Modern manufacturing has evolved into a sophisticated world of precision tools and metrics, serving as the backbone for quality products. CNC machining, specifically CNC turning, is an advanced technology revolutionizing manufacturing.

These types of equipment, including CNC turning centers, are used heavily in any industry where precise equipment is necessary, mainly in the automotive, aerospace, medical, and electronic industries. They are essential devices in manufacturing, as they create material in excellent and precise shapes with very little human interaction.

In this blog, we will explore a CNC turning centre, its functions, and its major benefits to all manufacturing industries. Whether you are new to CNC machining or know a lot about it, this article will educate you about CNC turning and why it matters in the current manufacturing industry.

What Is CNC Turning?

Before discussing the details of a CNC turning centre, we need to understand CNC turning as a process. CNC turning is a subtractive manufacturing process in which a workpiece is rotated on a spindle. At the same time, a cutting tool is applied to remove material, usually metal or plastic. This turning tool, which can operate in several dimensions, turns the material into round or cone shapes.

While manual turning is operated by hand through an operator controlling the machine, CNC turning is controlled through computer programming. The program controls the machine’s movements, including the cutting tool’s speed, position, and path. CNC turning allows for highly specialized, automated processes providing great accuracy, repeatability and high efficiency, making it particularly well-suited for components with close tolerances and complex configurations.

What Is a CNC Turning Center?

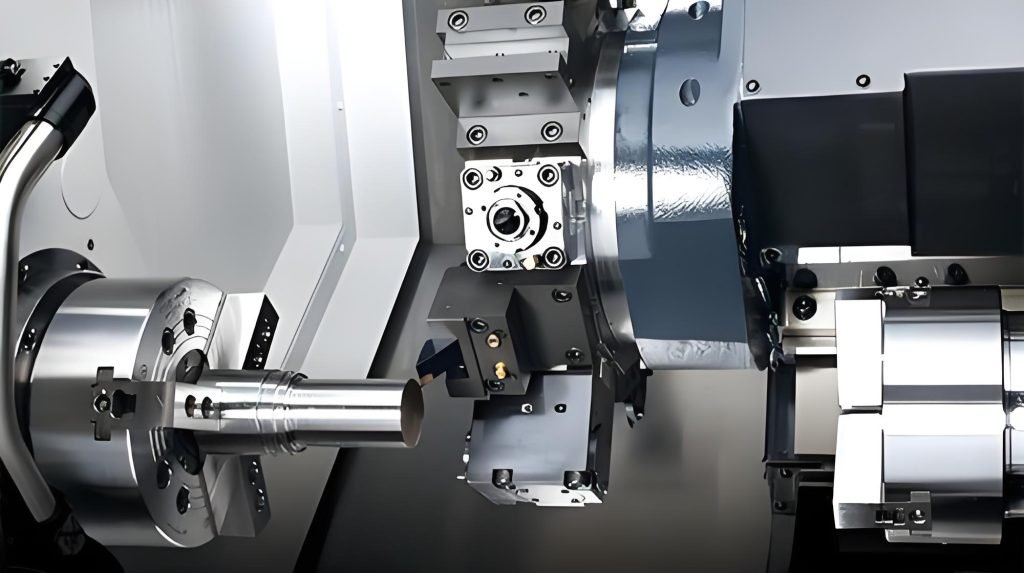

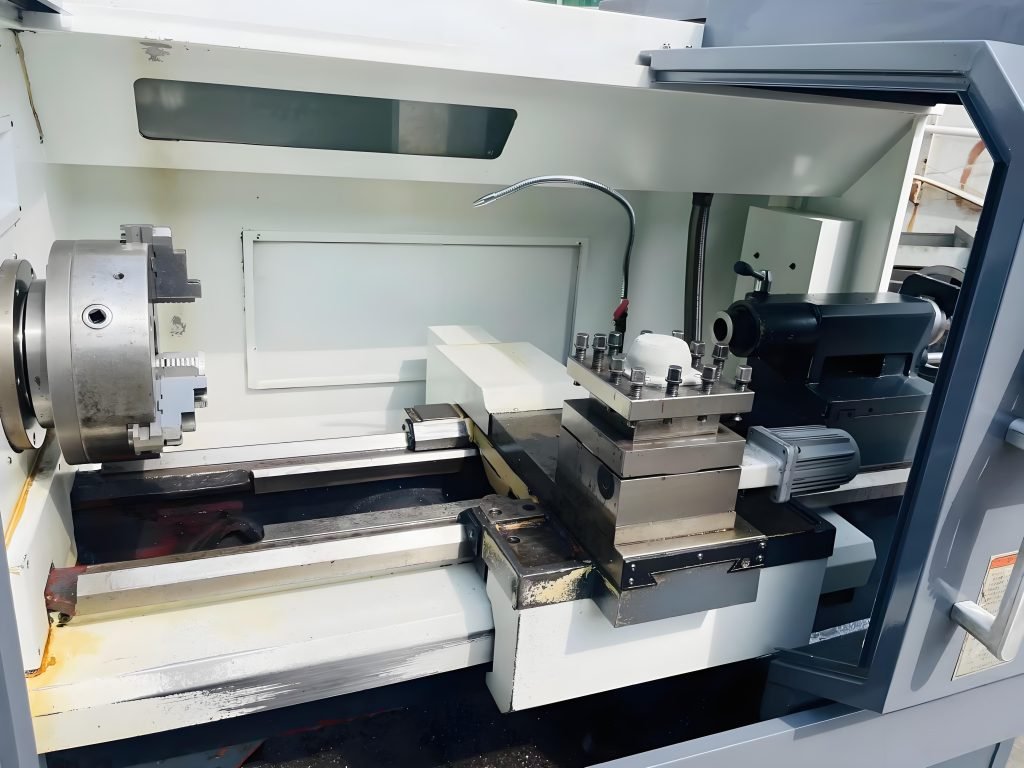

A detailed machine involved in CNC turning is a CNC turning centre that creates cylindrical/round-shaped parts. It consists of a revolving spindle that clamps the workpiece, which uses stationary or mobile cutting tools to remove matter from the surface and shape the part. A CNC turning centre is a wood or metal lathe that uses computer numerical control (CNC) to automate its movements.

The only difference between a CNC turning centre and other machines is its extra features. CNC turning machines typically perform only turning operations. Still, CNC turning centers feature additional capabilities, including drilling, milling, and tapping operations. The all-in-one versatility makes the CNC turning centre an essential tool for manufacturers aiming to boost productivity and minimize the necessity for numerous machines.

Key Features of a CNC Turning Center

Some key features of a CNC turning centre include: Here are some of its features:

- Rotary Spindle: This holds the workpiece and rotates the spindle at high speeds. The rotation allows the cutting tool to carve and chop away a part of the material, thus giving it the required shape.

- Turret Tooling: This allows multiple cutting tools to be mounted on a rotating turret and moved into position as necessary. A CNC turning centre (machine) can perform various operations without manually changing tooling during the machining process.

- CNC Control System: At the centre of the coverage is the CNC control system. It dictates the command to position and operate the cutting tools, controlling the machine’s pace, accuracy, and precision. This system guarantees that no program has latencies between each movement it executes.

- Automatic Tool Changer (ATC): In many CNC turning centres, the machine is fitted with an ATC that automatically changes tools, improving productivity by minimizing the time spent downtime between operations.

- B-Axis and C-Axis Capabilities: These axes allow you to do more complex cutting operations. With these additional axes, CNC turning centres can manage more complicated designs.

Types of CNC Turning Centers

Various CNC turning centers are available, each tailored for specific tasks. The three most common types are:

- Vertical CNC Turning Center: In this design, the workpiece is vertically mounted. It is ideal for larger or heavier workpieces since the cutting tool moves up and down. Having the fixture vertical makes loading and unloading parts easier, too.

- Horizontal CNC Turning Center: The workpiece is mounted horizontally in this design. This setup is commonly used for compact, tight-tolerance components that require a fast machining time.

- Twin-Spindle CNC Turning Center: Twin-spindle CNC turning centres have 2 spindles, enabling you to machine 2 parts simultaneously. This setup is best for high-volume production, as it speeds up the production process.

- Multi-Tasking CNC Turning Center: These sophisticated machines integrate CNC turning, milling, and drilling capabilities into a single unit. This minimizes the setups, thus machines and increases productivity while lowering production time as a whole.

How CNC Turning Centers Work

The working process of a CNC turning center can be broken down into the following steps:

- Setup: The workpiece is clamped to the spindle and cutting tools are loaded to the turret. It is followed by writing a CNC machining program to dictate to the machine how and where to move to cut the part out.

- Material Removal: As the workpiece is spun, cutting tools located at various axes remove the material. A cutting tool usually performs turning, drilling, milling, or tapping operations depending on the program.

- Inspection:Once the machining is complete, the part is inspected for surface finish and dimensional accuracy. As such, most CNC turning centers possess measurement systems that ensure the part is being produced correctly.

- Finishing: The component may receive further finishing processes like polishing or coating before being ready.

Benefits of Using a CNC Turning Center

Here are the benefits:

- Precision and accuracy: Given the nature of CNC machining, it can produce precise cuts and, as a result, parts that comply with tight tolerances.

- Increased Productivity: By executing multiple operations in a single setup reduces overall time of production and increases throughput and promptness in delivery

- Consistency: After programming, a machine can continuously make the same piece again and again, assuring quality and avoidance of human error.

- Flexibility: CNC turning centres can be used with many materials including metals like aluminium and brass, plastics, packaging and other tubular forms.

- Sustainable for the Future: CNC turning centres are well placed to address the increasing demand for sustainability in manufacturing.

- Increased Safety: Since the CNC turning center is automated, it requires minimal manual intervention, which helps to keep the workplace safer.

Applications of CNC Turning Centers

CNC turning centers are utilized in various industries because of their high precision and versatility. Here are some of the most common applications:

- Automotive: Components like engine parts, shafts and bushings.

- Aerospace: Turbine blades, housings and structural components

- Medical: For making precision parts such as surgical instruments, implants and prosthetics.

- Electronics: Making little components like connectors, housings, and sensors.

CNC Turning Center vs. Traditional Lathe Machine

One of the frequently asked questions during the discussions of the CNC turning centers is how they are different from conventional lathe machines. While both machines have similar processes, the main difference is in automation, precision, and versatility which CNC turning centers provide.

The conventional lathe machine is usually operated conventionally, which indicates that the operator should adjust the motion of the cutting tool and workpiece. While it can accomplish simple turning tasks, a manual lathe cannot match the automation and repeatability of a CNC turning center.

On the other hand, a CNC turning center automates the process using CNC machining, allowing it to run continuously with minimal to no human supervision after programming.

This higher degree of automation brings several benefits in relation to regular lathes. CNC turning centers allow for greater automation and can produce high rates of identical pieces, while conventional lathes might necessitate more manual work and more regular tool replacements during production.

In general, switching from a standard lathe machine to a CNC turning center can significantly enhance productivity, part precision, and cost-effectiveness, particularly for sectors that demand high-precision components.

CNC Turning vs. CNC Milling

CNC turning works best for producing cylindrical and round parts. At the same time, CNC milling is used when the components that need to be made have more complex shapes than just being round. What is a 5-axis CNC milling CNC turning solution? Many advanced CNC turning centers also have milling capabilities that allow manufacturers to perform multiple operations on the same machine.

Explore Precision Manufacturing Solutions at Fecision

Say goodbye to further delays with CNC machining solutions. At Fecision, we understand how the supply of CNC machining solutions directly impacts your production goals. Our CNC turning, mold tooling, and further advanced services can boost the efficiency and accuracy of your production methods with a commitment to quality and excellence.

With our industry expertise, we can help you with solutions with cutting-edge technologies that will help you optimize your production workflow, reduce waste, and improve your products’ overall quality.

For everything from basic CNC Turning to complex multi-tasking operations, Fecision provides custom solutions that exactly fit your applications. We follow our clients closely to identify their needs to offer high-performance, economical services. Every project is treated with care as if it is our prerogative to ensure your products receive the best quality possible.

With our diverse approach to CNC machining, we will create a program that best suits your needs! We are ready to assist you with your ideas and implement them accurately and creatively!

Conclusion

CNC Turning Center: A CNC turning center is a piece of equipment used in modern manufacturing that provides precision, versatility, and efficiency. From simple cylindrical parts to complex components that require multiple machining operations, CNC turning centers offer many advantages that contribute to improving productivity and reducing production costs.

Fecision is a professional provider of CNC machining services, such as CNC turning, injection moulding, and mould tooling. Our proficient technologies and experienced personnel guarantee your manufacturing requirements are fulfilled with accuracy, dependability, and economic effectiveness.

From streamlining your production process to designing complex features within a tight tolerance, we have the know-how and equipment to meet your back, front, and core results! Contact us today or visit our website to learn more about our services!