Subtractive manufacturing represents one of the oldest and most fundamental approaches to creating physical parts. The subtractive techniques remain the backbone of modern manufacturing, despite the rise of 3D printing, automation, and digital fabrication. They deliver unmatched accuracy, superior surface quality, and reliable repeatability across industries ranging from aerospace to consumer products.

Whether you’re a student, engineer, manufacturer, or curious hobbyist, understanding subtractive manufacturing is essential for navigating today’s production technologies. This article explains what subtractive manufacturing is, how it works, why it still matters, and how it compares to additive manufacturing.

What is Subtractive Manufacturing?

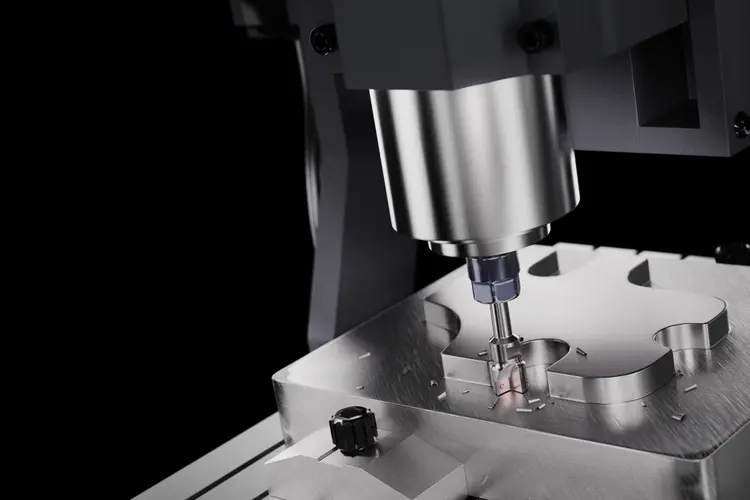

Subtractive manufacturing is shaping through material cut-offs. Most of the starting materials will be in block, rod, or bar form and are made of any material that contains metal, plastic, wood, composite, and stone. The unwanted material is removed by controlled machining until only the designed shape remains.

Today, most of the subtractive processes are dependent on CNC, or Computer Numerical Control, systems that convert the digital design files into machine instructions. These instructions later drive the cutting tools with incredible precision. This enables manufacturers to build tight tolerances, smooth surfaces, and repeatable results.

What Subtractive Manufacturing Creates

The products of subtractive manufacturing include everything from early-stage prototypes to high-precision industrial components, like:

- Mechanical machine parts

- Aerospace turbine components

- Medical instruments

- Automotive Engine Components

- Pieces of furniture made of wood

- Custom metal or plastic prototypes

It is widely used in industries where tolerances and finishes are vital because the process is highly accurate.

How Does Subtractive Manufacturing Work?

Subtractive manufacturing involves a structured workflow to develop a raw material into a finished component. The working process, from start to finish, is highlighted in a simple manner below.

1. Designing the Part (CAD)

Everything starts with a digital blueprint. Engineers utilize Computer-Aided Design software to create 2D drawings or 3D models, which define the part’s dimensions, tolerances, and surface features. This design serves as the foundation for the entire manufacturing process.

2. Converting CAD Models Into Toolpaths (CAM)

The next step is to transfer the design into a CAM system, which translates the geometry into toolpaths. These toolpaths direct the machine’s cutting tool exactly where to move and at what speed and depth to remove material.

3. Material removal by cutting tools

The raw material, sometimes referred to as a “workpiece,” is mounted onto a machine such as a CNC mill or lathe. Cutting tools start the processing of the piece through milling, turning, drilling, or grinding operations. Every one of the many motions takes off minute pieces of material until the component begins to take form.

4. Finishing and Inspection

Secondary processes further refine the part once the basic shape has been achieved. Finishing operations may include sanding, polishing, deburring, or heat treatment for added strength, appearance, or surface quality. Finishing is followed by inspection using measurement tools or coordinate measuring machines (CMMs) to confirm that the parts are accurate.

5. Machines Involved in Subtractive Manufacturing

Some of the most common machines include:

- CNC Mills – Ideal for complicated forms and multi-axis machining.

- CNC Lathes – Used for cylindrical parts

- CNC Routers – ideal for wood, plastic, and other soft metals

- Surface Grinders – For accurate smoothing and surface finishing

- Drill Presses – For making holes

These machines range in size from small benchtop units to large industrial machining centers used in aerospace and automotive production.

Benefits of Subtractive Manufacturing

Subtractive manufacturing remains popular because of several strong benefits it extends.

1. Exceptional Precision and Tight Tolerances

One of the greatest strengths of subtractive manufacturing is its accuracy. CNC machines can cut parts to very tight tolerances down to 0.025 mm or better. This is often better than that which most 3D printers could achieve. It’s perfect for parts that have to fit together perfectly or must have exact measurements.

2. Excellent Material Versatility

Subtractive manufacturing can work with metals, plastics, wood, and composite materials. This gives manufacturers the freedom to choose the best material for the job without being limited by the production method. In contrast, 3D printing often constrains which materials you can use.

3. Improved Surface Finish

Another main advantage of the use of CNC machining is the high-quality surface finish it provides. Subtractive processes produce smooth, uniform surfaces that mostly require little to no post-processing. The elimination of secondary finishing saves time and production costs while allowing parts to be ready for assembly or end use immediately following machining.

4. High Efficiency for Large-Scale Production

Subtractive methods yield unparalleled efficiency in mass production. What would take several days or even weeks for 3D printers to produce, a CNC machine can do in hours. Besides that, CNC equipment can work nonstop, with the exception of routine maintenance, which makes them very suitable for the heavy schedules that are characteristic of industrial production.

5. Excellent Scalability

Subtractive manufacturing accommodates anything from single prototypes to full production runs with the assurance of consistent quality. It also excels in making large components, with standard CNC milling machines capable of manufacturing parts up to 2000 × 800 × 1000 mm, far beyond the build size of most 3D printers.

6. Greater Material Integrity and Strength

The subtractive manufacturing process cuts material from a solid block, allowing the natural grain structure of the metal and its density to remain intact. This provides stronger, more reliable parts with consistency in mechanical performance. The method is especially valuable for components that need to withstand high stress, heavy loads, or sudden impacts.

Additive vs. Subtractive Manufacturing

The debate between additive vs subtractive manufacturing is common in modern production. Here are the top benefits of subtractive manufacturing:

| Feature | Additive Manufacturing (AM) | Subtractive Manufacturing (SM) |

| Process | Builds objects layer by layer | Removes material from a solid block |

| Materials | Plastics, resins, and limited metals | Metals, plastics, wood, composites, ceramics |

| Precision | Moderate | Very high (down to ±0.001 in) |

| Surface Finish | Rough, needs finishing | Very smooth, often final-quality |

| Best For | Complex geometries, prototypes | Strong, high-precision production parts |

| Production Volume | Low | Medium to high |

| Cost | Low setup cost, high per-part cost at scale | Higher setup cost, low per-part cost at scale |

| Limitations | Slow, weaker parts, limited materials | Waste material, limited internal geometry |

Ideal Use Cases

- Additive: Rapid prototyping, artistic parts, complex geometries

- Subtractive: Industrial components, tight tolerances, load-bearing parts

Most modern factories combine both methods: 3D printing of early prototypes and CNC machining in the final production stage.

Limitations of Subtractive Manufacturing

Despite its strengths, subtractive manufacturing has the following drawbacks:

- Material Waste: Material removal results in much more waste than additive methods.

- Limitations with Complex Geometries: Internal channels or intricate designs may not be able to be machined because of tool access.

- Machine and Tool Wear: The cutting tools lose their edge with time and may result in reduced accuracy, hence needing maintenance.

- Size Restrictions: Parts are constrained by the size of the machining equipment

- Surface Finish Issues: Some applications require additional finishing processes.

- High Initial Costs: Equipment and software are major investments.

- Operator Skill Requirements: Automation has not totally eliminated human error.

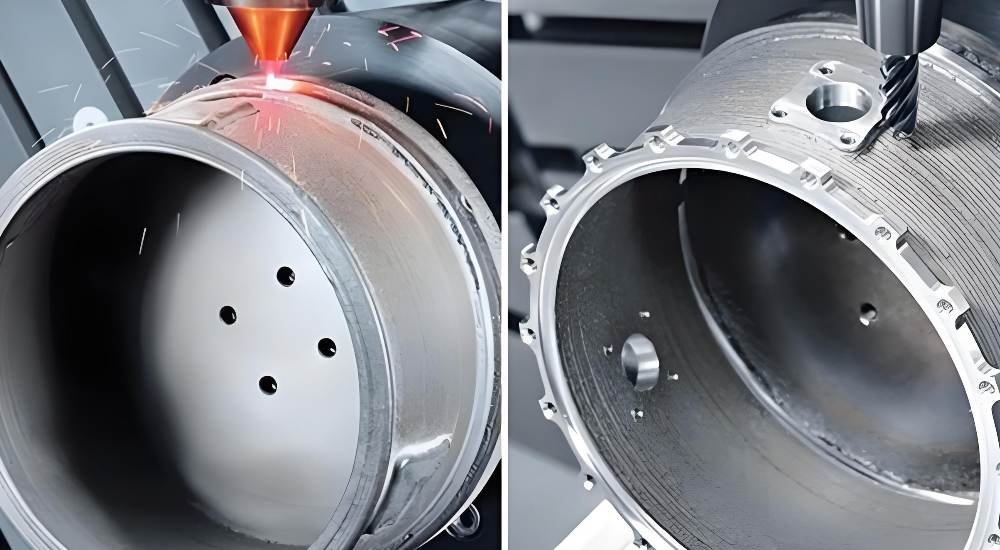

Many companies address these limitations by using hybrid workflows that combine additive flexibility with subtractive accuracy.

Subtractive Manufacturing Examples

Most of the industries that require durable, precise, and consistently manufactured parts depend on the subtractive process. Here are some common examples of subtractive manufacturing:

- Aerospace & Automotive: CNC machining produces high-performance components such as turbine blades, transmission housings, engine parts, and structural brackets. These industries rely on precision machining for safety-critical parts.

- Medical Devices: Surgical tools, implants, and specialized devices are machined from materials like titanium, stainless steel, and PEEK. These parts must meet strict biocompatibility and ISO certification requirements.

- Robotics & Electronics: Machined components include frames, brackets, housings, heat sinks, and sensor mounts, where dimensional accuracy is essential.

- Consumer Products & Industrial Equipment: Everything from metal prototypes to durable plastic components is produced with subtractive methods for strength and consistency.

- Woodworking & Furniture Production: CNC routers create detailed wooden parts, decorative elements, and structural furniture components.

- Construction, Defense & Heavy Machinery: Machined components play a foundational role in structural systems, vehicles, tools, and defense-grade hardware.

FAQs About Subtractive Manufacturing

1. What materials are utilised in subtractive manufacturing?

The process can be applied to metals like steel, aluminum, and titanium; plastics such as ABS, nylon, and acrylic; wood; composites; and high-performance alloys.

2. Does the rise of 3D printing make subtractive manufacturing less valid?

Yes, subtractive manufacturing remains highly relevant. While 3D printing is excellent for complex designs, subtractive manufacturing still cannot be beaten in precision, material strength, scale, and reliability.

3. Is CNC machining the same as subtractive manufacturing?

No, CNC machining is just a type of subtractive manufacturing. Subtractive manufacturing covers a wide range of processes in which material is removed from a solid block to create a part. CNC machining uses computer-controlled machines for the same purpose: to cut and shape material.

4. Which industries benefit most from subtractive manufacturing?

Aerospace, automotive, medical electronics, and consumer product industries rely heavily on subtractive processes.

5. Is subtractive manufacturing expensive?

Subtractive manufacturing tends to be more expensive in small batches or with complicated parts since it wastes more material, not to mention the time it takes to set up the machines. However, it becomes highly cost-efficient with medium to large-scale production.

Conclusion

Subtractive manufacturing continues to be one of the most important production methods in the world. Its unmatched precision, outstanding surface finishes, and broad material compatibility make it vital for aerospace, medical, and consumer manufacturing. Subtractive techniques remain the best choice for high-performance industrial components, although additive manufacturing is growing. Understanding the differences between additive vs subtractive manufacturing gives designers and engineers the knowledge to choose the best method for each project.

Are you ready to explore advanced CNC solutions and industrial manufacturing tools? Visit Fecision for top-tier manufacturing. Whether you need custom designs or large-scale production, we’re here to help.