From airplane panels to your pill blister pack, countless shapes are made using thermoforming. This process is vital for creating everything from simple packaging to large, complex plastic parts. If you are sourcing any custom plastic part, you really need to understand this method.

Thermoforming is accomplished by heating a plastic sheet to the appropriate elevated temperature, where it softens and becomes elastic. It can be shaped into a 3D mold and held in place through the use of pressure or a vacuum. When it returns to solid state, the flat sheet of plastic has a new and permanent three-dimensional shape. This guide will help you understand everything about thermoforming.

How Does Thermoforming Work? (The Thermoforming Process)

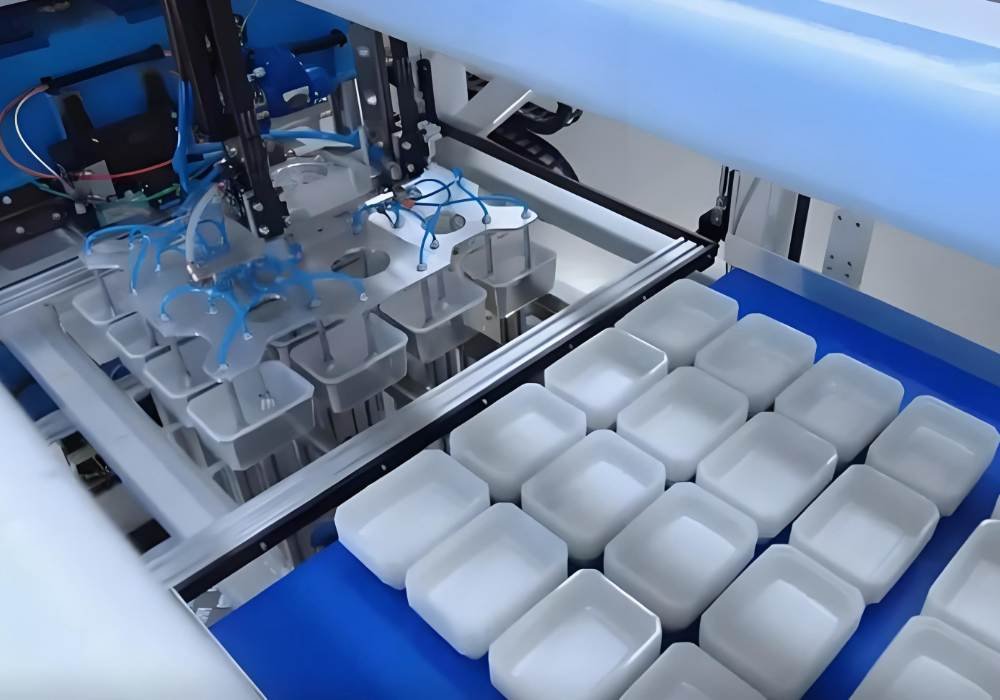

What is thermoforming? The process is simple and fast; it turns a flat plastic sheet into your finished component through these main stages: loading, heating, forming, cooling, and trimming.

Sheet Selection & Gauges

The right sheet thickness should be selected. Use thin-gauge (usually < 1.5 mm) for low-cost packaging and thick-gauge (generally > 3 mm) for strong parts. Consistent wall thickness for all thermoforming processes requires a strict tolerance on the plastic sheet. Discussing this with your supplier is vital for quality and final cost.

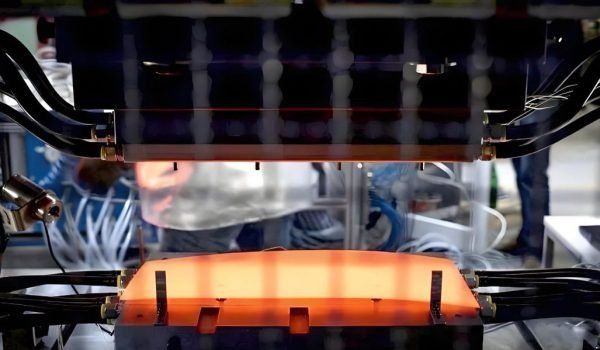

Heating Technologies

Thermoforming manufacturers use different heating technologies for best results. Radiant ceramic heaters are often chosen for fast cycle times in production. Contact rollers are preferred for stress-sensitive materials like PET to prevent damage. Hybrid ovens must be used for large part thermoforming to carefully avoid sheet sag.

Forming Force Options

The forming step uses different forces depending on the part detail needed. Vacuum-only forming uses about 90% of atmospheric pressure and is good for medium details. Pressure forming adds several bars of air pressure to achieve crisp undercuts and detailed textured surfaces. Twin-sheet forming is used to create strong, hollow components.

Mold Types & Materials

The mold material is chosen based on the production volume. For prototypes, medium-density wood or 3D printed resin are cost-effective choices. For high-volume production, temperature-regulated aluminum is essential. Aluminum provides repeatable thermoforming tooling life well beyond typical pilot volumes.

Cooling Strategy

Cooling must be tightly controlled to ensure a high-quality part. The heat loss is managed through the use of some controlled air, mist, or chilled water channels. A balanced cooling procedure should be used because it is important to prevent any warpage or residual stresses in the finished thermoformed parts.

Trimming & Post-Processing

Once cooled, the excess material must be trimmed from the part. This is usually done with a five-axis CNC machine or robotic water-jet. Sometimes an in-mold die-cut is used for speed. Edges can be roller-folded, bonded, or decorated in-line by the manufacturer to shorten your supply chain.

Why Use Plastic Thermoforming?

For many projects, thermoforming is a better choice. Its benefits in cost, speed, and freedom will help your budget and timeline greatly. Let’s see the advantages of thermoforming.

Economical Tooling

A major benefit is cost savings on molds. Aluminum thermoforming molds generally cost markedly less than high-pressure steel injection molds. This makes plastic thermoforming an ideal and affordable solution for mid-volume production programs.

Design Flexibility

Thermoforming allows for rapid design iterations in your product development. When you need to change your design, CAD changes can be machined into a new or modified mold within days. This agility enables you to benefit from true custom thermoforming.

Speed to Market

The speed of producing the first usable component is a huge advantage. You can receive your first article in a few weeks. This is much faster than the months required for many injection tools, making it perfect for seasonal consumer goods or urgent replacement components.

Part Size Freedom

When you need very large components, thermoforming excels. Vacuum forming tables can be measured in meters, making large part thermoforming much cheaper than building mega-sized injection molds, which can be extremely expensive.

Sustainability Gains

The process is environmentally efficient. The manufacturer can easily regrind the off-cuts and scraps to reuse the plastic on-site. In addition, because of the lower processing temperature, the overall CO₂ footprint of thermoforming is lower than that generated by high-heat injection molding.

Aesthetics Built-In

You can also add textures or custom colors, logos, and other detailing straight into the plastic sheet before forming, thus removing the cost of secondary operations such as painting, which often save a good deal of time, as well as per-piece cost savings.

Common Materials Used for Thermoforming

You have many plastics to choose from. Picking the right one is key for your part’s performance and cost.

ABS (Acrylonitrile-Butadiene-Styrene)

ABS is a tough, low-cost plastic that accepts paint well. It is very common in the automotive industry and often used for interior trim panels and protective housings. It balances good impact strength with affordability.

HIPS (High-Impact Polystyrene)

HIPS is extremely easy to form into complex shapes. It is an excellent choice for low-cost, high-volume items such as disposable medical trays and general product packaging. However, its chemical resistance is poor.

PET & PETG

PET and PETG offer crystal clarity, which is great for products where visibility matters. They are also easily sterilizable. PETG is often the go-to material for visible medical packaging that must survive gamma irradiation without losing its structural integrity.

PP (Polypropylene)

Polypropylene is known for its excellent chemical resistance and its ability to form a “living hinge.” It is used for items like laboratory cuvettes and certain detergent caps. It has a relatively high max use temperature.

HDPE (High-Density Polyethylene)

HDPE has very low moisture absorption and is often USDA-approved for food contact. Due to its durability and excellent chemical resistance, it is popular for large part thermoforming of industrial chemical tanks and large cutting boards.

PC (Polycarbonate)

PC is virtually unbreakable and is available in fire-rated grades, making it a high strength, premium material. PC is specified for critical components such as aircraft window bezels and protective electrical equipment housings, where the safety of the users is of the utmost importance.

PMMA (Acrylic)

PMMA, also known as acrylic, possesses glass-like clarity and is extremely UV-stabilized. This makes it a great material for outdoor applications (like retail signage and lighting lenses) as it does not yellow.

PVC/Acrylic Alloys

These specialized alloys are designed for safety, featuring self-extinguishing grades. They meet strict standards like UL 94 V-0 ratings. Thermoforming manufacturers specify these materials for internal electronic enclosures and housings where fire safety is a non-negotiable requirement.

Comparison Table of Thermoforming Materials

| Material | Impact Strength | Clarity | Chemical Resistance | Relative Cost | Typical Application |

| ABS | High | Opaque | Fair | Low | Automotive dash |

| HIPS | Medium | Opaque | Poor | Very Low | Disposable trays |

| PETG | High | Crystal | Good | Medium | Medical blister |

| PP | Medium | Opaque | Excellent | Low | Hinge-lid boxes |

| HDPE | High | Translucent | Excellent | Low | Chemical tank liner |

| PC | Very High | Crystal | Good | High | Aircraft bezel |

| PMMA | Medium | Crystal | Good | Medium | Retail light lens |

| PVC/Alloy | High | Opaque | Good | Medium | Electronic housing |

Types of Thermoforming

“Thermoforming” describes several different processes. The method you use will affect the part’s wall thickness, accuracy, and geometric complexity. Knowing what the different types are will help you determine which process to specify for your part.

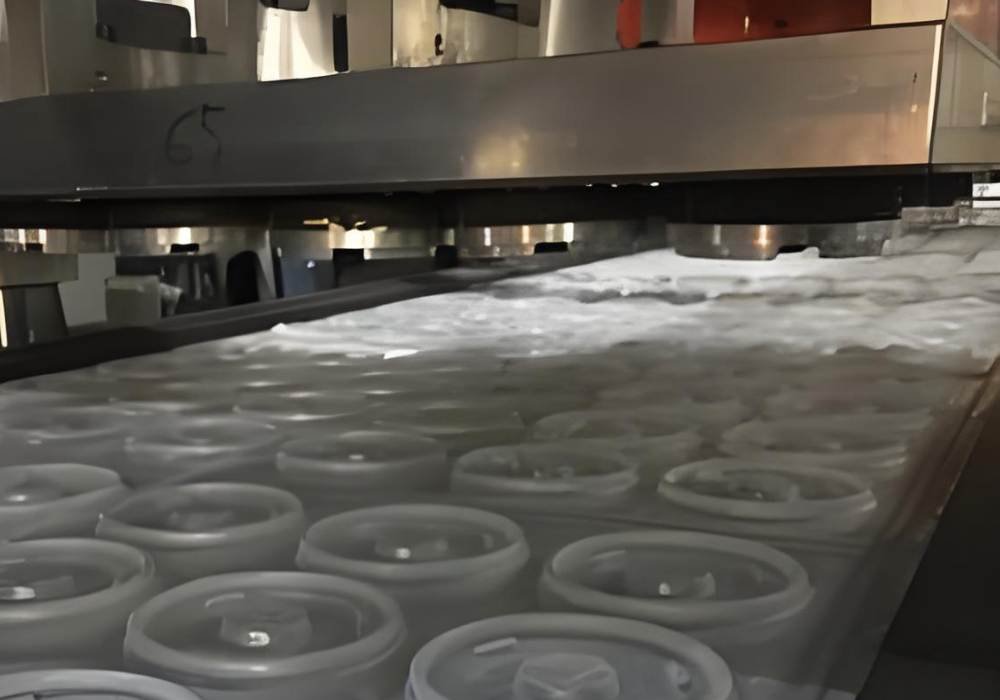

Vacuum Thermoforming

The heated sheet of plastic is clamped over a mold (which can be male or female). A powerful vacuum beneath the cavity then pulls the sheet tightly against the tool surface. It is often thought to be the simplest of the plastic thermoforming processes.

It is important for plastic vacuum thermoforming to have a consistent vacuum pressure across the entire surface. Non-uniform drawing can create thin or weak spots in the finished part. Many modern systems use pneumatic and hydraulic controls, allowing more consistency and faster repetition of individual cycles.

Pressure Thermoforming

In pressure forming, after the sheet is heated, the vacuum is applied beneath the cavity of the mold. In addition, compressed air (typically several bars of pressure) would be introduced above the sheet, which presses the material into every detail of the cavity.

This added air pressure is the main difference. It enables manufacturers to produce textured surfaces, undercuts, and much sharper edges that vacuum alone could never accomplish. Therefore, it is preferred to utilize the pressure forming process when a product has intricacy and high tolerances as a central requirement for manufacturing.

Matched-Mold Forming

In this process, the heated sheet is placed between male and female mold halves (made from metal, plaster, wood, or epoxy), and the two halves then close onto the sheet. A light vacuum is used only to suck out any air from between the mold and the plastic.

Matched-mold forming is a great method because it produces parts with highly consistent wall thickness. It also offers the tightest dimensional adherence compared to other methods. This gives excellent control, especially for complex or highly detailed shapes.

Twin-Sheet Forming

For twin-sheet forming, two separate plastic sheets are heated at the same time, each held in its own frame. Separate mold tools then form the top and bottom halves of the product. The molds are subsequently pressed together to weld the sheets along their perimeter.

This specialized process creates double-walled, three-dimensional hollow components. It is essential for products like air ducts, specialized pipes, and sealed tanks, providing high strength and a finished, seamless look.

To discuss your specific project needs with a proven partner, connect with Fecision today.

Applications of Thermoforming

Thermoforming is a versatile technique used across virtually every major industry. Its adaptability to material type and part size makes it suitable for products ranging from disposable items to high-strength aerospace components.

Packaging

The packaging industry is a huge user of thermoforming. It makes clamshells, blister packs, and trays ready for shelf and packaged products. PET and HIPS are the most common materials used. High speed roll-fed machines can produce thousands of units with a single shift.

Automotive & Mobility

For vehicles, thermoforming can help make interior components, such as door panels and trunk tubs. It also produces exterior parts like engine under-shields. Large part thermoforming often replaces heavier fiberglass components, which helps save noticeable vehicle weight.

Medical & Healthcare

In healthcare, thermoforming creates sterile items like surgical procedure kits, MRI coil covers, and dental-light housings. Reputable manufacturers offer clean-room compatible thermoforming services to ensure all parts meet strict ISO 13485 compliance standards.

Aerospace & Mass Transit

These industries demand materials with very specific properties. Seat backs, cabin sidewalls, and food service carts are typical products that may be thermoformed. Fire-rated PC alloys are often specified to meet the smoke density and flammability requirements for occupant safety in public settings.

Building & Construction

Thermoforming is also used in the construction sector to create large, durable exterior elements such as skylight domes, bathtub surrounds, and large plenum parts for HVAC systems. The products typically consist of UV-stable PMMA and impact-modified PVC; both materials are designed to carry a long outdoor life expectancy of the product.

Recreation & Sports

In the recreational industry, twin-sheet forming is often employed to produce items like kayak hulls and ski boxes. These have the air chambers sealed to help protect individuals from damage; it contributes significantly to the stiffness and rigidity of the component while not adding too much weight.

Tips on Choosing the Best Thermoformer Parts Supplier

Make sure that you weigh the options of not only process selection, but also thermoformer parts supplier selection. As a procurement specialist or engineer, you would need a partner to provide you with quality, consistency, and a full complement of capabilities.

Evaluate Tooling Expertise

Always check with potential suppliers to see if they design and machine the thermoforming molds in-house. This capability typically translates to faster turnaround times and more agile design adjustments for your project. It also offers better protection for your intellectual property and a lower overall total tooling cost.

Check Material Selection Support

A supplier you can trust should have more to offer than just a list of plastics to choose from; they should provide you with data sheets, flammability certifications, and anything else that helps provide sample chips to help evaluate or justify your choice of PETG, PC, or fire-rated alloys for your specific performance specification.

Look for Prototype-to-Production Scalability

The best partners can handle your project at every stage. They should use 3D printed molds for small pilots and then transition smoothly to hardened aluminum for high-volume production runs. Using one source avoids costly re-qualification steps.

Confirm Quality Systems

You must ensure traceability and consistent quality control. Look for suppliers who have ISO 9001 certification. If your parts are for medical or aerospace use, confirm they also hold ISO 13485 or AS9100 certifications, as these are non-negotiable standards.

Post-Processing Capabilities

Check to see what finishing work is done under one roof. Services like CNC trimming, solvent bonding, pad-printing, and Class-A surface painting should be available. Consolidating these processes slashes logistics costs and significantly reduces your overall project lead-time.

Why Choose Fecision for Custom Thermoforming?

Fecision offers full in-house tooling expertise, designing and machining molds to speed up design iterations and protect your IP. We provide full material support in the form of data sheets and certificates for compliance with your parts. This will allow you to scale seamlessly from prototypes to runs of any volume with high-quality molds.

Our quality system is non-negotiable, holding ISO 9001, ISO 13485 (Medical), and IATF 16949 (Automotive) certifications. We cut lead times by offering critical post-processing like CNC trimming and Class-A surface painting under one roof. Choose us for cost-effective, high-quality, and fully traceable custom thermoforming services.

Ready to optimize your procurement? Request a custom quote from Fecision today.