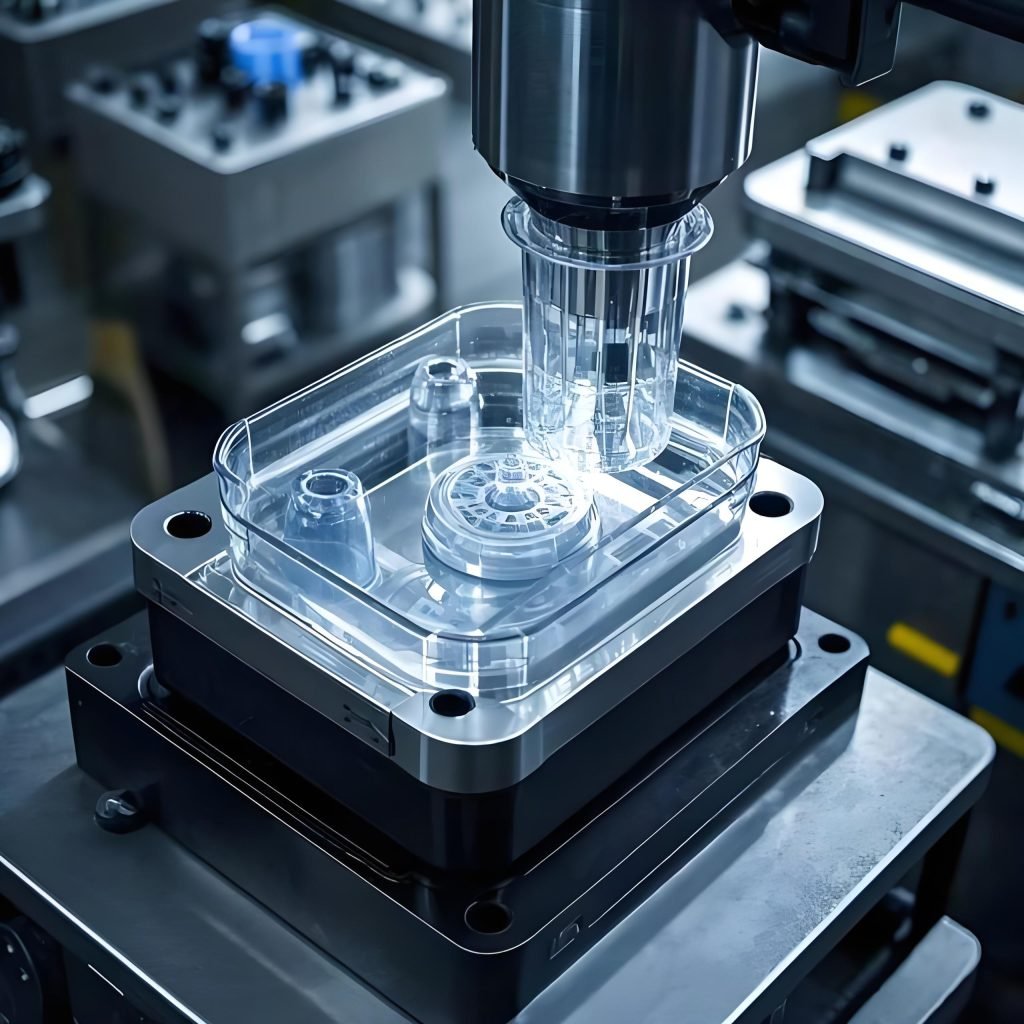

Plastic parts are everywhere in the products we use but not all plastics are the same. Some jobs need plastics that are stronger, more stable, and can handle tough conditions. That is where glass-filled nylon injection molding comes in. Manufacturers make plastic parts that are much stronger and last longer even in demanding situations. They do so by mixing nylon with tiny glass fibers.

This material is popular in areas like cars, electronics, and industrial machines because it performs well under pressure. Here we will explain what glass-filled nylon injection molding is and other details about it.

What Is Glass Filled Nylon Injection Molding?

Glass-filled nylon is regular nylon mixed with tiny glass fibers. This mix makes the material stronger and better at handling stress and heat compared to plain nylon.

The amount of glass fibers can vary usually between 10% and 40% of the weight of material. Adding glass fibers helps spread out stress evenly. So, the part is less likely to bend or break under pressure.

Glass-filled nylon injection molding is great for making high-performance parts that need to be tough and reliable. However, it doesn’t do well in very high temperatures and can lose strength when it gets too hot unlike some other engineering materials.

Glass Filled Nylon Injection Molding Advantages

Injection molded glass-filled nylon has many benefits. That is why it is popular for both industrial and everyday products.

Some of glass filled nylon properties include:

- Increased Rigidity

Adding glass fibers makes nylon much stronger and stiffer. This makes it perfect for parts that need to be tough and hold their shape well. Its strength is more than twice that of ABS plastic.

- Improved Wear Resistance

This material also lasts longer because it resists wear and can handle impacts better than standard nylon. That makes it a great choice for parts that face a lot of rubbing, stress, or rough use.

- Reduced Moisture Absorption

Nylon with glass fibers added soaks up less water. This helps parts to keep their size and shape even in hot and humid places.

- Improved Heat Resistance

Glass-filled nylon handles heat better than regular nylon. For example, reinforced Nylon-66 can resist heat up to 250°C without bending or warping.

- Better Dimensional Stability

One big benefit of glass-filled nylon is that parts made from it keep their size and shape very well. They don’t shrink or warp easily. This is really important when you need precise and accurate parts.

Common Glass Filled Nylon Types

Glass-filled nylon comes in different types, each with varying amounts of glass fibers and types of nylon.

PA12-GF

PA12 is a type of nylon also called Nylon 12 or Polycaprolactone. It is mixed with glass fibers to make it stronger. This type of glass-filled nylon is very stable in size, resists chemicals well, and doesn’t absorb much water.

The glass fiber amount can be between 10% and 30%. Adding more glass fibers makes the material stronger and stiffer. However, it also makes it less flexible and less able to handle impacts.

PA6-GF

PA6 is also popular as Nylon 6 or Polycaprolactam. It is a type of nylon mixed with glass fibers to make PA6-GF. This glass-filled nylon is tough and handles impacts well even in cold temperatures. It also keeps its shape well but can absorb some moisture.

PA6-GF usually has between 15% and 45% glass fibers. The material gets stronger and stiffer when there is more glass fiber. However, it becomes less tough and less able to absorb impacts.

PA66-GF

PA66 is also familiar as Nylon 66. It is a type of nylon mixed with glass fibers to make PA66-GF. This glass-filled nylon is stiffer, stronger, and better at handling heat and long-term stress compared to PA6-GF.

Manufacturers like PA66-GF because it keeps its shape well and absorbs less moisture. The amount of glass fiber in PA66-GF usually ranges from 13% to 50%. Adding more glass fibers makes the material stronger and stiffer. However, it also becomes less tough and less able to handle impacts.

Process Guidelines for Glass Filled Nylon Injection Molding

Glass-filled nylon melts and flows pretty much like regular nylon during injection molding. However, there are some special tips to follow for the best results in glass filled nylon injection molding. It is important to work with someone experienced as these details are handled by the injection molder:

Glass Filled Nylon Injection Molding Temperature Control

The mold needs to be heated between 100°C and 120°C to give the parts a smooth finish. If the plastic is not heated enough, the glass fibers inside can break into shorter pieces. This is especially at the back end of the machine.

This makes the part weaker. Molders use a special heating method that keeps the back zone hotter and the other zones cooler to avoid this.

Moisture

Glass-filled nylon soaks up moisture from the air. So, it needs to be dried before molding. The moisture level should be less than 0.2% for best results. The parts might absorb up to 2.5% moisture after molding which is normal.

Injection Speed

Glass-filled nylon cools and hardens quickly. So, it needs to be injected at medium to fast speeds. Often, the mold is filled in two steps:

- First, a fast fill that takes less than four seconds

- Then a slower fill to finish the process smoothly.

This helps make strong and regular parts.

Injection Pressure

Adding glass fibers to nylon makes the melted plastic thicker and harder to push through the mold. Higher injection pressures are essential because of this. It must be usually between 75 and 100 MPa to fill the mold properly.

Where Glass Filled Nylon Injection Molding Is Used?

Injection molding glass filled nylo is useful to make parts tougher and more resistant to wear. It also improves how well the parts handle chemicals except for very strong acids and bases. Glass-filled nylon injection molding is a popular choice for making strong and long-lasting parts because of this. It works great for both prototypes that need to function like real products and for final parts used in everyday applications.

You will find glass-filled nylon injection molding parts in many areas, including:

- Construction

- Manufacturing equipment

- Electrical parts

- Car parts

- Airplane components

Fecision is Your Trusted Partner for Quality Injection Molding Solutions!

We specialize in high-quality injection molding at Fecision. We use many types of materials to create strong and accurate parts for different industries. We help to bring your product ideas to life in areas you want with our experience and careful work.