Have you ever wondered how manufacturers achieve a flawless, transparent finish on plastic parts? The answer lies in a specialized technique, vapor polishing, that transforms rough, opaque surfaces into smooth, high-gloss finishes.

What Is Vapor Polishing

Vapor polishing is a chemical smoothing technique. It works by heating a solvent to its boiling point, producing vapors that are then applied to the plastic surface. These vapors cause the surface to melt and fill in small holes and scratches, resulting in a smooth, glossy finish. When the vapor dissipates, the plastic solidifies again, retaining its newly smoothed surface.

| Key Aspect | Description |

|---|---|

| Process | Chemical smoothing using heated solvent vapors |

| Effect on Plastic | Smoothes surface at microscopic level |

| Environment | Requires controlled environment for safety |

The Science Behind Vapor Polishing

To grasp how vapor polishing works, it’s essential to delve into the chemical and physical changes it induces on plastic surfaces.

Chemical Reactions During the Process

During vapor polishing, the solvent vapor interacts with the plastic surface, softening and partially dissolving it. This interaction smooths out imperfections and irregularities, resulting in a polished finish. Different solvents selectively dissolve the outermost molecular layers of plastic surfaces without compromising the structural integrity of the part.

The chemical reactions involved are critical to achieving a uniform and consistent finish. The solvent vapor recondenses on the plastic surface, removing any remaining imperfections and leaving a smooth finish.

Surface Transformation at the Microscopic Level

At the microscopic level, vapor polishing creates a chemical melt that reduces the surface’s valleys and peaks by liquefying and redistributing the material. This process clears surface roughness, resulting in a smooth, glossy finish. Surface tension effects play a crucial role in redistributing the melted polymer into a uniform layer.

By controlling factors like temperature, exposure time, and solvent concentration, you can achieve optimal surface transformation without damaging the plastic part.

How Does Vapor Polishing Work?

Vapor polishing is a sophisticated process that requires specific equipment and a controlled environment to achieve high-quality results.

Required Equipment and Materials

The vapor polishing process necessitates specialized equipment, including a vapor chamber, solvent heating systems, and safety apparatus. You’ll need a clean, heat-resistant container to heat the solvent until it vaporizes. A vapor chamber is crucial for containing the solvent vapor and ensuring it interacts with the plastic part uniformly.

Step-by-Step Vapor Polishing Process

The vapor polishing process involves several key steps. First, you must clean the workpiece thoroughly to remove any debris or contaminants. For certain plastics, like polycarbonate, manual polishing with different grit sanders (100-1200 grit) is required before vapor polishing. Next, heat the appropriate solvent in the prepared container until it vaporizes. Then, expose the plastic part to the solvent vapor for a specific duration, typically 2-3 seconds for most plastics. After exposure, allow recondensation to occur, which helps in achieving uniformity. Finally, dry the workpiece in a well-ventilated area and perform a final cleaning and inspection.

Safety Precautions and Controlled Environment

It’s critical to conduct the vapor polishing process in a controlled environment with proper safety equipment. You’ll need respirators, chemical-resistant gloves, and fume hoods to protect against the volatile solvents used. Ensuring proper ventilation and following handling procedures are crucial for safety. Vapor polishing should be performed by trained professionals to avoid potential risks associated with DIY attempts without proper safety measures.

Which Plastics Can Be Vapor Polished?

Vapor polishing is a versatile technique that can enhance the appearance and functionality of various plastic parts, particularly those produced through CNC machining or molding.

Ideal Materials for Vapor Polishing

Certain thermoplastic materials are well-suited for vapor polishing due to their molecular structure and response to solvent vapors. The most compatible materials include:

Acrylic (PMMA)

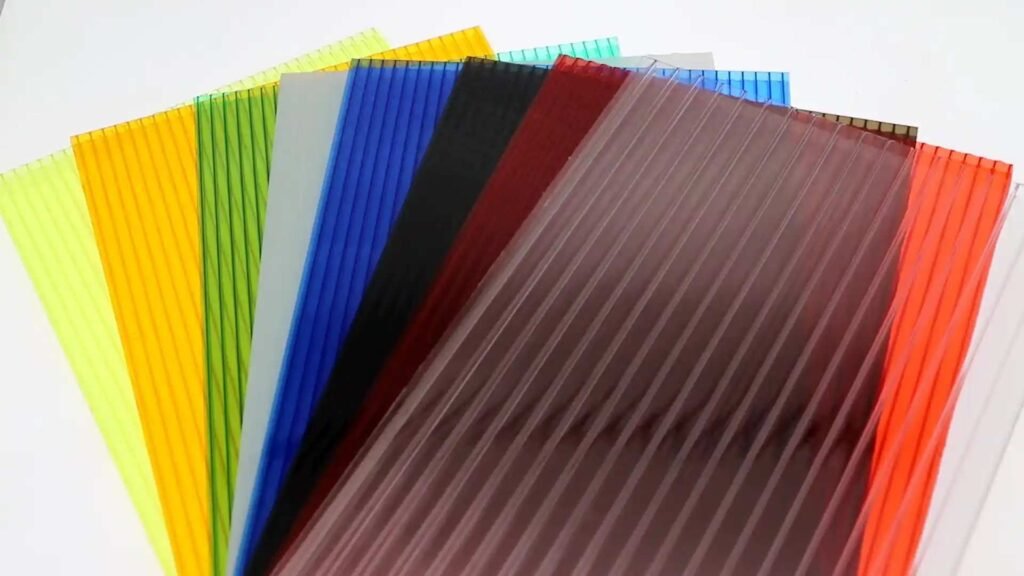

Acrylic, or PMMA, is considered ideal for vapor polishing. It achieves a glass-like transparency and significantly improves its optical clarity.

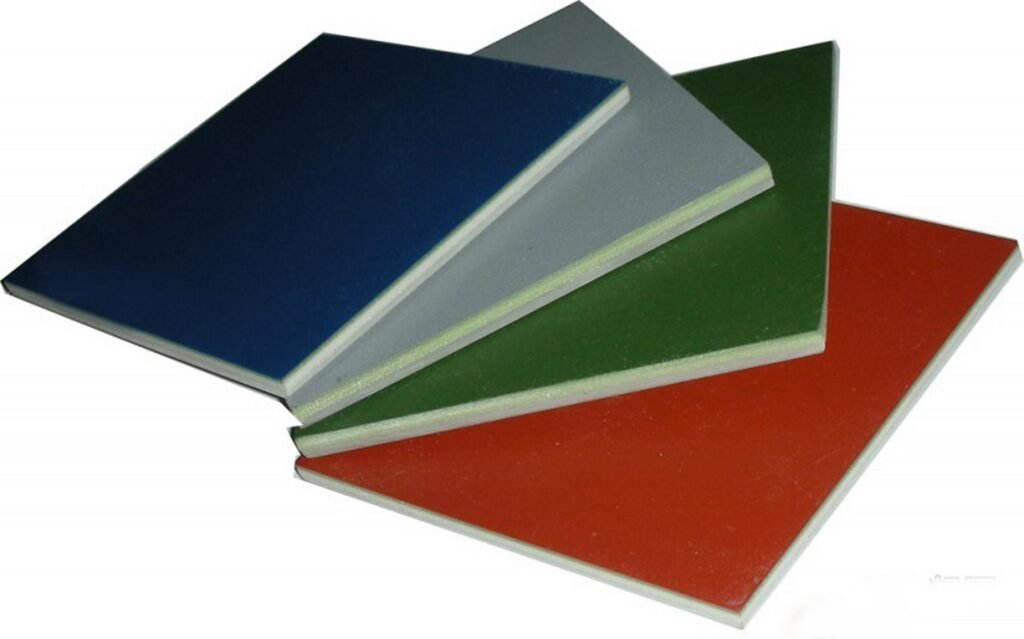

Polycarbonate (PC)

Polycarbonate also benefits greatly from vapor polishing, showing improved optical clarity and surface finish. While it doesn’t achieve the same level of transparency as acrylic, it remains a popular choice.

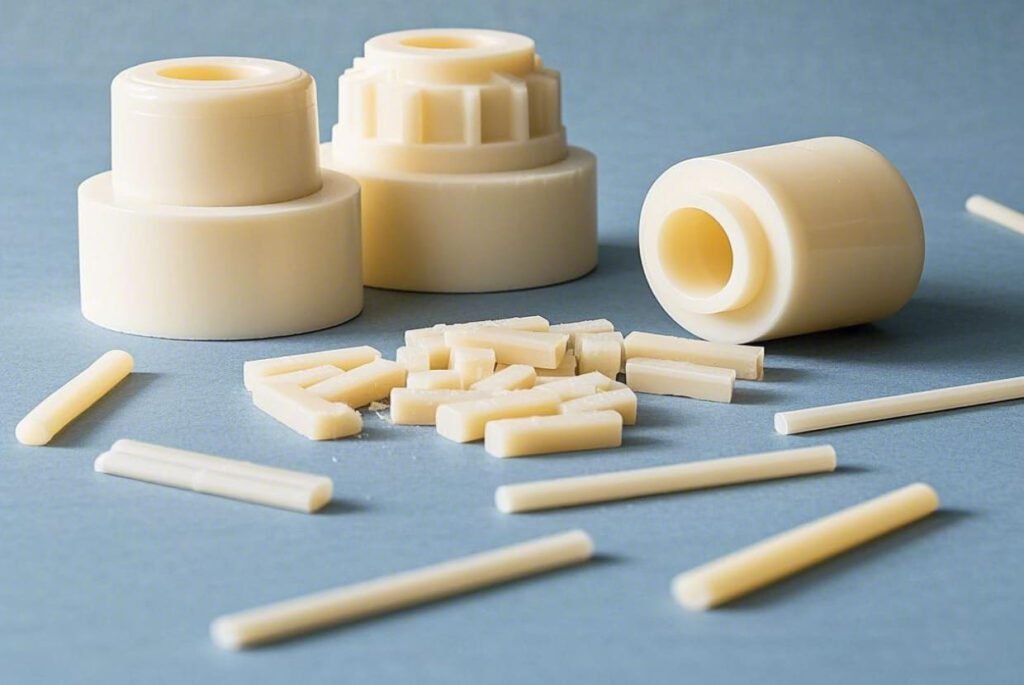

Other Compatible Thermoplastics

Other materials that can be vapor polished include ABS, PETG, PS, and specialized engineering plastics like Polysulfones (PSF) and Polyetherimide (PEI).

| Material | Vapor Polishing Effectiveness | Resulting Transparency |

|---|---|---|

| Acrylic (PMMA) | High | Excellent |

| Polycarbonate (PC) | High | Good |

| ABS | Moderate | Fair |

Materials Not Suitable for Vapor Polishing

Not all plastics are suitable for vapor polishing. Materials like HDPE and certain types of PP may not respond well to the process. It’s essential to test the material before proceeding with vapor polishing.

Vapor Polishing Techniques for Different Plastics

Achieving optimal results in vapor polishing requires understanding the unique characteristics of various plastics. Different plastics respond differently to vapor polishing due to their distinct chemical and physical properties.

Acrylic Vapor Polishing Process

For acrylic (PMMA), dichloromethane (DCM) and acetone are commonly used solvents. DCM has a strong dissolving ability and can quickly smooth the acrylic surface. The exposure time should be about 3 seconds to achieve the desired transparency.

Polycarbonate Vapor Polishing Process

For polycarbonate (PC), 1,2-Dichloroethane (DCE) and Tetrahydrofuran (THF) are recommended. DCE only needs to be vaporized for 2-3 seconds. It’s crucial to avoid using acetone for PC as it can cause whitening or cracking.

ULTEM (PEI) Vapor Polishing Considerations

For ULTEM (PEI), strong polar solvents like N-Methyl-2-pyrrolidone (NMP) and Dimethylformamide (DMF) may cause slight surface swelling under high-temperature conditions. Dichloroethane (DCE) can weakly dissolve PEI but requires prolonged contact. The exposure time for PEI is typically 3-5 seconds.

Advantages of Vapor Polishing

By utilizing vapor polishing, you can significantly enhance the optical clarity, surface finish, and durability of your plastic parts. This process offers numerous benefits that make it an ideal choice for various applications.

Enhanced Optical Clarity and Light Transmission

Vapor polishing dramatically improves the optical clarity and light transmission capabilities of plastic parts. It allows for an unobstructed passage of light, making it ideal for display, lighting, and visual applications where transparency is crucial. The process transforms rough, opaque surfaces into crystal-clear, transparent finishes that rival glass in appearance.

Improved Surface Finish and Aesthetics

The vapor polishing process enhances surface aesthetics by eliminating tool marks, layer lines, and other manufacturing artifacts. It provides an excellent water-clear finish and a high gloss, significantly improving the overall appearance of the parts. This is particularly beneficial for smoothing 3D printed parts with transparent SLA resin and CNC machined parts in acrylic and PC.

Increased Durability and Moisture Resistance

Vapor polishing increases part durability by sealing microscopic surface pores and cracks, making the surface more scratch-resistant and smoother. As a result, vapor polished surfaces gain improved moisture resistance and weatherability, extending the functional lifespan of plastic components in demanding environments.

Vapor Polishing vs. Manual Polishing

To determine the best polishing method for your plastic parts, it’s essential to understand the differences between vapor polishing and manual polishing. Both methods have their strengths and weaknesses, which are crucial in deciding the most suitable approach for your specific needs.

Efficiency and Time Considerations

Vapor polishing is generally more efficient and faster than manual polishing, especially for large batches of complex parts. While manual polishing can be labor-intensive and time-consuming, vapor polishing can achieve a high-gloss finish in a single process, significantly reducing production time.

Quality and Consistency Comparison

Vapor polishing produces a uniform, glass-like finish that is difficult to achieve with manual polishing. The vapor polishing process ensures consistency across batches, whereas manual polishing can result in variability due to human factors. This consistency is particularly important for parts with complex geometries or internal features.

Cost Analysis and ROI

Although the initial equipment costs for vapor polishing are high, the operational costs are lower compared to manual polishing, which has low initial costs but higher labor costs. By calculating the return on investment (ROI) for vapor polishing equipment, you can make an informed decision about which polishing method is more cost-effective for your manufacturing process.

Applications of Vapor Polished Parts in Various Industries

From medical devices to aerospace components, vapor polishing is revolutionizing the way parts are manufactured and finished. This process is enhancing the quality and functionality of plastic parts across multiple sectors.

Medical and Healthcare Applications

In the medical industry, vapor polishing is used to create smooth, biocompatible surfaces for diagnostic equipment, fluid handling components, and optical instruments. These vapor polished parts are easy to clean, non-porous, and comfortable to wear, making them ideal for medical devices.

Automotive and Aerospace Uses

Vapor polished components are used in the automotive and aerospace industries for their aesthetic appeal and functional benefits. In aerospace, vapor smoothing enhances the surface finishes of plastic components used in control systems, instrument panels, and aircraft interiors, reducing aerodynamic drag.

Consumer Products and Electronics

Consumer electronics manufacturers leverage vapor polishing to create high-gloss, transparent enclosures and displays that enhance brand perception and product value. Vapor polished parts reduce friction during skin contact and improve visual appeal.

Industrial Manufacturing Applications

In industrial manufacturing, vapor polished components improve performance in fluid handling, optical sensing, and precision mechanical systems. CNC machined parts with vapor polished finishes are replacing glass components in many applications, offering better impact resistance and design flexibility.

Conclusion: Transform Your Plastic Components with Vapor Polishing

For high-quality plastic parts, vapor polishing represents the optimal surface finishing solution, combining aesthetic appeal with functional performance. You can achieve exceptional surface quality and transparency in your plastic parts, elevating their overall value. The vapor polishing process transforms rough, opaque surfaces into smooth, transparent finishes that rival glass while maintaining the advantages of plastic, such as lighter weight and impact resistance.

By understanding the benefits and applications of vapor polishing, you can make informed decisions about implementing this technique in your manufacturing workflow, whether through in-house equipment or partnership with specialized service providers.