CNC Laser Cutting is an advanced, highly precise cutting technology that has transformed manufacturing and fabrication across industries. The technology combines the power of laser beams with the precision of computer numerical control (CNC) to create clean, accurate cuts, engravings, and etchings on a wide variety of materials. CNC Laser Cutting is used in applications ranging from automotive and aerospace to electronics and signage. In this article, we will explore what CNC laser cutting is, its process, its different types, and its applications, as well as compare it to other CNC Machining methods to help you understand its importance in modern manufacturing.

1. What Is CNC Laser Cutting?

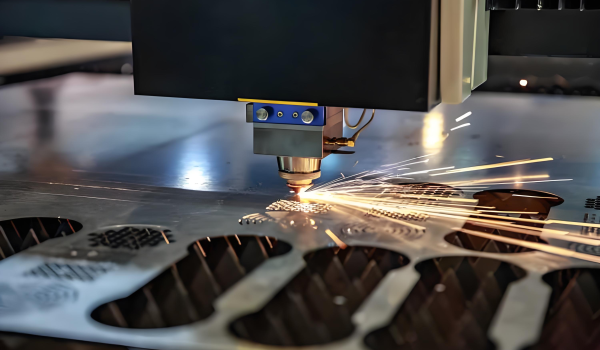

CNC laser cutting is a process that uses a focused laser beam to cut, etch, or engrave materials with exceptional precision. The laser beam is generated through a laser resonator and then directed toward the material to be cut. As the laser interacts with the material, it either melts, burns, or vaporizes the material, resulting in a clean, precise cut. A computer controls the movement of the laser beam and the workpiece through CNC technology, which ensures that the cutting is done accurately and efficiently according to a digital design. Laser cutting is extremely versatile and works on a variety of materials, including metals, plastics, wood, and ceramics.

Advantages of Using Laser Technology

Laser cutting technology has several key advantages that set it apart from other traditional cutting methods like plasma cutting or water jet cutting:

- Precision and Accuracy: The most significant advantage of CNC laser cutting is its ability to produce high-precision cuts. With tolerances of up to 0.1mm or even better, CNC laser cutting is ideal for industries that require tight tolerances, such as the aerospace, automotive, and electronics sectors.

- Minimal Material Deformation: Since the laser beam only touches the material’s surface, there is minimal heat transfer to the surrounding areas. This reduces the chances of warping, bending, or distortion that might otherwise occur during cutting.

- High-Speed Cutting: Laser cutting is typically faster than traditional methods like milling or EDM. This increased speed not only reduces production times but also lowers operational costs, making it an attractive option for manufacturers seeking efficiency.

- Low Material Waste: Laser cutting allows for precise cuts with minimal kerf (the width of the cut), reducing material waste and improving cost-efficiency. The ability to nest parts within a sheet of material further maximizes material utilization.

- Flexibility in Design: CNC laser cutting can handle complex designs with intricate details, which might be difficult or impossible with conventional cutting tools. With the use of CAD software, it’s easy to create and modify designs before sending them to the machine, offering flexibility for customization.

2. Types of Laser Cutting Processes

There are three primary types of laser cutting processes commonly used in CNC laser cutting systems: CO2 laser cutting, fiber laser cutting, and Nd:YAG laser cutting. Each of these has its unique characteristics and advantages depending on the material being cut and the application’s specific requirements.

CO2 Laser Cutting

CO2 lasers are one of the most common and oldest types of laser cutting technology. They use a mixture of gases, including carbon dioxide, nitrogen, and helium, to generate the laser beam. The beam is directed and focused onto the material, which is then cut, etched, or engraved. CO2 lasers are especially effective for cutting thicker materials like stainless steel, aluminum, and mild steel.

Advantages of CO2 Lasers:

- Ideal for thick materials: CO2 lasers work exceptionally well on thicker materials and metals like stainless steel and aluminum.

- Versatility: CO2 lasers are suitable for both cutting and engraving a wide range of materials, including metals, plastics, and wood.

- Cost-Effectiveness: CO2 laser systems are generally more affordable compared to other laser types, making them a popular choice for small to medium-sized businesses.

However, CO2 lasers are less energy-efficient than fiber lasers and require more maintenance, especially for the gas-based components.

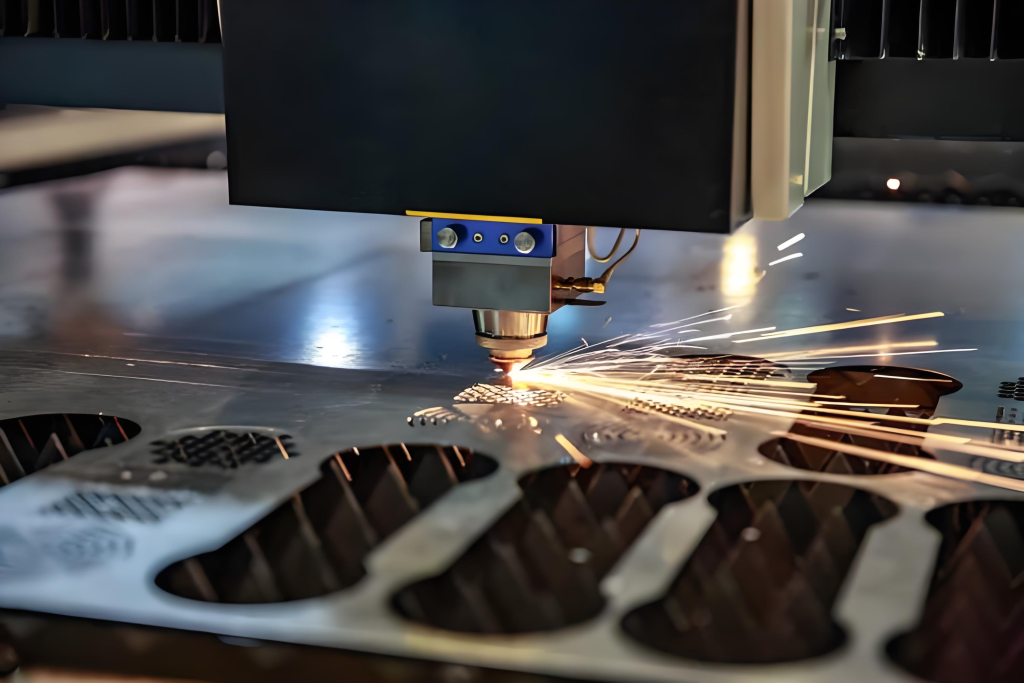

Fiber Laser Cutting

Fiber lasers use a solid-state laser generated by a fiber optic cable. The laser beam is produced by a laser diode and is transmitted through the fiber-optic cable. The fiber laser is known for its high energy efficiency and ability to cut through thinner materials at high speeds.

Advantages of Fiber Lasers:

- Higher Efficiency: Fiber lasers are highly energy-efficient, meaning they produce less heat and consume less electricity. This efficiency translates into reduced operational costs.

- Faster Cutting Speed: Fiber lasers are capable of cutting thinner materials at much faster speeds than CO2 lasers.

- Maintenance: Fiber laser systems have lower maintenance requirements because they don’t rely on gas-filled components, which can wear out over time.

Fiber lasers are ideal for cutting thin metals, including steel and aluminum, and are becoming the preferred option in industries that demand fast processing and high-quality cuts.

Nd:YAG Laser Cutting

The Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) laser uses a crystal as the medium to generate the laser beam. This type of laser is capable of delivering high-power beams that are well-suited for cutting thicker materials, such as titanium and hard alloys.

Advantages of Nd:YAG Lasers:

- High Power: Nd:YAG lasers provide excellent cutting capabilities on thicker materials.

- Precision: The Nd:YAG laser is capable of producing high-quality cuts with superior edge finishes.

- Versatility: Nd:YAG lasers can also be used for marking, engraving, and welding applications, making them highly versatile.

However, Nd:YAG laser cutting systems can be more expensive to purchase and maintain compared to CO2 and fiber laser systems.

3. Applications of CNC Laser Cutting

CNC Laser Cutting technology is used in a wide range of industries for various applications. Its versatility, precision, and speed make it suitable for industries ranging from aerospace to signage and electronics.

Metal Fabrication and Automotive Industry

One of the primary uses of CNC laser cutting is in the metal fabrication and automotive industries. Laser cutting is particularly effective for manufacturing parts, components, and assemblies with high precision. In the automotive industry, CNC laser cutting is used to cut sheet metal parts for car frames, engine components, and body panels. The precision of the process ensures that each component is cut to exact specifications, which is critical for both performance and safety in automotive manufacturing.

Electronics and PCB Manufacturing

In the electronics industry, CNC laser cutting is used for creating printed circuit boards (PCBs), microelectronics, and other small components. The technology allows for incredibly precise cuts and engravings, which are essential for the miniaturization of modern electronic devices. Laser cutting is particularly useful for the creation of components that require fine details, such as connectors, housings, and PCB layers. The ability to cut complex shapes with high precision means that laser cutting is well-suited for prototyping and low-volume production of electronic parts.

Signage and Engraving

Laser cutting has become increasingly popular in the signage industry. The technology allows for the creation of custom signs with intricate designs and high levels of detail. CNC laser cutting can be used on a variety of materials, including metals, acrylics, wood, and plastics, making it versatile for producing both indoor and outdoor signs. In addition to signage, laser cutting is also used for engraving applications. It is ideal for creating personalized gifts, awards, and promotional products.

4. CNC Laser Cutting Process and Techniques

How CNC Laser Cutting Works

The CNC laser cutting process begins with the design of the part to be cut, typically created using CAD software. The design is then transferred into a CNC system, which converts it into instructions that guide the laser head during the cutting process. The laser head moves along the material to cut it according to the design specifications. The power, speed, and focus of the laser are adjusted depending on the material being cut. Higher power is generally required for cutting thicker materials, while a lower power setting is used for thinner materials. The focal length of the laser is adjusted to ensure that the beam is concentrated at the optimal point on the material’s surface.

Role of CAD and CNC Programming

CAD software plays a critical role in CNC laser cutting. CAD allows designers to create detailed blueprints and models of the parts to be cut, ensuring that all measurements and tolerances are accurate. Once the design is finalized, it is transferred to the CNC system, which controls the laser cutter’s operations. The CNC programming translates the CAD model into CNC Machining readable instructions that direct the laser to follow the design path. The program can adjust parameters such as speed, power, and cutting depth, depending on the material and desired cut quality.

Importance of Laser Power and Beam Focus

The laser’s power and focus are critical factors in determining the cut quality. The power of the laser determines how deeply it can cut into the material, while the beam focus affects the intensity of the cut. A more focused beam results in a cleaner, finer cut, while a less focused beam may result in a wider kerf or less accurate cutting.

5. Materials Used in CNC Laser Cutting

CNC laser cutting is suitable for a wide range of materials, from metals to plastics and composites. The material type influences the laser settings required for the cutting process.

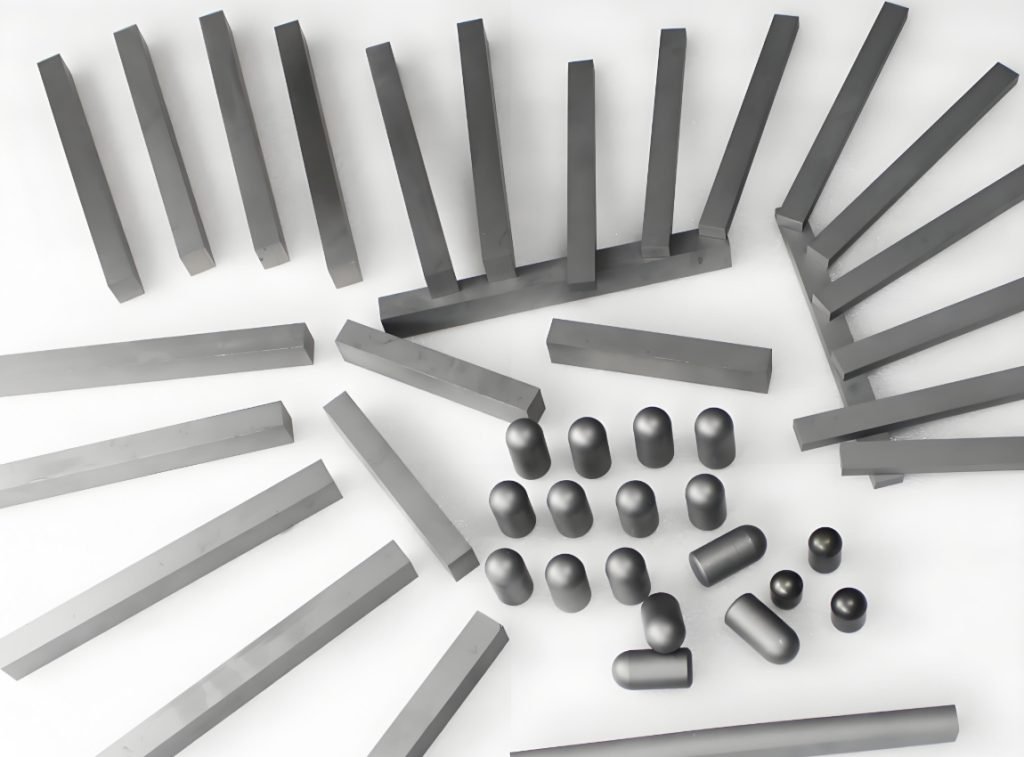

Metals (Steel, Aluminum, Copper)

Metals are among the most common materials used in CNC laser cutting. Steel, aluminum, and copper are often used in industries such as automotive, aerospace, and construction. Each metal has different properties, which require adjustments to the laser’s power and speed. For example, aluminum requires a higher power setting due to its reflective properties, while steel can be cut quickly and efficiently at moderate power levels.

Plastics and Composites

Laser cutting is also effective for cutting plastics and composite materials. Acrylic, polycarbonate, and fiberglass can be easily cut and engraved using CNC lasers. Laser cutting of these materials is popular in industries like signage, packaging, and consumer products. However, the laser settings must be adjusted carefully to prevent issues like material melting or burning.

Key Laser Cutting Operations

There are various key operations involved in CNC laser cutting, each serving distinct purposes in different industries.

Engraving vs. Cutting

Engraving involves etching a design or pattern onto the surface of the material, while cutting involves completely removing material to create a shape. The power and focus of the laser are adjusted differently for each operation. Engraving requires lower power and a broader beam, while cutting requires higher power and a narrower focus to achieve clean, precise edges.

2D vs. 3D Laser Cutting

CNC laser cutting can be used for both 2D and 3D cutting applications. Most laser cutting is performed in two dimensions (2D), but 3D laser cutting is becoming increasingly popular for creating more complex shapes. In 3D laser cutting, the laser head moves along multiple axes to cut or engrave three-dimensional surfaces.

6. Cost Factors in CNC Laser Cutting

Equipment and Operational Costs

The initial cost of CNC laser cutting equipment can be significant, with high-end systems often running into the hundreds of thousands of dollars. However, over time, these systems are cost-effective due to their high efficiency and low maintenance costs. The operational costs also depend on factors such as the material being cut, the thickness of the material, and the complexity of the design.

Cost Comparison with Plasma and Water Jet Cutting

While CNC laser cutting tends to have higher upfront costs than plasma and water jet cutting, it offers better precision and efficiency. Plasma cutting is faster but less accurate and generates more material waste, while water jet cutting is precise but slower and generally more expensive. The overall cost-effectiveness of CNC laser cutting makes it the preferred choice for applications where high-quality cuts are essential.

CNC Laser Cutting vs. Other Machining Methods

CNC milling uses rotating cutting tools to remove material from a work piece, while CNC EDM (Electrical Discharge Machining) uses electrical discharges to remove material. In contrast, CNC laser cutting uses a focused laser beam. While CNC milling is ideal for producing parts with complex geometries, laser cutting is better suited for cutting thin materials and creating intricate designs with minimal waste.

Efficiency, Accuracy, and Material Suitability

Laser cutting offers better precision and faster cutting speeds for thin and medium-thickness materials. CNC milling, on the other hand, is better suited for more complex shapes and 3D features. CNC EDM is typically used for hard materials and very fine details, but the process is slower and more expensive.

7. Conclusion

CNC Laser Cutting offers significant advantages, such as high precision, versatility, speed, and low material waste. It is ideal for industries that require accurate cuts and intricate designs, such as automotive, aerospace, electronics, and signage. The process is highly efficient, and its ability to cut a wide range of materials makes it an essential tool in modern manufacturing. When selecting a cutting method, it is essential to consider factors such as material type, cutting speed, precision, and overall costs. CNC Laser Cutting excels in applications requiring high precision and quality, making it the ideal choice for many industries.