You might be surprised to learn that hard anodizing is used in various industries, from aerospace to consumer goods, to enhance the durability of aluminum and other non-ferrous metals. This electrochemical process creates a robust surface that withstands harsh environments and intensive wear.

Understanding the hard anodizing process and its benefits can help you make informed decisions for your machining or molding parts. This article will explore the process, its features, and the industries that benefit from this surface treatment technology.

Understanding Hard Anodizing

Hard anodizing is a specialized form of anodizing. This process is crucial for enhancing the durability and performance of aluminum components in various industrial applications.

Definition and Basic Principles

Hard anodizing is an electrochemical process that transforms the surface of aluminum into a durable, ceramic-like aluminum oxide coating. The process involves immersing aluminum components in specialized cold electrolytes, typically containing sulfuric acid, where controlled electrical current causes oxygen ions to react with the metal surface. This reaction results in the formation of an oxide layer that grows both inward and outward, creating an exceptionally strong bond with the base material.

The anodizing process begins with the aluminum component acting as the anode in an electrolytic solution, with a cathode made of lead or stainless steel serving as the negative electrode. The electric current passed through the solution causes oxygen ions to be released at the anode, reacting with the aluminum surface to form a hard, non-metallic conversion coating.

History and Development of Hard Anodizing

The development of hard anodizing technology dates back to the mid-20th century, with significant advancements occurring in the 1960s. It was established as a critical industrial process for enhancing aluminum components, particularly for applications requiring extreme wear resistance, corrosion protection, and electrical insulation. Unlike decorative anodizing, hard anodizing was specifically developed to address industrial needs for durable aluminum parts.

Over the decades, hard anodizing technology has evolved to include various specialized processes, which offer enhanced properties through proprietary electrolyte formulations and process parameters. These advancements have expanded the range of applications for hard anodizing, making it a versatile and reliable surface treatment method for aluminum components.

The Hard Anodizing Process Explained

Hard anodizing is a multi-stage process that involves pre-treatment, electrochemical processing, and post-treatment to achieve a robust oxide layer on aluminum.

Pre-Treatment Steps

The hard anodizing process begins with crucial pre-treatment steps, including thorough cleaning, degreasing, and etching of the aluminum parts. This stage is essential to remove any natural oxide layers, oils, or contaminants that could interfere with the quality of the final coating. You must ensure that the aluminum surface is properly prepared to achieve optimal results.

The Electrochemical Process

After pre-treatment, the aluminum component is positioned as the anode in a temperature-controlled bath containing an electrolyte solution, typically sulfuric acid. A cathode made from an unreactive material completes the electrical circuit. During the electrochemical process, direct current is applied at higher voltages than regular anodizing, creating a controlled oxidation reaction that transforms the aluminum surface into aluminum oxide (Al₂O₃). The process parameters, including electrolyte temperature, acid concentration, current density, and immersion time, are precisely controlled to achieve the desired coating thickness and properties.

Post-Treatment and Sealing

Post-treatment typically involves thorough rinsing followed by a sealing process. You can use hydrothermal sealing, chemical sealing with specialized solutions, or impregnation with materials like PTFE to enhance specific properties such as lubricity or non-stick characteristics. The sealing process safeguards against corrosion and wear, ensuring the longevity of the hard anodized coating.

By understanding the intricacies of the hard anodizing process, you can appreciate the complexity and precision involved in achieving a high-quality, durable finish on aluminum parts.

Key Characteristics and Features of Hard Anodized Surfaces

The process of hard anodizing transforms aluminum by creating a durable and resistant surface layer. This transformation results in a surface that exhibits exceptional hardness, corrosion resistance, and other beneficial properties.

Exceptional Hardness and Wear Resistance

Hard anodized surfaces are known for their exceptional hardness, typically measuring between 400-600 on the Vickers hardness scale (HV). This hardness provides superior resistance to scratching, abrasion, and general wear, making hard anodized aluminum ideal for applications where durability is crucial.

Corrosion Protection Properties

The corrosion protection properties of hard anodized surfaces are outstanding. The oxide layer created through hard anodizing acts as an effective barrier against oxidation, salt spray, chemical exposure, and other corrosive environments that would quickly damage untreated aluminum.

Electrical Insulation Capabilities

One of the most valuable characteristics of hard anodized coatings is their excellent electrical insulation capabilities. The dielectric strength of these coatings increases with coating thickness, making them ideal for applications where electrical isolation is required.

Thermal Properties

Hard anodized surfaces demonstrate unique thermal properties, including low thermal conductivity compared to bare aluminum. This allows them to withstand temporary exposure to high temperatures while protecting the underlying metal from thermal damage.

Hard Anodizing vs. Regular Anodizing

You may be wondering what sets hard anodizing apart from regular anodizing, and the answer lies in their distinct process parameters and resulting surface characteristics. Understanding these differences is crucial for selecting the right anodizing process for your specific application.

Differences in Process Parameters

Hard anodizing (Type III) and regular anodizing (Type II) differ significantly in their process parameters. Hard anodizing utilizes lower temperatures, typically between 32°F to 50°F, and higher voltage, ranging from 25-100V, compared to regular anodizing, which is conducted at around 70°F with a voltage of 15-20V. Additionally, hard anodizing often involves modified electrolyte compositions, such as using sulfuric acid with a small amount of an organic acid like oxalic acid.

Comparing Layer Thickness and Hardness

The most striking difference between hard anodizing and regular anodizing is in the resulting layer thickness and hardness. Hard anodizing produces coatings between 25-100 microns thick, while regular anodizing creates much thinner layers of only 5-25 microns. Consequently, hard anodized coatings achieve significantly greater hardness, ranging from 400-600 HV, compared to regular anodized surfaces, which have a hardness of 150-300 HV.

Durability and Performance Distinctions

The differences in process parameters and layer characteristics translate into distinct durability and performance profiles for hard anodizing and regular anodizing. Hard anodized surfaces provide superior corrosion protection and wear resistance, making them suitable for harsh industrial environments. In contrast, regular anodizing is better suited for less demanding applications where appearance is a priority. While regular anodizing offers excellent dyeing capabilities with vibrant colors, hard anodizing prioritizes functional performance and offers limited color options, typically bronze-gray to black.

The cost and processing time also differ significantly between the two processes. Hard anodizing is generally more expensive and time-consuming due to the more complex process parameters and specialized equipment required.

Color Options in Hard Anodizing

Hard anodizing is known for its exceptional durability and performance, but its color options are somewhat limited compared to other anodizing processes.

Natural Color Characteristics

Hard anodized surfaces naturally develop a characteristic dark bronze-gray to black appearance due to the thickness and density of the oxide layer. The natural color can vary slightly depending on the specific aluminum alloy being treated, the exact process parameters used, and the final thickness of the oxide layer. This inherent coloration is a result of the hard anodizing process, which produces a thick, dense oxide layer.

Dyeing Possibilities and Limitations

While regular anodizing is known for its excellent dyeing capabilities with vibrant color options, hard anodizing presents significant limitations for coloring due to its thicker, denser structure. When color is required for hard anodized parts, it’s typically achieved through specialized processes that involve sealing the porous surface with colored dyes. However, the resulting colors tend to be more muted and limited compared to regular anodizing. Common color options for hard anodized surfaces include black, titan grey, blue, red, gold, and green, though these colors will appear darker and less vibrant than the same colors on regular anodized surfaces.

It’s also important to note that adding color through dyeing to hard anodized surfaces may slightly reduce some of the coating’s performance properties, particularly its abrasion resistance. This creates a trade-off between aesthetic appeal and maximum functional performance. You should carefully consider your application’s requirements when deciding whether to dye your hard anodized parts.

Industrial Applications of Hard Anodizing

You can find hard anodizing used in numerous industries, from aerospace to consumer products, due to its durability and performance.

Aerospace and Aviation Components

In the aerospace and aviation industries, hard anodizing is essential for critical components like landing gear parts, hydraulic actuators, and structural elements. These parts must withstand extreme conditions while maintaining precise tolerances and minimizing weight. The hard anodized surface provides a protective barrier against the demanding conditions encountered by aircraft components, ensuring optimal performance and longevity.

Automotive Industry Applications

The automotive industry extensively utilizes hard anodized aluminum for engine components, suspension parts, brake components, and various under-hood applications. Hard anodizing enhances the wear resistance and thermal stability of these parts, making them more durable and efficient. This results in improved vehicle performance and reduced maintenance costs.

Medical and Food Industry Uses

Medical and food industries benefit from hard anodizing’s non-reactive, corrosion-resistant surfaces that can be sterilized repeatedly without degradation. This makes it ideal for surgical instruments, medical device housings, food processing equipment, and commercial cookware. The hygienic nature of hard anodizing ensures that equipment remains safe for use in sensitive applications.

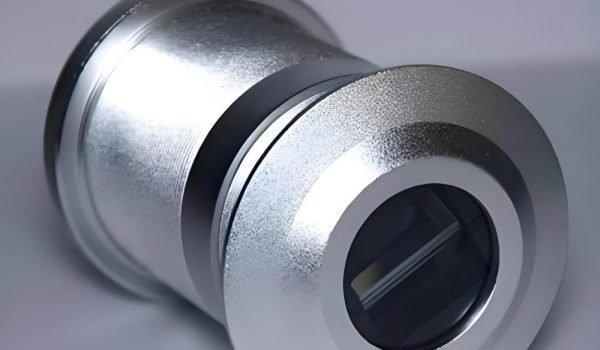

Consumer Products and Other Applications

Consumer products featuring hard anodized surfaces include high-quality cookware, camera equipment, sporting goods, electronic device housings, and architectural hardware. These products combine aesthetic appeal with durability, making them more attractive to consumers. Additionally, hard anodizing is used in industrial machinery, semiconductor manufacturing, and defense applications, further highlighting its versatility.

Conclusion: The Future of Hard Anodizing Technology

Ongoing research and innovations are paving the way for more sustainable and efficient processes. As you’ve seen, hard anodizing offers exceptional durability and versatility, making it a preferred choice for various industries. Its ability to enhance the performance, aesthetics, and longevity of products caters to diverse market needs.

Advancements in hard anodizing are focused on creating multi-functional surfaces and more environmentally friendly processes. The growing demand for lightweight, durable components in electric vehicles and aerospace applications is driving innovation.

As sustainability becomes increasingly important, hard anodizing offers significant advantages through its ability to extend component lifespan and enable the use of lightweight aluminum.