The quality and precision of any plastic part made by injection molding depend on how well we understand and control the allowed size differences, called tolerances. Tolerances are the small limits for how much the size of a part can change during the molding process.

Tolerances are very important in plastic injection molding. This is because even small differences can cause problems. For example, two parts need holes that line up for bolts. However, those holes are not the right size or in the right place because of poor tolerance control. It means the parts might not fit together properly. This can cause assembly mistakes and stop the product from working correctly.

This guide will explain why these plastic injection molding tolerances matter and how to adjust them for your specific project.

Factors Influencing Injection Molding Tolerances

Three main things affect the plastic molding tolerances, which include:

Thermal Expansion

Temperature is very important when designing plastic parts. This is because different plastics expand and shrink at different rates when heated or cooled.

Even if a part is made very accurately in the factory, it can change size over time. this is especially when used in real-life temperatures. That is why designers need to choose the right plastic material from the start. For example, PEI handles heat better than plastics like PP or PC. So, it stays more stable in hot conditions.

Materials Shrinkage

All types of plastic shrink a little when they cool down after being molded. This shrinking can change the final size of the part and affects the tolerances. Different plastics shrink at different rates. For example, crystalline plastics usually shrink more than amorphous plastics. This is because their structure changes as they melt and cool. So, the level of plastic shrinkage impacts the final results.

Warpage

When the plastic cools inside the mold, it shrinks. If the part has walls that are the same thickness all around, it shrinks evenly. This helps to avoid problems like warping or dents.

However, if the walls are different thicknesses, some parts cool and shrink faster than others. This can cause the part to bend or warp. If you need to have walls that are not the same thickness, make sure they don’t get too thick. It is better to stick to the recommended sizes to reduce these issues.

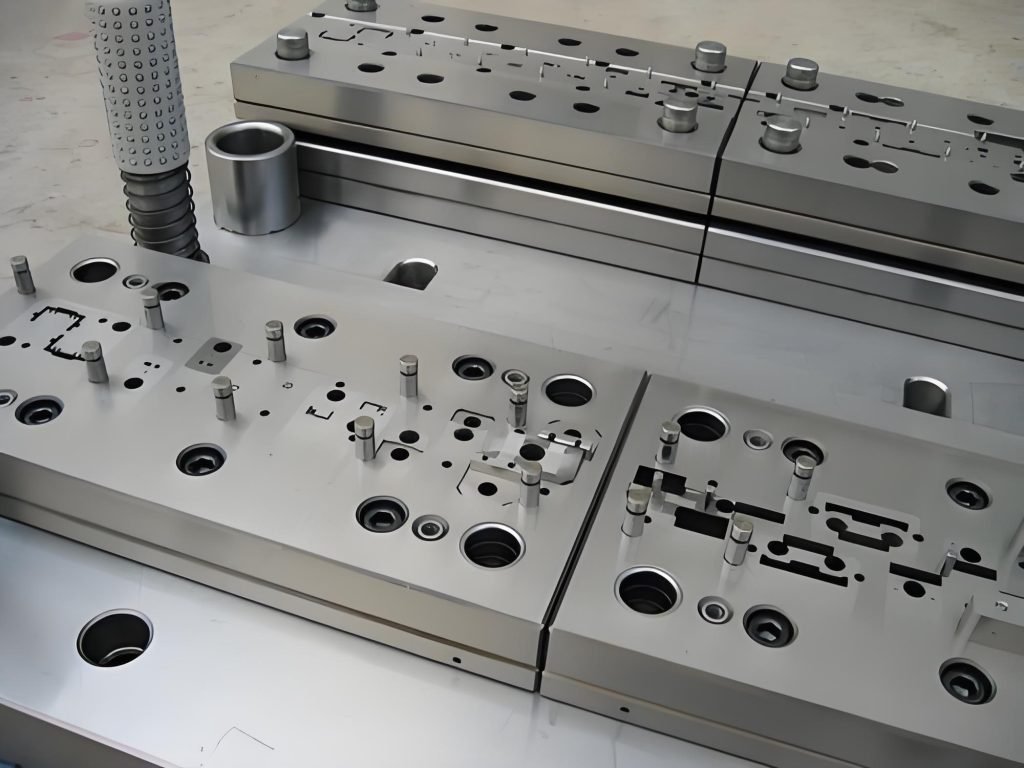

What Are Different Types of Injection Molding Tolerances?

There is not just one type of tolerance for an injection molded part. Tolerances can also be grouped by how precise they need to be. Understanding different types from standard injection molding tolerances to the tight tolerance injection molding is important. Different parts of the piece have their own tolerance limits.

Here are some common ones:

- Straightness or Flatness

This relates to how flat or straight large, flat areas stay. Good mold design like where the plastic enters and how it cools evenly helps reduce warping.

- Dimensional

This is about the overall size of the part. Bigger parts tend to shrink more as they cool. So, tolerances are often given based on size ranges.

- Hole Diameter

Bigger holes usually need a wider tolerance. This is usually because they shrink more during cooling.

- Blind Hole Depth

Blind holes are the holes that don’t go all the way through. So, they need special mold parts. If the plastic is injected with high pressure, then these mold parts can bend especially if the hole is deep.

- Concentricity/Ovality

Uneven shrinking can make them lose their perfect round shape for round parts with thin walls.

How to Mitigate Tolerances in Injection Molding?

You need to think carefully about different factors to get the best results when it comes to mitigating tolerances. These factors usually range from the product design to choice of materials, mold design, and how the process is managed.

Here we will explore some key factors that can help you to mitigate tolerances in injection molding:

- Maintaining Uniform Thickness of Wall

Two simple things can really help when you are designing a part. These things usually include keeping the wall thickness the same all around and making the design less complicated.

Having walls that are of the same thickness is important. It helps the part to shrink evenly. As a result, it keeps the right size. Even more, a simpler shape means there is less chance the part will change shape in unexpected ways.

Simply, it is important to follow Design for Manufacturing rules to avoid problems like shrinking, warping, or parts not fitting right. So, it becomes easy and cost-effective to make the products.

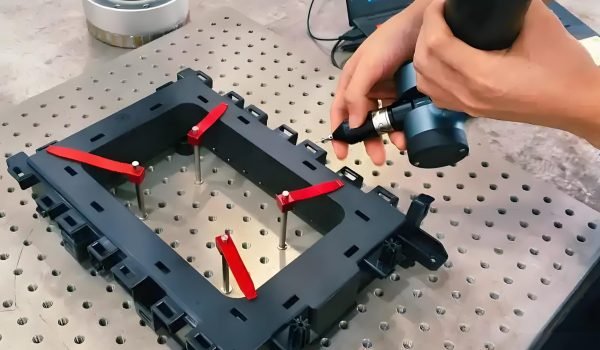

- Ensure Consistent and Stable Cooling

Injection molding tolerances depend a lot on how the mold is designed and how many cavities it has. If the mold does not cool the plastic evenly and steadily, parts can shrink too much or unevenly. This will be making it harder to keep the right size.

The mold and stable cooling are very important for making good-quality parts.

- Proper Process Control

Keeping tolerances tight in plastic injection molding is not just about good design. It also means carefully controlling the molding process. You need to manage different things closely, including:

- The temperature inside the mold

- How fast the plastic fills the cavity

- The pressure used all need to be managed closely.

Once the process is set up well, it is important to keep checking the finished parts over time. This will help you to make sure no unexpected problems show up. As a result, the parts stay high quality and fit just right.

- Material Selection

Picking the right plastic is really important. This helps to make sure that your part comes out the right size and shape. The plastic should shrink evenly and fit the size and design you want. Since different plastics shrink differently. So, it is good to keep this in mind when you pick the plastic and design the mold. This helps your finished part fit and work just like it should.

Choose Fecision for Your Next Project!

Are you looking for experts for your next plastic molding project? Fecision is here to help you with all your plastic injection molding needs. Our experts know how to handle shrinkage and keep tight tolerances. We can make even complex parts quickly and make ordering easy with smooth processes.