Compression molding has been one of the most reliable and cost effective manufacturing methods since the early 1900s. But what is compression molding and why does it still play such a big role in modern industry? In essence, compression molding is a manufacturing process that shapes raw materials like plastic, rubber or composites into solid, durable products using heat and pressure.

This process is used by industries that require high strength, heat resistant, and dimensionally stable components, such as the automotive, aerospace, electronics and construction sectors. This article explores a complete overview of the compression molding process, its benefits and applications.

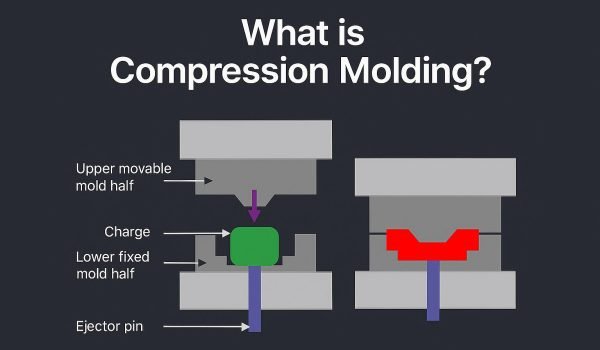

What is Compression Molding?

Compression molding is a high pressure manufacturing method where a measured amount of material (the charge) is placed into an open, heated mold cavity. Once loaded, the mold closes with a top force or plug member, applying heat and pressure that forces the material to conform to the shape of the mold. This process turns pliable materials into solid, dimensionally stable components through a curing reaction.

It works well with thermosets (epoxy, phenolic, polyester), thermoplastics (PEEK, nylon, HDPE) and various rubber materials. Its core advantage is producing large, complex components with high strength to weight ratio and minimal material waste.

Brief history and evolution

The history of compression molding goes back to 1905, when it was first used to produce Bakelite, the world’s first synthetic plastic. At that time, manufacturers were looking for ways to mold heat resistant electrical components efficiently.

Over the decades, the compression molding process evolved with material science. In the 1950s, thermosetting resins like phenolics became the norm for durable automotive and electrical components. By the 1970s, fiber reinforced composites entered the scene, expanding the process’s capabilities for lightweight, high strength parts used in aerospace and industrial sectors.

Today, compression molding is still important, with the global market valued at USD 12.4 billion in 2023 and projected to reach USD 25.1 billion by 2032.

How the Compression Molding Process Works

The compression molding process follows a precise sequence of steps to turn raw materials into finished components. Let’s go through each phase of this manufacturing method.

1. Preparing the charge

First, manufacturers measure the exact amount of material needed. This “charge” preparation is critical, too much material creates excess flash and waste, too little results in incomplete parts. For highly viscous materials, preheating reduces thickness and improves flowability, typically 1-3 minutes.

2. Loading the mold

Next, the preheated charge is placed into the open, heated mold cavity. This can be done manually or through automated loading systems. Precise positioning in the center of the bottom mold ensures optimal flow during compression.

3. Applying heat and pressure

Then the mold closes and applies precise pressure, forcing the material to contact all mold areas. Temperature control is key. If too high, the material will solidify too soon. If too low, curing will be incomplete. This step takes 30 seconds to 10 minutes.

4. Cooling and curing

Thermoset materials require heat activated curing, and thermoplastics need cooling to solidify. Curing times range from 2-15 minutes, depending on material type and part thickness.

5. Part ejection and trimming

Once cured, the mold opens and the part is removed either manually or through ejector pins. Flash (excess material) is then removed through manual trimming or cryogenic deflashing.

6. Mold cleaning and maintenance

Finally, mold cleaning prevents residual material buildup. Methods include dry ice blasting, ultrasonic cleaning or manual cleaning with appropriate solvents. Regular maintenance extends mold life and ensures part quality.

Materials Used in Compression Molding

Material selection is critical to the final properties of compression molded parts. Four main categories of materials dominate this manufacturing method, each with unique characteristics for specific applications.

Thermosets: epoxy, phenolic, polyester

Thermoset materials are the most commonly used in compression molding because they undergo irreversible chemical reactions when heated.

- Epoxy resins provide high strength for aerospace components, mainly in carbon fiber composites.

- Phenolic resins offer good heat insulation and electrical properties, used for frying pan handles and high-voltage electrical shells.

- Polyester resins balance cost and performance, ideal for automotive parts.

Thermoplastics: PEEK, nylon, HDPE

Thermoplastics can be melted and reshaped multiple times.

- Polyether ether ketone (PEEK) processes at 715°F to 740°F, with excellent environmental resistance.

- Nylon is versatile in amorphous and semi-crystalline forms.

- High-density polyethylene (HDPE) offers impact and weather resistance with a high strength-to-weight ratio.

Rubber materials: silicone, nitrile, EPDM

Rubber compression molding creates elastomeric parts with high resilience.

- Silicone withstands -75°F to 450°F, suitable for automotive and medical applications.

- Nitrile (Buna-N) excels in aerospace components due to oil, fuel and acid resistance.

- EPDM has excellent weather, UV and abrasion resistance for industrial applications.

Composite materials and fiber reinforcements

Fiber-reinforced composites combine glass or carbon fibers with polymer matrices. Carbon fibers provide more strength but at higher cost. Glass fibers are the most popular reinforcement for affordable strength enhancement. Hybrid approaches combine bulk charge materials with continuous fiber reinforcements for optimized performance.

Types of Compression Molding

Beyond the basic process, compression molding has several specialized variants for specific materials and applications. Each type has its advantages for particular manufacturing scenarios.

Rubber Compression Molding

Rubber compression molding places uncured rubber into a heated mold cavity, which is then closed and heated until curing is complete. This tried-and-true method is best for simple rubber parts with intermediate precision, conforming to RMA-A2 and ISO 3601 standards.

The benefits of this method are the lowest tooling cost, the shortest lead times and the easiest prototyping. So it’s the fastest and most economical way to produce simple, precise products. Various rubber materials are suitable for this process, including nitrile, SBR, EPDM, silicone and Viton.

Silicone Compression Molding

Silicone compression molding, also known as the vulcanization process, involves compressing pre-measured uncured silicone into a mold cavity using a hydraulic press. The process typically follows 5 steps: mold design, material preparation, vulcanization molding, cooling/demolding and quality control.

This method is particularly useful for producing bulky, thicker products with no weight limitations. Moreover, the structural stability of compression-molded silicone products is very high. Common applications include automotive parts (seals, gaskets), medical equipment components and daily necessities like kitchen supplies.

Advantages and Limitations of Compression Molding

Every manufacturing process has its pros and cons. Compression molding has its own advantages and limitations.

Pros

The continued success of compression molding lies in its unique advantages:

- High Strength and Durability: The molded parts are dense and strong, suitable for heavy-duty applications.

- Lower Tooling Costs: Molds are simpler and cheaper to produce than injection molding.

- Excellent Material Efficiency: Typically less than 5% of material is wasted.

- Supports Large or Thick Parts: Ideal for structural components that require rigidity and volume.

- Versatile Material Range: Compatible with rubber, thermosets, thermoplastics and composites.

- Dimensional Accuracy: Consistent quality and smooth surface finish.

Cons

While versatile, the compression molding process has some limitations:

- Longer Cycle Times: Each cycle can take 1–10 minutes, slower than injection molding.

- Limited Design Complexity: Best suited for simple or moderately complex geometries.

- Labor-Intensive Finishing: Parts may require trimming or deflashing after molding.

But with automation and precise mold design, modern compression molding companies like Fecision have minimized these drawbacks.

Compression Molding vs. Injection Molding

Although both processes form parts by molding materials under heat and pressure, they differ in many ways:

| Feature | Compression Molding | Injection Molding |

| Tooling Cost | Lower | Higher |

| Cycle Time | 1–10 minutes | A few seconds |

| Material Waste | Minimal | Moderate |

| Best For | Large, thick, durable parts | Small, intricate, high-volume parts |

| Typical Materials | Thermosets, rubber | Thermoplastics |

Compression molding is still the best method for producing heavy-duty, large-scale components that require strength and stability, while injection molding is for high-volume consumer goods.

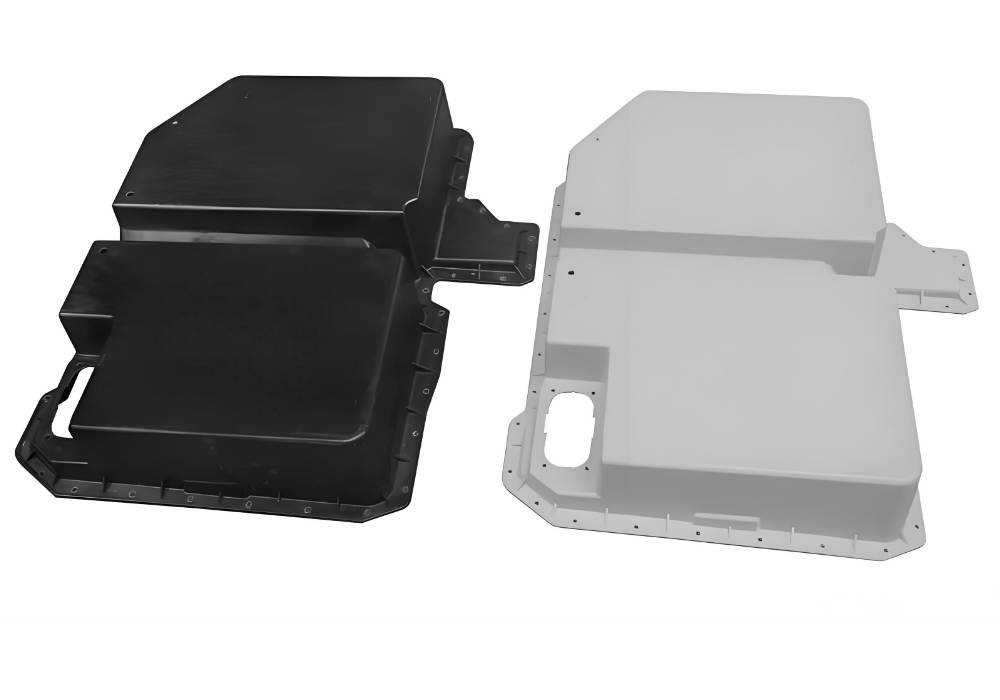

Common Compression Molded Parts and Their Applications

The range of compression molded parts is vast and growing. Some of the most common applications include:

- Automotive: bumpers, fenders, dashboards, brake pads and under-hood components.

- Aerospace: lightweight structural elements, interior panels and insulation components.

- Electrical: switch gear, connectors, insulators and housing enclosures.

- Construction: roofing tiles, insulation boards and floor mats.

- Medical: masks, seals, syringe stoppers and prosthetic components.

- Consumer Products: cookware handles, phone cases and silicone kitchen gadgets.

Each industry benefits from the process’s ability to produce dimensionally accurate and mechanically strong components at a reasonable cost.

Conclusion

So, what is compression molding? It’s more than just a traditional forming process. It’s a proven, flexible technology that shapes the future of manufacturing. The compression molding process produces high-strength, cost-effective and dimensionally accurate parts that serve industries from automotive to aerospace. Whether it’s rubber compression molding for seals or silicone compression molding for medical parts, this process offers great flexibility and performance. At Fecision, we focus on quality, innovation, and precision. Our compression molding services are designed to meet your needs and help your business grow.

Ready to get high-quality molded parts for your next project? Contact Fecision today and let us turn your ideas into reality.