Injection molding is a critical process for the development of the numerous products you encounter. From your phone to the parts in your car, the injection molding process is all around you. A common headache in injection molding is flash, which is the unwanted excess plastic that can ruin the quality and aesthetics of your parts. This article will help you understand what causes flash in injection molding and, more importantly, how to minimize it to achieve perfect injection-molded products.

What Is Flash in Injection Molding?

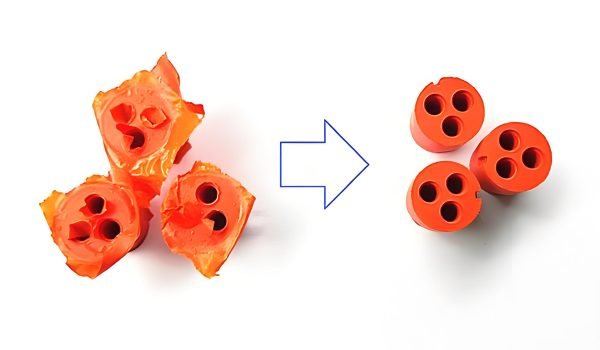

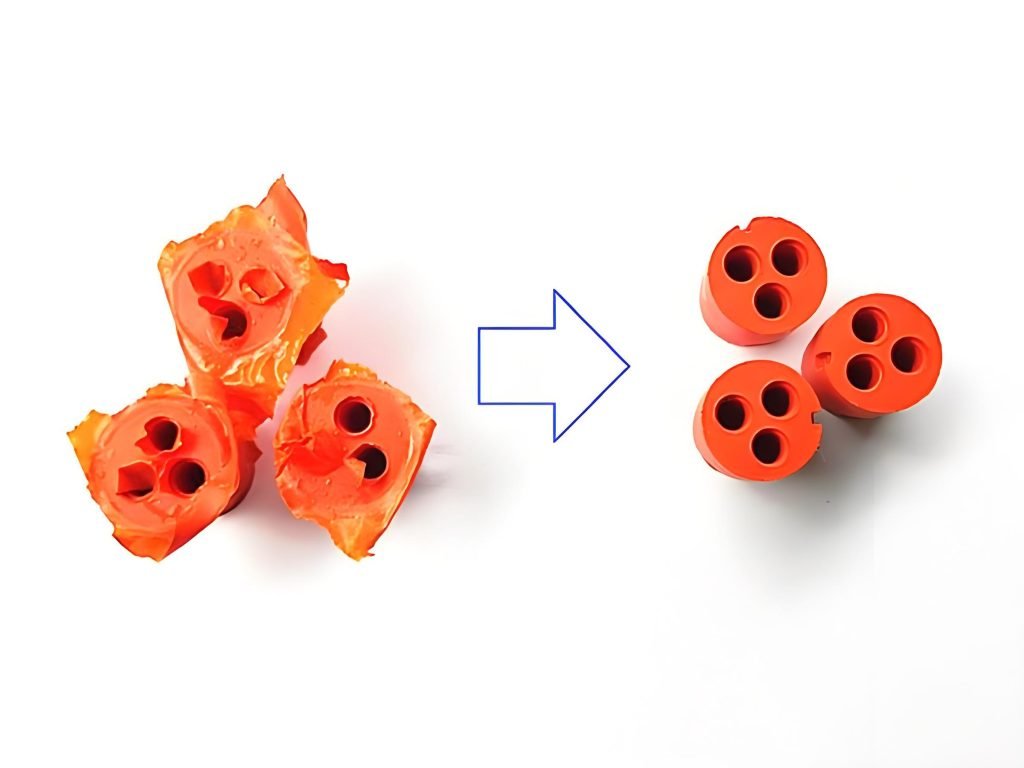

So, what is flash in injection molding? Generally, it is the extra plastic material that squeezes out of the mold cavity during the injection process. It takes the form of a thin layer or extrusion, most typically at the parting line of the mold where the different sections of the mold assembly come together. Sometimes you may also find it around ejector pins, inserts, or other spots that don’t have an absolute seal.

Think of the mold as an accurate container designed to hold molten plastic. If everything goes correctly, the plastic will fill the mold cavity and solidify in its mold form. However, if there is a gap or too much pressure, liquid plastic can be displaced out of a void point, leading to flash. Flash has a range of appearances, from light film to larger plastic protrusions. It is always brittle and can be snapped off with little effort. But regardless of the amount, it makes everything infinitely worse.

Flash can cause headaches not just visually, but also functionally, by causing parts to not fit together properly during assembly. Sometimes, flash may require labor and an added expense to remove the excess plastic afterward. This extra operation adds to the cost of producing the part and also risks damaging the part. Flash may also ruin the intended dimensions and tolerances of the molded component, which may detract from the value and quality of the parts.

The Main Causes of Injection Molding Flash

The understanding of injection molding flash begins with identifying the cause. Flash can occur at various points in the injection molding cycle and is either caused by the mold, processing, or material. Below are some reasons for flash:

Mold Flash During Injection Phase

During the initial injection of molten plastic into the mold cavity, several factors can lead to flash:

Parting Line Mismatches

The mold halves need to fit together to avoid gaps. Gaps or mismatches happen for different reasons. First, contaminants, like small plastic or debris, can be included between the halves of the mold and therefore not allow any sealing. Second, small imperfections to the surface of the mold vary over time and replicate this gap. Third, improper mold design with inadequate sealing surfaces can cause flash because the mold was designed this way. Think of trying to close a container with something stuck on the rim. It cannot seal, and if you were to fill it, any liquid would leak out. The same principle applies to your mold.

Improper Venting

When molten plastic fills the cavity of the mold, it must displace the air that fills it. Vents are small channels designed to allow air to escape. Back pressure created by insufficient vent size or poor vent placement can trap air in the mold cavity. It then forces the molten plastic out through the parting lines, which will cause flash. Think of trying to put liquid in a bottle while the lid is on. The air inside has nowhere to go, and therefore, the liquid does not flow smoothly into the container and will even overflow.

Mold Flash During Packing or Holding

Even after the mold cavity is filled, issues during the packing and holding phases can contribute to injection molding flash:

Low Clamping Pressure

The clamping force holds the mold halves tightly closed against the pressure from the injected plastic. Under low clamping force, the melted plastic, still under pressure from the packing and holding stages of the injection cycle, can push the mold halves apart just enough to “escape” and result in flash, just like trying to hold the lid on a pot of boiling water. If you don’t hold it down tight, the steam will escape.

Sprue Bushing Issue

The sprue bushing is the piece that allows the injection molding machine’s nozzle to connect to the mold’s runner (and ultimately to the cavities). If the sprue bushing is eroded, damaged, or not correctly aligned with the nozzle, the two will create a gap at the interface. Molten plastic can then leak out at this point, leading to a flash around the sprue area. Think of it as a leaky connection in a plumbing system.

Mold Flash Due to Flow Characteristics

The behavior of the molten plastic itself plays a significant role in the likelihood of injection molding flash:

Viscosity

Viscosity is a measure of the thickness, or how well the plastic resists flow. Low-viscosity materials are easy to flow and are thinner. It is good for fitting into the small details of a mold. However, low viscosity means the plastic will also find its way into any small gaps in the mold and therefore runs the risk of excessive flash. When you think about honey (high viscosity) versus water (low viscosity), water is much better at finding its way through any small cracks.

Barrel and Nozzle Temperature

The nozzle and barrel temperature of the injection molding machine will affect the plastic viscosity. Higher temperatures reduce viscosity and improve flow. While these are good parameters so that plastic can properly fill the mold, if the temperature is too high, it can amplify the difficulty of injection molding flash.

Overfill

Injecting too much plastic can create excessive pressure. Excessive pressure can potentially force the molten material out along parting lines or areas that could lead to leaks, which cause flash. It is similar to stuffing too much material into a container; at some point, something will overflow.

High Pressure

Similarly, using excessively high injection pressure to fill the mold, even with the correct amount of material, can exert too much force on the mold halves. If the clamping force isn’t sufficient to counteract this pressure, flash defect in injection molding can occur.

Over Packing

The packing phase is when we apply additional pressure after the mold is filled to counteract the shrinkage of the material as it cools, which is very important to achieve dimensional accuracy. But overpacking, or having too much pressure for too long, can cause high pressure in the mold and promote injection molding flash.

Effective Ways to Control Flash in Injection Molding

Now for the crucial part: how to avoid flash in injection molding? How do you prevent this unwanted plastic from appearing in the first place? Here are some effective tactics you could consider:

Design for Manufacturability (DFM)

The battle against flash in injection molding often starts at the design stage. Designing parts with manufacturability in mind substantially reduces the risk of flash. This includes separating a primary parting line in a simple manner to minimize the number of intersecting cores, as intersecting areas exhibit the greatest tendency for flash to occur.

Incorporating appropriate draft angles (the slight taper on vertical surfaces) can also ensure clean part ejection and prevent mold damage that could lead to future flash issues. Think about designing a container with a simple, flat lid rather than one with intricate, overlapping edges—the simpler design is less prone to leaks.

Slow Down the Injection Rate

By reducing the speed at which the molten plastic enters the mold, you can reduce the pressure in the cavity. The slow, gentle fill will allow the air more time to escape through the vents as well as reduce the force pushing the plastic out through any other gaps.

Specify a Flash-Free Mold

Investing in high-precision molds will also reduce flash in the long term, especially if you are manufacturing large quantities of plastic or close-tolerance parts. These molds will have tighter tolerances, better sealing surfaces, and better venting systems. While the initial cost may be higher, a reduction of secondary operations and quality improvement, in many cases, will be much less expensive in the long run.

Proper Mold Cleaning and Maintenance

Cleaning the mold of contamination on a regular basis, like dust, dirt, or plastic from previous injections, is also crucial. These tiny particles can prevent the mold halves from closing tightly, creating pathways for flash. Effective maintenance of the molds, for instance, examining for wear and tear on the surfaces of the mold, is necessary for maintaining a good seal, as well as avoiding flash.

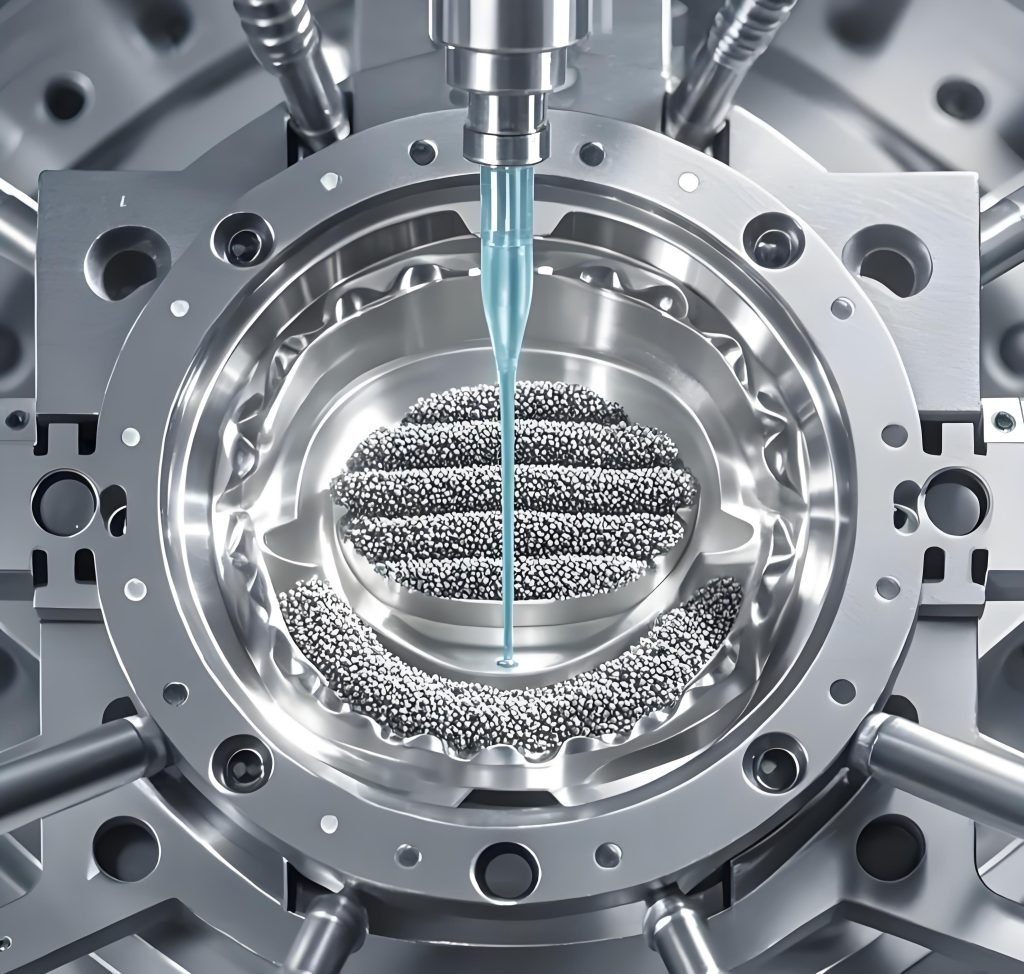

Process Optimization

An important step to manage flash is the fine-tuning of injection molding parameters. First, apply heat, adjusting barrel and nozzle temperatures to attain proper melt viscosity for the material being molded—not too hot (too thin) and not too low (hard to fill). Next, adjust the injection pressure to just fill the mold. Similarly, adjust packing pressure and time to fill the mold and minimize mold shrinkage issues. Adjusting these parameters for fill and pack is experimental, and it is generally best to monitor the mold process closely for a specific part with a specific material to find the best combination.

How to Know If Overmolding or Insert Molding Is Better for Your Project?

In addition, sometimes your parts will require different materials that may include pre-assembly. In these circumstances, you have the opportunity of including materials through either overmolding or insert molding; the difference will inform the opportunity to make a quality finished product and avoid flash defect in injection molding throughout.

Overmolding

Overmolding is the act of molding material over a substrate or another mold piece. This could be adding a soft-touch grip on a rigid handle, creating a wipe-water seal, or changing the aesthetics of a product with a different color. The first part is generally molded into the mold, and the second material is injected around the first material. The primary benefit is usually additional function, enhanced appearance, and a more cohesive design.

Insert molding

Insert molding is molding plastic around an inserted object that is placed. This can be a metal part, a threaded bushing, or another plastic part. The advantages of insert molding are the ability to create strong integrated features and add more functionality to plastic parts. Insert molding can also save considerable assembly time and costs by eliminating one operation of fastening.

So, how do you choose between the two? Consider your project requirements:

- For overmolding: if you want to add a layer or features to an existing part to add grip, to have a seal, or to change aesthetics with another material, use overmolding.

- For insert molding: if you want to add a pre-formed element into your plastic part, for example, threads in order to accommodate metal, electrical contacts, and reinforcement components, use insert molding.

A Skilled Partner For Your Flawless Injection Molding Project

Flash in injection molding is a common challenge, but it doesn’t have to be an inevitable one. By understanding the causes of flash—mold imperfections, improper processing parameters, and material flow characteristics, you can apply the right strategies to address flash. Designing for manufacturability, tuning your molding process, and ensuring good tooling are all steps towards receiving clean, on-target parts.

At Fecision, your success is built upon flawless, flash-free, injection-molded parts. We are your partner for consistently high-quality results. Our extensive experience and deep knowledge of flash control can guarantee that your parts are of the highest quality and functionality through a holistic approach.

- Advanced DFM Analysis: We meticulously review your part design with advanced DFM tools to pinpoint flash risks and optimize for seamless molding.

- High-Quality Molds: Partnering with trusted mold makers, we ensure high-precision molds with tight tolerances and optimal sealing—the foundation for flash prevention.

- Process Control: Our experienced technicians strictly control all molding parameters (temperature, speed, pressure) to ensure optimal flow and minimize flash potential.

Ready to achieve flawless, flash-free injection-molded parts for your next project? Contact us today to discuss your specific needs and discover how our expertise can benefit you!