Choosing the wrong mold maker means major risk: poor quality can quickly force you to scrap tools, costing you five figures and months of delays. Your success needs the right experts, not just the lowest quote. Read these questions now to save your budget and project timeline.

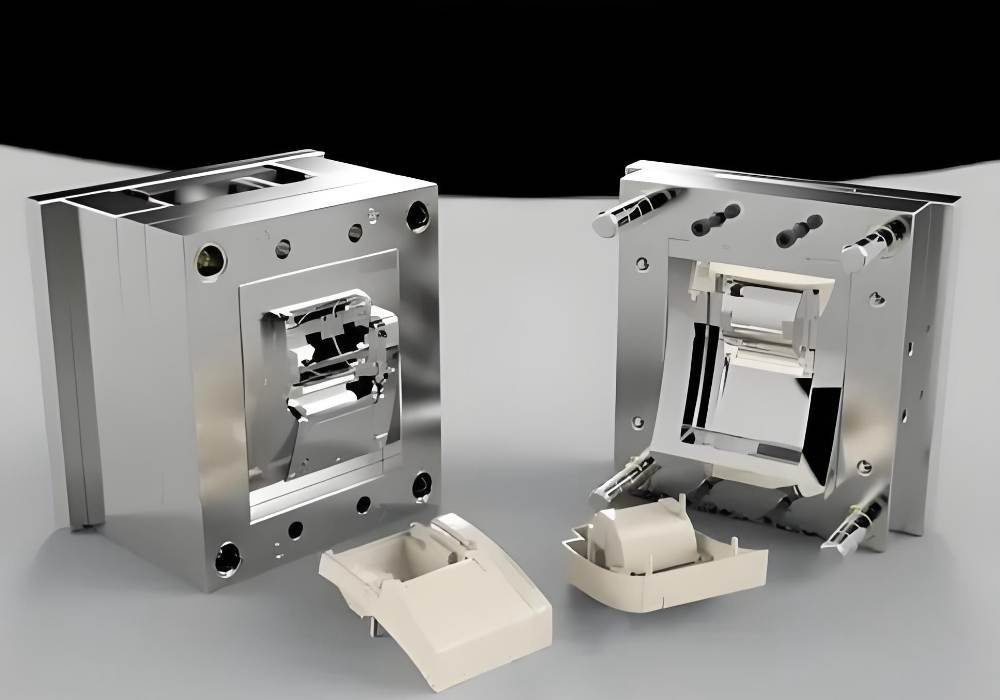

What Is Injection Mold?

The plastic injection mold process is a closed steel cavity in which molten polymer is injected at high pressure. After the plastic cools and solidifies into the shape of the part, the mold is opened, and the completed part is ejected. This process is the heart of modern mass manufacturing.

The steel tooling is built to strict global standards, such as those set by SPI, DIN, or HASCO. This guarantees consistency, wherever your tooling is manufactured. Common materials include thermoplastics like ABS, PC (Polycarbonate), or specialized resins like PEEK.

Importance of Manufacturer Selection for Project Success

Once the mold is cut, the majority of your part’s long-term cost is locked in. A poorly designed or cheaply made mold will run slower, require more maintenance, and result in higher scrap rates for years to come. This quickly erodes your profit margins over time.

Every extra week of tool tuning and revision erodes your market share and negatively impacts your cash flow. If you are in the medical or automotive industries, shortcuts taken by a careless injection mold manufacturer could trigger costly recalls, which can quickly destroy your brand’s reputation and value.

Top 10+ Questions to Ask Before Picking Injection Mold Manufacturers

Having laid the solid groundwork with your project, you are now ready to get into the details. Use these questions to make sure the injection mold manufacturer can deliver the quality and lifespan your parts demand.

1. Tool-Class Fit: Can you build a mold that hits my annual volume?

You must confirm the mold can handle your required volume. Demanding a quote that specifies the tool’s intended SPI Class (like the robust Class 101) based on your annual goal is crucial. If you receive a one-size-fits-all, general quote without mentioning qualified steel or cycle life, this should raise a red flag.

2. Warranty Terms: What exactly is covered & for how many cycles?

Warranties based on calendar years are often meaningless for tools running high volume. Always insist that warranty be clearly stated in cycle counts, which is the actual number of times the tool can run before maintenance. A reliable manufacturer will cover a stated number of cycles for repairs, showing confidence in their quality. Always get this cycle count in clear documentation.

3. Geography: Do you outsource overseas or manufacture in-house?

The location of the actual machine shop can greatly affect your lead time; the difference between a domestic shop and an overseas one can be anywhere from a few days to weeks long. If speed and cost are your main concerns, consider a near-shore option like a Mexico-based plastic injection mold manufacturer in USA for a bridge tool. Always ask about where the final assembly and quality control take place.

4. Prototype Path: Can you 3D print resin samples before steel is cut?

Prototyping is essential before you cut expensive steel; you must confirm the design is functional. A plastic injection mold manufacturer who can 3D print resin samples allows you to fully test the part’s form and fit, saving you significant revision costs later on. Look for one that offers a free or highly subsidized sample, as this shows a true commitment to Design for Manufacturing (DFM).

5. Size Extremes: Show me a similar large/micro part you molded.

Molding a massive car part is a completely different skill from making a tiny watch gear. You need proof that the manufacturer has expertise at the extreme size of your specific part. Ask for empirical data, especially the CPK (Process Capability Index) data, on those sample parts, which confirms they can produce complex parts accurately and consistently across their range. Find the best option for your project by searching for injection mold manufacturers near me and comparing their portfolios.

6. Material Compatibility: How do you handle abrasive or high-temp resins?

Materials like glass-filled nylon are very abrasive and will very quickly degrade standard tool steel. You should understand how the manufacturer will mitigate this deterioration in the mold design to have it last and achieve its cycle life. They should select appropriate steel, like H-13 or S-7, and inquire about nitride coatings, which act as a shield to significantly multiply the working life of the mold steel.

7. Tolerance Stack-Up: What is your dimensional validation protocol?

A critical measure of a China plastic injection mold manufacturer is their ability to hold precise dimensions. Clearly defined dimensional validation protocols are needed to prevent tolerance stack-up, which causes parts to fail assembly. You should demand a GR&R (Gauge Repeatability and Reproducibility) report showing low single-digit consistency and compliance with the tolerance chart for your quoted SPI class.

8. Hot-Runner & High-Cavitation Expertise: Can you handle high-volume systems like balanced manifolds?

If mass producing, you will require a hot runner system in order to reduce waste and increase the cycle time. You also need to validate that the injection mold manufacturer can build a perfectly balanced manifold system, ensuring that all cavities fill properly and evenly. Ask for a simulation report that proves this. If you need many cavities (like 32+), discuss the cycle-time math to confirm their claims are achievable and profitable for you.

9. Mold Sampling: Will you run the tool at my production cycle & cooling time?

Beware of the “sales sample” trap, where plastic injection mold manufacturers China run the tool unrealistically fast to show you a perfect part that cannot be repeated in real production. You must insist that the mold sampling runs the tool at your actual production cycle time, using the necessary cooling time for your planned volume. Always demand a detailed process log from that specific sampling run.

10. Special Processes: Two-shot, over-mold, insert-mold, LSR?

If your part requires advanced techniques, such as two-shot molding (combining plastics) or insert molding (embedding metal parts), you should find specialists, as general injection mold manufacturers USA cannot deal with advanced manufacturing techniques. For using brass inserts, ask to see proof of their vertical press capability. For complex operations, demand a video of their automated robot cell performing the operation to confirm their real-world experience.

11. Speed vs. Quality: Will you be honest about the trade-offs?

The general rule of thumb in manufacturing is that you can choose only two of the three: Fast, Cheap, or Good. Manufacturers that are seasoned and experienced will be upfront about this triangle trade-off. If you desire an aggressive timeline, you will pay an expedited premium. Be sure to talk openly with your supplier about this balance, and ultimately, you are paying for the time. Once the time reduces, the cost increases because of overtime or fast-track processes.

12. Post-Mold Support: Repair, spare parts, revision window?

A mold is a working asset that needs ongoing care, so you need to know the plastic injection mold manufacturers’ commitment to post-production support. This includes rapid repair services and the availability of spare parts. Ask about a rapid spare electrode kit to minimize downtime. A top-tier injection mold manufacturer will offer a cloud-based tool history portal where you can track maintenance and monitor your tool’s long-term performance.

Spotlight: Why Fecision Is Your Low-Risk Injection Mold Partner

Fecision offers expert, low-risk tooling for demanding projects, specializing in high-volume Class 101 molds for industries like automotive and medical. Our 15+ years of engineering experience and ISO-certified processes ensure you get unmatched precision and longevity, directly addressing your concerns about tool-class fit and material compatibility. We combine USA engineering guidance with a cost-efficient global base to deliver premium quality molds quickly.

- Precision for tight tolerances

- Engineering Excellence (15+ years of experience)

- Full Quality Certifications (ISO 9001, 13485, IATF 16949)

- High Speed & Efficiency

- Reliable Delivery (98% on-time)

- No Minimum Order (No MOQs)

Conclusion

Your project’s long-lasting success depends on your manufacturer. Use these questions to review every single partner and avoid delays, scrap parts, and retooling, which can become very costly mistakes. Choosing quality now saves you thousands later.

Ready to start with a trusted partner? Contact Fecision today to review your design and get a quote on high-performance tooling built to last. Our experts are here to turn your plastic part vision into a profitable reality.