The feeding system is the hidden network inside your mold. Think of it as a set of precise highways that carries molten plastic from the injection machine right into the part cavity. It’s also called the runner system. The exact shape of these channels greatly affects pressure loss, material heating, and how well the part packs. Ultimately, this geometry determines your final part quality.

Understanding the feed system in injection molding is key to making great parts and cutting costs. This article will take you through every essential piece of the system, from the nozzle connection to the gate. You’ll learn the differences between the three main types, core design rules, and a six-step process you can use for your next tooling project.

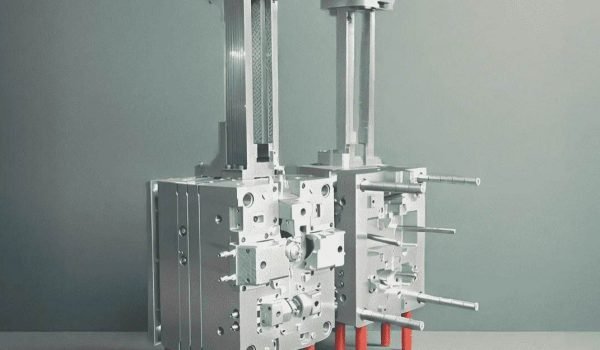

Components and Functions of the Feeding System

Now that you know what the system is, let’s break down its individual parts. Each component plays a unique role in guiding the plastic melt and ensuring a clean cycle.

Sprue – The Melt Highway On-Ramp

The sprue is the first part, a tapered channel connecting the machine nozzle to the runner. It guides the initial surge of molten plastic. A highly polished inner surface minimizes sticking and early freezing. Ensure you use an under-cut sprue puller, which is essential for guaranteeing that the sprue is cleanly and reliably ejected every single cycle from the mold.

Runner & Sub-Runner – Pressure Distribution Manifold

The runner and its branches distribute the melt across the mold. They are usually full-round or trapezoidal, sized near the part’s wall thickness. You are looking for a balance between minimizing pressure drop and avoiding excessive cooling time. A balanced layout ensures all cavities have the same flow length, so they fill uniformly at a similar pressure, which is critical for part consistency.

Gate – The Micro-Valve That Times Packing

The gate is the small opening where the melt enters the part cavity. Its depth controls the freeze-off time, setting the clock for the final packing phase. If the gate is too thin, you risk short shots; if too thick, you’ll get stringing. Keeping the “land length” short reduces shear heating, but it must maintain strength against injection pressure.

Cold-Slug Well – The Impurity Trap

Cold-slug wells are small, cylindrical pockets placed strategically at runner ends or before gates. Their job is to trap the initial, cooler, and higher-viscosity melt front. Capturing this ‘cold slug’ prevents it from entering the part. This step is crucial for preventing flow marks or weak weld lines on high-quality components, particularly those used in optical applications.

Vent & Vacuum Assist – Air Evacuation Pathways

As plastic flows in, the trapped air must escape quickly from the cavity. Micro-vents or porous mold inserts create pathways for rapid air evacuation. This is necessary to eliminate burn marks, particularly in high-speed, thin-wall systems. For very thin or deep sections, you can use vacuum channels to actively lower cavity pressure, allowing you to successfully mold thinner walls without defects.

Types of Feeding System in Injection Molding

When designing your tool, you have three primary choices for your injection molding central feeding system. Understanding the pros and cons of each is vital for profitability.

1. Hot Runner Injection Mold Feeding System

The hot runner system uses a heated manifold and specially designed nozzles. This keeps the entire runner network at the molten plastic’s processing temperature. Stationary plates encase internal heating elements, meaning the material never solidifies between injection cycles. This allows for a continuous, runner-free process.

Advantages

One of the biggest benefits is zero resin waste because there’s no runner to discard. You get runner-less part removal right out of the mold. The overall cycle time is also shorter since you don’t have to wait for a runner to cool. This type is perfect for multi-cavity molds or tools with complex part geometry, boosting your production output.

Disadvantages

The initial upfront cost for a hot runner system is significantly higher than that of cold runners. They also demand much tighter thermal control to function properly. If you need to change colors, it requires extensive purging of the old material. Heat-sensitive resins need careful management to avoid degradation from long residence times in the hot manifold.

2. Cold Runner Injection Mold Feeding System

In a cold runner system, the channels are simply machined directly into the unheated mold plates. The runner is allowed to cool and solidify along with the part during every injection shot. The entire system—part and solidified runner—is then ejected together at the end of the cycle.

Advantages

Cold runner systems offer much simpler construction, making them easy to maintain and clean. They also have wide compatibility with almost any type of plastic material. Quick color swaps are a major advantage, as you simply switch the pellets in your hopper. This simplicity makes them an excellent choice for low-volume or prototyping molds.

Disadvantages

The biggest drawback is the scrap generated every single cycle, as the runner is either discarded or reground. Handling this regrind material adds to your material and labor overhead. Also, the extra cooling time needed for the thick runner can often lengthen the overall cycle time compared to hot runners, impacting efficiency.

3. Insulated Runner Mold Feeding System

The insulated runner system is a hybrid approach. It uses an oversized runner channel. During injection, the outer layer of plastic freezes against the cold mold wall, forming an insulating shell. This insulating layer keeps the core material inside molten from one shot to the next. Sometimes, small cartridge heaters are used to assist in keeping the core molten.

Advantages

This system has a lower cost than a full hot runner setup. It also allows for faster material or color changes when compared to complex hot systems. By keeping the core molten, it significantly reduces material waste compared to a traditional cold runner. It’s a good middle-ground option for mid-range production volumes.

Disadvantages

The thermal stability of an insulated runner is weaker than that of a powered hot runner. This can narrow the processing window, especially when using engineering-grade resins. The cycle time is also typically longer than a hot runner. It demands very careful runner diameter optimization to ensure the core remains molten without freezing off.

Comparison of Feeding System Types

| Feature | Hot Runner | Cold Runner | Insulated Runner |

| Basic Principle | Heated manifold keeps plastic molten in runners. | Runners cool and solidify with the part. | Oversized runner freezes on the outside, stays molten in the core. |

| Runner Waste | None | Yes (must be discarded or reground) | Reduced |

| Cycle Time | Shorter (no runner cooling) | Longer (runner must cool) | Moderate (longer than hot runner) |

| Initial Cost & Complexity | High (complex system with heaters) | Low (simple machining) | Moderate (lower than hot runner) |

| Material/Color Change | Difficult (requires extensive purging) | Easy (just change pellets) | Easier than hot runner |

| Material Compatibility | Limited (not ideal for heat-sensitive materials) | Excellent (works with almost all materials) | Moderate (narrower processing window) |

| Best For | High-volume production, complex parts, expensive materials. | Prototyping, low-volume, frequent color changes. | Mid-range production, a balance between cost and waste. |

Principles of Injection Molding Feed System Design

A well-designed feed system in injection molding is your primary defense against defects, scrap, and long cycle times, ensuring predictable, high-quality output. Following these core principles will ensure your tool performs exactly as intended, cycle after cycle.

Secure Part Quality First

Your primary goal is always to ensure the best part quality. For example, you can improve weld-line strength by carefully optimizing where you place the gate and the melt temperature. In molds with multiple cavities, simultaneous filling keeps the weight variation between parts very low. This is critical for high-tolerance products like packaging closures.

Minimize Pressure Drop and Shear Heat

You should always keep the total flow length of the plastic within the recommended L/t ratio guidelines for your specific resin. To cut pressure loss, replace all sharp corners with generous radii. A smooth, mirror-polished runner surface helps in two ways: it minimizes friction and reduces the thickness of the frozen layer, improving flow.

Balance Cooling vs. Cycle Time

You need to be smart about runner volume; it should be as modest as possible. A large volume will require longer cooling, which lengthens your overall cycle time. For parts like high-speed, thin-wall lids, hot runners are excellent. They totally eliminate the runner’s solidification time, dramatically shortening the total cycle.

Facilitate Auto-Degating and Clean Separation

A great design allows for a clean separation of the part from the runner. Submarine gates placed at suitable angles shear cleanly as the part is ejected. Valve gates leave virtually zero vestige, which is essential for cosmetic housings. You should also design ejector pads near the gate areas to prevent the part from deforming during the snap-off process.

Respect Material Personality

Different plastics have different needs and personalities you must respect. For instance, shear-sensitive PVC requires generous, full-round runners to prevent overheating. Fast-crystallizing resins need a uniform temperature throughout the system, often favoring a hot runner injection mold feeding system. If you’re using hygroscopic materials, your entire injection molding central feeding system needs a dry-hopper integrated into it.

Reduce Waste and Energy Footprint

Designing for efficiency saves money and energy for your business. Short, small-diameter runners use less plastic and shrink the overall shot size, which saves energy per cycle. Hot runners are the ultimate solution here because they eliminate regrind handling costs and material waste entirely, boosting your sustainability efforts.

Plan for Maintenance Up-Front

Good design anticipates future servicing, saving you downtime and cost. Manifold heaters should be designed so you can replace them without needing to remove the entire mold from the press. Using split mold plates and easily threaded nozzle tips will drastically cut down on service time, and always document the wiring diagrams clearly.

Feeding System Design Steps

Designing a perfect injection molding central feeding system can feel overwhelming, but you can simplify the process. Use this simple, six-step workflow to approach your next mold design methodically and with confidence.

Step 1 – Select Feeding Philosophy

To start, you must evaluate your project’s commercial factors. Consider your annual volume, resin cost, cosmetic needs, and overall budget. You should choose a simple cold runner for low-volume jobs. For mid-range production, go with the insulated runner. Finally, select a hot runner system for high-cavitation or long-running jobs to maximize efficiency.

Step 2 – Gate Type and Location Study

Use mold-filling simulation software to analyze your part thoroughly. This lets you compare filling time, shear rate, and where weld lines will form. Your gates should be placed on surfaces that will be hidden, like on ribs or the bottom of the part. Ensure the plastic’s flow-path ratio is within the recommended limits for your chosen plastic resin.

Step 3 – Size Main Runner

Next, you need to calculate the correct diameter for your main runner. Base this calculation on your total shot weight and the maximum allowable pressure drop in the system. Make sure the initial shear rate you get from this size falls within the common process windows for most thermoplastics to avoid material degradation and maintain flow.

Step 4 – Balance Sub-Runner Network

A perfectly balanced system is crucial for multi-cavity tools. You can use a naturally balanced tree layout or create an artificially balanced system with flow restrictions. You may need to slightly adjust the depth of the sub-runners to help equalize the pressure reaching each cavity. Always verify this balance with a short-shot study during the mold trial.

Step 5 – Integrate Cold-Slug Wells and Vents

Machine the cold-slug wells at every major turn in the runner system, where the melt front will cool slightly. Design your vent depth on the parting line precisely according to your resin’s technical guidelines. If you are aiming for very high-speed, burn-free fills, you should also add vacuum grooves to the mold design.

Step 6 – Prototype and Optimize

The final stage involves physical testing and fine-tuning your design. Consider 3D printing or soft-machining the gate inserts for a quick, early validation of your design. Once validated, switch to hardened steel for the final beta tool. Collect precise process data on the part weight and dimensions, then iterate on the gate size until you meet your capability and quality targets.

Conclusion

A disciplined injection molding feed system design is your best insurance against issues like flash and cycle-time creep. By expertly sizing the sprue, balancing the runners, and timing the gate freeze-off, you convert molten plastic into high-quality, profitable parts, whether using cold, insulated, or hot runner systems.

At Fecision, we offer a complete range of plastic injection mold tooling options, from Rapid Tooling for prototypes and low-volume validation to durable, multi-cavity Production Tooling. We specialize in complex molds, including LSR, Two-Shot, and Micro Injection Molds, ensuring we meet your most demanding technical and production needs.

Our core advantage lies in engineering excellence and uncompromising quality. With expert engineers averaging 15+ years of experience, we guarantee optimal mold performance and longevity. You benefit from our cost-efficient designs and a reliable, industry-leading 98% on-time delivery rate, minimizing your supply chain risk.

Are you ready to turn an optimized feeding system into your company’s next market-leading product? Partner with Fecision Mold Tooling Services today and start cutting scrap and boosting efficiency before your tool even hits the press.