The need for strong and high-quality materials is growing all the time. One popular technology which is benefiting different industries is PVD coating. This advanced method is known for making materials tougher, more attractive, and more useful.

In this guide, we will look at PVD coating meaning, materials, process and more. These details will help you understand where it is applied, and why it is a great choice for many industries.

What Is PVD Coating?

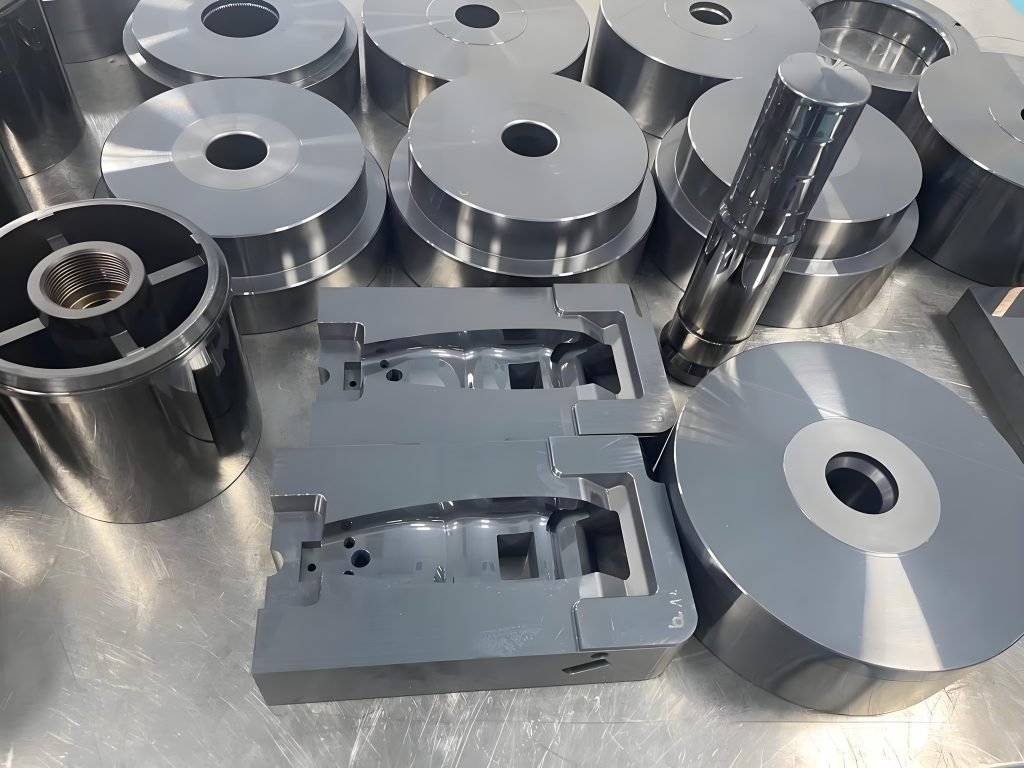

PVD is Physical Vapor Deposition which is also famous as thin-film coating. This is a special method used to put a thin but very strong layer of material onto a metal surface. This technique is helpful to coat the parts of any item to change their color, properties, or finish. That is why there are multiple PVD coating colors are available usually.

The PVD process involves heating a material in a vacuum chamber until it turns into vapor. Then applying that vapor onto the metal for forming a strong bond.

The science of PVD coatings might sound complex. However, in simple terms it just means adding a tough new layer to any surface to makes it look fresh.

A Quick Breakdown of PVD Coating Process

Creating a PVD coating takes place in a vacuum chamber. It happens at temperatures between 50 and 600 degrees Celsius.

This method is called a “line of sight” technique. This means that the atoms from the solid material turn into vapor and travel through the vacuum chamber. They attach themselves to whatever is in their way.

Different types of PVD coatings can lead to different properties in the materials. Even if two coatings look the same, don’t confuse. This is because the way you make them can greatly affect how they perform in their intended use.

Preparation of the substrate

The PVD coating process starts from cleaning and preparing the substrate with ion beam sputtering.

Ion beam sputtering is a process where an ion beam is aimed at a target material. This will bombard it with ions. This bombardment removes material from the target. It then gets deposited onto another surface which is substrate. When Fengchi adds reactive gases like oxygen, it allows for the sputtering of materials like dielectrics.

We can create additional ion bombardment on the substrate with an additional ion beam source. This helps influence the film that is forming to clean the substrate before the coating process.

Magnetron Sputtering

The next step is magnetron sputtering. It is a process that uses a special cathode with a permanent magnetic field. This helps to create a dense plasma at its surface. The ions will bombard on target material on the cathode.

This bombardment helps to remove material from the target. This also allows it to deposit onto another surface which is the substrate. Different setups in this process can lead to various properties in the layers that are created.

Evaporation

This PVD coating process’ step involves passing electricity through a tungsten filament. This causes it to emit electrons. High voltage then helps these electrons to gather and accelerate into a focused beam.

A magnetic field directs the electron beam so that it hits a crucible. The material inside the crucible is bombarded by the electron beam. The process will cause it to evaporate into a gas. This gas then deposits onto the surface of the substrate that you want to coat.

Post-Coating Steps

Once the coating process is complete, then you need to cool down the coated substrate. Then take it out of the vacuum chamber. Depending on its application, it may need some extra treatments to improve the performance of the coating.

Different Types of PVD Coating Materials

There are different types of PVD coating materials available. These PVD coatings are useful for different substrates.

Let’s learn about the common PVD coating materials here.

- Titanium

It is popular for its hardness and wear resistance. Moreover, the material is safe for the body. That is why it is popular to use in aerospace and medical industries.

- Zirconium

This material is resistant to corrosion. Therefore, it is common to use in engine valves and other areas that need to withstand the tough conditions.

- Gold

Gold is popular to use in aerospace electronics. This is mainly because it is tough to tarnish and can conduct electricity as well.

- Copper

Copper is excellent choice when it comes to conduct electricity. So, it is usually a part of electronic and electrical devices’ PVD coatings.

- Aluminum

It is both durable and lightweight. That is why it is common to use in functional and decorative coatings.

- Stainless steel.

Stainless Steel is rust resistant and strong. These properties are making it a popular choice for decorative and industrial applications.

Applications of PVD Coating

PVD coatings are used on precision parts in following:

- Airplanes

- Vehicles

- Machines

- Semiconductor technology

- Medical technology

- Power generation, etc.

These coatings help these parts work more reliably and efficiently. This leads to less friction and longer service life. This as a result is better for the environment. The performance and lifespan of PVD coated cutting and forming tools improve. This not only saves valuable materials. It also reduces environmental impact and helps protect natural resources.

The key to making PVD coatings successful is choosing the right coating solution for each specific use.

What Makes PVD Coating Worth-Considering?

Here is why PVD coatings are beneficial to use.

· Improved Durability

The application of PVD coatings happens in thin layers. This ultimately decreases substrate stress. As a result, it improves the overall durability of the coating.

· High-Temperature Resistant

These coatings have resistance against high temperatures. This is because high temperature used in its deposition leads to strong coating bonding with substrate. It results in the tolerance to high temperatures.

· Corrosion Resistant Coating

PVD coatings are applied in vacuum which makes them durable. This allows coating material deposition in pure and controlled form. As a result, you can achieve a harder and denser coating which is wear resistant and corrosion resistant.

Is PVD Coating Safe?

PVD coating is an environmentally friendly coating method. It uses fewer toxic substances. Overall, it is the preferred technology for the surgical and medical implant industry. This is mainly because PVD creates clean, very pure, and durable coatings.

Upgrade Your Products with Fengchi PVD Coating Services

If you want to improve how your products perform and look, don’t worry. Think about working with Fengchi for our expert PVD coating services. Whether you need PVD chrome coating or black PVD coating, don’t worry. We make sure your materials get the best coatings that fit your specific needs. This is true with our advanced technology and skilled team.

We can help you to create products that are both durable and visually appealing for any industry. So, you must choose Fengchi for unique PVD solutions that really stand out.