Have you ever seen a faint line on a plastic part that just doesn’t look quite right? That would likely be a weld line, a very common defect in injection molding. These lines look bad and can also affect the strength of the part. But don’t stress too much! In this article, we will talk about what weld lines are in injection molding, what causes weld lines in injection molding, and how to avoid weld lines in injection molding.

What Are Injection Molding Weld Lines?

So, what is weld lines in injection molding? Think about two rivers of molten plastic entering a mold. When the two streams meet, they should naturally bond together to make a single piece. In some cases, they miss the bonding and instead leave a visible line where they have “welded” together, but not quite seamlessly. These are what we call injection molding weld lines, and you might also hear them referred to as knit lines.

This imperfect fusion happens for a bunch of reasons. It could be how the plastic flows in its natural state and how fast or at what pressure it’s injected. It could also be the temperature or even the design of the mold. Think of it as if you are tying two ropes together. If conditions aren’t ideal, you might get a weak knot instead of a strong strand. The weld line in injection molding is the weak knot.

Causes of Injection Molding Weld Lines

If you understand why weld lines exist, it’s like a superpower that allows you to deal with them. Let’s outline the most common reason these pesky lines occur:

Pressure

If the pressure isn’t sufficient, the molten plastic flow fronts won’t have enough force to combine into a homogeneous part. Consider merging two pieces of playdough. If you don’t push with enough pressure, the two will not merge properly, with a separation or gap. Lack of pressure will not allow the polymers to truly become a single homogeneous part, contributing to a prominent weld line defect in injection molding.

Temperature

Temperature is vital. If the molten plastic cools down too much before the flow fronts meet, it solidifies. The result is a distinct, often weak, weld line. Maintaining the right temperature ensures the plastic remains fluid enough to bond completely.

Mold Design

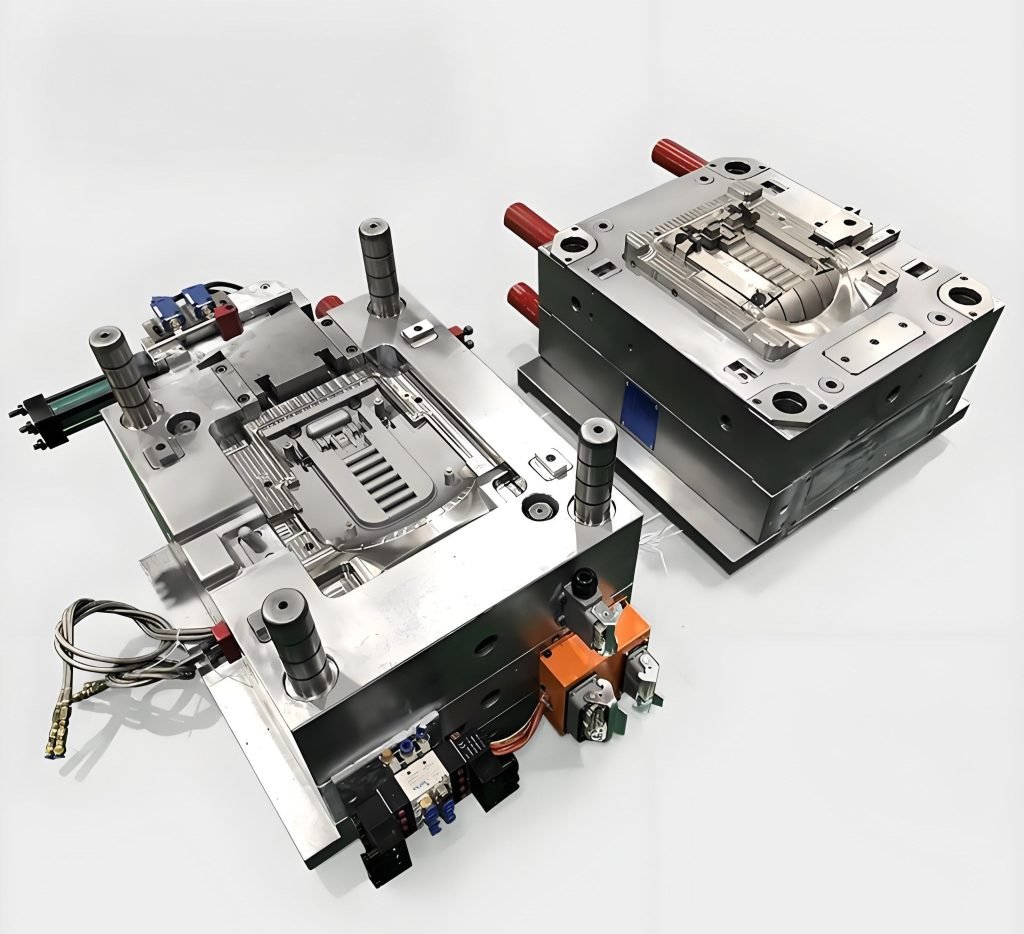

A poorly designed mold can be a major contributor to weld lines injection molding. If the gate locations (where the plastic enters) or the internal flow channels are poorly laid out, molten plastic will not flow smoothly. The molten plastic will split and rejoin in such a way that a weak, visible line is created. A good mold design will guide the plastic on its way, minimizing opportunities for these lines to form, thus answering how to reduce weld line in injection molding through design.

Speed

The injection speed plays a big role. If the molten plastic is injected too slowly, the flow fronts can cool down to a temperature where they will not fuse properly. Compare it to two slow-moving trains trying to couple; if they lose momentum before properly connecting, they will never properly couple. If the injection speed is too low, the plastic will not be fluid enough to bond together properly and will create a visible weld line. This directly impacts how to reduce weld line in injection molding.

Impurity

Unwanted contaminants can create turbulence, disrupting the orderly and uniform flow of molten plastic from the production shot into the mold’s cavity, stopping the flow fronts from merging accurately, and producing knit lines. Always ensure your resin is as pure as possible for optimal flow, as impurities are another factor in weld line injection molding.

Excess Mold Release

Mold release agents help parts eject easily, but too much can backfire. Too much mold release agent on the mold surface can create friction, requiring more force to push the plastic through. This added friction can provide for an uneven flow pattern, resulting in injection molding weld lines. It is a balancing act – plenty enough to avoid sticking, but not too much to impede the proper movement of the plastic.

Why You Should Avoid Weld Lines

Weld lines are much more than just an ugly-looking nuisance; they can reduce your part’s performance and integrity.

The strength of the injection molding weld lines is usually weaker, making them prone to structural failures like breaking or cracking when a load is applied or after repeated and continuous use. If your part will be subjected to loads or highly dynamic impacts, the weld line will provide the structure for the failure. The resulting failure can be costly, and worse, damage your product’s reputation.

Besides strength, aesthetics are important in many situations. For consumer electronics, automotive interiors, or medical devices, a visible weld line can raise quality concerns. Even if a part meets functional performance at 100%, the impression a weld creates can diminish a customer’s satisfaction of ownership. Thus, avoiding weld line defect in injection molding is crucial for both structural integrity and a flawless appearance for conforming and durable injection-molded plastics.

How to Avoid Weld Lines in Injection Molding?

Now for the solutions! Elimination of injection molding weld lines employs a number of facets of the part, your part design, mold design, and molding conditions. Addressing each of these factors could potentially lead to a great improvement in weld line reduction.

Part Design

The journey to a weld-line-free part often starts long before any plastic touches a mold. It begins at the design stage. Smart part design can preempt many of the issues that lead to weld line defect in injection molding.

Increase Wall Thickness

One of the simplest actions to mitigate and eliminate injection molding weld lines is to increase your part thickness in certain locations. Increasing wall thickness gives a pool of molten plastic more time and space to flow, and also the material has an increased time staying warm while filling the cavity or mold. A hotter plastic melt has a lower viscosity, which allows for better fusing of the two melt fronts to create a stronger and less obvious bond.

Reduce Part Thickness Ratio

You should also consider how to create a more evenly distributed thickness ratio throughout your part. Parts with sections whose thicknesses vary can create different flow and cooling rates of the plastic, which generally leads to problems when two melt fronts meet. By eliminating major differences in thickness, you create an environment that allows the molten plastic to flow together uniformly. A uniform flow is important to ensure that the melt fronts are still hot and molten enough to bond together and “close” potential weld lines in plastic injection molding.

Adjust Gate Dimension and Position

The gate size and positioning must be considered. The gate is the entry point for plastic into the mold cavity. A gate that is too small can impede flow or create a melt front that’s too late, and the plastic will cool before it fills the mold cavity. Even more important is the influence of the gate’s position on the weld line injection molding.

By adjusting the gate’s dimension (making it larger for better flow) and its position, you can control where the melt fronts meet. The goal is often to place the gate so that any potential weld lines form in less critical or less visible areas of your part. Ideally, you want these lines to form closer to the gate, where higher packing pressure can help to minimize their appearance and improve their strength. Strategic gate placement is a powerful tool in your fight against weld line defect in injection molding.

Mold Design

Outside of the part itself, the design of your mold can make a huge difference in avoiding weld lines injection molding. A well-designed mold will perform as a perfect conduit, directing the molten plastic in a flawless manner.

Increase Gate and Runner Size

The runners are the channels guiding molten plastic to the gates and into the mold cavity. If these runners and gates are too small, they restrict plastic flow, causing pressure drops and premature cooling. This can also trap air, hindering proper fusion. By enlarging your gates and runners, you can create plenty of room from the points of entry. The result is a better fusion of melt fronts and a significant reduction in weld lines in plastic injection molding.

Change Gate Design

The specific design of your gate—its shape and type, not just its size or location—can also profoundly influence weld lines. Different gate designs affect how plastic enters the cavity and how melt fronts converge. For instance, a fan gate can spread plastic more evenly, while a tab gate might suit thicker sections.

By choosing or modifying the gate design, you can influence where weld lines form or even eliminate them. The aim is to design a gate that promotes optimal fusion and minimizes visibility. Sometimes, a well-chosen gate design can ensure that any unavoidable injection molding weld lines form closer to the gate, where higher packing pressure can help compress them, making them less noticeable and stronger.

Proper Venting

Think about filling a water bottle without allowing any air to escape! Impossible, right? In injection molding, the same is true. As molten plastic comes in, all the trapped air has to go somewhere. If you do not vent your mold, the stuck air can keep the melt fronts from completely joining together, producing voids or weld lines.

Venting is all about small channels in the mold that allow air to escape as the plastic flows. This isn’t just for a clean appearance; it’s crucial for good mechanical properties. When air is effectively removed, plastic fills the cavity completely and uniformly, ensuring melt fronts meet without air pockets. This leads to better fusion, stronger parts, and fewer visible weld lines.

Adjust the Molding Conditions

Even with perfectly designed parts and molds, the molding process itself also needs to be considered when you think about improving the prevention of weld lines. The conditions under which the plastic is injected and cooled are crucial.

Increase Melt Temperature

Think of honey: it flows slowly when cold but easily when warm. Molten plastic behaves similarly. If your melt temperature is too low, the plastic will have too much viscosity and will cool down too fast to flow fully through the mold. This will make it difficult for melt fronts to fuse completely. When the melt temperature is raised, you create a more fluid melt and an opportunity for the plastic to stay molten longer, so the polymer can flow more completely together, which ensures stronger and less observable bonds.

Optimize Injection Speed and Pressure

Finding the correct injection speed and injection pressure is important. If the injection speed is too slow, then the melt cools before the mold is full, which will result in an incomplete fusion. If the injection speed is too fast, then the pressure will induce turbulence, and poor fill or cold spots will occur within the part.

Similarly, pressure is vital. You should obtain enough pressure to pack firmly and fill the cavity completely. It is very important to optimize for injection speed and packing pressure to ensure the cavity is filled uniformly, which gives the molten plastic the best chance at good fusion where the melt fronts meet. This balance results in parts with minimal weld lines in plastic injection molding and superior mechanical properties.

Conclusion

In conclusion, weld lines represent one of the common obstacles in injection molding. They typically lead to some loss of strength and visual flaws in parts. However, when you thoughtfully optimize your part design, meticulously complete your mold design, and thoroughly adjust your molding conditions, it helps ensure that injection molding weld lines are negligible or even nonexistent.

At Fecision, we understand the critical importance of producing flawless parts. That’s why our injection molding services are specifically designed to tackle and prevent injection molding weld lines. We leverage

- Advanced mold flow analysis to predict potential defects and help to eliminate them, even before you produce parts.

- Precision temperature and pressure control to ensure the best possible material combinations (fusion directed towards guaranteed merging of flowing plastic streams).

- Expert design and development assistance to help optimize both your parts and your mold and avoid any flow-related issues that could lead to weld lines.

Need weld-free, high-quality parts you can rely on? Look no further. Contact Fecision today for reliable and precise injection molding solutions.