In machining, the powder chuck plays a crucial role in efficiency, precision, and production, aiming to offer a record power chuck that provides a strong and stable clamping force. It is a vital tool in the modern operation. This article will take you on a deep dive into the powder chuck, exploring its key features and applications. We also offer you the best power checks solution to suit your machine’s requirements.

What Is a Power Chuck?

Power chucks are advanced work-holding devices designed for CNC lathes and automated machining systems. Utilizing hydraulic or pneumatic actuation, they provide automated jaw movement for precise, repeatable workpiece clamping – a significant upgrade from manual chuck operation. This automation delivers superior efficiency, consistent clamping force, and enhanced process stability, which is crucial for maintaining tight tolerances and operator safety.

Key Features:

- High-quality material

Standard powder chucks are used for foreign imported materials, which can ensure durability, strength, and abrasion performance.

- Automated operation

Hydraulic or pneumatic operation delivers reliable, powerful clamping force, making these chucks ideal for high-speed and heavy-duty machining applications.

- Versatile designs for powder chucks

Some power chucks have through-holes and can machine the long rods and shafts. Power chuck with a large wedge-type can easily handle large-diameter workpieces.

- Suitable for mass production

Optimized for CNC environments and mass production, maintaining consistent precision even during continuous operation cycles.

Types of Power Chucks

Powder chucks are widely used tools, and there are several types for you to choose from. Each type has a specific design to satisfy the handmade and performance. No matter whether you use it in precision machining, milling or other machining operations, choose a suitable power chuck are matches your machining requirements.

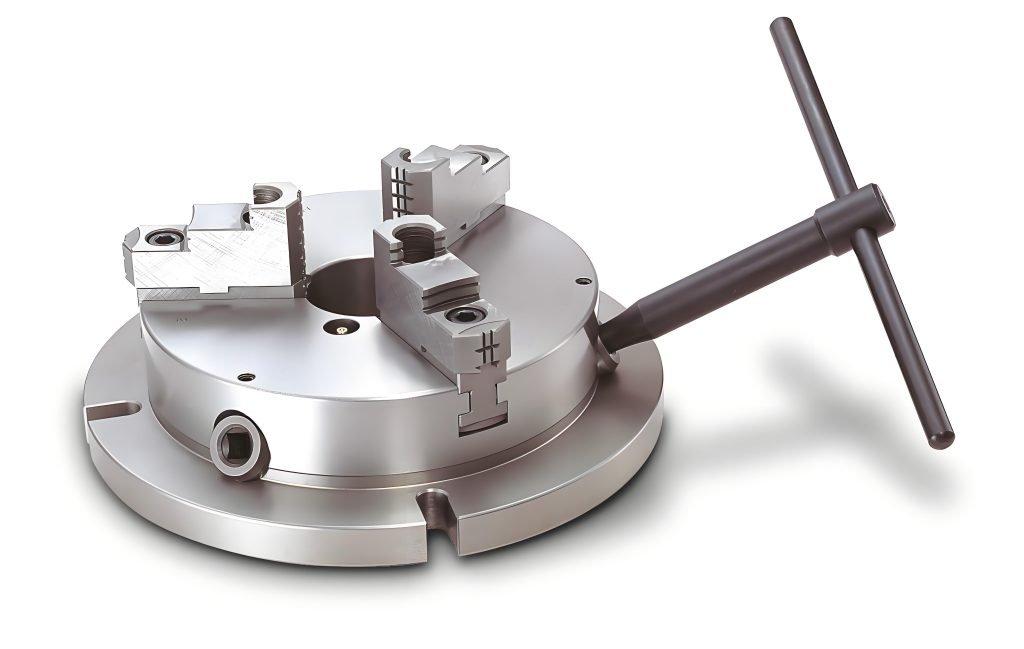

- Three-Jaw Power Chucks

Three-jaw power chucks are the most common and widely used type in machining applications. This power lathe chuck has three jaws, with three clamps arranged in a circular pattern. This kind of power chuck can provide uniform and symmetrical clamping force.

Three-jaw power chucks are suitable for clamp workpieces with regular geometric shapes such as circles or hexagons. They are always used in high-speed spin and take a short time to install, such as turning, face grinding, and cylindrical grinding.

- Four-Jaw Power Chucks

Compared with three-jaw power chucks, the four-jaw power chucks are the with greater flexibility and universality. They are equipped with 4 jaws that can be adjusted independently, and they are capable of achieving precise alignment and clamping of irregularly shaped or asymmetrical workpieces. Four-jaw is especially suitable for fitting square, regular, and irregular workpieces. These workpieces need precise direction and alignment.

- Collet Chucks

Collet chucks are powerful fixtures specially designed for securely holding small-diameter workpieces with high precision. Different from the traditional power chucks, collet chucks have the chucks with a spring mechanism, which can uniformly clamp the workpiece around its circumference. This uniform clamping method can ensure coherence and repeatability. These hydraulic fixtures are used for high precision and extremely small part tolerances. Collet chucks are used in CNC machining, Swiss-style turning, and the precise processing of small parts (such as shafts, pins, and bolts).

- Hydraulic Power Chucks

Hydraulic power chucks utilize hydraulic pressure to quickly and firmly clamp and release the workpiece. This kind of power chucks have powerful clamping and excellent grasping force, fitting for heavy-duty processing applications and high-speed machining operations.

Hydraulic power chucks in all chucks can offer consistent grasping, ensuring that there is uniform grip and stability during the processing. They are often used in lathes, machining centers, and other CNC machines for operations such as turning, milling and drilling.

- Pneumatic Power Chucks

Pneumatic power chucks use compressed air to drive the clamping mechanism to operate. These power chucks are fast and sensitive to clamp. You can take the pneumatic power chucks in the application that needs to quickly change the workpiece and provide a highly efficient working environment.

Pneumatic power chucks are popular for simplicity, reliability and ease of use. They are widely used in industries such as automobile manufacturing, aerospace processing, and others where efficiency and productivity are of crucial importance.

Key Benefits of Power Chucks

- Boosted Productivity

Power chucks dramatically reduce setup times and enable faster machining cycles, significantly improving overall production efficiency.

- Superior Precision

Their ultra-stable clamping ensures exact workpiece positioning and maintains tight tolerances for high-accuracy machining operations.

- Versatile Adaptability

Available in multiple configurations to securely hold workpieces of varying sizes, shapes, and materials for diverse applications.

- Enhanced Safety

The powerful, reliable grip minimizes workpiece slippage risks while protecting both machining quality and operator safety.

Common Applications of Power Chucks

Power chucks serve as essential work-holding solutions across multiple industries, offering reliable performance for precision machining operations. Key applications include:

Industrial Machinery Components: High-accuracy machining of gears, shafts, and mechanical assemblies

Automotive Manufacturing: Production of critical drivetrain components including axles, transmission parts, and wheel hubs

Aerospace Engineering: Fabrication of precision aircraft components requiring tight tolerances

Heavy Equipment Production: Secure clamping for large-scale parts in construction and agricultural machinery

General Metalworking: Versatile solutions for various turning, milling (power milling chucks), and grinding applications

Power Chuck vs. Manual Chuck

Before we take a chart to compare power chuck vs. manual chuck, let us have a simple understanding of manual chucks.

What is a Manual Chuck?

Manual chuck is the traditional chuck device. The operator needs to use a chuck key or wrench to manually tighten and loosen the chuck jaws. This kind of chuck is used in traditional lathes and some milling machines. It offers an effective choice for clamping the workpiece.

Key Features of Manual Chucks

Manual operated: You need to use a chuck key or wrench to tighten or loosen the chuck jaws.

Reliable and easy to repair: No need for additional power

Fit for small-scale production: It is fit for workshop and small-batch manufacturing environments.

The installation process is slow: Every time a workpiece is processed, manual adjustment is required.

Comparing Manual Chucks vs. Power Chucks

| Feature | Manual Chuck | Power Chuck |

| Installation Rate | Slowly | Fast |

| Clamping Force | Depends on the operator’s strength. | Use the hydraulic or pneumatic drive |

| Precision | Applicable to general processing | High precise and tight tolerence |

| Production Volume | Suitable for small batch tasks | Apply for mass production |

| Application | General turning, milling | CNC machining and high speed |

| Cost | Initial investment is low. | The investment is relatively high, but there will be savings benefits in the long term. |

Which One Should You Choose?

Opt for a Manual Chuck When:

- Your operations involve small-scale or low-volume production.

- Workpiece changes are infrequent (minimal adjustments needed).

- Cost efficiency and easy maintenance are top priorities.

Opt for a Power Chuck When:

- Your application demands high precision, repeatability, and speed (e.g., CNC machining).

- You handle mass production or heavy-duty machining requiring consistent clamping force.

- Reducing setup time and boosting productivity are critical.

Precision-Engineered Power Chucks for Every Industry

Fecision delivers a diverse range of high-performance power chucks, designed to meet the exacting demands of modern machining across automotive, aerospace, medical, and industrial applications.

Our ISO 9001-certified power chucks deliver ≤0.005mm precision for flawless CNC performance. Hardened steel construction and dynamic balance testing ensure unmatched durability. With industry-proven expertise, we offer advanced clamping technologies for superior stability. Customizable bore sizes, hydraulic/pneumatic actuation, and adaptive designs provide tailored solutions for unique machining challenges.

Engineered for precision, built for longevity—Fecision power chucks set the standard for quality and reliability in high-stakes manufacturing environments. Ready to make your solution, with precision and efficiency? Contact Fecision for a tailored solution right away!