Injection molding and blow molding are processes used in making plastic parts with commercial and industrial applications. Despite the shared term “molding”, injection molding and blow molding are different. Operators and manufacturers often struggle to select the right one for their project, potentially leading to suboptimal part performance and increased costs.

This article provides a detailed comparison of blow molding and injection molding, covering their manufacturing processes, designs, and other key aspects.

What is Blow Molding?

Blow molding is a manufacturing process used to create hollow plastic products like bottles and containers. Its core principle is to inflate a heated, softened plastic tube—called a parison—inside a closed mold using compressed air.

The process begins by extruding the parison vertically. The mold then closes around it, sealing both ends. Compressed air (typically around 80-100 psi) is injected, inflating the parison to match the mold’s interior shape. After cooling and solidifying under pressure, the mold opens to eject the finished part. Finally, excess material (flash) is trimmed off and typically recycled.

Types of Blow Molding

Here are the types of blow molding:

Injection Blow Molding

Injection blow molding starts by injection molding a precise preform (like a test tube shape) onto a core rod. This assembly is then transferred to a blow mold, where air is injected through the core rod to expand the preform into its final shape.

Extrusion Blow Molding

Extrusion blow molding consists of two variations: continuous and intermittent. Continuous variation is feeding the parison to the mold and cutting it off after cooling, which is an ideal choice for high-volume operations. Intermittent extrusion, on the other hand, produces a parison of specific length in a single stroke after the previous part has been ejected and the mold is ready again. This is suitable for larger parts or lower volumes.

Injection Stretch Blow Molding

This process combines blow molding and injection molding to create complex plastic parts with finesse. The preform is first heated to an optimal orientation temperature. It is then stretched longitudinally by a mechanical rod while simultaneously being inflated with pressurized air to expand radially, achieving biaxial orientation for improved strength and clarity.

Applications of Blow Molding

Blow molding is a rapid process that accelerates production, consuming low energy and requiring a short processing time, an ideal choice for making uniform and thin-wall hollow parts. Blow molding designs of plastic parts primarily feature thin walls and simple hollow structures, as the process does not accommodate complexity. Its applications include household chemical bottles, toys, planters, recreational products, shampoo, and cosmetic containers.

What is Injection Molding?

Injection molding is a plastic parts manufacturing technology that injects the molten plastic into the mold at high pressure. The pressure forces the material to flow inside. After injection, cooling occurs, capturing all details and texture on solidification.

3 Main Types of Injection Molding

Conventional Injection Molding

Conventional injection molding is a process that injects molten material into a mold cavity under high pressure. It allows for multi-material or multi-color injection in a single cycle to create parts with combined properties or aesthetics.

Gas-assisted Injection Molding

After partially filling the mold with molten plastic, inert gas (like nitrogen) is injected. The gas forms channels within the thicker sections of the part, pushing the plastic against the mold walls. This creates hollow structures, reduces sink marks, and saves material.

Co-injection Molding

This method involves using two or more different materials in the mold simultaneously or in order, where the plastic is formed by hardening and softening materials, aiming to increase the strength and reduce the production cost.

Advantages of Injection Molding

- A high-precision and cost-effective method for high-volume and high-requirement production

- Injected material with multi-option and color choice

- Suitable for highly detailed molds to produce multi-cavity plastic parts

Applications of Injection Molding

Injection molding is used in the high-volume production of precise solid parts, such as container caps, combs, and mobile phone cases. It is also widely used for producing automotive parts and medical parts in the manufacturing industry.

Differences Between Blow Molding and Injection Molding

In this section, let’s take a look at the difference between injection molding and blow molding as regards molding process, mold design, materials, and color options, manufactured parts, and cost.

Blow Molding vs Injection Molding: Molding Process

In terms of the molding process, blow molding and injection molding operate differently. Injection molding involves sealing molten plastic into an injection chamber, from which it is forced into a prepared mold. In contrast, blow molding begins by heating plastic and extruding it to form a hollow tube, known as a parison. This parison is then placed into a mold, where compressed air is introduced to expand it into the final hollow product.

Blow Molding vs Injection Molding: Mold Design

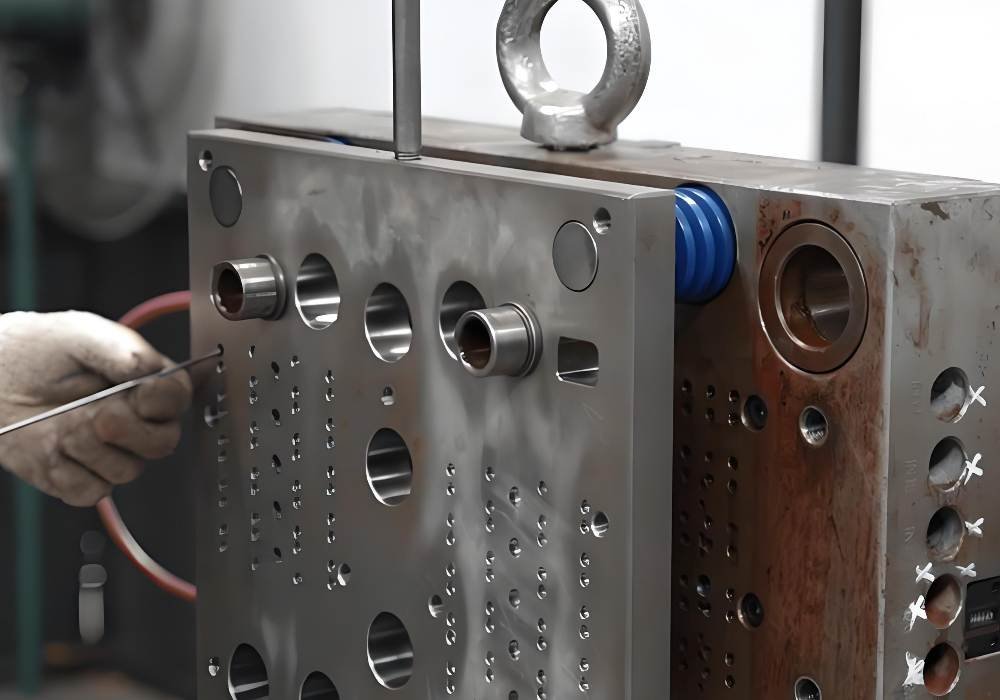

Other important factors that differentiate injection molding from blow molding are mold design. Injection molds are required for the accurate flow of molten plastic material during injection. Injection molds are very precise for forming plastic parts with complex designs. These kinds of molds are made of strong and durable materials to ensure production repeatedly in high quality. Blow molds are generally simpler in structure but must be durable to withstand high-volume production cycles. However, there are some issues that appear during the molding process, like leaks, wall thinning, streaks, and flashes.

Blow Molded vs Injection Molded: Materials and Color Options

Both processes utilize most thermoplastics, yet each excels with specific materials. Polyethylene is favored in blow molding for its excellent formability, strength, and chemical resistance, making it ideal for containers and bottles. Meanwhile, injection molding accommodates a broader spectrum, from standard plastics and elastomers to specialty compounds like metal-filled polymers, enabling high-precision, multi-material components.

Injection Molding vs Blow Molding: Manufactured Parts

The most distinctive difference between blow and injection molding is that the former is suitable for hollow parts, and the latter is applicable for making solid parts. Injection molding is the right method for producing complex, high-strength parts that are suitable for engineering applications. In contrast, blow molding can only produce hollow, thin-walled parts, like drinking bottles and containers.

Blow Molding vs Injection Molding: Production Speed & Cost

Another important factor that differentiates blow molding from injection molding is cost and production speed. Cycle time comparison depends on part geometry and size. Injection molding often achieves very fast cycles for small, solid parts, while blow molding offers efficient single-step forming for hollow containers. Blow molding is cheaper than injection molding in mold cost and has lower energy requirements. Injection molds are significantly more expensive than multiple molds for parallel production.

Blow Molding vs Injection Molding: Volume Comparison

Both processes are suited for high-volume manufacturing. The choice depends on whether the part is hollow (favoring blow molding) or solid/complex (favoring injection molding), with injection molding offering lower per-part costs at very high volumes despite higher initial tooling investment.

Comparison Table Between Blow Molding vs Injection Molding

| Category | Blow Molding | Injection Molding |

| Tooling Cost | Generally lower to moderate for simple molds. | Typically high due to complex, precision-engineered molds. |

| Volume of production | Well-suited for high-volume production of standardized hollow parts (e.g., bottles). | Excellent for high to very high-volume production of solid parts. Economies of scale offset high initial tooling costs. |

| Speed of production | Moderate to fast | Very fast |

| Design Flexibility | Primarily for hollow, thin-walled parts with relatively simple geometries. | Best for large and complex shapes |

| Capability of Part Size | Small to very large parts | Small to medium-sized solid parts |

| Material Options | Uses ductile, melt-strength thermoplastics (e.g., HDPE, LDPE, PP, PET, PVC). | Can process almost all thermoplastics, many thermosets, and composites (e.g., ABS, PC, Nylon, Acetal, PEEK, filled resins). |

| Suitable for | Hollow parts requiring uniform wall thickness. Ideal for containers, bottles, and fluid holding tanks. | Solid, complex, high-precision parts. Ideal for gears, housings, consumer products, automotive components, and medical devices. |

| Typical Applications | Water/soda bottles, shampoo containers, fuel tanks, hollow toys, air ducts, industrial drums. | Electronic housings, automotive dashboards, medical syringes, bottle caps, kitchenware, connectors, and structural components. |

Create Your Custom Plastic Molded Parts

Ready to choose between blow molding or injection molding for your custom plastic parts? Fecision offers end-to-end manufacturing solutions that ensure optimal process selection, superior quality, and on-time delivery.

As an ISO 9001:2015 certified manufacturer with advanced facilities and a dedicated engineering team, Fecision provides expert guidance throughout your project — from design review and process comparison to material selection, prototyping, and full-scale production. Whether your design calls for high-volume hollow containers via blow molding or complex precision parts through injection molding, we deliver reliable, cost-effective plastic parts tailored to your specifications.

Conclusion

Blow molding and injection molding meet different production demands. These processes differ in terms of the production volume they can handle, cost of tooling, material compatibility, part size, and wall thickness. Blow molding excels in producing thin-walled parts on a large scale, while injection molding excels in producing structurally complex, high-precision parts.

Fecision is a one-stop solution provider for your plastic part production. Our company guides you through every aspect of the production process from design to delivery. Let’s partner with us for your projects today!