The core is an indispensable part of the injection molding machine and is responsible for shaping plastic products’ internal structure. That works with the cavity to part of which forms the outer surface of the mold structure. The heart is necessary for the production of voids, narrow regions and undercuts in molded articles. The proper design and integration of the core is a key consideration to dimensional accuracy, reliable quality, and efficient mold performance.

A good design of the core will also enable smooth flow of the material during production, adequate cooling and easy removal of the parts. Mold engineers must analyze core-cavity interaction to control and improve the molding process and product quality.

In this article, the core functionality, design concepts, and their effect on the injection molding process are discussed.

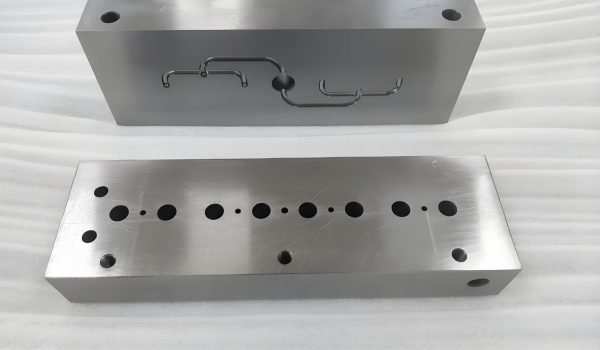

Core and Cavity in Injection Molding

In an injection mold, the core and cavity are two main parts. The cavity gives the outward appearance of the part, and the core gives the direct internal features. Between them, they specify the overall molded product shape. The flow is injected through the gate into the core and cavity, and it is Solidified form in the cavity; it is formed as per the shape of the cavity it is to be.

Typically, the core is a solid metal insert forming voids or undercuts in the part. It enables complex internal designs, such as holes, ribs and undercuts. The cavity, however, forms the outer surface and is typically larger to accommodate the external size of the part. The fit, and thus the occurrence of defects such as flash and under-fill, is dependent on the accuracy of the core cavity interaction.

Core design has an effect on many of the molding parameters. It affects material flow, coolant flow effectiveness, and release of the part. Badly designed cores may cause an inability to remove the part from the mold, damage to the part and the mold, or may cause a slower production time. Considerations for mold makers are core strength, thermal conductivity, and mold material compatibility.

Here at Fecision, we have the experience and technical know-how to design and fabricate injection molds with the highest quality in cores and cavities. We pay attention to details to provide customers with parts with great dimensional accuracy and surface finish. With an optimized core and cavity design, Fecision helps customers get uniform and high-quality products.

Knowing the core and cavity relationship is necessary for a successful injection mold and product function.

Mold Components

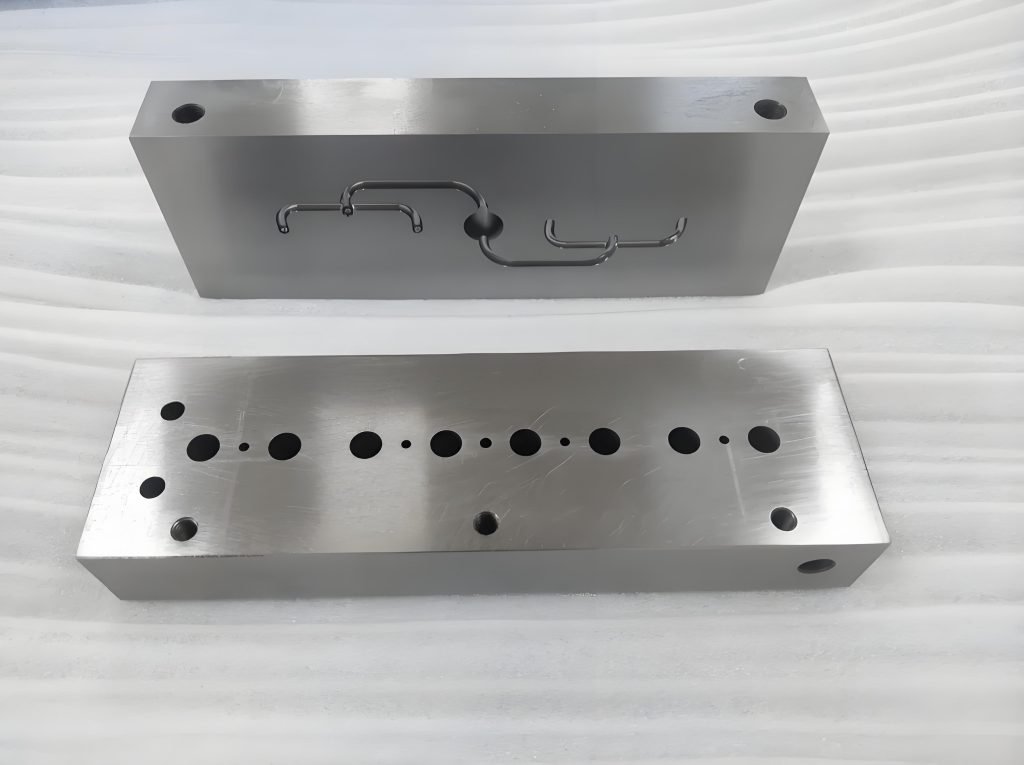

An injection mold is composed of a number of components; the core and cavity, among all, are the most critical components for shaping the part. However, in molds, several other important components serve the operation of the molds during die casting as well. It is these items that cooperate to keep the system free-flowing, in shape, cool and ejected.

Besides the core and cavity, important mold parts include:

- Sprue and runners: Channels that guide molten plastic from the injection nozzle to the mold cavities.

- Ejector system: Pins or plates that push the cooled part out of the mold after solidification.

- Cooling system: A network of channels that circulate coolant to remove heat from the mold and solidify the part quickly.

The part is all about the core and the cavity, but these ancillary items are just as important to the ability to get in and out of the tool in a good cycle. Appropriate molding of all mold parts decreases defects and increases production efficiency.

The overall design itself also affects the final product, as it’s responsible for forming internal features and dimensional accuracy. For instance, a core should have sufficient strength to resist injection pressure and retain shape under exposure to thermal stress. The cooling channels by the core aid in temperature control and prevent warping.

The design and location of every component of a mold demand analysis to strike the right balance between cost, quality and production rate. These parts work together in a complex system to create high-quality injection molded products.

Types of Cores in Injection Molding

Cores are important tools for creating inside geometry in injection molded parts. They are available in different types to address a wide variety of aspects and levels of complexity, depending on design needs. There are two types of cores: fixed cores and movable cores. Each type has its functions and is selected according to the design of the part, mold complexity, and production requirements.

Solid Cores

Solid cores are hard and cannot be moved or retracted within a mold. It is used for simple internal shapes and is fixed to the core print or molding machine with the help of screws and dowels. They are typically constructed of steel or other robust material and, in some cases, are installed flush with the mold base. Solid cores are suitable for simple sections of hollow cavities, tubes or holes, with no undercuts or complex features.

The durability and fabricability are the features of solid cores. Insofar as they do not move, solid cores provide a more rigid tool for the injection and cooling process. They are also very easy to clean and maintain. On the other hand, a solid core is not flexible. They cannot create parts with intricate interiors requiring side actions or release mechanisms.

Movable Cores

A movable core (or slide or side) is designed to make complex internal features or undercuts that cannot be done with a fixed core. These cores are movable in and out of the mold cavity during each cycle of molding to produce parts of complex shapes.

A hydraulic, pneumatic, or mechanical system commonly powers actuatable cores. They open (retract) when the mold opens to eject the molded article without damage. These cores complicate the mold design and are more costly to manufacture but are permissible in producing parts with many details and/or close tolerances.

Examples of Core Configurations

In addition to standard solid or movable cores, specialized core designs exist as part of the molding process. For instance, collapsible cores are employed to produce hollow parts having deep undercuts, such as bottlenecks. These cores shrink to the center to dispense the component in a completely safe manner without either damaging the mold or the component.

Another example is hot-runner cores, which keep the resin molten in the mold channels. These cores result in faster cycle times and less waste.

It is very important to determine the appropriate type of core to produce and quality part and to provide the best plan of production. Mold makers should take into consideration part geometry, molding material and production volume to determine the type of core.

Design Considerations for Cores

Designing the part core is a complex process for injection molding, and several factors need to be considered so that the mold functions properly and generates good parts. A properly designed core will affect material flow, cooling, part release, and overall mold life.

Key considerations in core design include:

- Strength and Durability: The core has to be able to resist high injection pressures without bending. They often use materials that can help keep them in some sort of shape and also prolong the life of the mold.

- Cooling Efficiency: Did you position the cooling lines properly near the core so the rest of the mold can stay cool and cycle faster? Good cooling can avoid warping and cold shrinkage, making the model more high precision.

- Ejection Mechanism: An efficient ejection system is key. The cores must release the molded part without being marked. Ejector pins, sleeves or sleeves with stripper plates are sometimes incorporated.

- Shapes and Undercuts: If the part has undercuts or complicated internal volumes, the core design has to incorporate slides or lifters. These functions assist in releasing the part without damaging or deforming the same.

- Surface Finish: The surface finish of the core affects the appearance of the final part. A smooth surface finish can reduce friction when ejection and extend the life of the mold.

- Tolerance and Fit: Close tolerances between the core and cavity minimize flash (excess material) and provide a seamless fit with accurate dimensions of finished parts.

When these factors are taken into account in core design, the number of defects is reduced, and the production efficiency is enhanced. Designers must further weigh the cost against complexity and choose appropriate general features for the core while avoiding overburdening with costly features.

Final Thoughts

The core is an essential part of the injection mold, which will affect the internal organization and the final quality of the plastic products. Proper design and mating into the cavity are crucial to accurately size and feed material and adequately eject the product. Critical attention to core types, strength, cooling, and surface finish is required to decrease defects and achieve the best possible mold life.

Modern core designs, for example, moving or collapsible cores, can be used to manufacture complex geometries while preserving mold life. Good mold design balances technical needs with cost and manufacturability.

Fecision offers such strong core and mold design capabilities that every project will be from start to finish in a performance that is a reliable and high-quality place. Understanding what the core does allows manufacturers to create predictable, quality parts that are crucial to today’s high-performance applications.