Need several related plastic parts fast and cheap? A family mold injection molding strategy allows you to shoot them all in one cycle—cutting your tooling spend and lead time dramatically. It’s a smart way to get matched components quickly.

This guide will fully explain family injection molds—their types, core design rules, cost factors, and practical applications. You will learn precisely when and how to integrate this highly effective technique into your manufacturing strategy.

What Is Family Mold in Injection Molding?

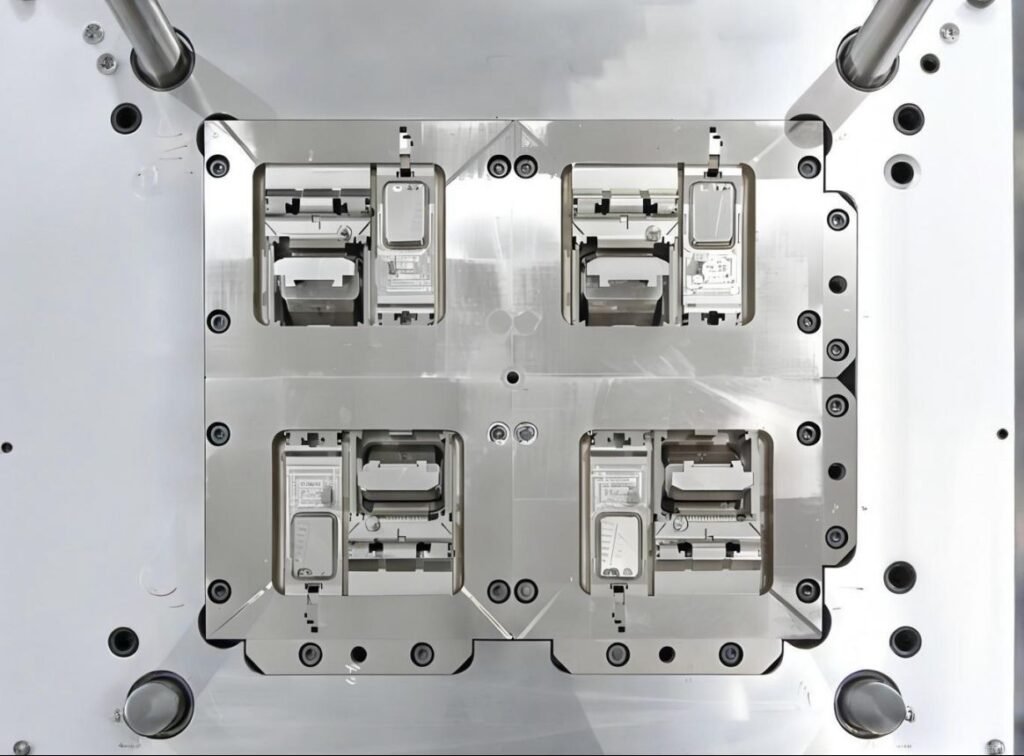

A family mold houses two or more non-identical cavities in the same base. This enables the simultaneous production of different yet complementary parts in a single shot. Manufacturers sometimes call it the “one-shot assembly starter” because the full set arrives instantly.

Molten resin travels through a single, common runner system before it branches out into each unique cavity. The goal is balanced filling, packing, and cooling to deliver a mixed “family” of parts every cycle, all ready for immediate kitting and assembly.

Key Advantages

Family tool injection molding can significantly reduce tooling investment compared to building separate molds for each part. This approach requires only one mold setup, one injection machine, and one operator. It directly increases Overall Equipment Effectiveness (OEE) and improves production efficiency.

Since all components are molded simultaneously, material batches remain consistent across the entire product set. This ensures perfect color matching and full material traceability from a single lot. This simultaneous production also means the complete part kit arrives together, significantly speeding up your downstream assembly process.

Typical Drawbacks

You must consider the need for a highly complex flow balance during design. This is critical because uneven flow creates a risk of defects like short-shots in small cavities or flash on larger parts. Also, optimizing individual part cycle times is difficult since they are forced to cool together.

A key logistical drawback is that if any one part requires mold maintenance or a repair, the entire tool must stop running. This means that a problem with just one component temporarily halts the production of all other parts in the family.

Family vs Multi-Cavity vs Single-Cavity

A multi-cavity mold produces many identical copies of one part. A family mold produces many different parts in one shot. A single-cavity mold makes only one part per cycle. Family molds are typically selected when you need “all the puzzle pieces” at moderate production volumes.

Types of Family Injection Molds

Family molds aren’t universal solutions. They come in several standard layouts. The optimal configuration depends completely on part geometries and required gate locations.

Two-Plate Family Mold

This is the simplest type, using parting-line gating. It’s best for open, shallow shells, such as a toy car’s left and right body halves. The lowest upfront cost is a major benefit, but you should be aware it leaves a gate vestige on the edge of the finished part.

Three-Plate Family Mold

In a three-plate mold, the runner plate floats free upon opening. This design allows manufacturers to use pinpoint gates on the part’s top surface. It’s ideal for cosmetic lids or medical pipette tips that must avoid side-gate scars for a clean, visually appealing look.

Hot-Runner Family Mold

This mold uses a heated manifold that keeps the plastic molten before it enters the cavities. This effectively eliminates runner waste and significantly reduces the overall cycle time. While the upfront price is higher, this type is unbeatable for programs requiring over 50,000 shots.

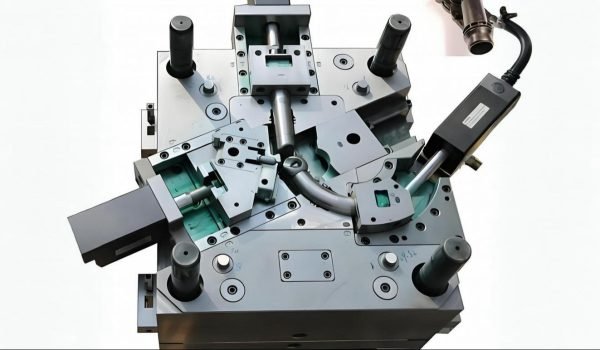

Side-Action (Core-Pull) Family Mold

This design incorporates angled lifters or hydraulic slides to release complex features like undercuts, snap-fits, or louvers. These mechanisms are common in automotive interior tools that mold a “button family” of components with complicated geometry.

Stripper-Plate Family Mold

A stripper plate moves to actively strip parts off the fixed cores. This robust mechanism is excellent for manufacturing thin-walled containers or caps that tend to stick tightly to the core side after molding, ensuring clean, damage-free ejection every time.

Rotary/Index Plate Family Mold

The mold actually spins between shots to allow for the placement of inserts or to change the cavity orientation. This innovative process enables the over-molding of, for example, a gasket and its housing in the very same injection cycle, adding efficiency.

Hybrid Valve-Gate Family Stack

This type combines stacked cavities with individual valve pins for precise, sequential filling control. It offers the highest productivity for high-volume injection molding family kits, such as complex shells and covers for professional drill batteries.

Major Design Considerations for Family Molds

Successful family molding demands precise engineering far beyond a simple multi-cavity tool. Pay close attention to these critical factors to ensure optimal part quality and process stability.

Cavity Layout & Flow Balance

Manufacturers should place the heaviest cavity nearest the sprue and use rheological simulation software. This is done to equalize the fill time within a tight tolerance. Uneven flow balance is the primary cause of warpage and rejected parts.

Uniform Wall Thickness & Volume

A maximum volume delta of 20 percent between different parts should be targeted. Otherwise, the packing pressure will diverge significantly; small cavities may flash while the larger ones suffer from short-shots due to insufficient material.

Shared Cooling Strategy

Cooling channels should be machined so that each cavity experiences the same change in temperature (ΔT). Manufacturers can insert high-conductivity copper-beryllium inserts near potential hot spots to synchronize the shrinkage and prevent distortion.

Parting-Line & Gate Placement

The design should strive for a common parting height for all components to avoid the need for extra slides or complex actions. Gate placement should aim at the thickest sections of the part. This helps to hide the witness marks and allows the plastic to flow into the cavity more easily, reducing stress in the material.

Ejection Harmonization

The ejector stroke and pin diameter must be synchronized to ensure thin parts don’t buckle during release while still achieving a clean separation for thick parts. Stripper bars or air poppets are often used to help harmonize the ejection process.

Steel Selection & Mold Life

Manufacturers should use pre-hardened H-13 steel for cores that will be subject to wear and use 420 stainless steel for any optical cavities. The correct steel choice stretches the tool life past 500,000 cycles, even under the high stress of family mold injection.

Shut-Off & Modular Inserts

Good design incorporates removable, modular inserts for each unique part number. This design allows you to swap out or even temporarily disable a single cavity if it requires maintenance or if one part’s design changes. This is far more cost-effective than having to scrap or heavily modify the entire costly family injection mold base.

Need a Partner for complex family mold design? Fecision specializes in flow analysis and modular mold construction. Consult our engineers to design your next multi-part tool.

Are Family Injection Molds Expensive?

Understanding the cost structure of a family mold is crucial for making the right investment decision. While the initial spend is higher than a single-cavity tool, the long-term savings are significant.

Tooling Cost Breakdown

The increased complexity of a family mold usually adds about 15 to 30 percent to the cost compared to a single-cavity mold. However, it is still significantly cheaper, typically 20 to 40 percent less, than building several unique, dedicated molds. The savings sky-rocket when you need four or more parts.

Piece-Part Economics

The combined cycle effectively amortizes the machine’s hourly rate across multiple Stock Keeping Units (SKUs). You can generally expect a 10 to 25 percent lower final piece-part cost versus a scenario where you run a single-cavity mold for each part separately.

Volume Sweet Spot

Family molds are most economical for a production volume of 5,000 to 100,000 sets per year. Below 5,000 sets, options like 3-D printing or multiple single-cavity runs might be more cost-effective. Conversely, above 100,000 sets, dedicated high-cavitation multi-cavity tools typically offer better returns.

Hidden Savings

Beyond the direct molding costs, there are several hidden savings. You only need one Production Part Approval Process (PPAP) and one Installation/Operational Qualification (IQ/OQ) for the entire family set. Plus, you benefit from reduced inventory because the parts arrive together, and lower freight costs when sourcing China family mold injection molding.

Applications of Family Injection Molds

Family molds are highly versatile, offering massive logistical and quality benefits across many industries. Let’s look at how companies use them to streamline the production of multi-component products.

Automotive Interior Kits

A typical use is molding a door-handle base, a button bezel, and a soft-grip pad together. This ensures a perfect color harmony across all parts and significantly streamlines the Bill of Materials (BOM) logistics for assembly.

Medical Device Housings

In the medical field, family molds are used to minimize contamination risks. An upper pump housing, the lower shell, and the battery cover can be shot in one cleanroom cycle. This single-shot production minimizes contamination exposure and helps reduce the extensive validation paperwork required for multiple tools.

Consumer Electronics

For consumer electronics, this technique is perfect for feeding JIT (Just-In-Time) assembly lines. Components like remote-control halves, the battery tray, and the small logo lens are delivered as a perfectly matched set. This guarantees all pieces are available simultaneously for immediate production.

Packaging Closures

Family molds are a standard choice for complex packaging components. A dispensing cap, its tether ring, and the internal seal membrane can be molded in a single shot. This family layout guarantees a precise fit and avoids mixed-lot leaks that can occur when components are sourced from different molds or batches.

Appliance Knobs & Bezels

Manufacturers use family molds for appliance parts to eliminate color or shade mismatch. An oven control dial, its indicator window, and the back plate are molded from the same single lot of glass-filled nylon. This shared material source and molding cycle ensures a perfect aesthetic match.

Toy & Game Assemblies

In the toy industry, a family mold can create a complete play-set in one box. A board-game pawn, a dice cup, and the lid can all be shot in bright ABS plastic. This efficiency means that one master carton contains all the necessary components to complete the final assembly immediately.

Aerospace Cable Clamps

In aerospace, the clamp half-shells, the wedge, and the cushion insert might be molded in PEEK carbon blend. This method helps to lower the “buy-to-fly” ratio by optimizing the use of costly, high-performance resin.

Family Molds vs. Dedicated Molds

To decide if a family mold is right for your project, you must weigh its trade-offs against dedicated single-part tooling. Review this comparison to understand the strategic differences between the two methods.

| Decision Factor | Family Mold | Dedicated Mold |

| Mold Cost | One base is 20–40 % cheaper than multiple unique tools. | Each unique SKU requires its own dedicated tool. |

| Part Quality | Tougher to balance fill; greater risk of flash or short shots. | Much easier to optimize and control individual cavity quality. |

| Production Rate | Simultaneous set production; rate is comparable to a 2-cavity dedicated tool. | Scales freely with how many cavities you decide to put in the mold. |

| Design Flexibility | Shared runner limits gate location and wall-thickness range. | You have complete design freedom for each individual part. |

| Volume Suitability | The 5,000–100,000 sets/yr range is the most economical sweet spot. | Suitable for any volume, and often preferred for over 100,000 per SKU. |

| Maintenance Impact | One single breakdown halts the production of the entire family set. | A fault is isolated to a single cavity, the others can often keep running. |

| Lead Time (Tool) | Single design and build process leads to a faster overall lead time. | Multiple designs are needed, resulting in a much longer overall project lead time. |

Conclusion

Family mold injection molding is undeniably the smartest shortcut you can take to launch multi-part plastic products efficiently, on time, and within budget. This is provided, however, that the tool is expertly engineered with meticulous flow balance, cooling harmony, and modular foresight. It’s an ideal solution when you need coordinated, lower-volume production sets.

Choosing Fecision, a leading China family tool injection molding manufacturer, for family molds means you get complete product sets in a single, cost-effective cycle. This process significantly reduces your setup time and overall production costs for multi-component products. Our engineering ensures tight tolerances and unmatched efficiency for your complex assembly needs.

Fecision excels in optimizing these complex molds with advanced design validation and CMM inspection. We use strategic material selection and CNC machining to guarantee the mold’s longevity and part precision. This focus on quality delivers reliable, perfectly matched components cycle after cycle.

Partner with Fecision for streamlined manufacturing of your complete product assemblies. Discuss your project specifications with our engineering team today!