The CNC lathe machine uses the concept of CNC (Computer Numeric Control), a technology that enables workers to automate the machining process through computer programming. It allows the precise shaping of metal, plastic, alloys, wood, and other composites.

If you’re wondering how this entire process works—from design phase to execution—this blog is for you. We’ll discuss each step, along with the application of the CNC lathe machine and its advantages in various industries.

What is a CNC Machine?

A CNC machine is an automated manufacturing tool that uses computer programming to control machining operations with extreme precision.

Unlike manual machining, where operators control tools by hand, CNC machines follow pre-programmed instructions. They cut, drill, mill, or shape materials like metal, plastic, wood, and composites.

You might have come across these machines if you work in the aerospace, automotive, or medical industry. By using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, CNC machines can create complex parts with minimal human intervention.

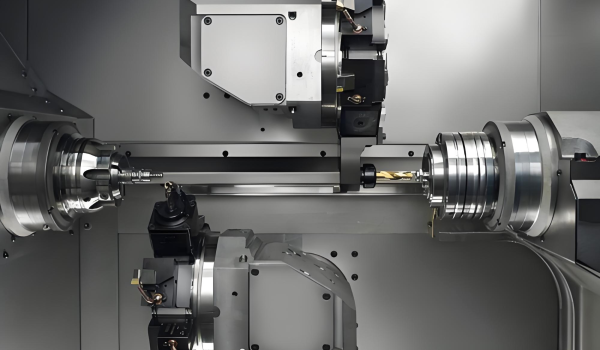

Key Components of a CNC Lathe Machine

A CNC machine comprises several critical components that work together to ensure precise and automated machining. Below are the key components and their functions:

1. Headstock

The headstock houses the main spindle, motor, and gear system, which drive the rotation of the workpiece. The spindle holds the chuck (which grips the material) and rotates it at controlled speeds while the cutting tool removes the material.

2. Lathe Bed

The lathe bed is the base of the CNC lathe, providing structural support to all other components. Made from cast iron or steel, it ensures stability, vibration resistance, and alignment during machining.

3. Chuck

The chuck is a clamping device mounted on the spindle that securely holds the workpiece as it rotates. CNC lathes typically use:

- 3-jaw chucks: Self-centering and ideal for round workpieces.

- 4-jaw chucks: Independently adjustable for irregular shapes.

- Collet chucks: Used for smaller, high-precision parts.

4. Tailstock

The tailstock is positioned opposite the headstock and provides extra support for long or thin workpieces. It prevents bending or deflection by holding the end of the material steady. This part can easily be adjusted along the lathe bed for different part lengths.

5. Foot Pedal

The foot pedal is a convenient control mechanism used by operators to perform certain functions without using their hands. It is commonly used for:

- Opening and closing the chuck to load and unload parts

- Controlling spindle speed in manual operations

- Engaging or disengaging the tailstock

6. Coolant System

During machining, high-speed rotation and cutting generate heat, which can affect precision and tool life. The coolant system helps regulate temperature by lubricating and cooling the cutting area.

How Does a CNC Lathe Machine Work?

Here’s how a CNC machine works.

1. Design Phase

Prior to CNC machining, the parts are designed digitally using CAD (Computer-Aided Design) software like SolidWorks, AutoCAD, or Fusion 360. This step allows engineers to:

- Define the exact shape, size, and dimensions of the part.

- Ensure proper tolerances and surface finishes.

- Identify any complex features that may require special machining techniques.

Once the design is finalized, the CAD file is converted into a CNC-compatible format and ready for programming.

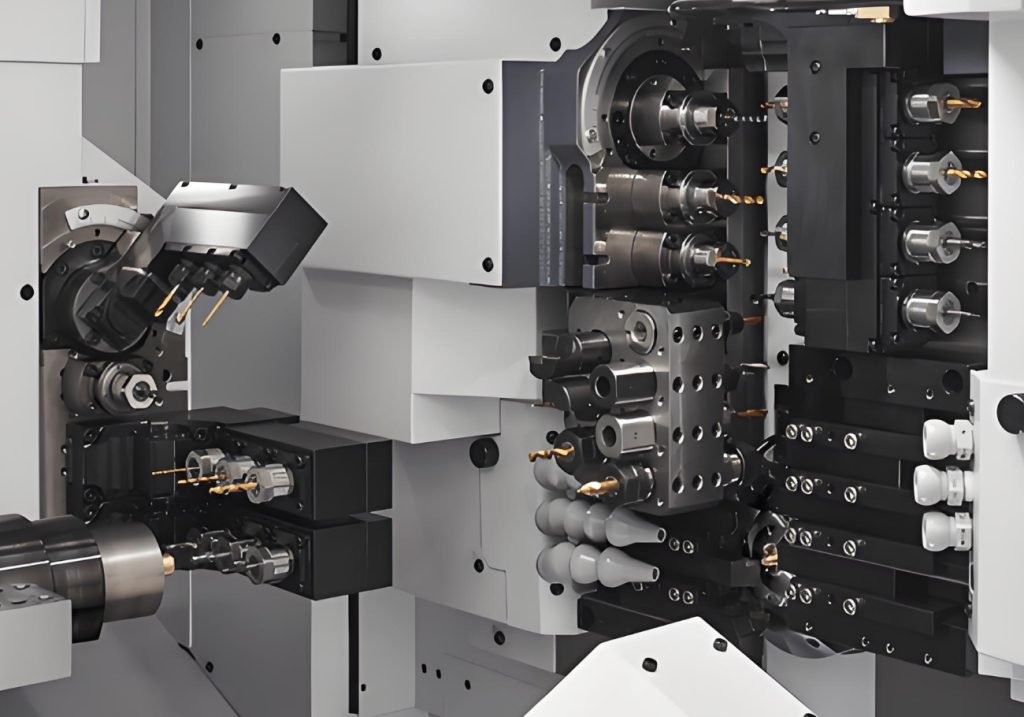

2. Programming

The digital design must be translated into machine-readable instructions. This is done using CAM (Computer-Aided Manufacturing) software, which converts the CAD file into G-code. It controls the CNC lathe’s movement, determining how fast to rotate, where to cut, and at what depth.

As an operator, you can manually adjust feed rates, spindle speeds, and tool paths for efficiency. Once the G-code is verified, it is uploaded into the CNC lathe’s control system.

3. Configuring the CNC Machine

Before execution, the CNC lathe must be configured and calibrated to ensure perfect alignment and precision. This step includes:

- Securing the workpiece in the chuck.

- Selecting and loading the correct cutting tools.

- Calibrating spindle speed, feed rate, and depth of cut.

- Testing coolant flow and lubrication.

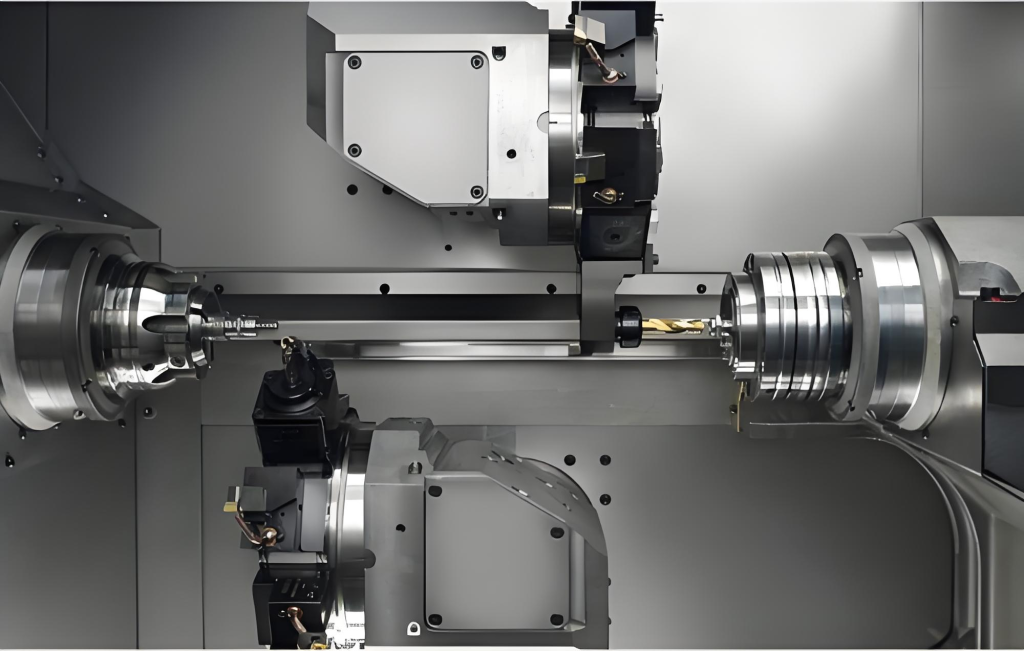

4. Machining Execution

Once the CNC is programmed and set up, the machining process begins. The spindle rotates the workpiece at a precise speed, while the cutting tool follows the programmed path to remove material and shape the part.

The lathe performs turning, facing, drilling, and threading on the design. Turning creates cylindrical shapes, facing smooths the ends, drilling adds holes and threading cuts grooves for screws.

After machining, the CNC lathe stops, unlocks the chuck, and ejects the finished part. You can now call the inspection team to see if it’s perfect.

CNC Lathe Machine Applications

CNC lathe machines are used for various machining operations to shape, refine, and finish materials with high precision. Some real-world applications include:

- Automotive Industry: Used to manufacture engine components, shafts, brake discs, and gear parts with high accuracy.

- Aerospace Industry: Essential for producing aircraft parts such as turbine blades, landing gear components, and structural fasteners.

- Medical Industry: Creates precise surgical instruments, prosthetic joints, and dental implants that require extreme accuracy.

- Electronics Industry: Used for machining electronic device connectors, heat sinks, and precision casings.

- Oil & Gas Industry: Produces valve components, pipeline fittings, and drill bits for heavy-duty industrial use.

Advantages of a CNC Lathe Machine

The major advantages of using a CNC machine are:

| Advantage | Description |

| Precision and High Accuracy | CNC lathes use computer-controlled movements to ensure consistent and highly precise machining, reducing human error. |

| Faster Production | Automated operations allow faster production cycles, reducing manufacturing time and increasing efficiency. |

| Personnel Safety | CNC machines operate with minimal human intervention, which reduces direct contact with sharp tools and ensures a safer work environment. |

Invest in Excellence and Take Advantage of Modern CNC Lathe Technology

CNC lathe machines offer unmatched precision, speed, and safety, which makes them essential for high-quality manufacturing. Whether you’re producing custom parts or large-scale components, investing in CNC machining is highly recommended.

If you’re someone who’s in search of the best CNC machining services, then we’re here to help. We offer state-of-the-art CNC machining services to deliver precision-crafted parts according to your requirements.

Contact us today to discuss your project and get the best machining solutions!