Manufacturers who operate in today’s accelerating manufacturing sector value precise metal products which maintain both high endurance levels and affordability. Metal die casting stands as one of the most dependable manufacturing approaches which manufacturers frequently use today. Manufacturers get access to create intricate metal parts which demonstrate excellent dimensional accuracy along with superior mechanical properties and smooth surface finishes through this process. Companies use die casting technology to create premium components through mold injection of molten material under high pressure which delivers strong and reliable parts for different industries.

None of the automotive industry and the aerospace industry as well as consumer electronics and industrial equipment sector can operate without die cast metal parts because these components combine productivity with strength and operational efficiency for big-scale production. The production of complex shapes through metal die casting occurs faster and cheaper than alternative metal-forming methods while generating reduced manufacturing waste. The following analysis details the die casting manufacturing approach with its various forms as well as explains essential benefits and outlines the service selection process for business operations.

Understanding Die Casting

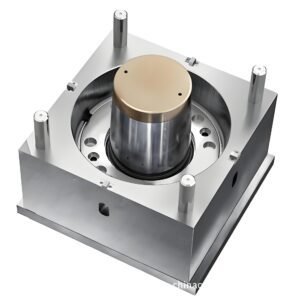

Die casting constitutes a sophisticated metal manufacturing operation that utilizes steel mold dies to create accurate components through forceful molten metal injection. The manufacturing process builds pressure until the metal material consumes every inch of selected mold interior for exceptional pattern replication. Manufacturers select die cast metal for their industries because it enables production of complex designs while meeting stringent dimensional requirements.

The use of metal die casting eliminates the volumes of discarded materials and eliminates the requirement for post-production machining that results in cost reduction. The efficiency of die casting makes it a prominent choice for manufacturing process since this technique achieves high consistency and precision in addition to structural strength. The finished products possess enhanced durability together with excellent surface quality allowing them to be deployed either for direct application or for further engineering operations.

The Die Casting Process

Quality production through the die casting process requires multiple essential stages that decrease the number of product flaws. The various stages specifically contribute to creating a final die cast metal product by enhancing its strength alongside improving surface finish and overall functionality.

1. Mold Preparation

The initial step involves die cleaning and subsequent lubrication application for avoiding sticking and making final product removal simple. The mold needs preheating treatment to enable even metal flow and avoid formation of defects like cracks or cold shuts. The preparation of molds leads to higher efficiency during metal die casting operations thus extending die longevity and producing better quality casted parts.

2. Injection

During the process the finished mold receives molten metal into the die cavity through high-pressure injection. During high-pressure injection of metal into the mold each detail becomes completely filled leading to parts which demonstrate exceptional precision and fine detail. Die casting demonstrates superior capability in producing complex forms which explains why industry professionals choose it for making intricate mechanical and structural components.

3. Cooling and Solidification

The molten material that enters the die cavity starts to cool because of which the metal begins its transformation into solid form. The cooling of molten metal for casting depends on the chosen metal type in combination with the thickness of the produced pieces. The desired mechanical qualities in die cast metal parts require proper cooling since it affects both their strength and density and internal structure formation.

4. Ejection

When solidification of the metal is complete the mold automatically opens to release the newly made casting. Modern metal die casting workplaces use automated systems to perform this operation which eliminates manual labor while providing operational speed.

5. Trimming and Finishing

Once ejected, the cast part may have excess material, (e.g. flash, runner, sprue) which are removed to produce the final part shape. In some applications, the die cast metal component may also undergo additional finishing processes for the purposes of improving appearance and improving usability such as polishing, plating, painting and machining.

Types of Die Casting

According to the type of metal used and the way of injecting molten raw metal, the die casting process is divided into two main types. There are different methods that have their own advantages and are applicable with particular applications.

1. Hot Chamber Die Casting

However, metals having low melting point such as zinc, magnesium and some lead based alloys are mostly used in hot chamber die casting. During this process the metal is kept in heated chamber and through it is directly injected into mold. Because the cycle times are fast, this method is favored for high volume production and is extremely efficient for high volume production. The hot chamber technique is ideal for small to medium size parts needing precise detailing and high surface finishes and is a metal die casting technique.

2. Cold Chamber Die Casting

In some other instances (aluminum, copper, brass) metals with higher melting points are cold chamber die cast. Melt of the metal is in the same way done in the separate furnace, put into the die cavity. It is slightly slower than the previous method but is essential for metals that have to resist to higher temperatures. Cold chamber casting die cast metal parts are well known for their superior strength, corrosion resistance, and high thermal conductivity which is a perfect fit to applications in the automotive and aerospace industry.

Benefits of Die Casting

Despite the surface defects usually present, die casting is probably one of the most preferred methods of producing precision parts directly from molds.

1. High Precision and Consistency

Metal die casting is very accurate, thus allowing manufacturers to produce intricate shapes and tolerances. Mass production is therefore ideal since this high repeatability of the process guarantees identical die cast metal components from each.

2. Strong and Durable Components

New parts that are effectively produced using die casting exhibit excellent mechanical properties including high tensile strength and impact resistance. Due to its dense, non porous structure of die cast metal, it is very durable and so long lasting in rough environments.

3. Cost-Effective for Large Production Runs

Although the equipment cost of casting dies of metal is high, the cost of this process decreases significantly if the scale of production is large. This enables rapid production of thousands of parts that are the same.

4. Smooth Surface Finish

Produce parts with a smooth surface finish is a big advantage for die casting because then no extensive post processing is required. Reducing machine work also cuts costs of material usage and improves appearance of the final product.

Choosing the Right Die Casting Service

One such decision that affects quality, performance, and cost of your final product is choosing the right metal die casting service. Actual key aspects in the evaluation of service providers are the industry expertise, technical knowhow, material capabilities, production capacity and extremely strict quality control. Reputable die caster manufacturers are able to thoroughly understand different metal alloys and recommend the proper metal for your application depending on the specific solving it (aluminum, zinc, magnesium).

Fecision is a company that produces high quality die cast metal components that are suitable for a large number of industrial requirements. We are equipped with our state of art manufacturing facilities that have advanced metal die casting technology to sue to make highly precise and durable parts with excellent consistency. From mold design and material selection, through final inspection and finishing, quality control is held to the strictest standards throughout every stage of the die casting process. We take pride in making sure that every die cast metal component is at its highest standards possible in the industry.

However, cost efficiency is another crucial factor when selecting a metal die casting service, other than quality. Fecision makes the best value for our customers’ money by packing our production processes full with the least waste of materials and with lowest cost in operation. Offering both small prototype batches as well as large-scale production, we dedicate ourselves to providing you with the best in die casting for your unique needs.

Conclusion

Die casting is a very important manufacturing process, which provides unmatched precision, strength and cost efficiency of the metal parts in different industries. Metal die casting is a perfect mid-range offering in between a high volume production and custom designed parts that provide durability coupled with design flexibility. Die cast metal has the ability to create complex geometries that are required with tight tolerances that make it an ideal material for automotive, aerospace, electronics and industrial applications.

Fecision owns a leading edge metal die casting service that provides superior product quality and reliability. Delivering die cast metal components and high performance standards is our expertise, our technology, and our rigorous quality control. We are a trusted partner if you are searching for a reliable die casting company, and we’d like to be your choice of partner for precision engineered manufacturing solutions.