Injection molding is a fundamental process for mass manufacturing plastic parts. Every flawless plastic part has a significant but often overlooked partner: the injection mold base. It serves as the foundation and skeleton for the entire molding operation.

Without a mold base manufactured with high-quality standards and attention to detail, even the finest-made mold cavities and cores would not work reliably. This article will help you understand everything about injection mold bases — the basic structure, common injection mold base materials, design considerations, and various types.

What Is an Injection Mold Base?

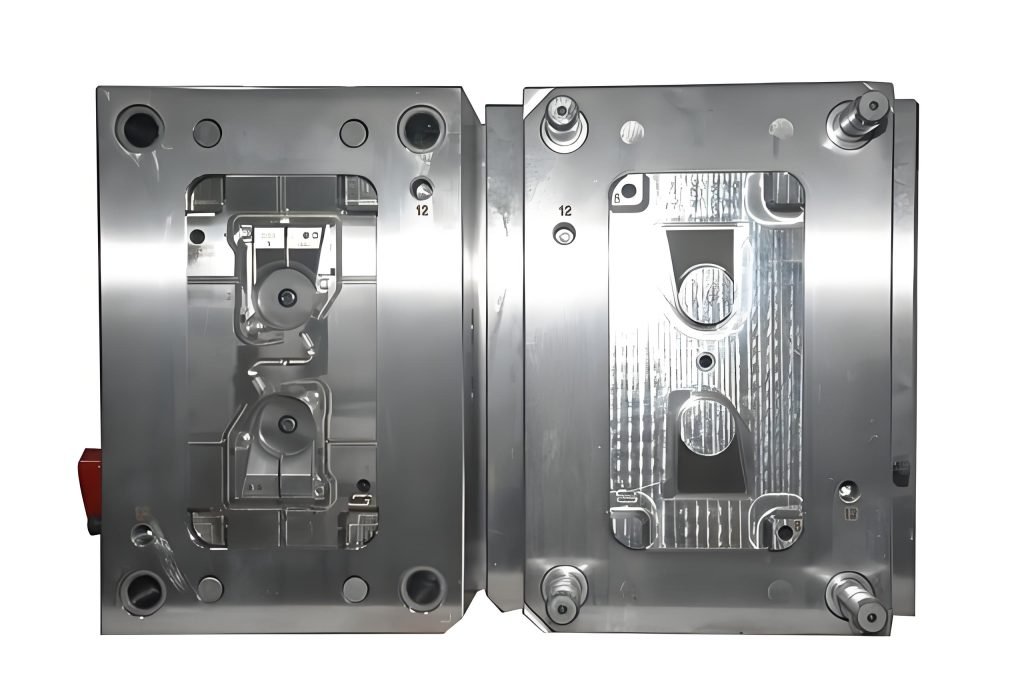

A plastic injection mold base is a standardized, pre-manufactured framework of steel plates and standard elements that provides support to the cavity and core inserts. It is the essential interface between your injection-molding machine and the parts that form the actual product. If there is ever a flaw in the design of the mold base, the entire mold process will likely break down.

A typical injection mold base typically consists of A plate/B plate, top clamp plate/rear clamp plate, return pins, etc. While the mold cavity demonstrates the shape of the part, the mold base facilitates and supports the entire molding process.

Why Is It So Important?

A mold base has a few responsibilities. It provides a rigid, warp-proof structure within which your cavity and core inserts will remain aligned perfectly. In terms of part quality, this is a big deal. It also contains the ejection, cooling, and sometimes the hot-runner system, which enables these systems to operate efficiently and smoothly.

A mold base also needs to be tough enough to absorb all the tremendous clamping force and injection pressure without distortion. Lastly, it provides standardized patterns to reduce the time it takes to transfer the mold from one machine to another.

Mold Base Structure

A mold base is a complex assembly. Understanding each key plate and component is essential for building a reliable and efficient mold.

Top Clamp Plate

The top clamp plate is the plate that bolts to the stationary part of the injection molding machine. It’s the very first part of the mold base and it securely holds the mold in place. It also helps to locate the mold’s feed system, which is where the plastic enters, using a locating ring.

A-Plate

The A-plate is where the cavity insert is fixed, or it can be directly machined with the cavity itself. This is the plate that first faces the molten plastic as it’s injected. Because of this direct contact, the A-plate needs to have very good surface hardness to resist wear and tear over time.

Stripper Plate

You might use a stripper plate when ejector pins would leave marks on a cosmetic or transparent part. Instead of the pins pushing the component from the mold, the stripper plate, or a stripper ring, helps “peel” the part away from the core. This way, you can be sure the final part has a clean surface as well.

B-Plate

The B-plate holds the core insert, which forms the inner shape of your part. It can also be designed to extend the runner system. Its thickness is important because it influences both its overall strength and the layout of the cooling channels. A thicker B-plate offers more stability and allows for more complex cooling designs.

Support Plate (Optional)

A support plate is sometimes added under the B-plate when the projected cavity pressure is very high. If the B-plate alone isn’t thick enough to handle the stress, this extra plate provides additional support. It helps prevent plate deflection, which can lead to part defects and can even damage the mold.

C-Plate (Spacer Block)

The C-plate, or spacer block, creates the height for the ejector housing. The height of this space is important because it dictates how far the ejectors can travel to push the part out. The taller your part, the taller the spacer blocks need to be.

Rear Clamp Plate

The rear clamp plate fastens the moving half of the mold to the machine’s ejector-side platen. This is the part that moves back and forth during the molding cycle. It works with the front clamp plate to ensure the mold is securely mounted to the machine.Ejector Pin & Retainer Plates

The plates work in conjunction with each other to capture and guide the ejector pins, sleeves, or blades. They are the nucleus of the mold’s ejection system. The ejector pins are pushed forward by the machine’s ejector mechanism, and this pushes the finished product out of the cavity. The stroke is limited by the height of the spacer blocks.

Return Pins

Though small, return pins are crucial. Their job is to force the entire ejector set to retract or pull back prior to the mold closing. Ejector pins that do not fully retract will be crushed by the core and cavity during the mold closing sequence, causing damage.

Commonly Used Mold Base Materials

The injection mold base material is very important because it impacts everything from the durability to the cost of the mold. Below are the most common materials used for injection mold bases.

Steel

This is the most common mold base material chosen for its strength, wear resistance, and long-term use. There are several grades of steel to use for different requirements.

No. 1 Steel (P-20)

P-20 steel is a cost-effective general-purpose steel commonly used for injection mold bases. It is pre-hardened and is ready for machining, easy to work with. Designed to be machined and polished quickly, it helps minimize tooling costs. This is an excellent material for almost any standard molding project.

No. 3 Steel (S-7)

S-7 steel is an excellent choice when your mold needs to handle a lot of stress. It has high impact toughness and is very resistant to chipping. This makes it ideal for molds that undergo frequent changes in shut-height or for molding with abrasive resins. S-7 steel is generally tougher than P-20, giving you added durability for more demanding applications.

No. 7 Steel (H-13)

H-13 is a hot-work grade steel made for harsh environments. It will keep its strength and hardness, even at high temperatures. This makes it an excellent material for molding high-temperature plastics such as PEEK, or for doing very long production runs where the mold will heat up and stay hot.

Aluminum Alloy

Aluminum alloys are a fantastic choice for prototype or short-run plastic injection mold base projects. They weigh only one-third of what steel does, are much faster to machine, and have superior heat removal properties. This means you can get your parts made much faster. However, the wear resistance of aluminum alloys is less critical.

Design Considerations for Mold Bases

You should also consider a few elements that will directly affect your final part when designing a plastic injection mold base.

Part Design and Intricacy

The design of your part will heavily influence the type of mold base you need. For simple, open parts, an A-Series base offers a broad insert pocket depth and the lowest added cost. If your part has complex features like undercuts, you might need an AX-, T-, or a custom base.

Integration of Advanced Functions

Modern injection mold base suppliers can pre-mill special features right into your mold base, and you have to plan them on a specification sheet ahead of time. This may include clearance pockets for hot runners, slots for hydraulic cylinders, and vacuum manifolds for in-mold labeling. Prefabrication of any special features into your mold base would save you several hours.

Production Volume

The volume that you plan is a major consideration in injection mold base material selection. If you are running low to moderate production volumes, A- or B-series are flexible and cost-effective choices. If you need to produce over a million shots or have very fast cycles, you can consider a No. 7 stainless base to maintains accuracy over time.

Particular Injection Molding Criteria

Every job is different. If you plan to work with tight tolerances, you will want thicker plates, ground to a precise parallelism. If you will be working with some high-temperature resins, you may need even more cooling channels, and you will also make sure the mold base is made of a corrosion-resistant material; otherwise, you run the risk of damaging the mold.

Overall Dimensions and Plate Thickness

A good rule of thumb is that the plate deflection under clamping pressure should be less than 0.05 mm. For large plates, it becomes a necessity to perform finite-element checks. This way, you can predict precisely how the plates will act when under pressure, and confirm that the plates are thick enough to avoid warping or other issues.

Cost Optimization

You can optimize costs by starting with a standard A- or B-series catalog size and only customizing the plates that absolutely affect your mold’s function. Another great option is to use interchangeable Xpress plates for emergency replacement. Instead of machining a new one, you can get a pre-machined plate for rapid delivery.

Types of Mold Bases & Applications

Let’s see the several types of bases and their applications. Selecting the correct base can create sustainable time savings and savings on the overall cost of the project.

A-Series – Standard Two-Plate

The A-Series is the most versatile and commonly used type of mold base; it is a standard two-plate design, meaning it has a single parting line, and both the runner and the part come out together. The A-series would be an excellent choice for many products, including automotive interior panels, consumer electronics housings, and toys.

B-Series – Five-Plate Economy

The B-Series is a great option when cost and height are a concern. It’s often called a five-plate economy base because it combines the top-clamp plate with the A-plate and eliminates the support plate to save on steel. It’s perfect for high-volume disposable packaging, like medical petri dishes.

T-Series – Top Runner with Automatic Degating

The T-Series uses two floating plates to create a separate runner drop, which allows the gate to break automatically as the mold opens. This is a game-changer for parts that can’t have any gate vestige, like multi-cavity caps, closures, or cosmetic containers. The gate is automatically removed, which saves you a secondary operation.

AX-Series – Enhanced A-Series for Complex Cores

The AX-Series is an elevated version of the A-series that has an extra floating plate on the cavity side. The second plate can be used to pull internal undercuts, which are features that cannot be accomplished with a simple open-and-close mold. The AX-series would be ideal for parts such as threaded bottle necks, pump housings, or connectors.

X-Series – Stripper Mechanism for Round Parts

The X-Series is a design with a stripper plate placed between the A and B plates. The stripper plate pushes on the edge of the part, which is ideal for parts with thin walls or round parts like yogurt cups, paint cans, or medical vials. Because the stripper plate pushes on the edge of the entire part, the mold will not leave witness marks that ejector pins would have left.

Custom Mold Bases – Tailored for Unique Projects

In cases where the project has unique needs that are outside of the standard configurations, a fully custom mold base is the answer. Non-standard sizes, special material needs, or integrated mechanisms are examples where fully custom is necessary. At Fecision, we specialize in the design, engineering, and manufacture of high-quality custom injection mold bases to suit your specific needs. Review our custom mold base capabilities to ensure your project starts off on the right foot.

Final Words

The plastic injection mold base is more than a holder for cores and cavities — it is the fundamental framework that defines the mold’s performance, durability, and dependability. The selection of type, material, and design is a critical decision that impacts part quality and total production cost.

In the process of acquiring injection mold bases, an important decision is partnering with injection mold base suppliers who can guarantee quality. Fecision is a recognized industry leader who can provide:

- Quality Materials: We use only top-quality, traceable materials to ensure the long-term performance and life span of your base.

- Complete Quality Process: A base from Fecision will pass a strict inspection process that ensures perfect alignment, hardness, and dimensional accuracy.

- Superior Stability: Our quality machining creates a mold base that is stable, even during high-pressure cycling, which generally reduces wear and prevents significant and costly downtime in your production.

- Full Customization: We have both standard types and fully custom designs to provide you with the foundation for your specific application.

Ready to build a tool that lasts for millions of cycles? Contact Fecision now to partner with an expert mold base supplier.