Have you ever wondered how your car doors, appliances, or even airplane panels are made with such precision and durability? The answer lies in sheet metal stamping. It is one of the most widely used yet least understood manufacturing processes.

According to Precedence Research, the global metal stamping market is projected to reach $324 billion by 2034. This shows the growing demand for this process in the automotive, aerospace, and electronics industries.

In this guide, we’ll explain how sheet metal stamping works and why it continues to be a go-to solution for high-volume, high-precision metal part production.

What Is Sheet Metal Stamping?

Sheet metal stamping is a manufacturing process used to turn flat metal sheets into specific shapes using tools called dies and a stamping process. Think of it as using a cookie cutter, but instead of dough, it’s thin sheets of metal, and instead of baking, it’s shaping with intense pressure.

In this process, a metal sheet is placed into a stamping press, which then uses a die to cut, bend, or shape the material into the desired form. These forms can be as simple as brackets or as complex as automotive body panels.

Steel Sheet stamping is widely used in modern manufacturing because it’s fast, highly accurate, and ideal for consistently producing high volumes of parts.

Step-by-Step Sheet Metal Stamping Process

Here’s how the stamping manufacturing process typically works:

1. Designing the Part

Every metal stamping project starts with a great design. Engineers use CAD software to design the part, and the custom dies needed to shape it. This phase is crucial because even a small design error can result in costly scrap or production delays.

During this phase, tolerances, bend angles, hole placements, and material behavior are all accounted for. The goal is to ensure that the part performs as expected in its final application once stamped.

2. Choosing the Right Material

Next, you’ll need to select the appropriate type and thickness of sheet metal. For example, steel sheet stamping is ideal for high-strength applications, while aluminum is better for lightweight or corrosion-resistant parts.

Here’s what’s considered during material selection:

- Tensile strength: Can the material withstand the pressure of stamping?

- Formability: Will it hold its shape without cracking?

- Corrosion resistance: Is it suitable for outdoor or high-moisture environments?

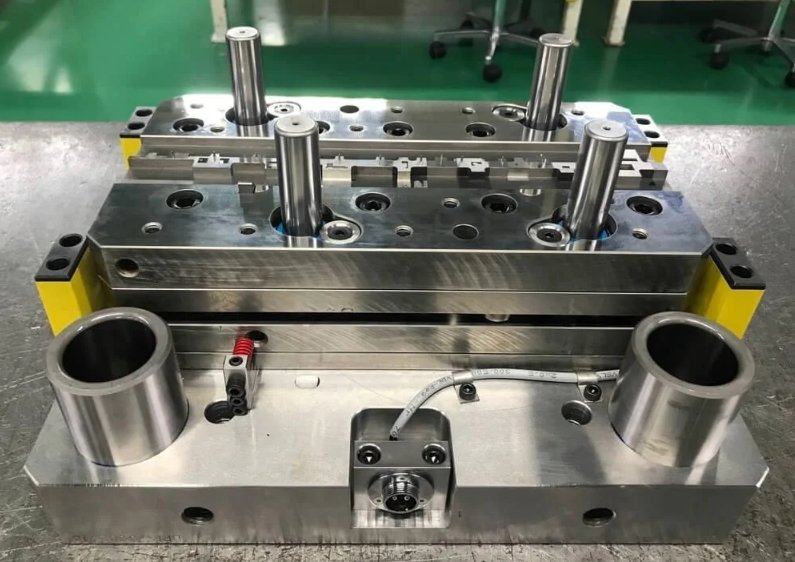

3. Tool and Die Setup

Now, it’s time to prep the tooling, the custom-built dies that shape the metal. These dies are created based on the part design and mounted inside a stamping press. Tooling setup includes calibrating the press, installing the die sets, and configuring feeders if coil material is used.

Even a tiny misalignment can ruin hundreds of parts in the precision stamping manufacturing processes, so accurate setup is non-negotiable.

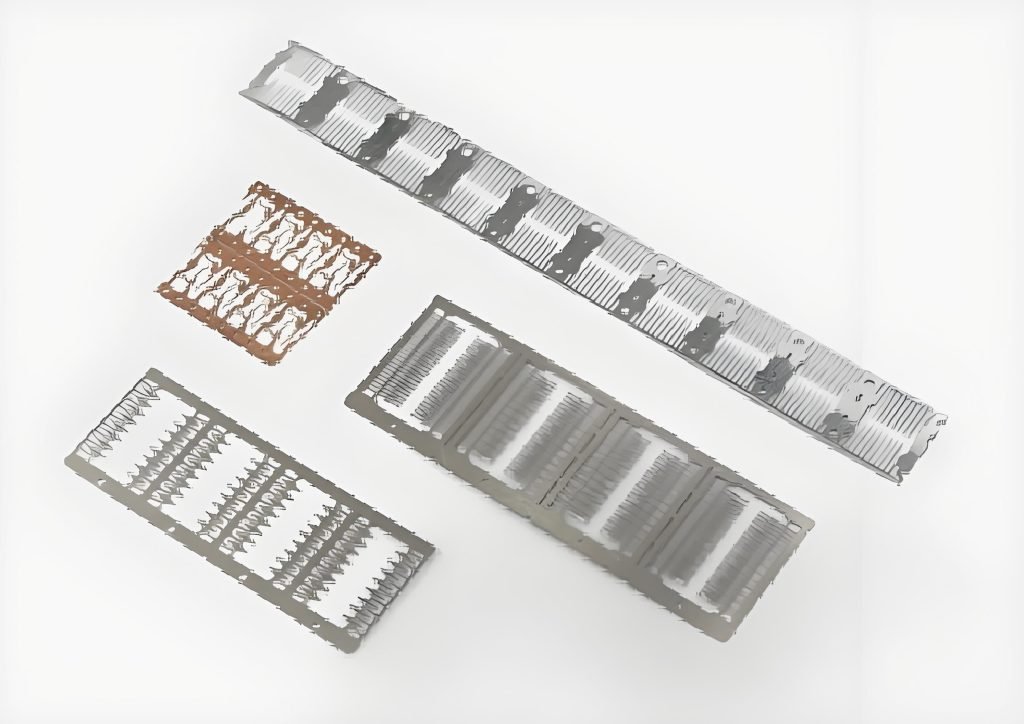

4. Blanking, Bending, Forming, and Coining

The stamping process typically involves several forming techniques in sequence:

- Blanking: Cutting flat shapes from the sheet, like cutting dough with a cookie cutter.

- Bending: Folding the metal into specific angles or curves.

- Forming: Stretching or compressing the metal to create complex 3D shapes.

- Coining: Applying high pressure to stamp fine details or create sharper edges.

These steps may happen in a single die or across multiple stations, depending on part complexity.

5. Secondary Operations

Once the initial stamping is done, many parts require secondary operations to be functional or assembly-ready. These may include:

- Deburring: Smoothing out sharp edges left by punching or cutting.

- Tapping or drilling: Adding threads or holes if not completed in the main press.

- Plating or coating: Applying a protective or decorative finish.

- Heat treating: Hardening the metal for added durability.

Common Types of Stamping Techniques

Below are four of the most widely used techniques in the stamping process:

| Stamping Technique | What It Does | Best For | Downsides |

| Progressive Die Stamping | Uses a continuous strip fed through a die with multiple stations. | High-volume production of small to mid-sized parts. | High tooling cost upfront. |

| Transfer Die Stamping | Moves individual blanks from one station to another. | Larger and more complex parts like chassis components. | Slower than progressive stamping. |

| Deep Draw Stamping | Forms flat sheets into deep, hollow shapes. | Cylindrical parts such as cans, sinks, and oil pans. | Limited to ductile materials. |

| Fine Blanking | High-precision process that creates clean edges and tight tolerances. | Precision gears, washers, seat belt components, etc. | More expensive process and requires specialized equipment. |

Benefits of Sheet Metal Stamping

If you’re thinking of using a sheet metal stamping technique, here’s what you can expect as an outcome:

1. High Production Speed

Sheet metal stamping is incredibly fast. Once the tooling is set up, the press can produce hundreds or thousands of parts per hour. This makes it perfect for industries where time matters, like automotive or appliance manufacturing. The speed keeps the production lines moving and reduces delivery timelines.

2. Cost-Effectiveness for Large Volumes

While the initial tooling setup can be expensive, metal stamping becomes surprisingly affordable when produced in large quantities. The more parts you make, the lower your cost per part. That’s why this process is widely used for mass production, as it spreads the tooling cost over thousands of pieces.

3. Precision and Repeatability

Stamping machines are designed to apply consistent pressure with each cycle, which means the parts they produce are nearly identical. Whether you need 1,000 or 100,000 pieces, metal stamping ensures every part has the same dimensions, hole placements, and bends with little room for error.

4. Versatility in Part Complexity

From simple brackets to complex 3D shapes, metal sheet stamping and other techniques can handle a wide range of designs. Multiple features, like holes, curves, and embossing, can all be done in a single press cycle. This makes stamping flexible for both basic and intricate component designs.

Sheet Metal Stamping vs. Other Metal Forming Methods

Here’s a simple comparison between the stamping process and other metal-forming methods:

| Method | Best For | Speed | Precision | Cost | Material Waste |

| Sheet Metal Stamping | High-volume, uniform metal parts. | Very High | High | Low | Low |

| Laser Cutting | Custom, low-volume parts with complex shapes. | Medium | Very High | Medium to High | Moderate |

| Casting | Complex, large, 3D parts. | Low | Medium | Low (Large Batches) | Low |

| Forging | Extremely strong components. | Medium | Medium | Medium | Low to Moderate |

| CNC Machining | High-precision, low-volume custom parts. | Low to Medium | Extremely High | High | High |

Partner with Fecision for Precision

Sheet metal stamping is more than just a manufacturing method—it’s the backbone of scalable, high-precision production. But getting great results doesn’t just depend on the process; it also depends on who you trust to deliver it.

If you’re actively working in the manufacturing industry, we’re here to help. At Fecision, we specialize in mold tooling, CNC machining, and custom molding services that are customized to your exact specifications.

Let Fecision provide the tools and expertise to turn your designs into perfectly finished parts!