The injection molding is commonly used to manufacture plastic parts in high volumes with consistent high quality, but the cost of tooling can be one of the biggest expenses. Selecting the right type of mold can protect you from unnecessary costs.

In this article, we’re going to discuss multi cavity molds, which are employed to produce multiple parts in a single molding cycle, and you’ll learn what they are, how they operate, and some important considerations when using them on your next project.

What Is Multi Cavity Mold in Injection Molding?

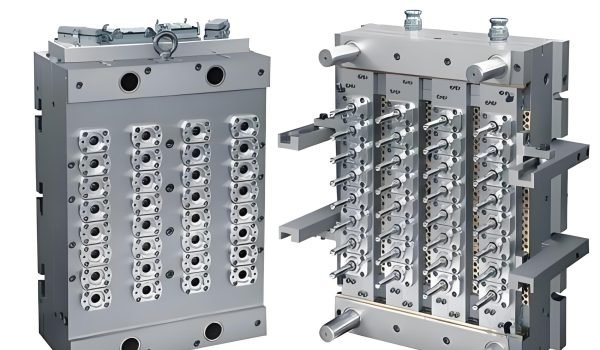

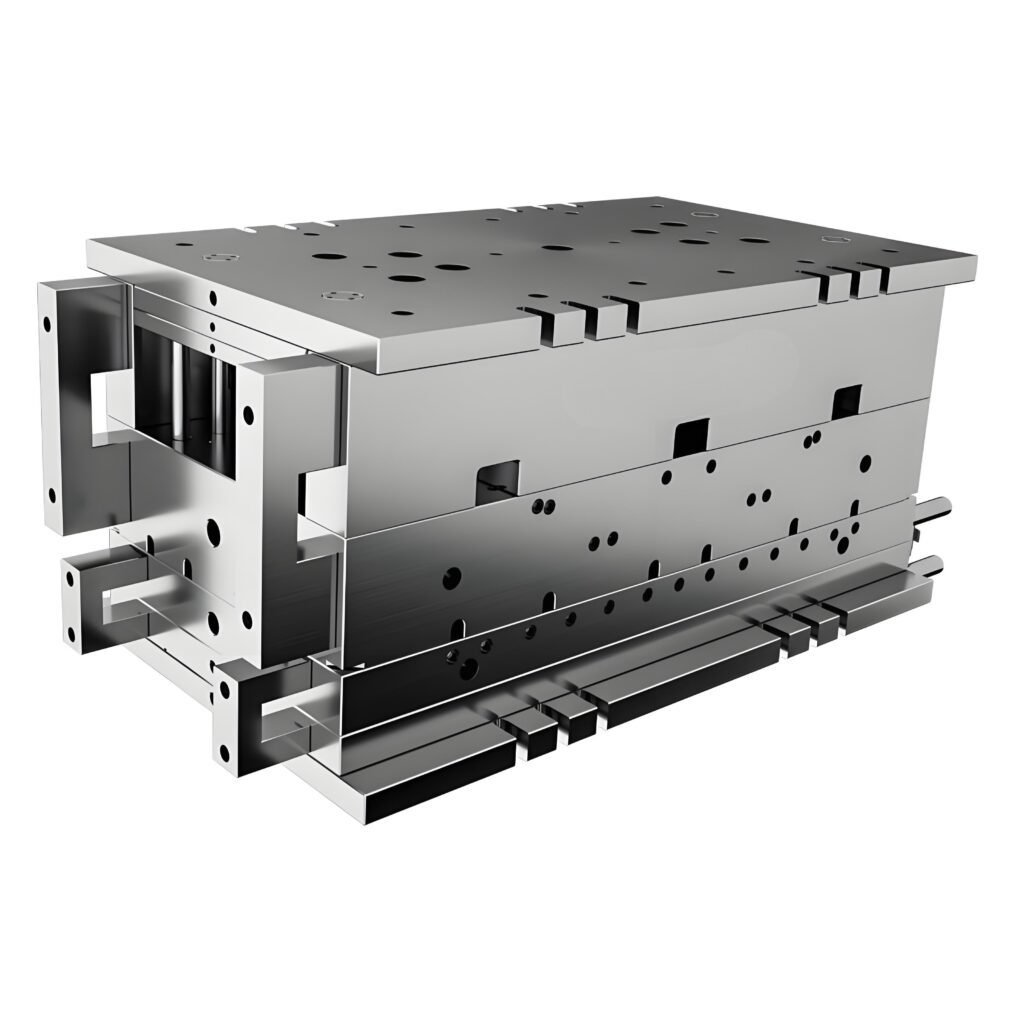

A multi cavity mold is an important type of injection molding equipment with several identical cavities, sometimes referred to as a multiple-impression tool. Unlike a single cavity mold, which can only make one part at a time, a multi cavity mold can produce many identical parts in a single shot, and is efficient for high-volume manufacturing.

Many companies use multi cavity molds, with careful planning for the multi cavity mold design. Runners and gates, in particular, have to be placed in a way that each cavity is filled evenly with the same pressure. It is important not to confuse this process with multi-shot molding, which injects different materials into the same mold to create hard and soft sections.

Benefits & Limitations of Multi Cavity Molding

In order to appreciate the value of multi cavity molds, it’s essential to analyze the benefits and drawbacks. Here is an overview of each key benefit and drawback that should be considered for your particular project.

- Benefits

Multi cavity molds have several strong benefits that make them an excellent choice when producing high-volume projects. They span from the incredibly increased speed of production to cost savings.

Higher Throughput

By producing a high number of parts in one cycle, these molds can dramatically lower your lead time. You might be able to shrink your production schedule from weeks to days, enabling you to fulfill production orders quickly and efficiently in a high-volume production context.

Lower Part Cost

The machine cost, labor cost, and energy cost are spread across every part produced in a single shot; thus, the cost per piece will be lower. Substantial cost savings can be realized after a certain volume is produced, making it a cost-effective option for large jobs.

Color Consistency

A multi cavity soft plastic mold produces all parts from one batch of melted plastic. This eliminates variation, resulting in all parts having the same color and shade. By using this method, you can eliminate the slight variations that can happen when you produce multiple production batches separately.

Better Utilization

These molds permit the production of a large number of parts, with fewer presses, operators, and less floor space. A single, efficient mold may run rather than using many machines, giving you an optimal factory floor plan and maximum usage of limited resources.

- Limitations

While the positives are considerable, it is also important to discuss the challenges. Tooling costs more initially, and there are certain technical risks that need to be planned for. Let’s see in detail.

Higher Tool Cost

The initial cost for a multi cavity mold is higher than a single cavity tool. The large mold base and complex systems for balancing flow and cooling will add considerably to your initial startup spending, leading to a greater initial investment.

Flow Imbalance Risk

With so many cavities to fill, even a minor difference in the gates or cooling can cause problems. You might get a “short shot” where a cavity isn’t fully filled or a “flash” where plastic leaks out. Because of this risk, mold flow simulation is a mandatory step.

Longer Mold Build

A multi cavity mold has extra cavities, wiring, and cooling circuits. It will take longer to build an intricate tool with more parts. Planning and extended lead times will need to be noted, as you should expect delivery to take longer than for a simpler mold.

Not Viable for Low Volume

For a multi cavity soft plastic mold to be cost-effective, you need to produce a very large number of parts. The break-even point is typically at a high volume. When the production quantity is fairly low, a single cavity mold is nearly always the less expensive and more viable option.

Single Cavity vs. Multi Cavity vs. Family Mold

Now, let us contrast the different kinds of injection molds. Knowing the differences between single cavity, multi cavity, and family molds will help you identify the best one for your project.

Single Cavity Mold

A single cavity mold is the most basic type to operate. It will only produce one part per molding cycle, making it the easiest and cheapest tool to make. A single cavity is particularly effective if you are producing very large parts or a small number of parts (typically below 10,000) – it is a good choice for prototypes and small production runs.

Multi Cavity Mold

Multi cavity molds are designed to create a lot of identical parts quickly. This makes them the fastest and most effective way to produce high-volume items. Think of bottle caps, spacers, or other everyday common parts. Use this mold type for high-volume orders, ranging from thousands of parts up to mass production runs.

Family Mold

A family mold is a unique tool that has different, non-identical cavities inside the same mold base. It is designed to produce a complete sub-assembly of parts in a single molding shot. The downside is that it can suffer from uneven filling. This often leads to longer cycle times and more labor to sort the finished parts.

Mold Type Comparison

| Feature | Single Cavity Mold | Multi-Cavity Mold | Family Mold |

| Cavity Configuration | One cavity per mold. | Multiple identical cavities. | Multiple different cavities. |

| Initial Tooling Cost | Lowest. | Highest. | High, but lower than multiple single-cavity tools. |

| Cost-Per-Part | Highest at high volume. | Lowest at high volume. | Varies; often higher than multi-cavity due to labor. |

| Production Efficiency | Lowest; one part per cycle. | Highest; many parts per cycle. | Medium; multiple parts per cycle, but with longer cycle times. |

| Part Consistency | High. | Very high; all parts from a single shot. | Challenging due to different part sizes and filling characteristics. |

| Design & Maintenance | Simple to design and maintain. | Complex design and maintenance; flow balancing is critical. | Highly complex to design; maintenance is difficult due to varying parts. |

| Flexibility | Most flexible for design changes. | Less flexible; designed for one part. | Flexible; can make a complete assembly in one mold. |

| Best Suited for | Prototyping, large parts, and low-volume production. | High-volume production of identical parts. | Small to medium runs of related parts for a single assembly. |

Making the Right Choice for Your Project

The decision hinges on your project’s specific requirements. Your ideal mold choice will be a balance between your production volume, budget, and part design.

Choose a Single Cavity Mold for prototyping, complex parts, or very low volumes where a low initial investment is most important.

Choose a Multi Cavity Mold for high-volume production of identical parts where efficiency and the lowest possible per-unit cost are critical.

Choose a Family Mold for low- to medium-volume production of a complete assembly where investing in individual molds for each part is not justified.

Best Tips on Multi Cavity Mold Design

Designing a multi cavity mold is a science. These tips will assist you in understanding some of the fundamental principles of creating a perfect part, such as balancing the flow of the plastic and selecting the appropriate steel for the multi cavity mold design.

Cavity Balancing

To ensure every part is molded perfectly, you need to make sure the plastic pressure is equal in every cavity. This is called cavity balancing. The best molds use a naturally balanced runner system. Some advanced molds use adjustable valves to fine-tune the flow to each gate. This ensures that every cavity gets the exact same amount of plastic.

Runner Sizing Rule

The runner is the channel that brings melted plastic from the machine to the cavities. Proper runner sizing prevents excessive heat, which can degrade the plastic. Engineers use formulas to figure out this size by keeping shear rate limits to have a good quality part.

Gate Location & Type

The gate is where plastic enters the cavity. Placing it in the right spot is essential for a good part, so it should be located at the thickest section. For cosmetic parts, a valve gate hot runner system is often used, as it minimizes the gate vestige, which is the small mark left on the part.

Cooling Uniformity

One of the key contributors to good parts is uniform cooling. If a mold does not cool uniformly, the parts could shrink differently and warp against each other. A quality mold maker will utilize special conformal cooling channels that will follow the shape of the part closely enough to minimize the potential difference of temperature across all cavities.

Vent & Ejector Layout

Vents are tiny channels that let air escape from the mold as plastic fills the cavity. If the air can’t escape, the part will be incomplete. Vents are incredibly small, just fractions of a millimeter deep. Ejector pins are used to push the finished parts out. It’s important that these pins are arranged symmetrically to prevent uneven push.

Steel Choice & Coating

The type of steel used for the mold depends on how many parts you need. A standard steel like P20 is good for hundreds of thousands of shots. For projects that require over 1 million shots, a tougher steel like H13 is better. To further protect the mold and reduce wear, special coatings like nitriding or DLC are applied.

Industry Uses of Multi Cavity Molds

So you might be asking, “Where are multi cavity molds used in real life”? Take a look around your car, even the medicine you take, multi cavity molds are everywhere, producing high-volume parts with incredible efficiency.

Automotive

The automotive industry utilizes multi cavity molds for high volume parts. These molds can make anything, like fasteners, clips, and sensor housings. Multi cavity molds may make millions of total parts per year for tier-one suppliers. This has a tremendous impact on delivering parts quickly and consistently at a low cost, especially in automotive production.

Medical Disposables

In the medical field, cleanliness and precision are everything. Multi cavity molds are used to make disposable items like syringe barrels and pipette tips. Molds with a high number of cavities run continuously in clean rooms. This helps meet the massive demand for medical supplies and feeds 24/7 assembly lines with perfectly formed parts.

Consumer Packaging

Go to a grocery store, and you’ll see multi cavity molds everywhere. They are used to make things like flip-top caps and thin-walled food containers. Molds with 4 to 16 cavities, combined with hot runners, can achieve incredibly fast cycle times. These fast cycles are essential for mass-producing packaging at a low cost.

Electronics

The electronics industry also uses multi cavity molds for various components. These include connector shells and cable ties. These parts require very tight tolerances. A premium multi cavity soft plastic mold with sequential valve gating, for example, can hold precision across multiple cavities, ensuring that every single part fits into the final assembly.

Construction & Hardware

Multi cavity molds play an important role, even in construction and hardware. They can be used, for example, to produce wall anchors and pipe clamps. These are parts that typically require high strength, so they are produced with materials like glass-filled nylon (PA6). These molds can efficiently produce such high-strength parts and hold costs down for the end consumer.

How to Choose the Best Multi Cavity Mold Manufacturers?

Picking the right multi cavity mold manufacturers will greatly impact the cost, schedule, and quality of your project. The best manufacturers go beyond basic service to provide advanced engineering and support.

| Aspect | Basic Standard | Excellence Standard |

| Design & Validation | Offers simple 3D mold design. | Provides comprehensive mold flow analysis and simulation to prevent defects and optimize cycle times. |

| Production Capability | Builds molds for standard production runs. | Engineers molds for mass production using high-hardness steels and advanced heat treatment. |

| Cavity Strategy | Recommends a cavity count based on machine availability. | Performs a detailed ROI analysis based on production volume and part requirements to recommend the most cost-effective cavity configuration, |

| Quality & Inspection | Supplies initial samples for visual inspection. | Provides full-dimensional reports and process window studies to guarantee part consistency. |

| After-Sales Support | Limited or no support after delivery. | Offers global spare-part hubs, on-site training, and strategic capacity management for urgent needs. |

Why Fecision Stands Out

At Fecision, we go beyond manufacturing multi cavity molds to become your dedicated engineering partner. We offer a full range of services from initial part design analysis and material selection to CNC machining, quality control, and after-sales service to ensure that we are providing you with a mold that is manufactured to spec and optimized for its performance and longevity.

Here’s why you should choose us for your next project:

- Unmatched Production Efficiency & Speed

- Expert Multi Cavity Mold Design & Engineering

- Durability for 1,000,000+ Shot Lifecycles

- Precision 5-Axis CNC & EDM Machining

- 98% On-Time Delivery Guarantee