You require tiny precision parts, but traditional CNC keeps letting you down; the parts are not precise enough, or it’s too slow to make. We hear you! You want a solution that provides both speed and exceptional accuracy.

In this guide, you will learn about why Swiss machining is the fast, accurate answer you need. With this amazing technology, you can make even the smallest most complicated parts perfectly every time. Continue reading to find out why thousands of engineers now select CNC Swiss machining for mission-critical projects in the medical, aerospace, and electronics sectors.

What Is Swiss Machining?

Definition

So what exactly is Swiss machining? Also known as Swiss type CNC machining, it is a specific process whereby a CNC machine uses a special sliding headstock and guide bushing, allowing it to do incredibly tight tolerances, sometimes as low as ±0.0001 inches.

This technology was originally developed to create watch parts, which required maximum precision. Now it has become a commonly used technique for manufacturing a large quantity of tiny, detailed parts, which need to be perfect every time.

Swiss Machining vs. Other CNC Techniques

You may be curious how Swiss precision machining compares to other conventional CNC processes. Let’s take a look:

Traditional CNC Lathes

These are great for making larger parts. However, when it comes to long, slender parts, Swiss machining is a great option, as its setup usually doesn’t allow the material to bend or vibrate, which could easily ruin those delicate parts.

Mill-Turn CNC

This combines both milling and turning operations. While very versatile, it usually does not have the special guide bushing used with Swiss machine; therefore, it is not always able to accomplish the same micro-precision as Swiss precision machining. The guide bushing is critical to minimizing vibration and deflection, which results in a superior surface finish and higher accuracy.

Swiss vs Traditional CNC: Quick Comparison

| Feature | Swiss CNC | Traditional CNC |

| Support | Guide bushing (close support) | Chuck (more overhang) |

| Movement | Material moves | Tools move |

| Precision | ±0.0001” | ±0.001” |

| Part Size | <38mm diameter | Any size |

| Long Parts | Handles 20:1 ratio | Limited to 4:1 |

| Operations | Multiple tools at once | Single tool |

| Setup | More complex | Simpler |

| Best For | Medium/large runs | Prototypes/small batches |

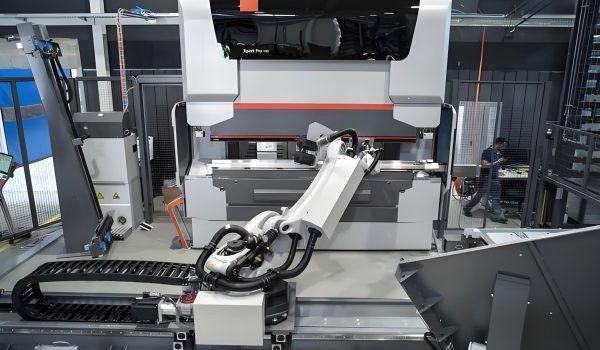

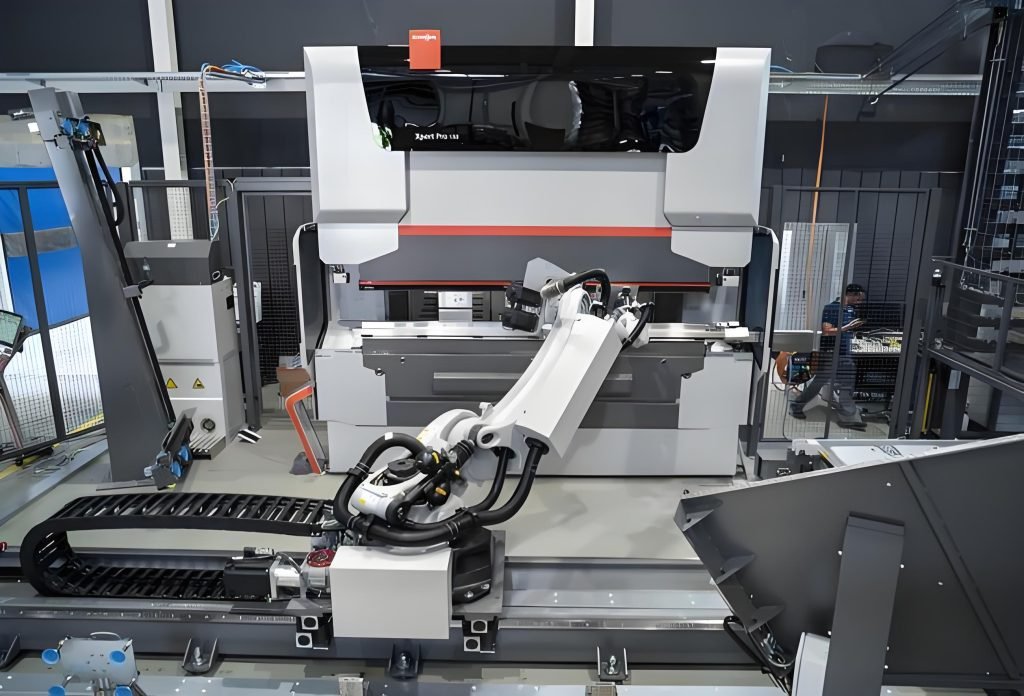

Key Components of a Swiss CNC Machine

To understand how Swiss machining achieves such incredible precision, let’s look at its main components:

Sliding Headstock

Unlike a regular lathe, a Swiss machine has a sliding headstock. This part moves the metal bar forward and backward. As it moves, it pushes the material through a guide, showing only the section to be cut. This clever movement lets you machine long, thin parts without any wobbling or bending, ensuring great accuracy.

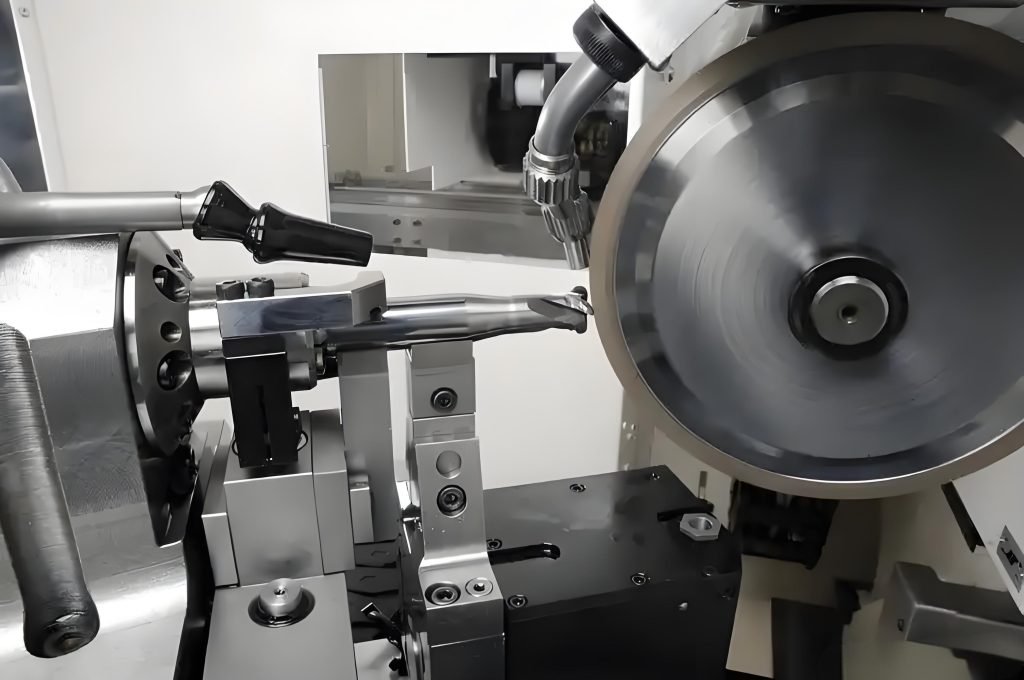

Guide Bushing

The guide bushing is key to Swiss precision. It’s a tight sleeve right by where the cutting happens. It supports the metal bar firmly to such a degree that vibrations almost disappear. This solid support produces a super smooth, mirror-like finish and an incredible tight tolerance, allowing your parts to be straight and dimensionally accurate every time.

Tooling System – Turning / Milling / Drilling

A Swiss machine’s tooling system is incredibly versatile. It’s not just about turning (shaping the outside of the part). Swiss machines are equipped with “live tools.” These are tools that are capable of rotating on the spindle, so drilling, milling, and complex operations can be accomplished simultaneously with the primary process of turning.

That means turning, milling, and drilling all happen in one setup with the part, without needing to be moved to another machine. For instance, you can turn the shaft while cross-drilling a side hole and milling a flat surface, all in the same cycle. This saves a huge amount of time while ensuring perfect alignment of features.

How Does Swiss Machining Work?

CNC Swiss precision machining is a continuous, highly automated process. This section simplifies that breakdown for you, and here’s how it will create those precise parts:

Material Feeding & Supporting

It all starts with the material. A long rod, perhaps stainless steel or titanium, goes into a bar feeder. This feeder automatically pushes the rod into the machine’s sliding headstock. The headstock then feeds the rod forward, but only exposes the tiny section needed for immediate work. This precise, controlled feeding is super important for achieving the accuracy Swiss machining is known for.

Role of the Guide Bushing

As the material moves forward, it passes through the guide bushing. Think of this bushing as a super steady hand, holding the bar perfectly still and straight. The cutting tools are working so close to the support point that the material will not bend. This is very important for long, thin parts as it eliminates any wobble that would otherwise affect tolerance.

Multi-Tool Cutting Operations

Here’s where the magic happens! With the material held firmly, different tools start working at the same time. Front tools shape the outside, side tools can drill holes or mill surfaces, and end tools create threads or slots. The amazing part is that many operations run simultaneously. This means the machine doesn’t stop to change tools, drastically cutting down the time it takes to make each part.

Completion & Ejection

Once all of the features are done on a section of the rod, a cut-off tool makes a precise cut on the finished portion. As soon as one part is cut, the bar feeder automatically moves the rod forward again, so the process begins again. A continuous and automated system like this allows you to churn out hundreds of exactly the same parts, with almost no human input needed. This is what makes Swiss machining a highly effective option when you have big orders.

Advantages of Swiss CNC Machining

When precision and efficiency are critical, Swiss CNC machining offers unmatched benefits:

Precision & Accuracy

If your parts demand ultra-tight tolerances, Swiss machining is a top choice. Its unique guide bushing offers incredible stability, letting you consistently achieve extreme precision. This is perfect for Swiss type electronic machining parts, where even a tiny error can affect how well they work.

Efficiency & Productivity

Swiss machines are super efficient because they can do many things at once and need few setup changes. This means shorter times per part and much higher output, especially for big orders. You’ll get more parts, much faster, boosting your overall productivity.

Versatility

Swiss machines are not picky about materials. They work with many metals, including steel, titanium, aluminum, and brass, and plastics such as PEEK. Because of this versatility, you can soon receive customized Swiss-type machining parts made from the best material for your specific job.

Reduced Material Waste

Swiss machines minimize waste. By supporting the material right where it’s cut, they remove only what’s needed. This results in “near-net shaping,” producing parts close to their final form with little scrap. This significantly lowers waste and saves you money on materials.

Automation & Consistency

Many Swiss CNC machines can run for long periods without constant human help. This automation ensures a steady output of top-quality parts, 24/7. It also cuts down on human errors, giving you more reliable and uniform products consistently.

Applications of Swiss CNC Machining

Swiss CNC machining is the preferred method for parts in many high-stakes industries due to its precision and efficiency:

Medical: You’ll find Swiss-machined components in critical medical devices like bone screws, intricate dental implants, surgical instruments, and connectors for diagnostic equipment. Accuracy here is literally life-saving.

Aerospace: The aerospace industry demands extensive reliability with every component. A Swiss machine can produce precision parts like fuel injector nozzles, sensor housings, or miniature hydraulic components that operate at extremes of conditions.

Electronics: To obtain those tiny, complex parts that exist in electronic devices, a Swiss type electronic machining process is used. This can include very small micro-connectors and precision pins for complex circuit boards.

Automotive: The automotive sector uses Swiss type machining to produce high-precision steel parts for fuel systems, brake components, various sensors, or anything that is dependent on accuracy to ensure these components will perform safely.

Optics: Parts can also be designed to the microscopic level using Swiss machining; lens mounts for high-end cameras and even tiny components for microscopes require the precision to provide clarity and accuracy when indicating vision.

Custom Projects: Outside of the larger overall sectors, Swiss machining is a viable option for any type of tailored Swiss-type machining parts project that requires exceptionally small, complex, and precise components. If you have a unique challenge, Swiss machining might be your answer.

Compatible Materials and Selection Factors

Swiss machines are highly versatile; this machine could operate with different materials.

Material List

Here are some common materials you can use with Swiss machining:

| Material | Characteristics | Common Use Cases |

| Aluminum | Light, good strength-to-weight ratio, excellent for aluminum Swiss screw machined parts. | Aerospace, drone components, lightweight consumer electronics. |

| Stainless Steel | Strong, excellent corrosion resistance, biocompatible. | Medical implants, surgical tools, marine applications. |

| Titanium | Extremely strong, lightweight, biocompatible, corrosion-proof. | Medical (implants), aerospace (engine parts), high-performance. |

| Brass | Easy to machine, good conductivity, cost-effective. | Excellent for Swiss type electronic machining parts, connectors. |

| Copper | High electrical and thermal conductivity. | Electrical contacts, heat sinks, electronic components. |

| Plastics (PEEK, Delrin, Nylon) | Non-magnetic, chemical resistant, good insulators. | Medical devices, electrical insulators, small gears. |

| Tool Steel | Very hard, wear-resistant, high strength. | For hard automotive Swiss-type machining steel parts, molds. |

Factors for Material Consideration

Choosing the correct material is important to ensure the success of your part. Here are some factors to help you consider material selection:

| Factor to Check | What It Means for You | Recommended Materials |

| Biocompatibility | Safe for implants or instruments that touch the human body | Titanium, Medical-grade Stainless Steel |

| Strength-to-Weight Ratio | Strong yet light parts for drones, aerospace, racing | Aluminum, Titanium |

| Corrosion Resistance | Long life in marine, chemical, or outdoor environments | Stainless Steel |

| Machinability | Faster cycles, lower tool wear, reduced cost | Brass, Aluminum |

| Cost vs. Volume | Balance material price against total part count | Aluminum (high volume), Titanium (low volume but high value) |

Challenges and Considerations

While Swiss machining offers incredible benefits, it is valuable to understand its drawbacks, and when it would not fit your project:

Design Constraints

Swiss machining can produce phenomenal levels of precision, but it always works best when applied to small, cylindrical parts that will be long and thin. If you are going to rely on Swiss capabilities, it is generally not a good choice for very large, flat, bulky components.

If your design consists of large, plate-like shapes or requires milling over extensive areas, other CNC methods will be a better fit. Along with selecting the correct material, it is important to understand the shape and size of your part and take this into consideration very early in the design process.

Cost Implications

The initial setup for Swiss machining can seem higher because the machines are complex, and programming is intricate. However, this higher upfront cost is usually offset by a much lower cost per part for bulk orders. For high-volume production, the efficiency and faster cycle times quickly make it a very economical choice.

Setup Complexity

Programming a Swiss machine and configuring it must be performed by skilled technicians with knowledge specific to Swiss machining. The multi-axis and simultaneous operations require understanding the capabilities of the machine so that optimal time and efficiency can be realized while producing precise and consistent parts.

Low-Volume Limitations

Swiss machining is typically best when working with larger quantity runs, usually 100 parts or more, to realize efficiencies in time and cost. If you are only looking for a few prototypes or a very small batch, it will not be economical as it has a longer set-up time. For very small quantities, other prototyping options, or simpler CNC machines, may be better options for cost and flexibility of the number of part

Conclusion – Choose Fecision Swiss Machining Services

When you need high-precision CNC Swiss machining for very complex small-diameter parts, Fecision has expertise and reliability! Our Swiss machining services bring cutting-edge technology and decades of experience to the table as they are matched with recognition of worldwide experts in producing:

- Ultra-Precise Components: We achieve ±0.001mm tolerances for critical parts, like automotive steel components and electronic parts.

- Efficient High-Volume Production: We have multi-axis Swiss CNC systems that run simultaneous operations, and thus cut cycle times for your components like aluminum Swiss screw machined parts.

- Industry-Specific Solutions: We focus on tailored Swiss machining services for demanding industries, from medical implants to aerospace fasteners.

Why Partner with Fecision?

- Advanced multi-axis Swiss machines

- 20+ years precision expertise

- AS9100/ISO 9001 certified

- Guaranteed on-time delivery

For customized Swiss-type machining steel parts or high-volume micro-components, trust Fecision’s end-to-end solutions. Contact Fecision Today!