TPU injection molding process turns soft, rubber-like pellets into tough, elastic parts. From phone cases to car seals, one shot delivers remarkable flexibility, abrasion resistance, and vivid color right off the press. This guide will teach you how TPU pellets for injection molding are selected, how the ideal TPU injection molding temperature is tuned, and how to design perfect walls and ribs.

What Is TPU Injection Molding?

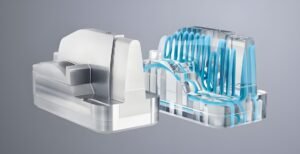

TPU injection molding is a high-pressure manufacturing method that creates durable, elastic parts. The process involves quickly injecting the molten, flexible polymer into a closed, precision mold. The TPU then cools and solidifies fast inside the cavity. This allows for the rapid, reliable production of complex shapes with excellent size consistency.

TPU offers a remarkable range of physical properties right in the same machine press. You can achieve a wide Shore A–D hardness range simply by changing the material grade, from very soft grips to semi-rigid structural parts. The ability to use regrind also helps reduce waste, and TPU can be successfully over-molded onto PC or ABS.

Understanding TPU Pellets for Injection Molding

The initial and most important step for a successful project is selecting the correct grade. TPU chemistry is extremely flexible, providing various fundamental types designed to meet specific needs of different environments.

Types of TPU Pellets

TPU pellets for injection molding are primarily categorized by their chemical backbone (like polyether or polyester), which determines basic performance, and then refined into specialized compounds for specific applications.

Polyether-based TPU

This type of Polyether-based TPU offers excellent low-temperature flexibility and typically has minimal water absorption. This makes it the preferred choice for specific applications. These include winter sports equipment, flexible medical tubing, and outdoor weather seals that must perform reliably in cold climates.

Polyester-based TPU

If your part will be exposed to harsh environments, polyester-based TPU is recommended. It provides much better oil and UV resistance. Therefore, it is often selected for demanding industrial applications like under-hood automotive seals and high-performance industrial belting.

High-flow grades

If you are designing parts that have thin walls, like small electronic cases, or long, narrow channels, you need to select high-flow TPU. These grades have a high MFI (Melt Flow Index). This high flow helps the material quickly fill the entire mold without needing huge amounts of pressure from the machine.

Reinforced compounds

Sometimes you need the flexibility of TPU but also require extra stiffness. In these cases, you can use reinforced compounds. These pellets are pre-compounded with materials like glass or aramid fiber to significantly boost the material’s modulus while still retaining a high degree of useful elasticity and toughness.

Key Material Properties

Every TPU grade comes with a specific data sheet outlining its core capabilities. Understanding these properties helps you match the material to the performance your part needs.

Hardness Spectrum

The Shore hardness of TPU covers a vast range, from very soft grades like 60 A (similar to a pencil eraser) up to semi-rigid grades at 70 D (like a hard plastic tire). This spectrum allows you to use TPU for soft grips as well as more structural, semi-rigid elements in one material family.

Abrasion & Tear Resistance

TPU is highly regarded for its toughness. It consistently outperforms most TPEs in demanding Taber abrasion and trouser-tear tests, making your parts last much longer in applications where sliding or pulling forces are present, such as in conveyor systems or footwear.

Compression Set

This is a critical property for sealing applications. Compression set measures how well the material recovers its original shape after being squeezed for a long time. TPU generally recovers very well, making it the superior material choice for long-term gaskets, dampers, and cushioning elements.

Chemical & Hydrolysis Behavior

Material grades must be matched to fluid exposure conditions. Ether types resist hydrolysis (breakdown by water), while ester types withstand oils and fuels better. Carefully check the manufacturer’s data sheets to ensure the material you choose will survive your specific operating environment.

Regrind Stability

Sustainability is key, and TPU helps you achieve it. Up to 30% regrind can often be incorporated without significantly impacting the material’s key mechanical properties. However, manufacturers must ensure the regrind is properly dried and screened for contaminants before reuse.

TPU vs TPE Injection Molding

You might be debating between these two flexible materials for your product. Understanding the core differences between TPU vs TPE injection molding is crucial for performance and cost.

Chemistry Snapshot

The difference lies in the molecular structure. TPU contains hard urethane blocks that are chemically bonded and form an ordered, strong structure. Generic TPE (Thermoplastic Elastomer) is typically a simpler styrenic or olefinic blend that lacks these ordered, segmented hard components, resulting in less inherent strength.

Abrasion Performance

When you look at how materials wear down, injection molded TPU consistently shows much less mass loss in Taber wear tests compared to styrenic TPEs. This superior resistance to abrasion means that TPU is a better investment for any component that deals with friction, such as protective pads, wheels, and coatings.

Processing Window

TPU maintains a very stable processing temperature range, typically between 180°C and 220°C. This wide and reliable window makes machine setup and adjustment easier for manufacturers. In contrast, many TPE grades risk thermal degradation or “burning” when processed near the upper end of this temperature range.

Part Cost

Raw TPU material generally costs more per kilogram than basic TPE. However, because TPU has inherently higher strength, you often have the flexibility to design and mold thinner walls while maintaining performance. This strength advantage can ultimately help balance the overall production expense in large manufacturing runs.

Quick Comparison

| Feature | TPU (Thermoplastic Polyurethane) | TPE (Thermoplastic Elastomer) |

| Structure | Ordered (Urethane Blocks) | Broad Category (e.g., Blends) |

| Inherent Strength | Higher | Lower |

| Abrasion Resistance | Superior | Good |

| Chemical Resistance | Excellent | Moderate |

| Processing Window | Stable / Wide | Narrower / Risk of Degradation |

| Raw Material Cost | Higher | Lower |

| Thin Wall Capability | Good (Stronger) | Fair (Weaker) |

The TPU Injection Molding Process

TPU is highly versatile, but achieving successful molding requires specific, precise control over the machine settings. Now, let’s review the key steps and critical adjustments that manufacturers must carefully follow.

Drying Requirement

Moisture control is fundamental to part quality. Pellets require drying at 80-110°C for 2-4 hours until moisture content measures below 0.02%. Inadequate drying generates surface defects including flow marks and gas bubbles from moisture vaporization during injection.

Screw & Barrel Set-up

Manufacturers should use a low-compression screw with a moderate L/D ratio, such as 20:1. The screw and barrel surfaces must be smooth or nitride-coated. This specific design helps to effectively minimize excessive shear heat. It also actively reduces the chance of the very sticky TPU material adhering to the metal surfaces.

Temperature Ladder

A typical melt profile involves a gradual increase in heat: the rear zone might be set at 180°C, the middle at 200°C, and the nozzle at 210°C. It is also important for operators to keep the screw RPM moderate. This ensures the plasticizing process is effective while still limiting the shear heating that can degrade the material.

Injection Profile

The injection cycle should start with sufficient peak pressure and speed to quickly fill the mold cavity. After the cavity is mostly filled, the pressure must drop to a lower pack pressure. The manufacturer must carefully adjust this profile to ensure the part is fully dense while simultaneously avoiding cosmetic defects like jetting or weak weld lines.

Mold Cooling Strategy

The main objective is cooling the cavity surface just enough for rapid solidification. Yet, the surface must remain warm to help material flow and prevent premature freezing. Using turbulent water flow within the cooling channels is essential for achieving reliable and consistent temperature control (mold temperature maintained between 15°C and 50°C) across the entire part.

Defect Quick-Fix Matrix

| Defect | Root Cause | Quick Fix |

| Splay Marks | Wet material | Dry pellets thoroughly (2-4 hrs at 80-110°C) |

| Sticking | Material tackiness | Apply mold release; Polish mold surface; Increase draft |

| Warpage | Uneven cooling/shrinkage | Optimize cooling; Adjust pack pressure; Ensure uniform wall thickness |

TPU Injection Parts Design Guide

Designing for TPU requires specific considerations to manage its unique elasticity and shrinkage behavior. Applying these rules will guarantee your part functions perfectly and molds efficiently.

Uniform Wall Thickness

For the best results, target a wall thickness between 1 mm and 3 mm. Softer grades of TPU generally require a bit more thickness to help the molten material flow properly. Conversely, harder TPU grades can usually tolerate slightly thinner sections without any issues. Avoid sudden, massive changes in wall thickness.

Shrinkage Compensation

TPU shrinks more than many commodity plastics. When designing the mold, manufacturers must make the cavity oversize by approximately 1–2% for most grades to compensate for this. You should always use simulation software to confirm the final shrinkage, especially when using complex side-action mechanisms or slides.

Corner Radii & Stress Relief

Generous curves significantly improve the tear strength of your final part. You should ensure the inside radius is about half the wall thickness. The outside radius should then equal the inside radius plus the wall thickness. Using these large radii is critical for reducing stress concentration points.

Rib Thickness Rule

To prevent visible sink marks on the aesthetic surface of your part, you should keep the rib base around 50% of the nominal wall thickness. Furthermore, the height of the rib should be limited. This design constraint adds the necessary strength and rigidity while actively reducing the potential for a visible sink on the opposite side.

Flow-Length Control

Flow length-to-thickness ratios should be kept moderate (below 150:1) in your design. Abrupt changes in the part’s cross-section cause a significant thickening of the shear zones in the mold, which can unfortunately lower the final part strength. You should always use smooth, gradual transitions between different section thicknesses.

Rib Spacing for Fill Integrity

To ensure a complete and solid fill, the manufacturer should space ribs at least twice the wall thickness apart. This necessary separation helps to prevent air from becoming trapped in the mold. This prevents air pockets and incomplete packing in those thin channels, which could lead to weak spots.

Over-mold Substrate Prep

When designing for over-molding, you must select substrate materials like ABS, PC, or PA with melting points 30°C higher than the TPU injection molding temperature. The manufacturer should degrease the substrate and apply plasma or a primer for a chemical bond. You should also incorporate undercuts or thru-holes for a strong mechanical interlock.

Need expert DFM analysis for your TPU part design? Send us your design file for a manufacturability review.

Applications of TPU Injection Molding

TPU’s excellent durability, flexibility, and chemical resistance make it a top choice across many industries. Here are some examples of where this material is indispensable.

Automotive Sealing Systems

In automotive manufacturing, injection molded TPU is highly valued because window seals and interior gaskets stay incredibly flexible at very low temperatures and resist exposure to oil and road grime. This superior durability means TPU parts consistently outlast many conventional rubber materials, reducing maintenance costs.

Medical Wearable Devices

For medical applications, biocompatible ether-grade TPU is frequently used to form flexible straps, tubing, and housing components. These specific grades are capable of passing stringent requirements like ISO 10993 tests and also withstand long-term simulations involving contact with human sweat and cleaning agents.

Consumer Electronics Protection

You will often find TPU used for protecting consumer electronics. Over-molded TPU corners are excellent at absorbing impact from drops, keeping sensitive components safe. Clear grades are also available that stay transparent for a long time, making them ideal for durable, yet good-looking, phone cases and tablet covers.

Industrial Robot Grips

In automated manufacturing, soft TPU pads are essential for industrial robot end-of-arm tooling. These pads supply very high friction for secure gripping without any risk of scratching polished or sensitive parts. They are a common replacement for silicone pads, which tend to wear out much more quickly in high-cycle environments.

Sports & Recreation

TPU is widely utilized in performance sports equipment. Its unique combination of high energy return and excellent abrasion resistance is leveraged for items like running shoe mid-soles and durable skate wheels. This material choice ensures a long life for the product while maintaining the necessary performance characteristics.

EV Charging Connectors

For electric vehicle infrastructure, chemically resistant TPU is a key material. It is used to encapsulate high-voltage pins inside charging connectors. This robust material passes demanding hot-plug cycle requirements and resists environmental factors without any electrical tracking issues, ensuring reliable and safe power transfer.

Conclusion

Injection molding TPU is key to making tough, flexible products. By correctly choosing the grade, drying the material, and following design rules, you guarantee parts with superior elasticity and resistance. This process ensures high-quality production consistently.

Fecision excels in TPU injection molding by offering exceptional material versatility. We handle complex grades, ensuring your elastic parts achieve maximum durability and chemical resistance. Our precision tooling and rigorous quality control guarantee consistent part-to-part performance. This is perfect for demanding medical or automotive applications.

Our experienced team supports your project from initial design to final delivery. We optimize wall thickness, manage complex draft angles, and use advanced processes like overmolding for your TPU parts. This focus on TPU material injection molding expertise translates directly into cost-efficient, high-quality, and scalable production for your critical components.

Ready to start your high-performance TPU project with Fecision? Get a quote now.