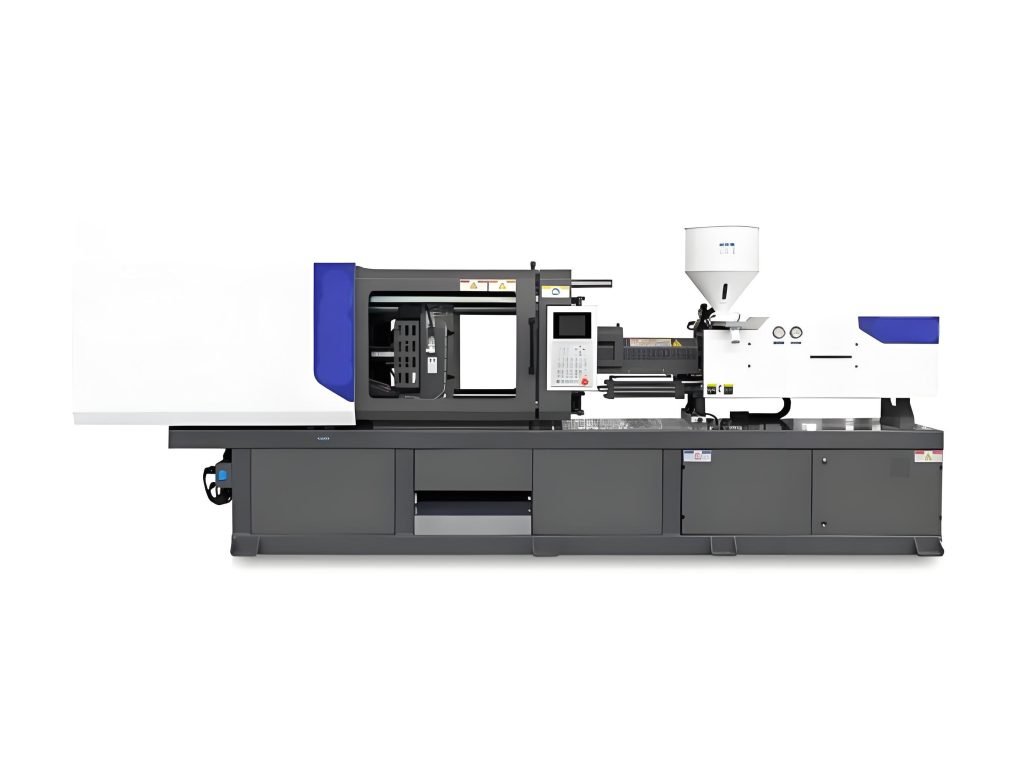

Injection molding machines are essential tools for every facet of plastics processing, from medical applications to the automotive industry, consumer goods and other sectors where plastics are integral to daily life. These systems mold raw plastic material into complex geometries with accuracy, and speed. By melting plastic and injecting it into a mold, they can make anything from small gears to large panels.

What’s more, it is fast, relatively cheap and versatile, and thus is a mainstay among manufacturing processes. Injection Molding Machines UniloyMilacron injection molding machines are designed with the features of the industry’s most respected machines and engineered to deliver consistent quality performance. Even that little bit of understanding of their operation helps us realize why they are so essential in the making of high-quality, long-lasting products.

This post will explain in details how injection molding machines work, and guide you to figure out the device best fit to your application! From the feeding of material to moulding parts, every function is coordinated with the performance of the machine. No matter whether you are a beginner or a professional this value packed guide will provide all you need to know about plastic injection and how to operate an injection molding machine.

Main Components of Injection Molding Machines

Injection Molding Machines have a number of components that can contribute to process repeatability, part quality, and other process factors. These are the injection unit, the clamping unit, and the mold, and each is essential to the process.

- Injection Unit: Melts raw plastic pellets and injects the plastic material (molten) into the mold. The feed hopper, heating barrel, and plunger (or a screw) are the three major parts of an injection unit.

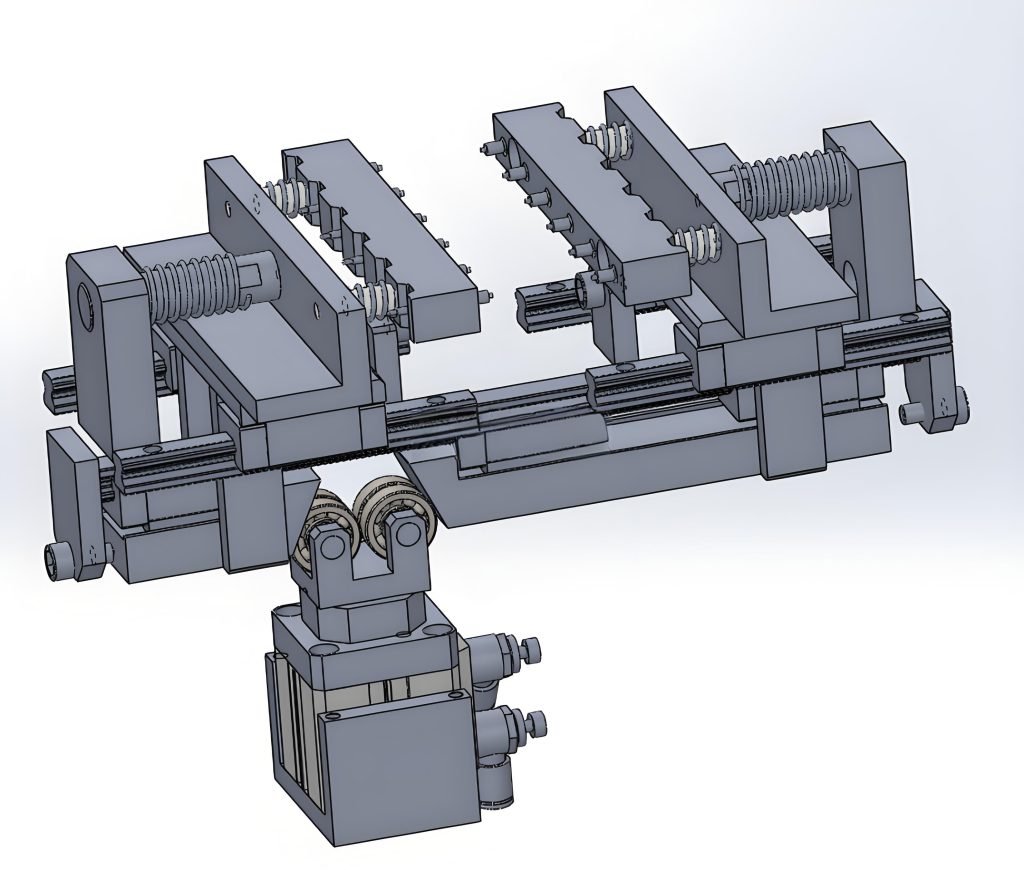

- Clamping Unit: The machine is used to extrude the mold through a clamp unit, which presses the mold closed and resists the pressure generated by the injection of the molten plastic. This guarantees that the mould is sustained and the part shape is preserved.

- Mold: The mold is a pre-built metal cavity into which the melted plastic is injected to manufacture the part. Constructed from sturdy steel or aluminium, it can handle high pressure and regular use.

These parts are driven by hydraulic or electric systems that control the motion of the machine. Combined, they allow for complex parts to be produced with very tight tolerances (making the machines susceptible to precision). Injection molding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars.

The Injection Process Step-by-Step

The injection molding process creates parts by injecting molten material into a mould. It starts by feeding plastic pellets into the hopper of the machine, which is gravity-fed into the injection unit. Internally, the pellets are melted to their molten state with the heat ranging between 200–300°C, depending on the material. This molten plastic is then forced into a mold cavity forming the part(s) under tremendous pressure, typically more than 20,000 psi, as it is pressed into the cavity through a rotating screw or plunger.

After the mold is filled – and before releasing it – the plastic is held in an elevated pressure state so that it can more fill the mold’s shape, accounting for any shrinkage as it cools. Next comes the cooling stage, in which the mold’s channels pass water or oil to cool the plastic and bring it to a solid state, which generally lasts from a few seconds to several minutes. When cool, the clamping unit opens the mold, and the ejection mechanism, typically pins or plates, pushes the part out of the mold.

The process is rapid, taking less than 10–60 seconds for the largest parts, depending on the size of the parts and details of the part design. This fast process makes injection molding a very popular option for high-production runs. It has the advantage of high precision, providing component repeatability through the exact control of every step of the fabrication process, which is important for industrial applications where intricate, resilient parts are not an option.

Clamping Unit Function

Clamping part is very important for injection molding machine, which is responsible for the mold clamping system while injection machine is working. It uses such magnitudes of force, sometimes 10 to more than 5,000 tons, to resist the force by which molten plastic is injected. This is the force which keeps the mould closed; these are the defects you will see if the clamping force is too low – flash as well as short shots.

- Mould security: The die locking part is tightly closed, preventing mold–edge raise and has no relative displacement for the pressure casting.

- Pressure Maintain: It can keep the pressure, and it can keep the shape of plastic well, without deformation.

- Flexibility: Clamping units adapt for molding molds of all sizes and part designs.

Usually operated by hydraulic or electric, the clamping process is carefully controlled to control the mould so as to meet the requirements of the products. Once the plastic has cooled, it opens the mold so that the part can be ejected. Due to this strong control, such excellent parts free from defects are formed, providing the essential features of an injection moulding operation.

Injection Unit Function

The injection unit is used to melt the plastic and then inject it into the mold. It starts with raw plastic pellets that are fed by gravity from a hopper into a heated barrel. Intemally, a screw or plunger turns and thrusts heated plastic through a 200 to 300°C heat and friction zone, before injecting the molten plastic under high pressure into a mold, to flow into every nook and cranny of the cavity.

- Melting Precision: The injection unit assures consistent melt temperatures for uniform resin melting.

- Injection Control: Through compression or clamp, the desired amount of molten plastic is injected and no more or no less.

- Material Flexibility: The machine processes all plastics that range from pp to ABS for different purposes.

The flight design of the screw promotes good mixing and material uniformity. Once injected, the unit pulls back, ready for the next one. This procedure is essential to the manufacturing of high-quality plastic parts in a cost-effective manner. Therefore, the injection is a fundamental component of injection moulding technology.

Cooling and Ejection Mechanisms

Cooling and ejection actions are also vital operations for part removal in injection molding. Once the mould is filled, the molten plastic cools down with the help of a cooling system. Water or oil is circulated through channels in the mould and removes heat from the hot plastic, cooling it to a solid state at a rate that is determined by the thickness of the part and can range from 5 to 30 seconds. This will make sure the part stays in shape and does not warp.

- Optimal Cooling: Cooling channels ensure faster cycle times and maximize heat dissipation.

- Shape Stability: Chill, durable, and strong-willed to hold shape or sculpt to the shape you want without deformation.

- Ejection Precision: Ejection pins and plates eject the part cleanly, with no burrs or scraps tampered with.

When it gets cooled, the ejection mechanism is started. The solidified part is then ejected out of the mould by means of pins, plates or air blasts with distortion. This timing method is tuned to balance part quality and cycle time. Both these processes ensure that high-quality parts are always being produced and are available for industry applications.

Types of Injection Molding Machines

There are different types of injection moulding machines, depending on what they are used for. Horizontal and vertical machines are categorized according to the orientation of moulding and the method of clamping. The most common are horizontal machines, which fit into the larger part of the machine list.

These are constructed for optimum efficiency and feature high-volume production of parts such as automotive components and consumer goods. Vertical machines are particularly effective at insert moulding applications, where metal or other components can be placed into the mould and encapsulated by plastic, and are well suited for use in electronics.

- Horizontal Machines: Ideal for large production numbers and quick part changeovers, as well as automatic part removal and reinsertion.

- Vertical Machines: These machines require less floor space and are ideal for precision applications such as overmolding.

- Specialized Machines: Add multi-shot or all-electric for multicolour or energy-saving production.

Other configurations are hydraulic, electric, and hybrid machines. Hydraulic machines for heavy clamping power and hydraulic clamp stroke, and electric machines for precision, energy efficiency and high-speed production of smaller, complex components. Hybrid machines do both for flexibility.

They’re crafted to satisfy varied industry requirements, from medical devices to packaging, so that manufacturers can choose the optimum machine for their production purposes.

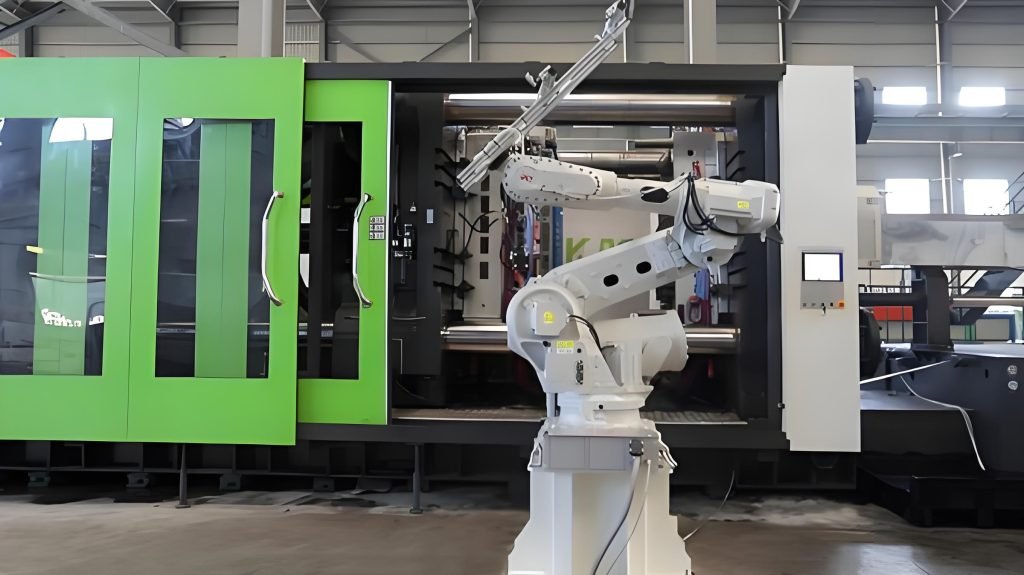

Automation and Control Systems in Injection Molding

Automatic and control systems greatly improve the performance and accuracy of injection moulding machines. Sophisticated sensors and software control everything from material feeding to part ejection to ensure consistent quality. Machine operations are controlled by programmable logic controllers (PLCs), which optimize parameters such as temperature, pressure and cycle time on a real-time basis.

- Accurate Control: Press and temperature are held automatically for perfect parts.

- Efficiency: Automated systems have shorter cycle times, increasing the rate of production and decreasing waste.

- Quality Control: Our sensors detect defects early, so only quality parts get made.

Robotic arms frequently take care of removing parts and loading material, cutting down on labour costs and human error. Operators can also make adjustments with ease thanks to the addition of touch-screen interfaces to newer machines. Performance is being monitored through data analytics to predict maintenance and avoid downtime.

These systems have made injection molding extremely dependable and able to manufacture complex parts with great precision for industries such as aerospace and medical devices. Automated systems bring manufacturers up to faster, more efficient production without losing quality.

A Final Word

Injection molding machines are necessary equipment for manufacturing plastic products in almost every industry. Quality Guaranty In All Stages From Melting, Throwing To Jetting. Fecision’s leading injection molding solutions promote the reliability of the manufacturing industry. From varying machine sizes and automation to multiple material types, these systems are engineered to produce high-quality, long-lasting parts for the automotive, medical, moulding, and other industries.