Are you aware of the potential pitfalls that can turn your injection molding project into a costly and time-consuming ordeal?

When it comes to manufacturing, injection molding is often the go-to process for producing large quantities of consistent parts at a relatively low cost. However, without proper design considerations, even experienced engineers can fall into common traps that lead to production delays, quality issues, and unexpected expenses.

Understanding the intricacies of the process and avoiding design missteps can save you thousands of dollars and ensure the success of your project. In this comprehensive guide, we’ll walk you through the most common design mistakes and provide expert solutions to help you achieve smoother production cycles and higher quality parts.

The Critical Role of Design in Injection Molding Success

Injection molding design plays a pivotal role in determining the quality and cost-effectiveness of your production. A well-designed product can significantly reduce production costs and time, while a poorly designed one can lead to numerous problems.

Why Design Matters in Injection Molding

Design matters in injection molding because it directly impacts the quality of the final product. Manufacturers and potential entrepreneurs with new product concepts can run into problems without properly considering all aspects of the process. This can lead to inferior part quality and manufacturing delays.

A good design ensures that the product can be manufactured efficiently and effectively, reducing the likelihood of costly rework or production halts.

The Cost of Design Errors in Production

Design errors discovered late in the production process can be extremely costly. They can increase project costs by 5-10 times compared to addressing them during the design phase. Tooling modifications required to fix design problems after mold creation are expensive and can delay production timelines.

Poor design choices often lead to quality issues such as warping, sink marks, and structural weaknesses. Investing in proper design review and optimization upfront can deliver a return on greater investment by preventing costly production issues.

Common Injection Molding Design Mistakes to Avoid

To ensure successful injection molding, it’s crucial to steer clear of frequent design mistakes. Injection molding is a complex process that requires careful consideration of various design elements to produce high-quality parts efficiently.

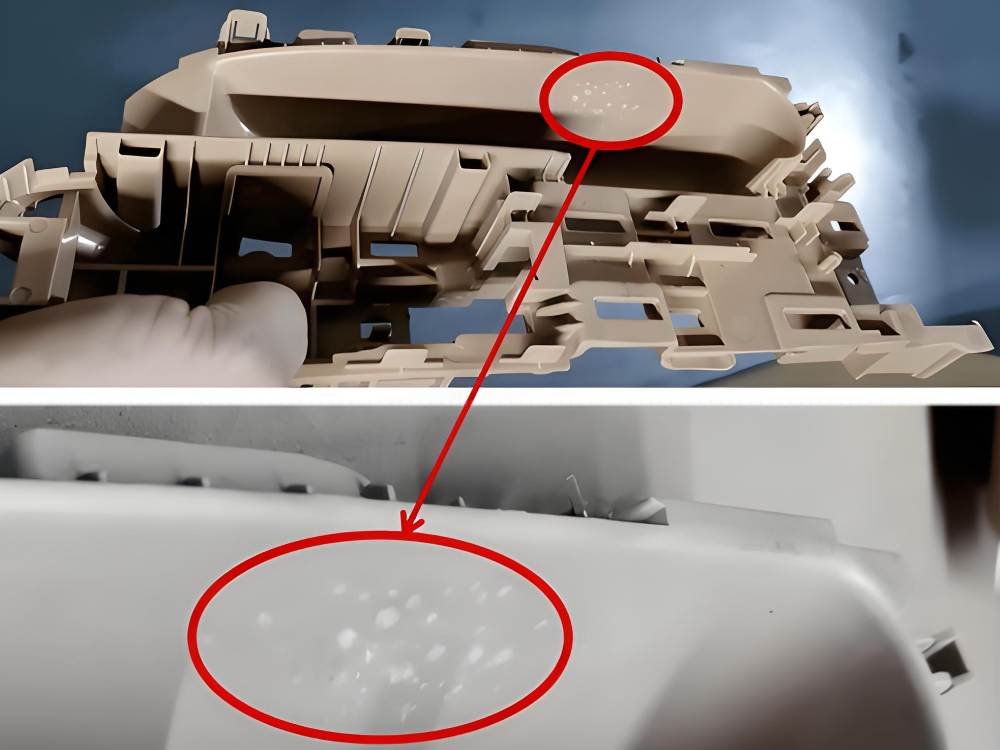

Inconsistent Wall Thickness Issues

Inconsistent wall thickness can lead to significant issues in injection molding, including sink marks, warping, and uneven cooling. To avoid these problems, it’s essential to maintain uniform wall thickness throughout the part. This not only improves the cosmetic appearance but also enhances the structural integrity of the molded part.

Insufficient Draft Angles

Draft angles are critical in injection molding as they facilitate the ejection of parts from the mold. Insufficient draft angles can cause parts to stick in the mold, leading to production delays and increased costs. A minimum draft angle of 1-2 degrees is typically recommended, depending on the complexity and depth of the part.

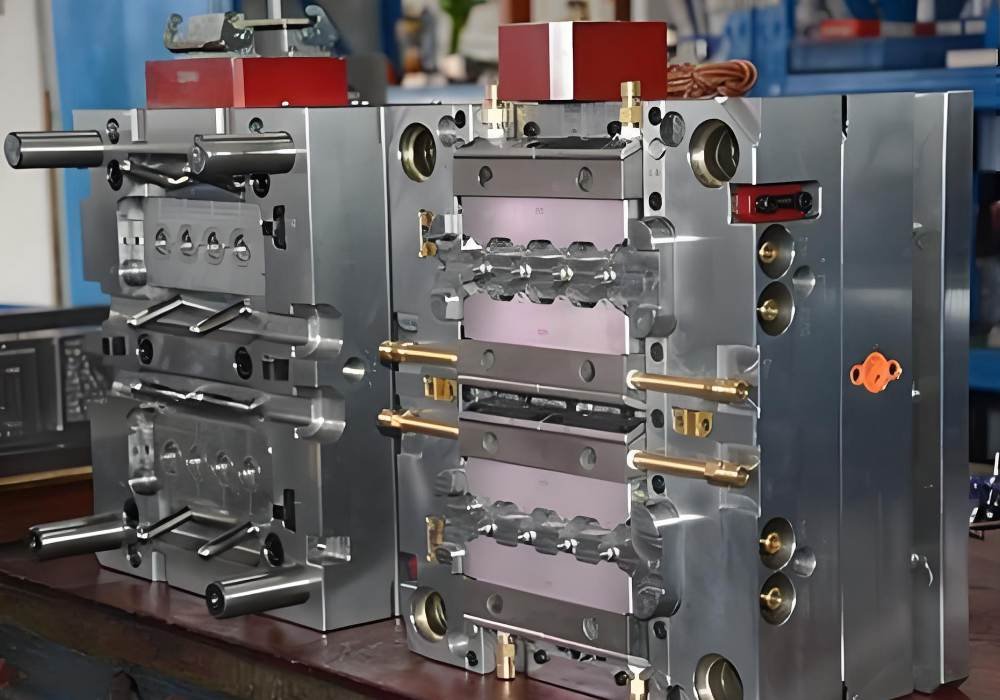

Problematic Undercuts

Undercuts can complicate the molding process by requiring additional mold components or actions, such as slides or lifters, to release the part. While sometimes unavoidable, undercuts should be minimized or designed carefully to avoid adding unnecessary complexity and cost to the mold.

Improper Parting Line Placement

The parting line, where the two halves of the mold meet, significantly impacts the aesthetics, structural integrity, and manufacturing efficiency of the part. Improper placement can result in visible flash, requiring secondary operations for removal. Ideally, parting lines should follow natural edges or features of the part to minimize visibility and potential issues.

Material Selection and Processing Errors

Selecting the right material and optimizing processing conditions are essential steps in ensuring the success of your injection molding project. The material you choose and how you process it can significantly impact the quality, functionality, and cost-effectiveness of your final product.

Choosing the Wrong Material for Your Application

Choosing a material that doesn’t match your application’s requirements can lead to part failure, increased costs, and project delays. You must consider factors like mechanical properties, environmental resistance, and compatibility with other components. For instance, selecting a plastic material that’s not UV-resistant for outdoor applications can result in premature degradation.

Improper Material Preparation

Improper preparation of the material before injection molding can cause defects and inconsistencies in the final parts. Ensuring that the material is correctly dried and handled according to the manufacturer’s specifications is crucial. Failure to do so can lead to issues like moisture-induced defects or inconsistent material properties.

Not Considering Material Shrinkage Rates

All plastic materials shrink as they cool, but the shrinkage rates vary significantly between different materials. Not accounting for these rates can result in parts that are out of specification. You should consider the anisotropic shrinkage behavior, especially for precision components, and utilize modern mold flow analysis software to predict and compensate for shrinkage patterns.

CAD and File Format Considerations

In injection molding, the precision of CAD design and appropriate file format selection are key factors. Your CAD design not only dictates the shape and functionality of your part but also influences the manufacturability and cost-effectiveness of the production process.

Avoiding STL File Format Problems

The STL file format is widely used for 3D printing and injection molding. However, it can sometimes lead to issues such as facet defects or inaccurate representations of complex geometries. To avoid these problems, ensure that your CAD software is configured to export STL files with appropriate resolution and tolerances.

Best Practices for CAD Design for Injection Molding

Effective CAD design for injection molding requires more than just basic 3D modeling skills. You should use feature-based, parametric modeling techniques for easier modification and incorporate design for manufacturability (DFM) principles from the start. This includes designing uniform wall thicknesses, proper draft angles, and appropriate radii on inside corners.

Utilize CAD software’s analysis tools to evaluate draft angles, undercuts, and wall thickness before finalizing your design. Creating assembly models to verify fit and function with mating parts is also crucial. Clearly documenting critical dimensions and tolerances will guide the mold designer’s decisions regarding gating and processing.

Expert Tips for Great Injection Molding Design

To ensure the production of high-quality injection molded parts, it’s crucial to follow best design practices. Effective design is critical for the manufacturability and functionality of the final product.

Design for Manufacturability Principles

Design for manufacturability (DFM) is a crucial aspect of injection molding. It involves designing parts that are not only functional but also optimized for the manufacturing process. Considerations include material selection, wall thickness, and draft angles.

Importance of Prototyping and Design Iterations

Prototyping and iterative design are essential for validating design assumptions and making necessary adjustments before moving to production. This process helps in identifying potential manufacturing issues early on.

Using Radii and Fillets Effectively

Using radii and fillets effectively reduces stress concentrations and improves material flow during molding. Sharp internal corners can create stress concentration points, while appropriate radii distribute stress more evenly, improving part strength.

- Sharp internal corners in injection molded parts create stress concentration points that can lead to part failure.

- Adding appropriate radii to internal corners distributes stress more evenly, improving part strength.

- External corners benefit from smaller radii to maintain a crisp appearance.

- Strategic use of radii in flow-critical areas guides material through complex geometries.

- Avoid placing radii across parting lines to prevent undercuts and flash.

- Consistent use of standardized radii simplifies mold manufacturing and maintenance.

Ensure Your Injection Molding Project Success with Fecision

When it comes to injection molding, partnering with the right expert can make all the difference in your project’s success. To achieve a successful injection molding project, it’s essential to consider the overall cost, not just the upfront costs, as low initial expenses can sometimes hide more significant problems later on.

By partnering with Fecision for your injection molding project, you gain access to decades of specialized expertise. Our comprehensive design review process identifies potential manufacturing issues early, saving you from costly tooling modifications and production delays. Our team collaborates with you to optimize your part design for both functionality and manufacturability, ensuring a cost-effective production approach.