Injection molding produces accurate plastic parts for a variety of industries. But short shots can negatively affect production. These imperfections occur when the molten plastic from the injection moulding machine does not fill the cavity of the mould. Parts are, therefore, incomplete, section-missing, or just weakened. “Short shots increase costs on account of rework, scrap.”

To be awarded quality nozzle Loads, the Manufacturer must know how to spread short shots. These are the most common causes, including material problems, settings of the machine, mold design problems and external influences. The identification of these problems is a method for companies to be able to prevent the defects themselves.

Fecision, as an injection molding solution leader, can assist enterprises to overcome the challenge of short shot. This post reviews common causes of short shots and provides some easy, practical remedy ideas. With the proper approach, manufacturers can guarantee the parts will be high-quality, and production will be seamless.

Definition of Short Shots in Injection Molding

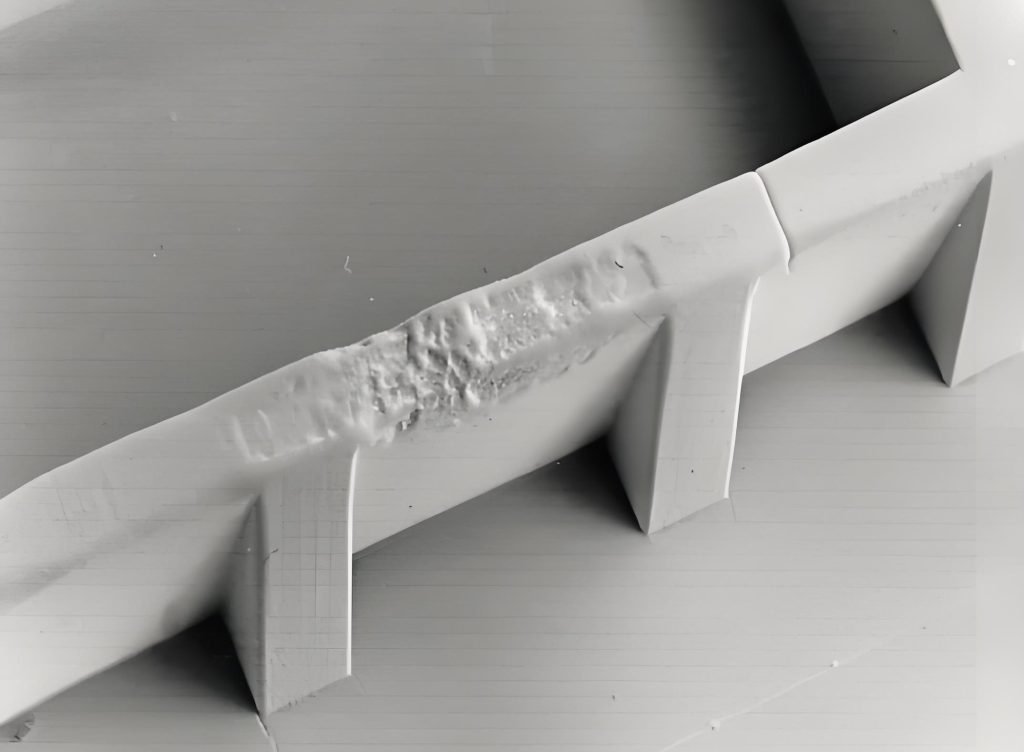

A short shot is an incomplete injection molding that the mold cavity is not filled. As a result, the part has holes in it, thin walls, or is in some way incomplete. This problem compromises the integrity and performance of the part. Short Shots Sometimes Trashy Tooling Or the Wrong Machine Setting the mold incorrectly, or if the tooling is bad or wrong materials are used, the shot will be bad.

Low pressure or temperature, for instance, can prevent plastic from flowing into all parts of the mold. Discovering short shots early is important in order to prevent any waste. Defects of this kind are observed by the manufacturers in the course of quality testing or visual inspection.

To correct short shots, you must know what causes them, such as materials or processing conditions. By solving these issues, companies can ship production-quality parts. Fecision’s many years of experience are an important advantage for manufacturers who want short shots stopped fast to achieve the best product quality and minimize downtime.

Common Causes of Short Shots

Short shots happen for various reasons in injection molding. Physical problems, such as low viscosity or contamination, interfere with flow. In like manner, machine parameters such as low pressure or temperature can restrict the fill of the cavity. Furthermore, there are inadequate material movement because of the errors in mold design, such as insufficient venting or small openings. Environmental conditions, such as temperature fluctuation, are also a factor. In addition, operator mistakes may interfere with the procedure and lack some parts. Knowing the reasons why allows molders to diagnose short shots effectively.

- Compromised Material: Viscosity too low or resin contaminated with debris impedes flow.

- Issues With the Machine: Unproper settings prevent the filling of the whole mold.

- Mold Design: Venting is poor, or the gate size won’t allow enough plastic to flow.

Through an analysis of these issues, organizations can identify the root cause. With the powerful weapons, Fecision can find out and fix this problem effectively. And it will help manufacturers cut down on defects and increase production.

Material-Related Issues

Material issues are a common cause of short shots when it comes to injection molding. For example, low viscosity can mean that plastic has difficulty flowing into complex molds. Resin with moisture can cause bubbles and uneven flow. Again, contamination, such as dirt or foreign matter, can also block the material. They also note that using an inappropriate type of resin in the design of a part causes problems. As a result, the cavity is not completely filled, and poor parts are formed.

- Moisture in resin: If the resin is wet, it will interfere with the flow.

- Blockage: Soil or debris impede routes for mold.

- Inappropriate Resin Selection: If the Resin is mismatched, it will not fill the mold.

To solve these issues, the resin needs to be dried adequately before utilization by the manufacturers. Furthermore, inspection of materials’ quality avoids contamination. It’s also crucial that the correct resin is chosen the mold is for. Through Fecision’s materials testing services, resins can be optimized for their suitability for production, leading to reduced short shots and consistent parts.

Machine and Process Parameters

Short shots are directly affected by the machine. For instance, insufficient injection pressure does not shove plastic into all mold regions. Also, the material is solidified prematurely due to the low barrel or mold temperature. The same applies to unsteady cycle times, which interrupt the flow of material to produce imperfect parts. Improper screws and can result in a low material output. These are the things behind a short shot and a schedule delay.

- Poor Pressure: Little or no force restricts the flow of material.

- Low Temperature: Early gelation because the heat is low.

- Irregular Cycles: Drivers and material do not arrive on the same day.

Pressure and temperature settings should be appropriately adjusted by manufacturers to avoid short shots. Routine machine maintenance helps maintain peak sewing performance. Moreover, process stability is being raised by observing cycle times. Fengchi app’s machine calibration function allows enterprises to adjust parameters; it contributes to non-defect production and avoids waste.

Mold Design Factors

There are a lot of variables in mold design which lead to short shots. For example, inadequate venting will allow air to become trapped in the mold preventing plastic from flowing. Also, all of the cramped or misplaced gates tend to impede the passage of material. Developed mold designs with thin walls or long flow lengths can also contribute to the resistance. Thus, the plastic freezes before it can fill the cavity.

- Bad Venting: The airlock acts as a restriction to the full filling of the bag.

- Small Gates: Small openings that restrict the flow of plastic.

- Elaborate Designs: Slow Path Material Traversal: Long paths build up material in the bends.

Proper venting and the placement of gates are required to prevent short shots. Moreover, the symmetric flow paths allow materials to extend into all sections. Design software can help identify problems early. Fecision has mold-optimizing tools, which can design highly efficient moulds to avoid short shots and improve production quality.

Environmental and Operational Causes

Environmental and process-related causes for short shots. Material behaviour is influenced by unstable room temperature or humidity, for instance. High humidity can allow moisture to enter the resin, which will create flow problems.

Likewise, inadequate cooling yields a cast with non-homogeneous solidification. Operator mistakes, for example, incorrect machine setups, also induce defects. Such things cause disruptions in production and a reduction in the quality of the part.

- Instability: Depending on temperature, temperature or humidity will act on resin.

- Bad Cooling: Inadequate cooling does not make for a full fill.

- Operator Errors: When the setup is not proper, it will yield process errors.

To address these concerns, vendors need to personally manage the environment in which the products are being produced. Cooling systems that keep solidification uniform. The operators need training so they don’t make mistakes. Fecision environment monitoring system to keep the conditions stable to avoid underfilled parts and increase productivity.

Fecision’s Role in Preventing Short Shots

Fecision offers creative ways to solve the problems of insufficient clamping force in injection molding. Advanced Material Testing that resins are dry and free from contaminants! Finally, our machine’s calibration tools allow us to maximize pressure, temperature and cycle times. We provide mold design software to increase venting and gate location as well. Besides, our environment monitoring systems keep stable production conditions. Fecision’s training programmes support operators in avoiding mistakes whilst keeping their operations running smoothly.

- Material Solutions: Test, then decide on the best resin.

- Machine Knowledge: Adjust settings for consistent results.

- Mold Optimization: Design the mold so that flow is not affected.

By working with Fecision, manufacturers can minimize short shots and optimize part quality. Our products are specifically designed to support production while providing a more efficient, dependable and cost-effective performance.

Methods to Prevent and Fix Short Shots

This problem can only be tackled by treating its underlying cause; in other words, to prevent short shots, it is necessary to eliminate the root problem. First, select and dry the correct resin. Then, fine-tune machine settings, such as raising the pressure or temperature. In fact, Enhance mold designs for improved venting and bigger gates. Lastly, manage the environment and train the operators accordingly to prevent mistakes. These actions allow for a full cavity fill and good part quality.

- Material Tests: Dry and test resin before use.

- Machine Settings: Customize pressure and temperature.

- Mold Enhancements: Vents; gate sizes.

Fecision’s advanced injection molding services allow manufacturers to efficiently avoid short shots. Using these techniques, the organization can minimize defects and increase production. Preserving the measurements over time in a routine check-up also guarantees robust data to support the measurements.

A Final Word

Short shots in the injection moulding process result in parts that are unfinished, leading to cost and delay. The common factors are material reasons, machine conditions, mold design problems and ambient conditions. However, when it comes to short shots, manufacturers may have more control than they realize. Resin selection, machine set-up, mold design and production conditions are covered.

Fecision’s cutting-edge products and services can solve these problems for companies and guarantee top-level parts and efficient production. Manufacturers can minimize waste and enhance their competitiveness by working consistently and methodically to address short shots.

Through Fecision, partners can attain reliable, defect-free injection molding, meet the needs of the industry and get repeatable performance.